ECO mode NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 8 of 1701

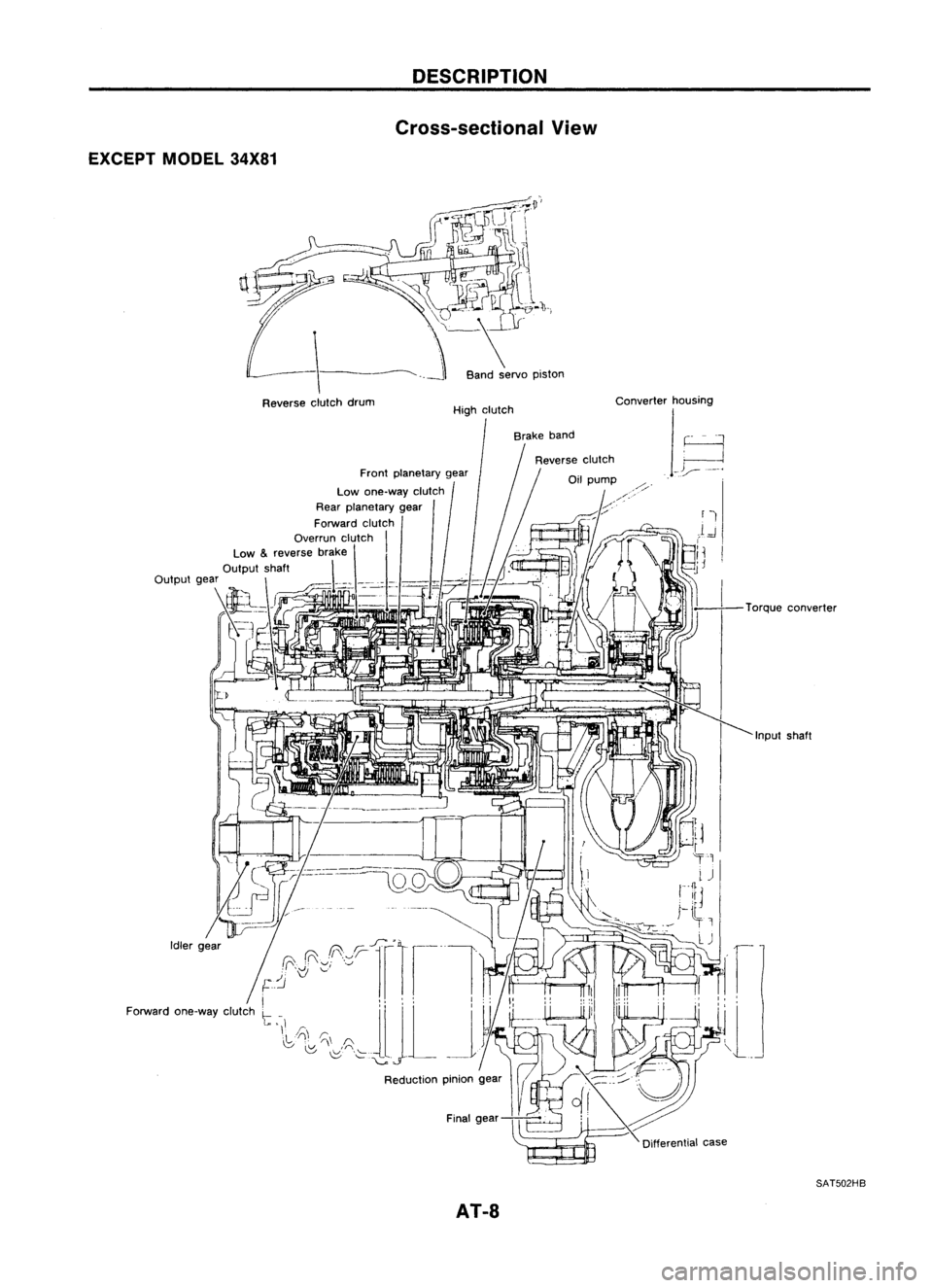

EXCEPTMODEL34X81

Reverse clutchdrum

DESCRIPTION

Cross-sectional View

Band servo piston

High clutch

Brake band

AT-8

Converter

housing

Torqueconverter

SAT502HB

Page 19 of 1701

TROUBLEDIAGNOSES

Road Testing (Cont'd)

SHIFT SCHEDULE

Drive thevehicle forapprox. 10minutes. Measuretheoiltem-

perature. Whentheoiltemperature becomesbetween50and

80°C (122and176°F), carryoutthis check.

VEHICLE SPEEDWHENSHIFTING GEARS

Model 34X68

Throttle posi- Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2

->

0

3

0

3

->

0

4

0

4

~

0

3

0

3

->

O

2

O

2

->

0,

1

2

~

1,

Full throttle

48

-56 88

-96 133

-141

80-88 37-45 45-53

(30 -35) (55-60)

-

(83-88)

(50-55) (23-28) (28

-33)

Half throttle

31

-39 54

-62 102-110

75-83 44

-52

7-15 45

-53

(19 -24) (34

-39)

(63-68) (47

-52)

(27-32) (4

-9)

(28-33)

Model 34X69and34X70

Throttle pas

i-

Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2~

0

3

0

3

->

0

4

0

4~

0

3

0

3

->

O

2

O

2~

0,

1

2~

1,

Full throttle

51

-60 94

-102 136-144

85-93 40

-48

48-56

(32 -37) (58-63)

