warning NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 7 of 1701

PREPARATIONANDPRECAUTIONS

Service Notice

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag" usedalong withaseat belt, helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

Ii

Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

•

Before proceeding withdisassembly, thor-

oughly cleantheoutside ofthe transaxle. Itis

important toprevent theinternal partsfrom

becoming contaminated bydirt orother for-

eign matter.

• Disassembly shouldbedone inaclean work

area.

• Use lint-free clothortowels forwiping parts

clean. Common shopragscanleave fibers

that could interfere withtheoperation ofthe

transaxle.

• Place disassembled partsinorder, onaparts

rack, foreasier andproper assembly.

• Allparts should becarefully cleaned-witha

general purpose, non-flammable solvent

before inspection orreassembly.

• Gaskets, sealsandO-rings shouldbe

replaced anytime thetransaxle isdisassem-

bled.

• Itis very important toperform functional tests

whenever theyareindicated. •

The valve bodycontains precision partsand

requires extremecarewhen partsare

removed andserviced. Placedisassembled

valve bodyparts inorder, onaparts rack,for

easier andproper assembly. Carewillalso

prevent springs andsmall partsfrombecom-

ing scattered orlost.

• Properly installedvales,sleeves, plugs,etc.

will slide along theirbores inthe valve body

under theirownweight.

• Before assembly, applyacoat ofrecom-

mended ATFtoall parts. Apply petroleum

jelly toprotect O-ringandseals, orhold bear-

ings andwashers inplace during assembly.

Do not use grease.

• Extremely careshould betaken toavoid dam-

age toO-rings, sealsandgaskets when

assembling.

• After overhaul, refillthetransaxle withnew

ATF.

•

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag" andused along withaseat belt,helps toreduce therisk

or severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists of

an air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

AT-7

Page 222 of 1701

PRECAUTIONS

Service Notice

• When removing orinstalling variousparts,placeacloth orpadding ontothevehicle bodytoprevent

scratches.

• Handle trim,molding, instruments, grille,etc.carefully duringremoving orinstalling. Becareful not

to soil ordamage them.

• Apply sealing compound wherenecessary wheninstalling parts.

• When applying sealingcompound, becareful thatthesealing compound doesnotprotrude from

parts.

• When replacing anymetal parts(forexample bodyouter panel, members, etc.),besure totake rust

prevention measures.

SupplementalRestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists ofan

air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

BT-2

Page 229 of 1701

BODYEND

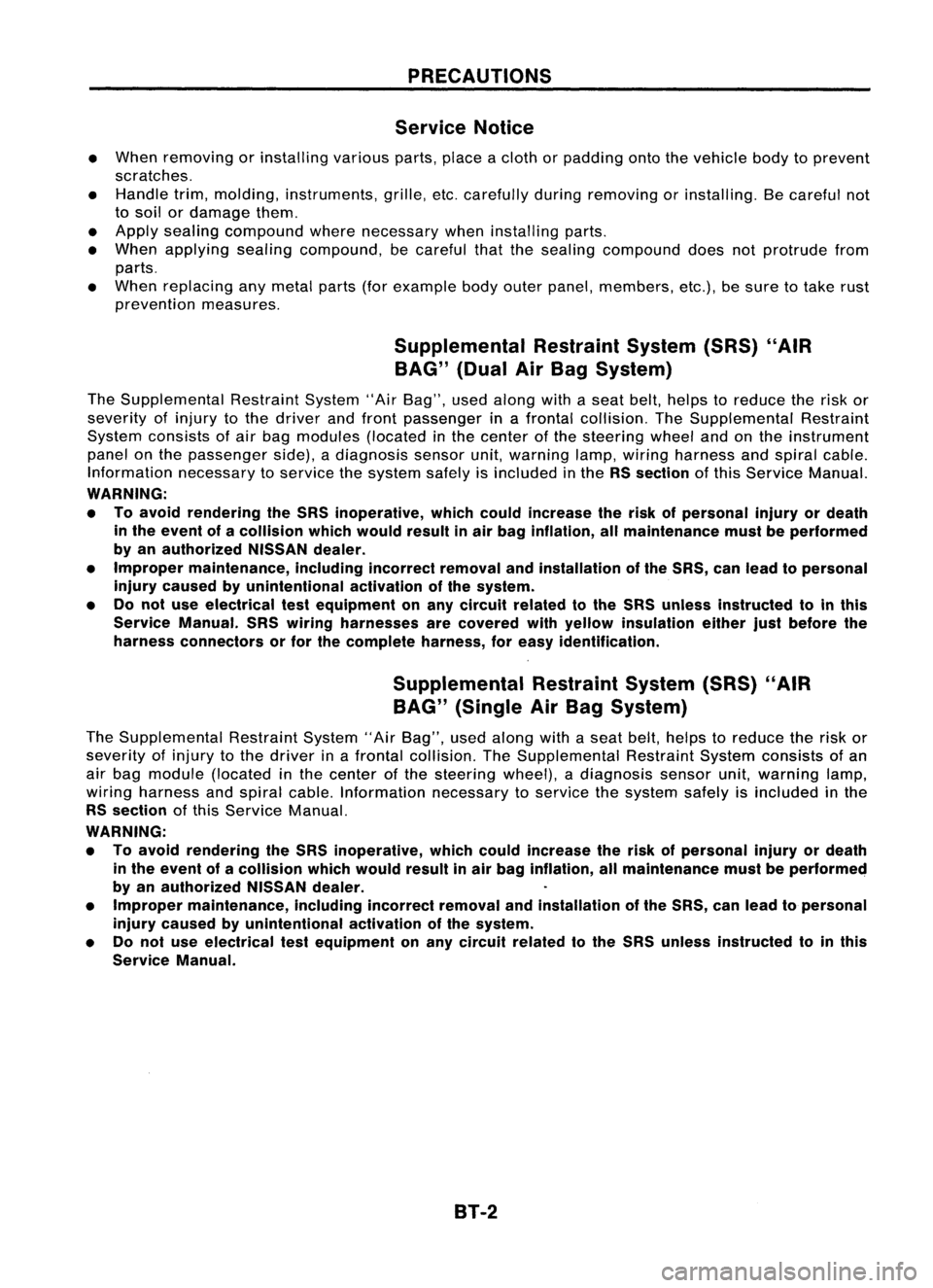

Body RearEndandOpener (Cont'd)

3-DOOR AND5-DOOR HATCHBACK

• Back dooradjustment: Adjustathinge-body portionforproper backdoorfit.

• Back doorlocksystem adjustment: Adjustlock

&

striker sothat they areinthe center. After

adjustment, checkbackdoor lockoperation.

WARNING:

• Becareful nottoscratch backdoor staywhen installing backdoor. Ascratched staymay cause gas

leakage.

• The contents ofthe back doorstayareunder pressure. Donot take apart, puncture, applyheator

allow firenear it.

• Opener cable:Donot attempt tobend cable usingexcessive force.

• After installation, makesurethatback doorandfuel filler lidopen smoothly.

REMOVAL -Rear bumper assembly

(1)

Remove boltssecuring leftand right rearfenders tobumper fascia.

@

Remove boltsandclips

@ill>

securi-ng bumperlowersidetobumper fascia.

@)

Remove clips~ securing rearpanel upper tobumper fascia.

@

Extract bumper fasciaassembly.

rn

~\\\\\\\\\\\\\\\\\\\\\\

I,"-

1f;

Openercable

l

'\ '--- adju~~m~nl

omm~

(0

in)

B1-9

[O.J

:

N.m (kg-m, Il-Ib)

~ :N'm (kg-m, in-Ib)