-

(85-89)

(53-58) (25

-30) (30-35)

Half throttle

30

-38 52

-60 97-105 67-75 42-50 8-16

48-56

(19 -24) (32-37) (60-65) (42-47) (26-31) (5-10) (30-35)

Model 34X80

Throttle posi- Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2

->

0

3

0

3~

0

4

0

4

->

0

3

0

3

~

O

2

O

2

->

0,

1"

->

1,

Full throttle

52

-60 100-108 145

-153

90-98 40

-48 49-57

(32 -37) (62-67)

-

(90-95) (56-61) (25-30) (30

-35)

Half throttle

30

-38 53-61 103

-111

69-77 42

-50 8-16 49-57

(19 -24) (33-38) (64-69) (43-48) (26-31) (5-10) (30-35)

Model 34X81

Throttle posi- Vehicle

speedkm/h(MPH)

tion

0,~O

2

O

2

->

0

3

0

3

~

0

4

0

4

->

0

3

0

3

->

O

2

O

2

~

0,

1

2~

1,

Full throttle

58

-66 107

-115 160

-168

96-104 39

-47 48-56

(36 -41) (66

-71)

-

(99-104) (60-65) (24

-29) (30

-35)

33 -41 57-65 105

-113 69-77 45-53 8-16 48-56

Half throttle

(21-25) (35-40)

(65-70) (43

-48) (28-33) (5-10) (30

-35)

AT-19

•

Page 40 of 1701

REMOVALANDINSTALLATION

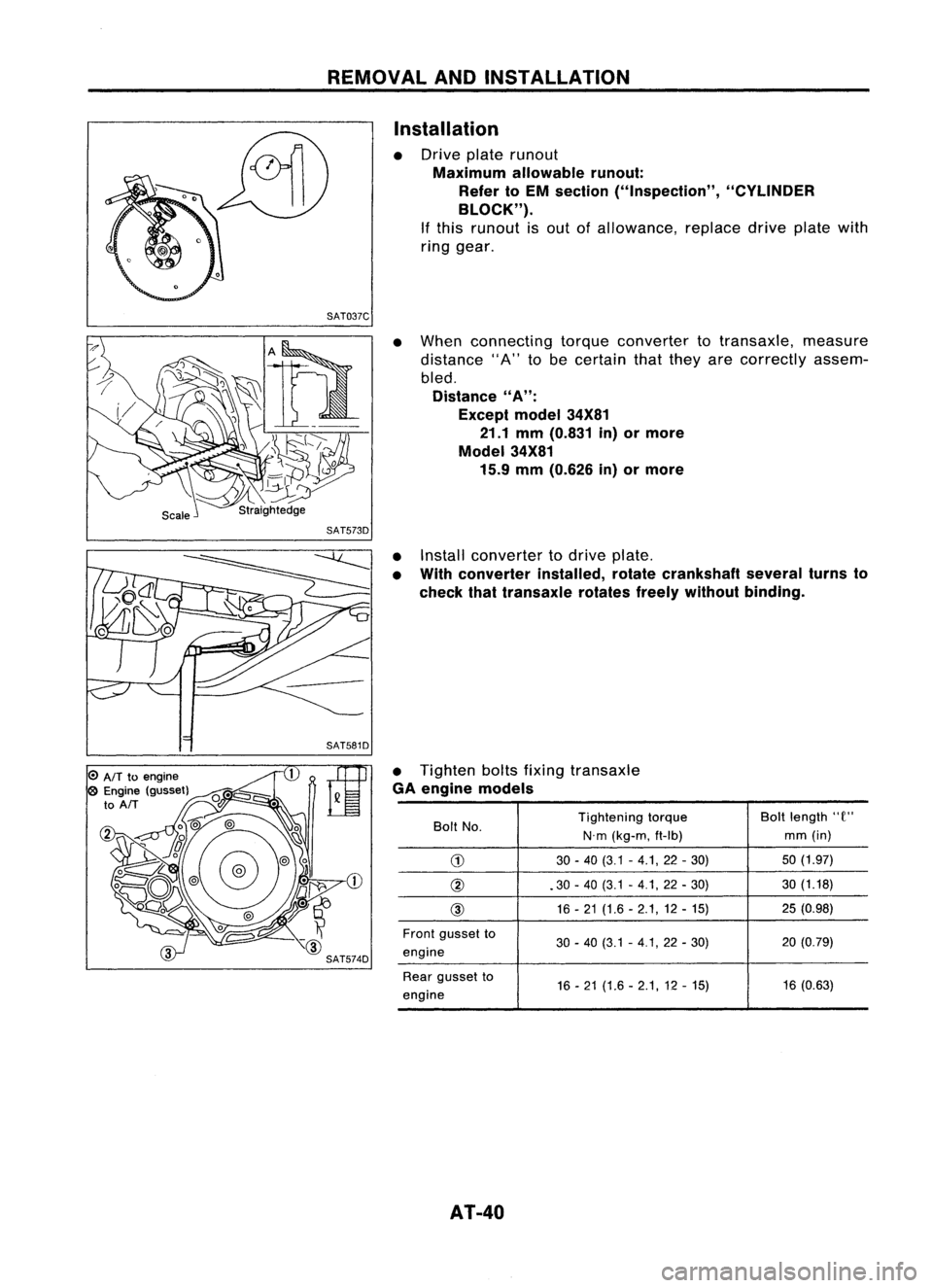

Installation

• Drive platerunout

Maximum allowablerunout:

Refer toEM section ("Inspection", "CYLINDER

BLOCK").

If this runout isout ofallowance, replacedriveplatewith

ring gear.

SAT037C

•When connecting torqueconverter totransaxle, measure

distance "A"tobe certain thatthey arecorrectly assem-

bled.

Distance

"A":

Except model34X81

21.1 mm(0.831 in)ormore

Model 34X81

15.9 mm(0.626 in)ormore

o

AIT

toengine

o

Engine (gusset)

to

AIT

SAT573D

•Install converter todrive plate.

• With converter installed,rotatecrankshaft severalturnsto

check thattransaxle rotatesfreelywithout binding.

• Tighten boltsfixing transaxle

GA engine models

Bolt No. Tightening

torque Boltlength

"e"

N.m (kg-m, ft-Ib) mm

(in)

G)

30-40 (3.1 -4.1,22 -30) 50

(1.97)

@ .30-40 (3.1 -4.1, 22-30) 30

(1.18)

@ 16

-21 (1.6 -2.1,12 -15) 25

(0.98)

Front gusset to

30-40 (3.1 -4.1,22 -30) 20

(0.79)

engine

Rear gusset to

16-21 (1.6 -2.1,12 -15) 16

(0.63)

engine

AT-40

Page 61 of 1701

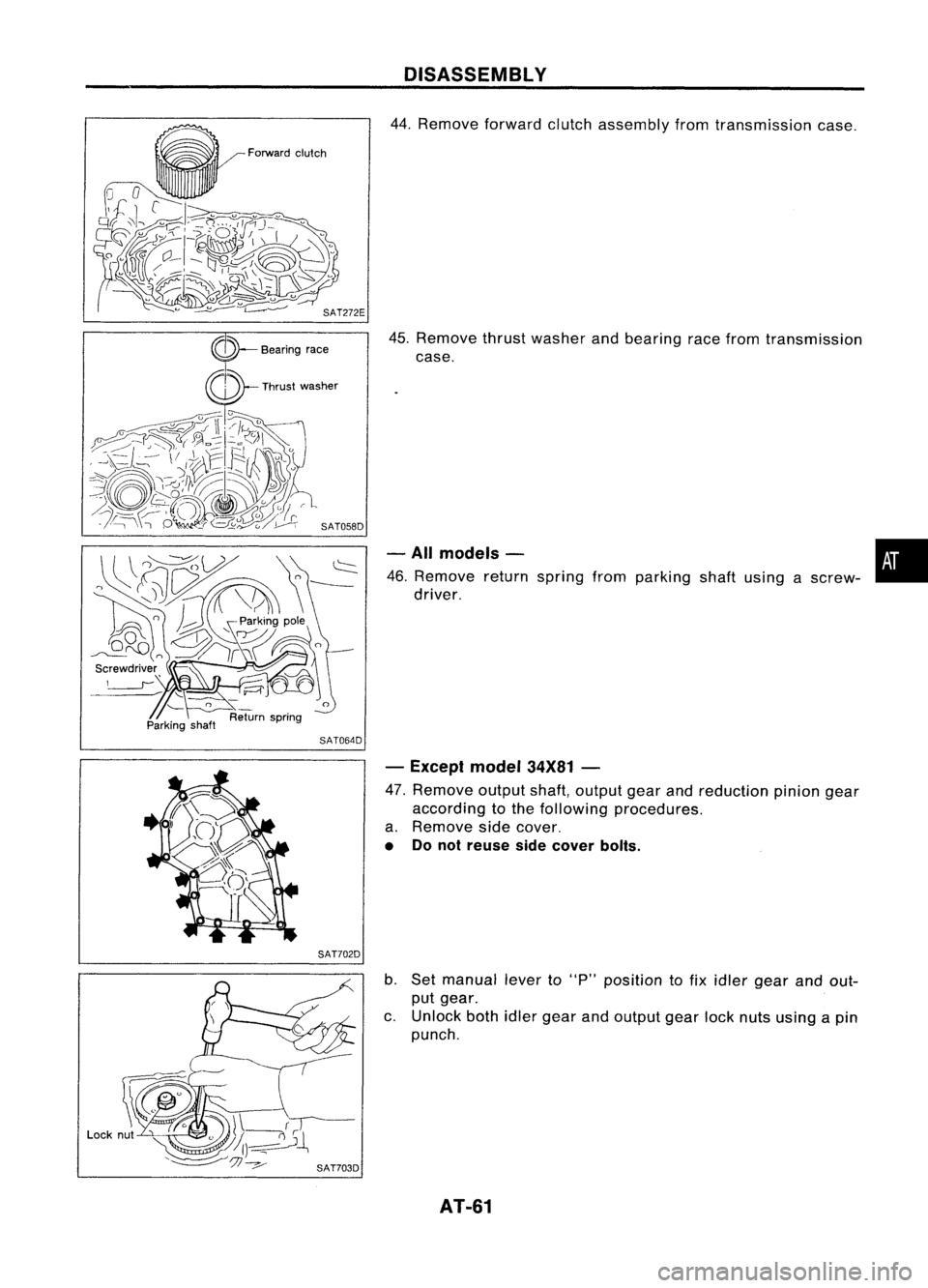

Parkingshaft

SAT064D

SAT702D DISASSEMBL

V

44. Remove forwardclutchassembly fromtransmission case.

45. Remove thrustwasher andbearing racefrom transmission

case.