SBT041

•

Page 263 of 1701

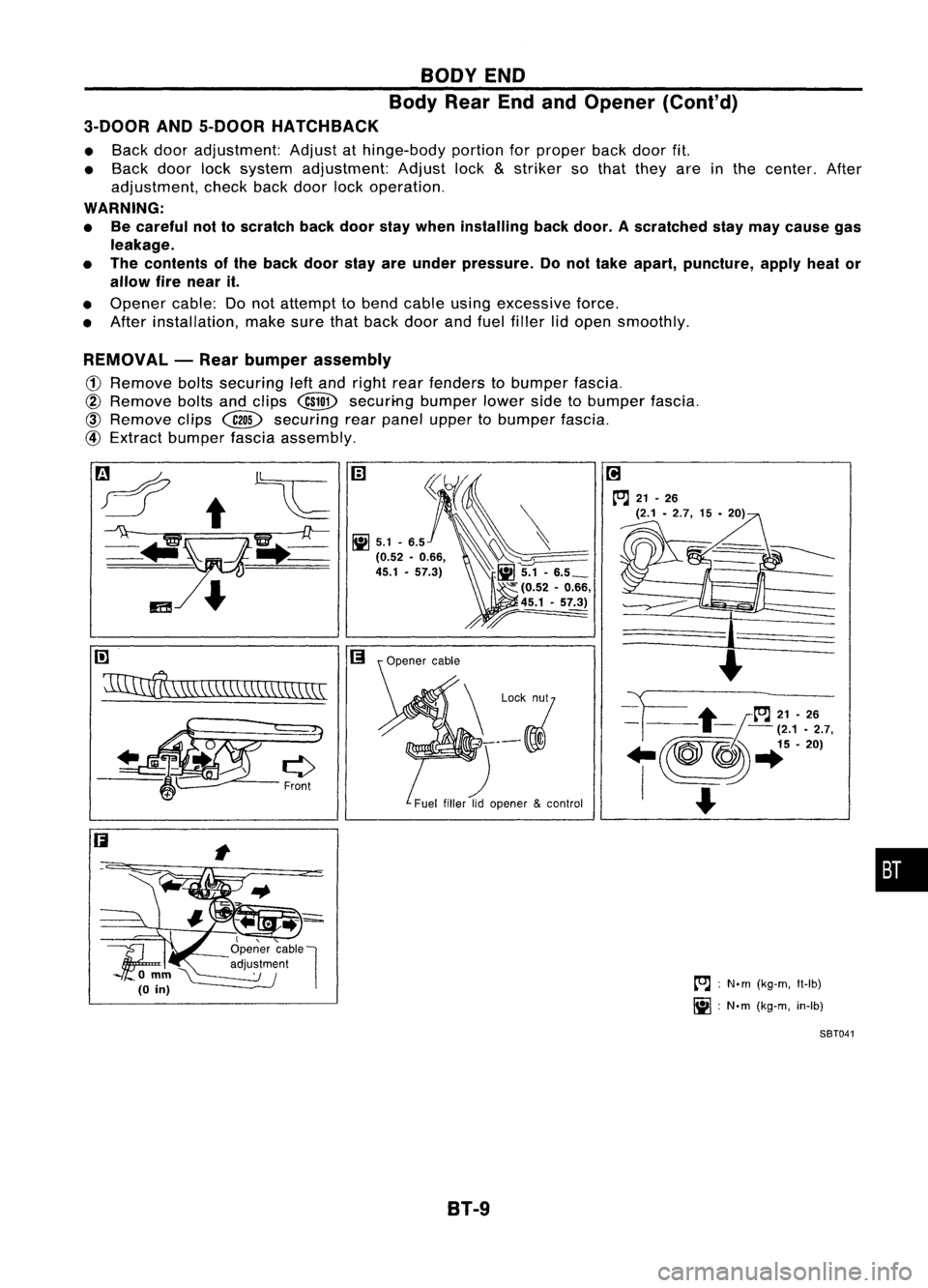

WINDSHIELDANDWINDOWS

Cutting sealant

SBF034BREMOVAL

After removing moldings, removeglass,

CAUTION: Be careful nottoscratch glasswhen removing.

INSTALLATION

• Use genuine NissanSealant kitorequivalent. Follow

instructions furnishedwithit.

• After installing theglass, thevehicle shouldremain station-

ary until thesealant hardens.

WARNING: Keep heatandopen flames awayasprimers areflammable.

CAUTION:

Advise usernottodrive thevehicle onrough roadsuntilseal-

ant has properly vulcanized.

•. Donot use sealant whichispast itsusable term.

• Donot leave cartridge unattended withitscap open.

• Keep primers andsealant inacool, dryplace. Ideally, they

should bestored inarefrigerator.

• Molding mustbeinstalled securely sothat itis in position

and leaves nogap.

Windshield andRear Window

•

Rear

window

Vehicle center

8 (0.31)

Glass

side

Install dam

rubber.

Windshield

8(0.31)

12 -15

(0.47 -0.59)

Apply

sealant evenly.

Windshield andrear window

7 •8 (0.28 •0.31)

Unit:mm(in)

S8T083

fj

'@8(0.31)1:@

Joint8(0.31)

8 (0.31)\ portion

(J

Joint portion "

O,m ,"bb"~

G,,,,

Double-laced

adhesive tape8(0.31)

V

Fastener

P'""~

Double-laced

adhesive

tape

•

Body

side

Install spacer topanel.

Windshield

447.2 (17.61)

Rear window

t==\

h¥:~'

po"II"

markmg

•

400 (15.75)

Install molding fastener.

When installing it,heat body panel and

fastener toapprox. 30to40°C Upper

&

side molding lasteners

(86 to104°F).

0;-.

REPAIRING WATERLEAKSFORWINDSHIELD

Leaks canberepaired withoutremoving andreinstalling glass.

If water isleaking between caulking materialandbody orglass, determine theextent ofleakage. This

can bedetermined byapplying waterwhilepushing glassoutward.

To stop theleak, apply primer andthen sealant tothe leak point.

81-43

Page 273 of 1701

PRECAUTIONSANDPREPARATION

Precautions

SUPPLEMENTAL RESTRAINTSYSTEM(SRS)"AIRBAG"

(DUAL AIRBAG SYSTEM)

The Supplemental RestraintSystem"AirBag" usedalong with

a seat belt,helps toreduce therisk orseverity ofinjury tothe

driver andfront passenger inafrontal collision. TheSupple-

mental Restraint Systemconsists ofair bag modules (located

in the center ofthe steering wheelandonthe instrument panel

on the passenger side),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoser-

vice thesystem safelyisincluded inthe

RSsection

ofthis Ser-

vice Manual.

WARNING:

• Toavoid rendering theSRS inoperatiYe, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

SUPPLEMENTAL RESTRAINTSYSTEM(SRS)"AIRBAG"

(SINGLE AIRBAG SYSTEM)

The Supplemental RestraintSystem"AirBag" andused along withaseat belt,helps toreduce therisk

or severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists of

an air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

BR-3

•

Page 274 of 1701

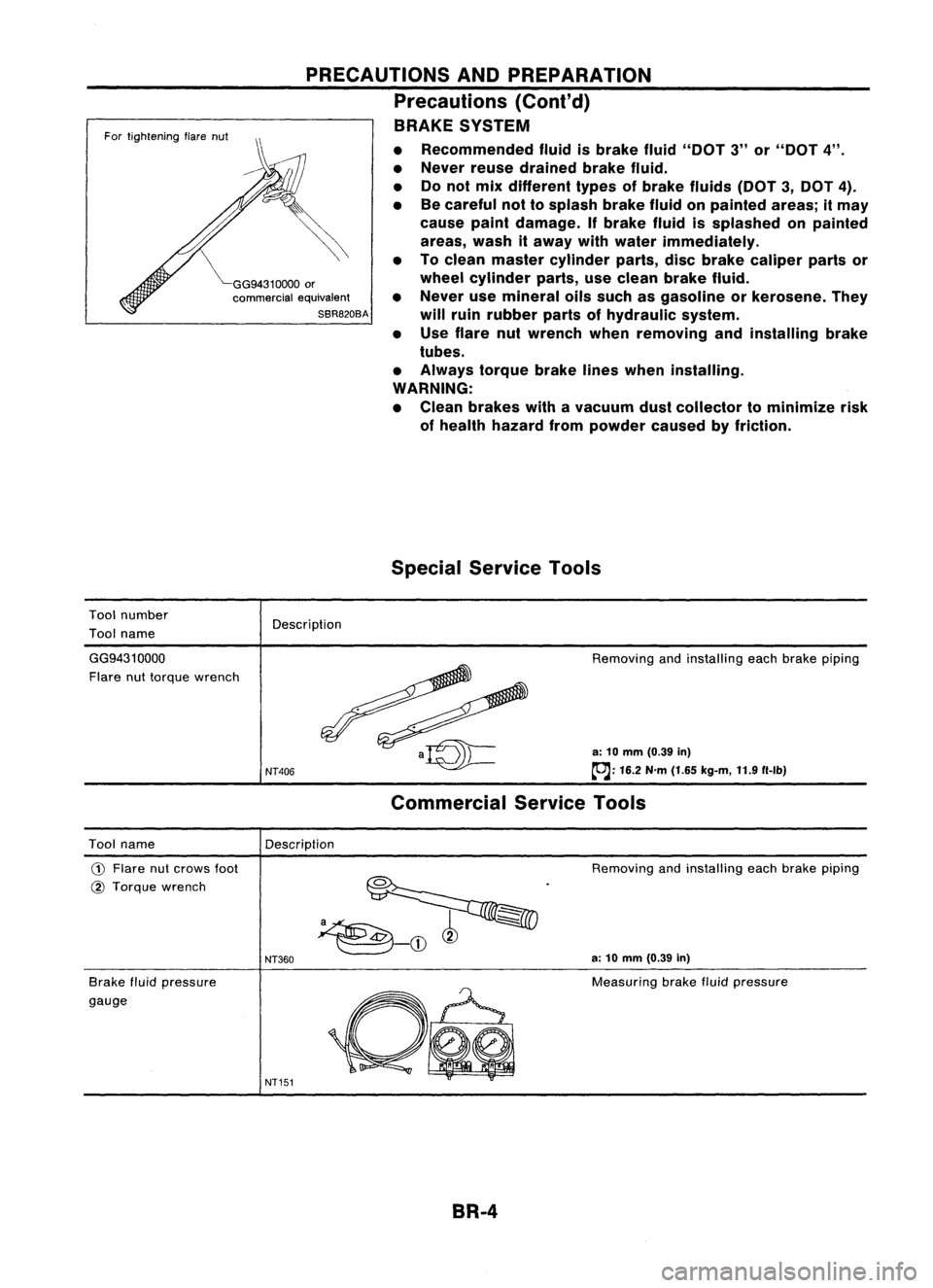

GG94310000or

commercial equivalent

SBR820BA

For

tightening flarenut

Tool number

Tool name

PRECAUTIONS

ANDPREPARATION

Precautions (Conl'd)

BRAKE SYSTEM

• Recommended fluidisbrake fluid"DOT 3"or"DOT 4".

• Never reusedrained brakefluid.

• Donot mix different typesofbrake fluids (DOT3,DOT 4).

• Becareful nottosplash brakefluidonpainted areas;itmay

cause paintdamage. Ifbrake fluidissplashed onpainted

areas, washitaway withwater immediately.

• Toclean master cylinder parts,discbrake caliper partsor

wheel cylinder parts,useclean brake fluid.

• Never usemineral oilssuch asgasoline orkerosene. They

will ruin rubber partsofhydraulic system.

• Use flare nutwrench whenremoving andinstalling brake

tubes.

• Always torquebrakelineswhen installing.

WARNING:

• Clean brakes withavacuum dustcollector tominimize risk

of health hazard frompowder causedbyfriction.

Special Service Tools

Description

GG9431 0000

Flare nuttorque wrench

NT406

Removing

andinstalling eachbrake piping

a: 10 mm (0.39 in)

~: 16.2N'm(1.65 kg-m, 11.9f1-lb)

Commercial ServiceTools

Description

Tool name

CD

Flare nutcrows foot

@ Torque wrench

Brake fluidpressure

gauge

NT360

NT151

Removing

andinstalling eachbrake piping

a: 10 mm (0.39 in)