- All models - •

46. Remove returnspring fromparking shaftusing ascrew-

i

driver.

- Except model34X81-

47. Remove outputshaft,output gearandreduction piniongear

according tothe following procedures.

a. Remove sidecover.

• Donot reuse sidecover bolts.

b. Set manual leverto"p" position tofix idler gear andout-

put gear.

c. Unlock bothidlergear andoutput gearlocknuts using apin

punch.

AT-61

Page 62 of 1701

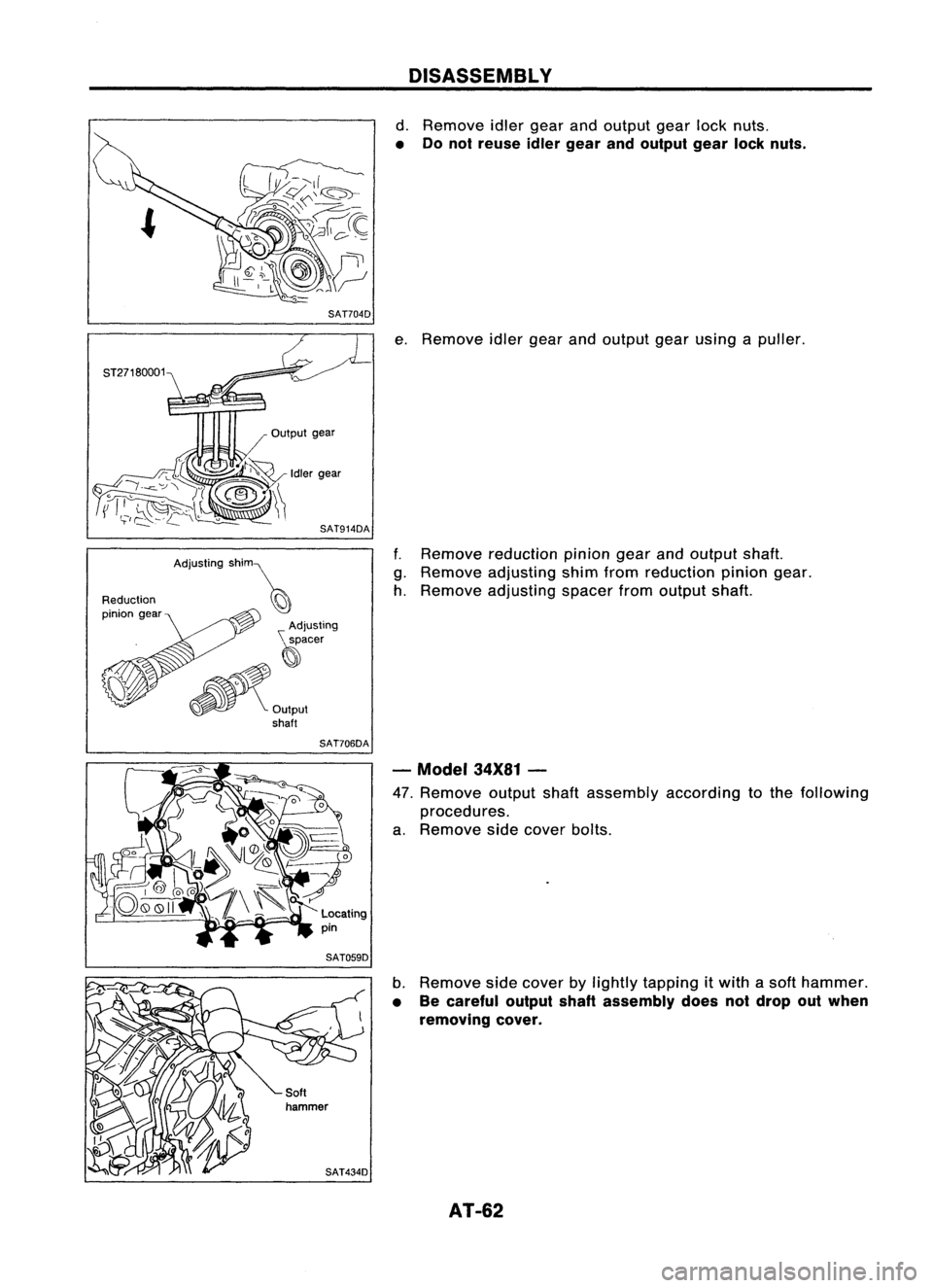

SAT704D

Reduction

pinion gear

SAT706DADISASSEMBL

V

d. Remove idlergear andoutput gearlocknuts.

• Donot reuse idlergear andoutput gearlocknuts.

e. Remove idlergearandoutput gearusing apuller.

f. Remove reduction piniongearandoutput shaft.

g. Remove adjusting shimfromreduction piniongear.

h. Remove adjusting spacerfromoutput shaft.

- Model 34X81-

47. Remove outputshaftassembly according tothe following

procedures.

a. Remove sidecover bolts.

b. Remove sidecover bylightly tapping itwith asoft hammer.

• Becareful outputshaftassembly doesnotdrop outwhen

removing cover.

AT-62

Page 74 of 1701

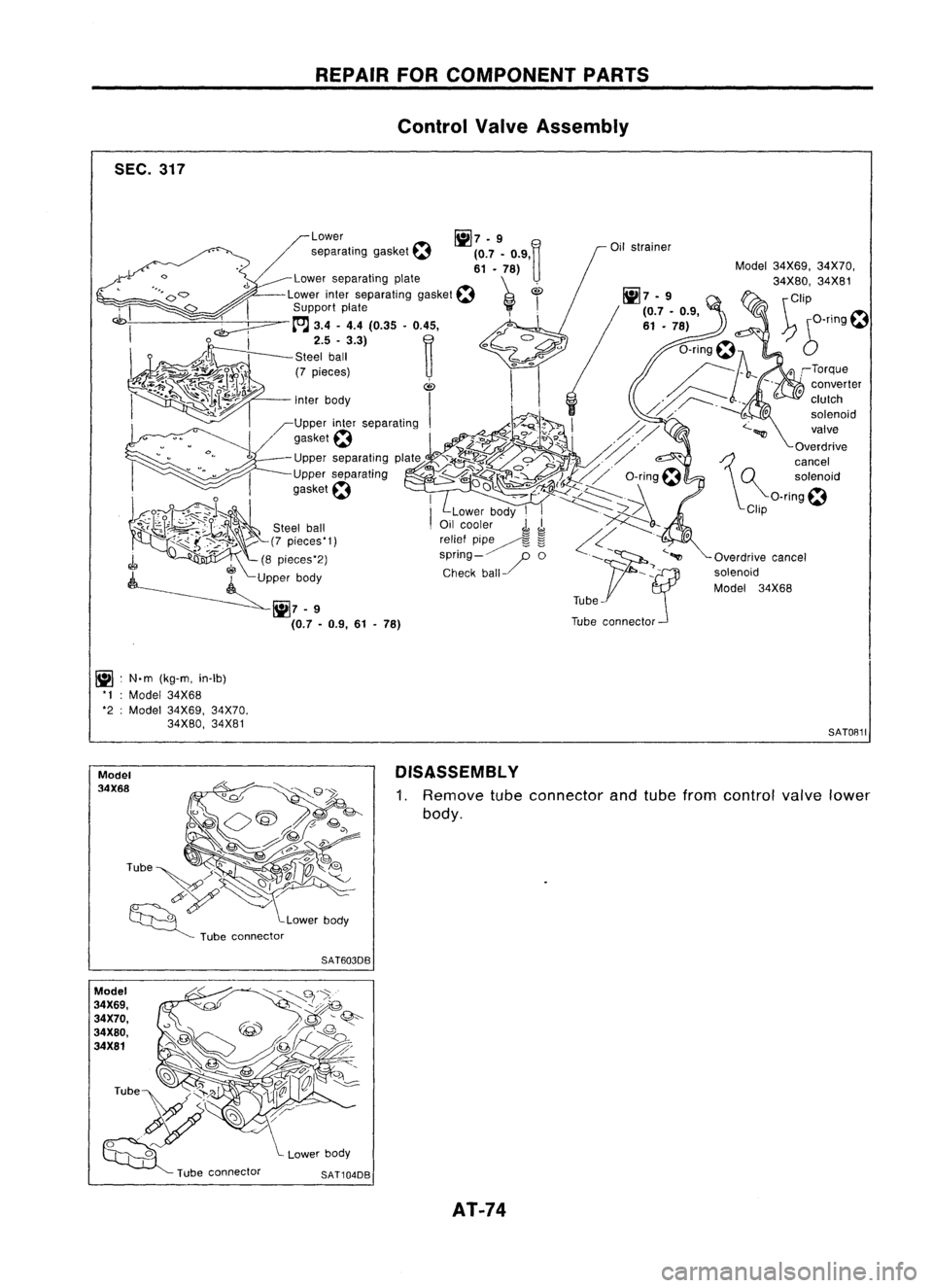

SEC.317

~ :N.m (kg-m, in-Ib)

'I :Model 34X68

'2 :Model 34X69, 34X70.

34X80, 34X81

Model

34X68

Model

34X69,

34X70.

34X80,

34X81 REPAIR

FORCOMPONENT PARTS

Control ValveAssembly

Model34X69, 34X70,

34X80, 34X81

\ Clip

~ 6-T1ng~

SATOB11

DISASSEMBL Y

1. Remove

tubeconnector andtube from control

valve

lower

body.

SAT603DB

SAT104DB AT-74

Page 75 of 1701

SAT245EB

Nut

Section Z- Z

Reamer bolt

•

Bolt

symbol

@

@ @@

CID

cD

Bolt length 'T'

13.558.0 40.0 66.033.078.0

~Qmm(in)

(0.531)

(2.283)(1.575)(2.598) (1.299)

(3.071)

Number ofbolts

4

3 611

22

Bolt symbol

@

@ @@

CID

CD

Bolt length" ("

13.558.0 40.0

66.0 33.078.0

~ (0.531)(2.283)

(1.575)(2.598) (1.299)(3.071)

>-,-1

Qmm (in)

Number ofbolts

53 611

22

With

torque converter clutchsolenoid valve

@

@

REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

2. Disassemble upper,interandlower bodies usingthefollow-

ing procedures.