Measuring brakefluidpressure

BR-4

Page 275 of 1701

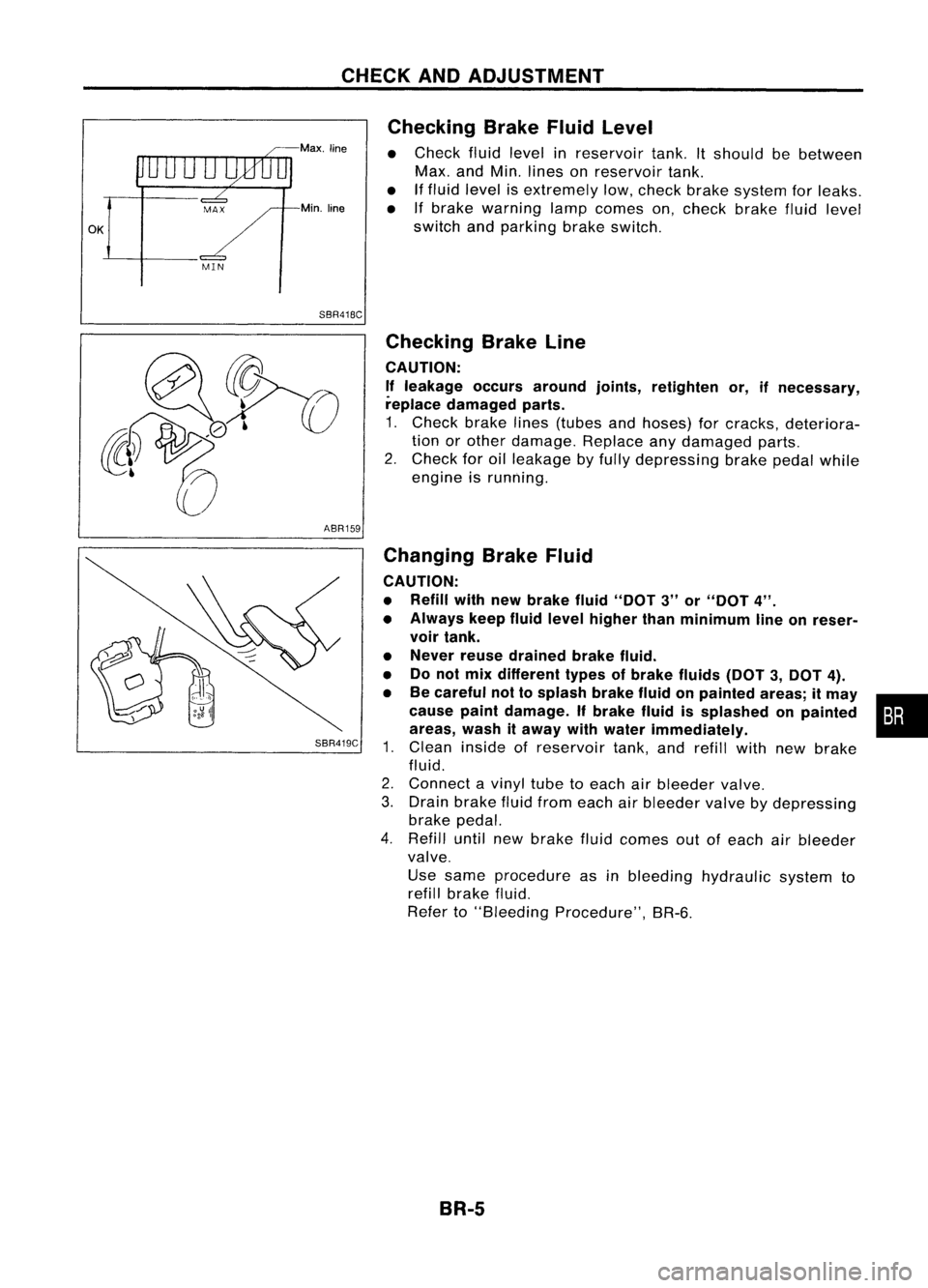

CHECKANDADJUSTMENT

OK

MINMax.

line

Min. line

SBR418C

Checking

BrakeFluidLevel

• Check fluidlevel inreservoir tank.Itshould bebetween

Max. andMin. lines onreservoir tank.

• Iffluid level isextremely low,check brakesystem forleaks.

• Ifbrake warning lampcomes on,check brakefluidlevel

switch andparking brakeswitch.

ABR159

SBR419C

Checking

BrakeLine

CAUTION: If leakage occursaround joints,retighten or,ifnecessary,

replace damaged parts.

1. Check brakelines(tubes andhoses) forcracks, deteriora-

tion orother damage. Replaceanydamaged parts.

2. Check foroilleakage byfully depressing brakepedalwhile

engine isrunning.

Changing BrakeFluid

CAUTION:

• Refill withnewbrake fluid"DOT 3"or"DOT 4".

• Always keepfluidlevel higher thanminimum lineonreser-

voir tank.

• Never reusedrained brakefluid.

• Donot mix different typesofbrake fluids(DOT3,DOT 4).

• Becareful nottosplash brakefluidonpainted areas;itmay •

cause paintdamage. Ifbrake fluidissplashed onpainted :•

areas, washitaway withwater immediately.

1. Clean inside ofreservoir tank,andrefill withnewbrake

fluid.

2. Connect avinyl tubetoeach airbleeder valve.

3. Drain brake fluidfrom each airbleeder valvebydepressing

brake pedal.

4. Refill untilnewbrake fluidcomes outofeach airbleeder

valve.