Bolt length, number andlocation:

Without torqueconverter clutchsolenoid valve

CD

Plain

washer

Section

y- y

Model

34X68

Section Y- Y

@Bolt~

Support plate

f

(E)BOIt~

Support plate~

(f)

Plain

washer

Nut SAT515HB

Model 34X68

a.

Remove bolts@,@and

CB

shown inthe illustration.

b. Remove oilstrainer fromcontrol valveassembly.

AT-75

Page 76 of 1701

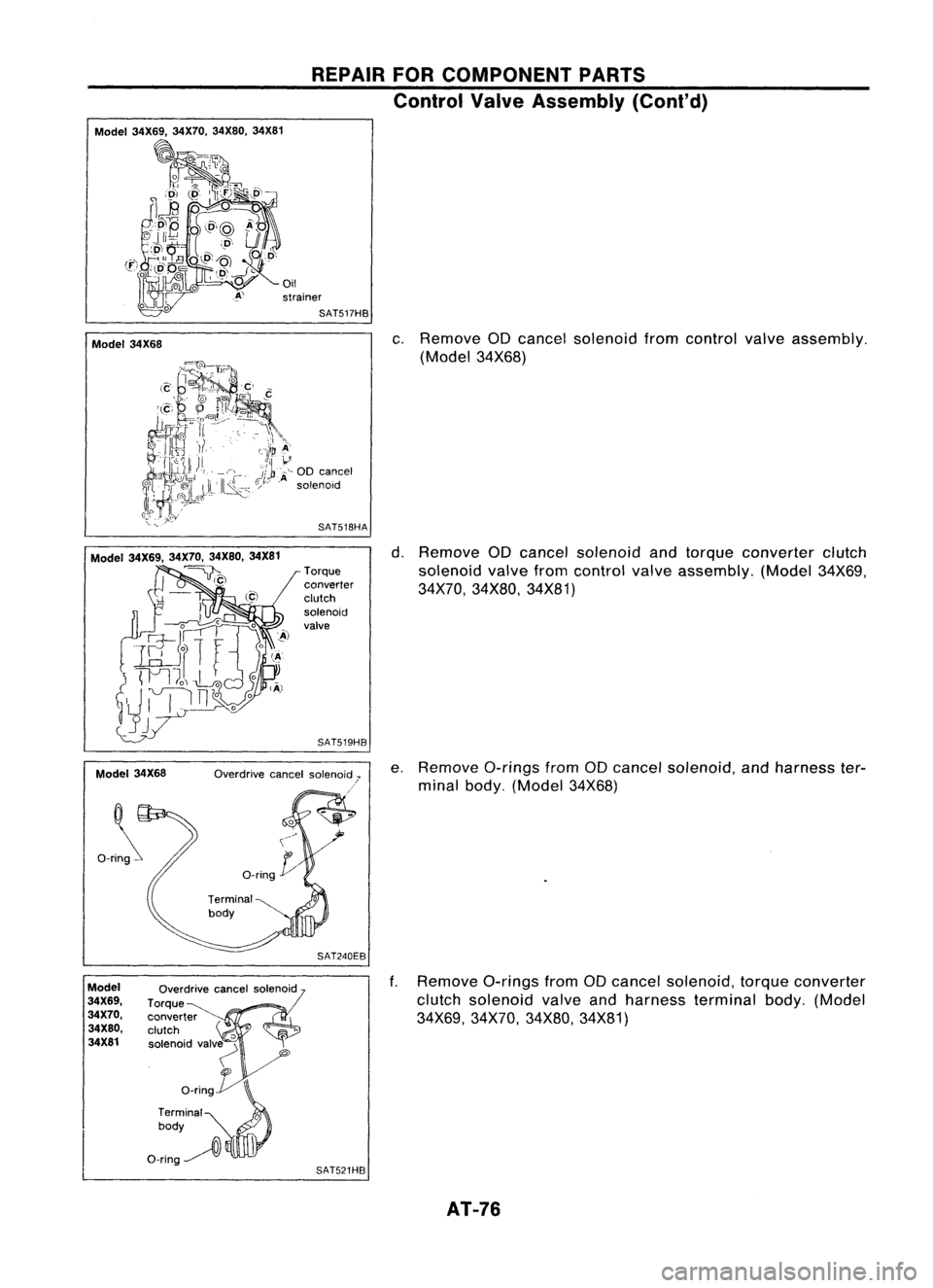

Model34X69. 34X70.34X80,34X81 REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

Model 34X68

c.

Remove aDcancel solenoid fromcontrol valveassembly.

(Model 34X68)

Model 34X69. 34X70,34X80.34X81

~)

Model 34X68

Ori~

Torque

converter

clutch

solenoid

valve

SAT519HB

SAT240EB

d.

Remove aDcancel solenoid andtorque converter clutch

solenoid valvefromcontrol valveassembly. (Model34X69,

34X70, 34X80, 34X81)

e. Remove a-ringsfromaDcancel solenoid, andharness ter-

minal body. (Model 34X68)

ModeJ

34X69.

34X70.

34X80.

34X81

Overdrive

cancelsolenoid

Torque

converter

clutch

'0

solenoid valv~

"

o_rin~

Terminal

0

body

O-ring~

l\

SAT521HB

f.