Use same procedure asinbleeding hydraulic systemto

refill brake fluid.

Refer to"Bleeding Procedure", BR-6.

BR-5

Page 288 of 1701

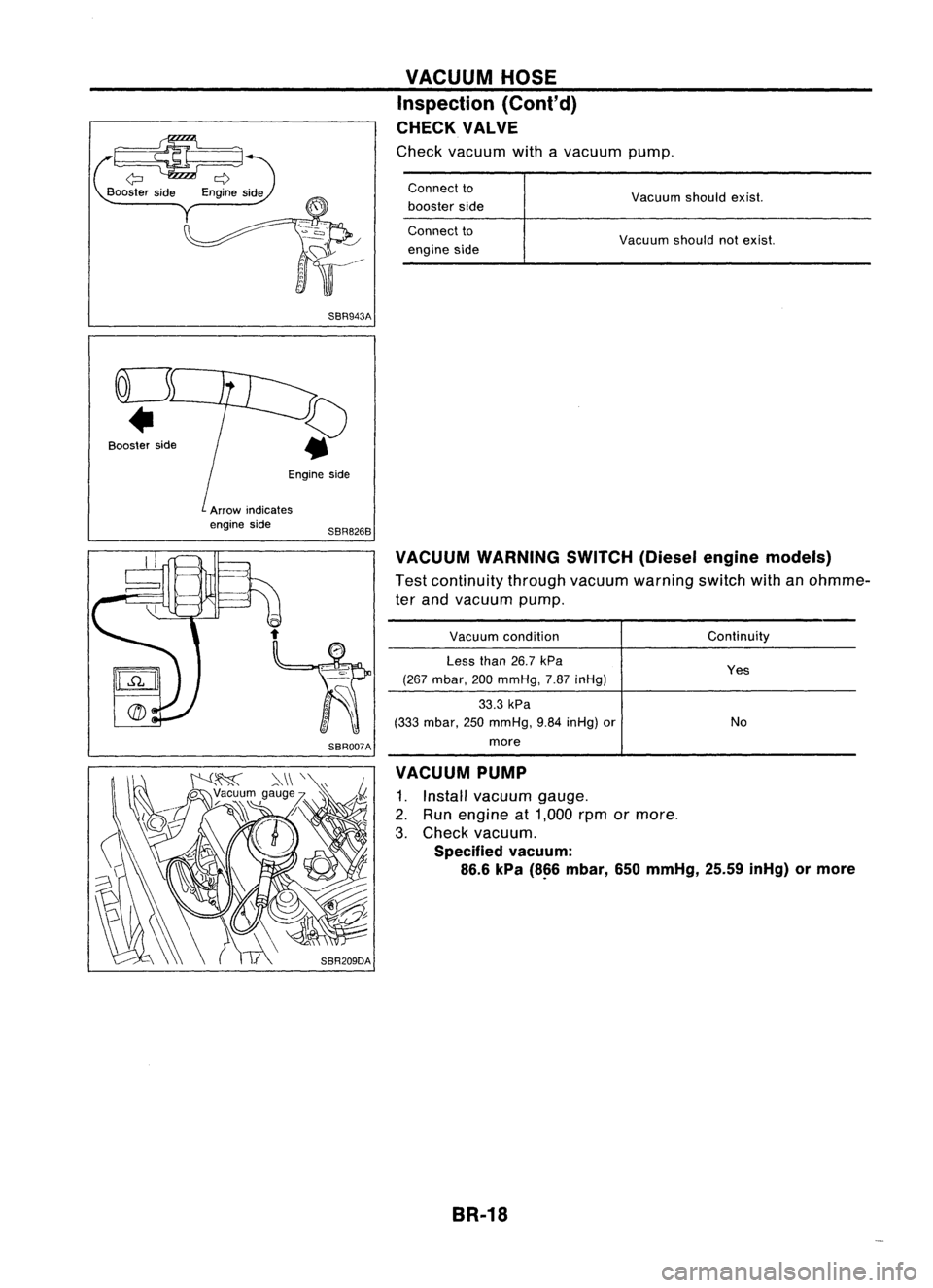

VACUUMHOSE

Inspection (Cont'd)

CHECK VALVE

Check vacuum withavacuum pump.

~

Booster side

SBR943A

Connect

to

booster side

Connect to

engine side Vacuum

shouldexist.

Vacuum shouldnotexist.

Engine side

VACUUM WARNING SWITCH(Dieselenginemodels)

Test continuity throughvacuum warning switchwithanohmme-

ter and vacuum pump.