Remove a-ringsfromaDcancel solenoid, torqueconverter

clutch solenoid valveandharness terminal body.(Model

34X69, 34X70, 34X80,34X81)

AT-76

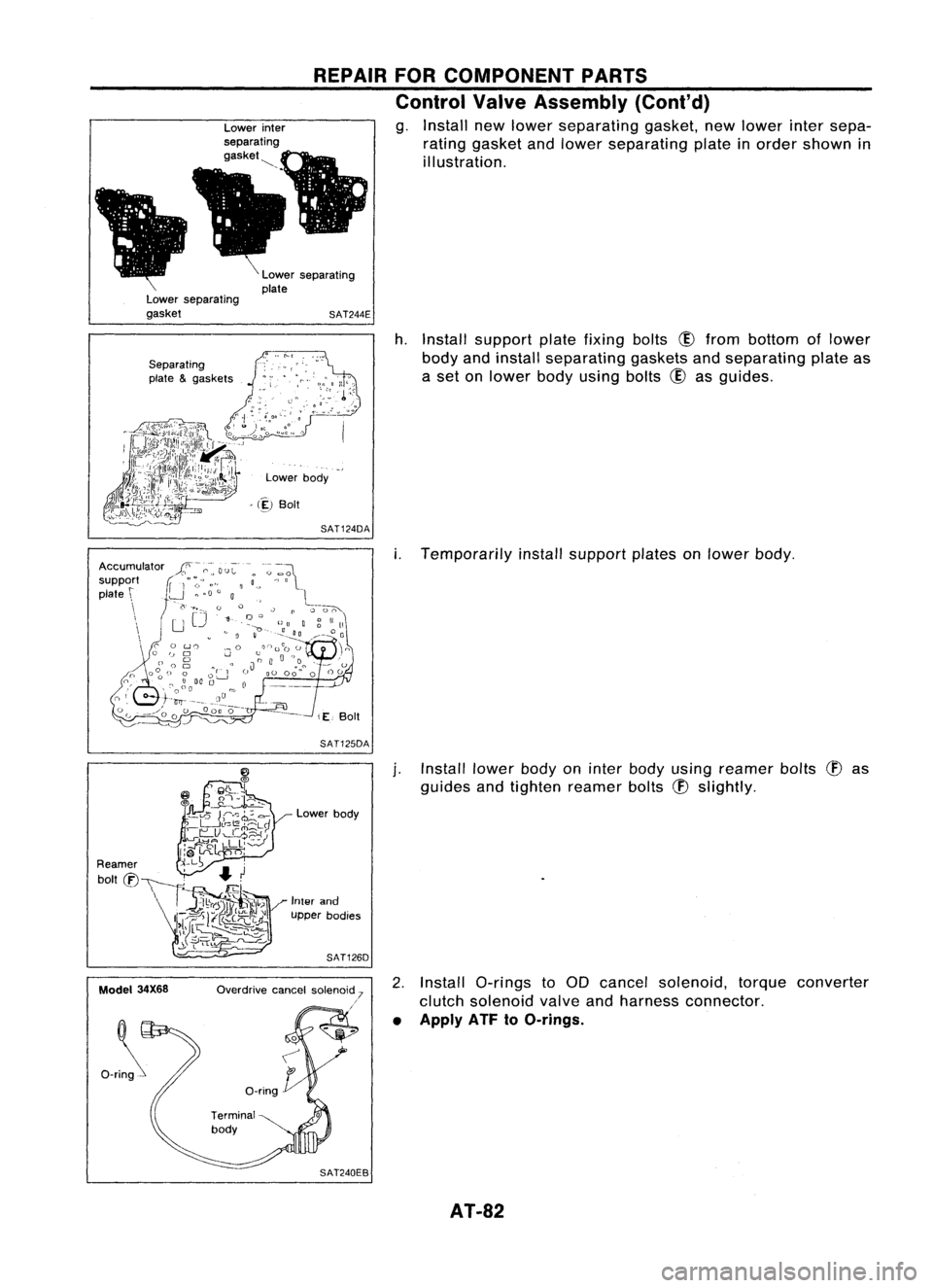

Page 82 of 1701

Lowerseparating

gasket REPAIR

FORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

g. Install newlower separating gasket,newlower intersepa-

rating gasket andlower separating plateinorder shown in

illustration.

Lower separating

plate

SAT244E

Separating

plate &gaskets

Lowerbody

> (~)

Boit

SAT124DA

h.

Install support platefixing bolts

CID

from bottom oflower

body andinstall separating gasketsandseparating plateas

a set onlower bodyusing bolts

CID

asguides.

SAT125DA

i.

Temporarily installsupport platesonlower body.

Model 34X68 Lower

body

Inter and

upper bodies

SAT126D

Overdrive cancelsolenoid 7

.'

j.

Install lowerbodyoninter body using reamer bolts

(f)

as

guides andtighten reamer bolts

(f)

slightly.

2. Install a-rings toaD cancel solenoid, torqueconverter

clutch solenoid valveandharness connector.

• Apply ATF

toO-rings.