Booster

side

Arrowindicates

engine side

SBR826B

SBR007A

Vacuum

condition

Less than26.7kPa

(267 mbar, 200mmHg, 7.87inHg)

33.3 kPa

(333 mbar, 250mmHg, 9.84inHg) or

more Continuity

Yes

No

VACUUM PUMP

1. Install vacuum gauge.

2. Run engine at1,000 rpmormore.

3. Check vacuum.

Specified vacuum:

86.6 kPa

(8~6

mbar, 650mmHg, 25.59inHg) ormore

BR-18

Page 289 of 1701

~0

tJ

L:{SR020D

FRONT

DISCBRAKE

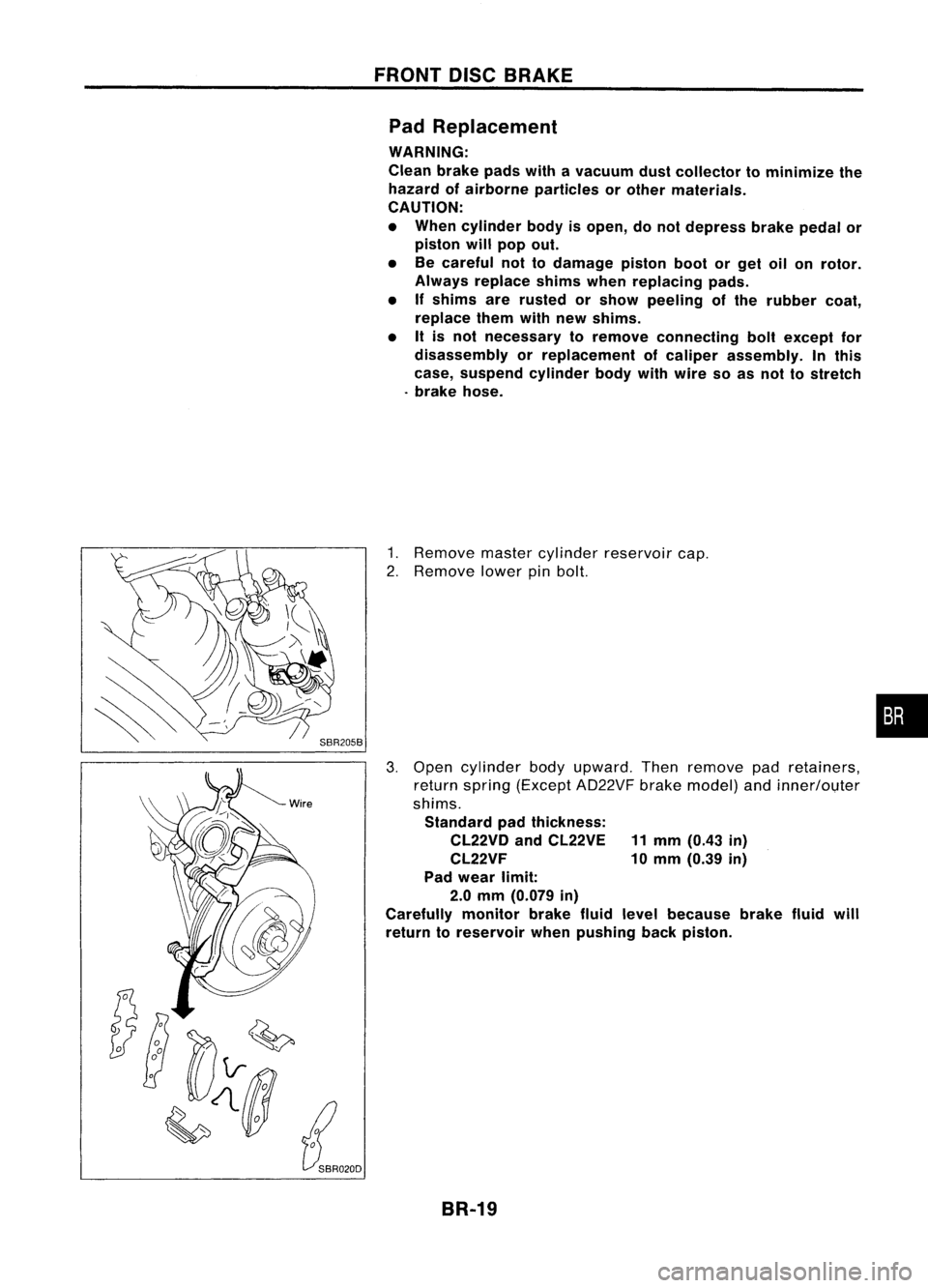

Pad Replacement

WARNING:

Clean brakepadswithavacuum dustcollector tominimize the

hazard ofairborne particles orother materials.

CAUTION:

• When cylinder bodyisopen, donot depress brakepedalor

piston willpop out.

• Becareful nottodamage pistonbootorget oilonrotor.

Always replace shimswhenreplacing pads.

• Ifshims arerusted orshow peeling ofthe rubber coat,

replace themwithnewshims.

• Itis not necessary toremove connecting boltexcept for

disassembly orreplacement ofcaliper assembly. Inthis

case, suspend cylinderbodywithwire soasnot tostretch

. brake hose.

1. Remove mastercylinder reservoir cap.

2. Remove lowerpinbolt.

3. Open cylinder bodyupward. Thenremove padretainers,

return spring (Except AD22VF brakemodel) andinner/ol,lter

shims. Standard padthickness:

CL22VD andCL22VE 11mm (0.43 in)

CL22VF 10mm (0.39 in)

Pad wear limit:

2.0 mm (0.079 in)

Carefully monitorbrakefluidlevel because brakefluidwill

return toreservoir whenpushing backpiston.

BR-19

•

Page 292 of 1701

AD22VF SBR776B

SBR772 FRONT

DISCBRAKE

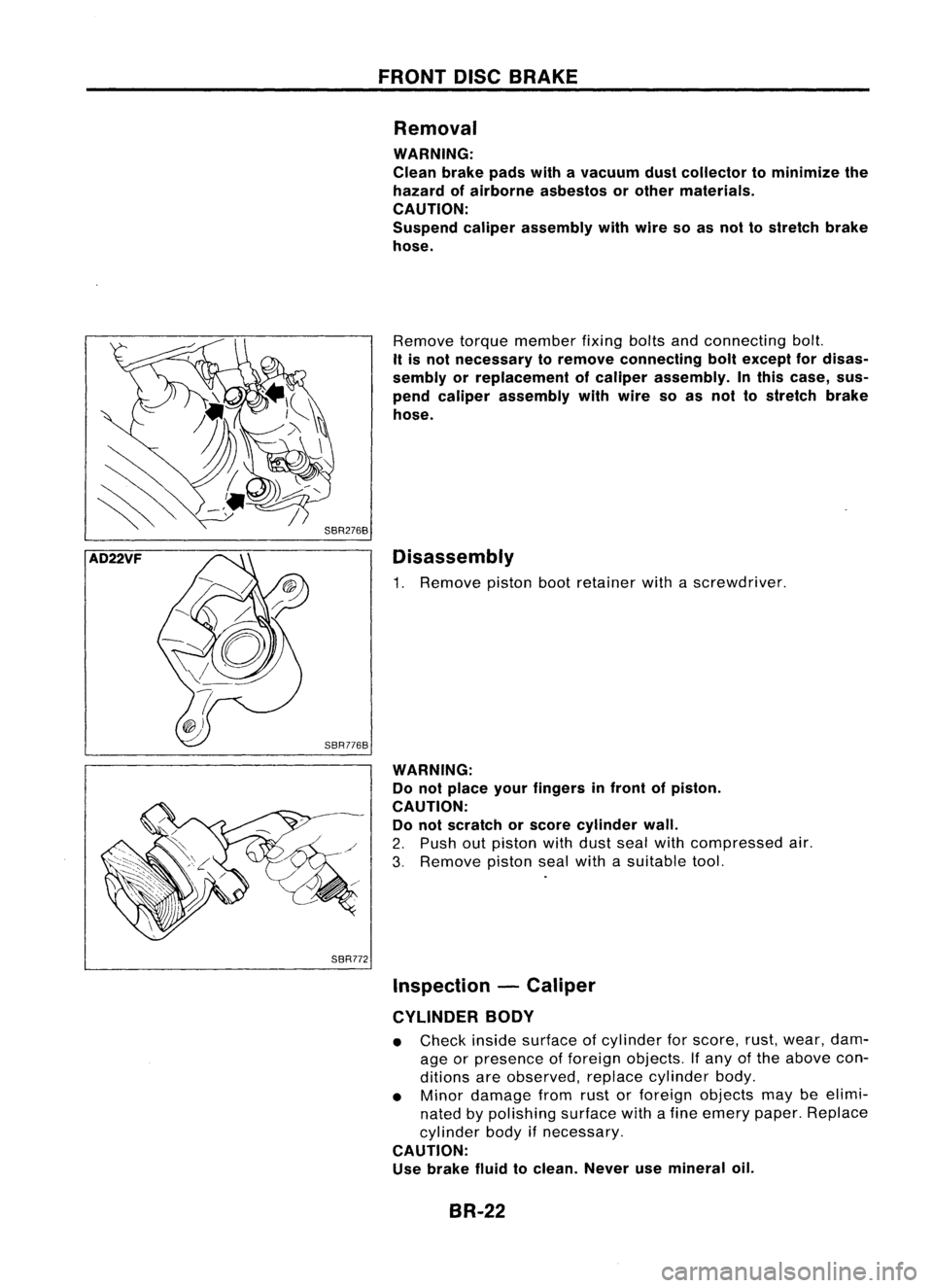

Removal

WARNING:

Clean brakepadswithavacuum dustcollector tominimize the

hazard ofairborne asbestos orother materials.

CAUTION:

Suspend caliperassembly withwire soasnot tostretch brake

hose.

Remove torquemember fixingboltsandconnecting bolt.

It is not necessary toremove connecting boltexcept fordisas-

sembly orreplacement ofcaliper assembly. Inthis case, sus-

pend caliper assembly withwire soas not tostretch brake

hose.

Disassembly

1. Remove pistonbootretainer withascrewdriver.

WARNING: Do not place yourfingers infront ofpiston.

CAUTION: Do not scratch orscore cylinder wall.

2. Push outpiston withdust sealwithcompressed air.

3. Remove pistonsealwith asuitable tool.

Inspection -Caliper

CYLINDER BODY

• Check insidesurface ofcylinder forscore, rust,wear, dam-

age orpresence offoreign objects. Ifany ofthe above con-

ditions areobserved, replacecylinder body.

• Minor damage fromrustorforeign objects maybeelimi-

nated bypolishing surfacewithafine emery paper.Replace

cylinder bodyifnecessary.

CAUTION: Use brake fluidtoclean. Neverusemineral oil.

BR-22