AT-82

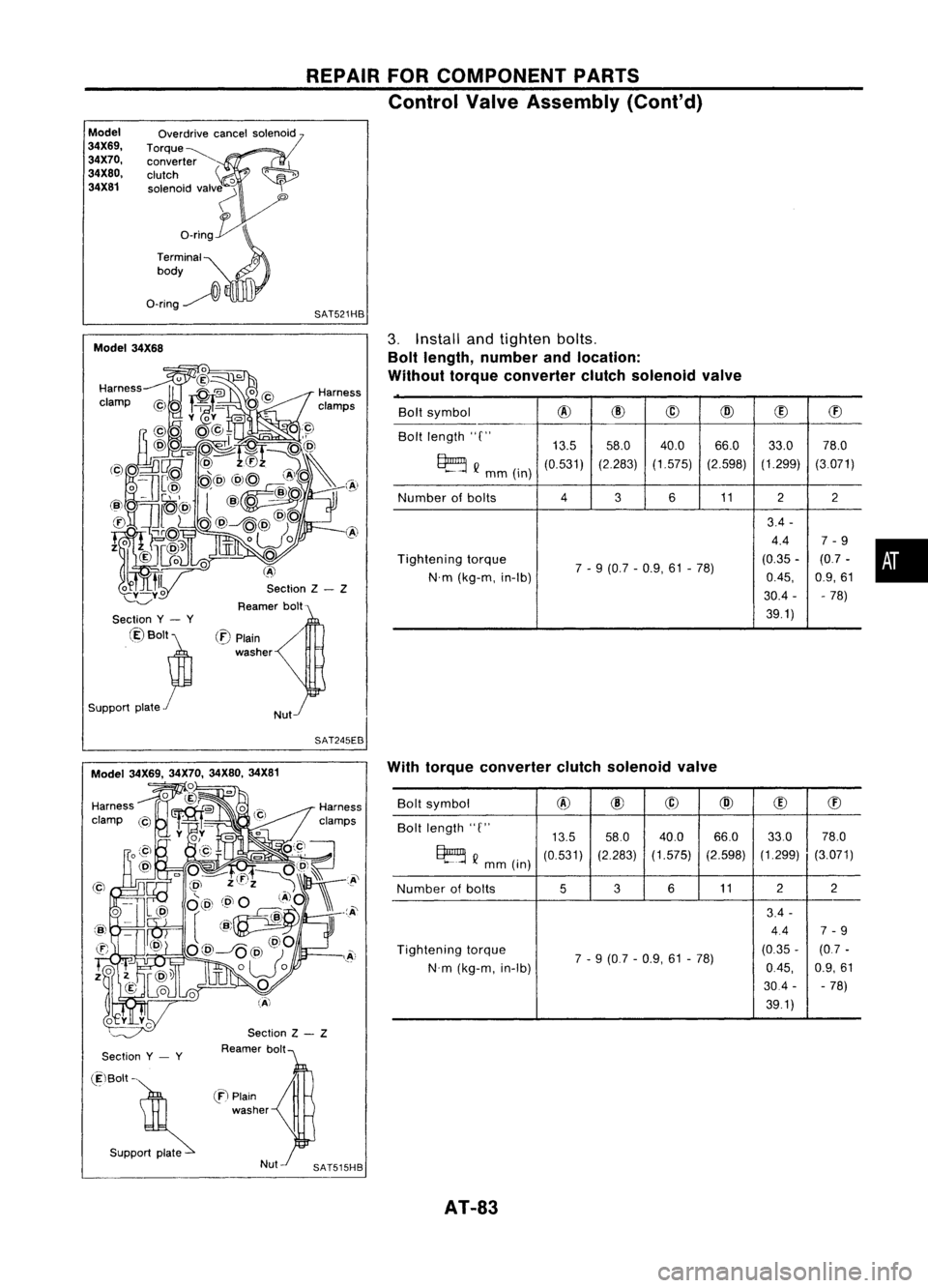

Page 83 of 1701

REPAIRFORCOMPONENT PARTS

Control ValveAssembly (Cont'd)

Model

34X69, 34X70,

34X80, 34X81 Overdrive

cancelsolenoid

Torque~ converter

clutch

'0

solenoid valv~

'"

o_rin~

Terminal

0

body

O-ring~

l\

SAT521HB

Section Z- Z

Reamer bolt

Model

34X68

•

Bolt

symbol

@

@

@

@

(!)

ffi

Bolt length "C"

13.558.0 40.0 66.0

33.078.0

~ Q

mm(in)

(0.531)

(2.283)(1.575) (2.598)(1.299)

(3.071)

Number ofbolts

4

3611

22

3.4 -

4.4 7-9

Tightening torque

7-9 (0.7 -0.9, 61-78) (0.35

-(0.7 -

N'm (kg-m, in-Ib)

0.45,

0.9,61

30.4 - -78)

39.1)

3.

Install andtighten bolts.

Bolt length, number andlocation:

Without torqueconverter clutchsolenoid valve

/

Nut

(:E)

Plain

washer

Section

y- y

@Bolt~

Support plate

r

SAT245EB

Section

y- y

Section

Z- Z

Reamer bolt With

torque converter clutchsolenoid valve

Bolt symbol

@

@

@

@

(!)

ffi

Bolt length "C"

13.558.0

40.0 66.033.0

78.0

~ Q

mm (in)

(0.531)

(2.283)

(1.575) (2.598)(1.299)

(3.071)

Number ofbolts

536

11 2

2

3.4 -

4.4 7-9

Tightening torque

7-9 (0.7 -0.9, 61-78) (0.35

-(0.7 -

N'm (kg-m, in-Ib)

0.45,

0.9,61

30.4 --

78)

39.1)

(ElBolt -

. S"PP~

en

Plain

washer

AT-83