brake light NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 6 of 2493

The security indicator is located on the combi meter. The indicator

blinks when the ignition switch is in ªOFFº or ªACCº position.

Therefore, NATS warns outsiders that the vehicle is equipped with

the anti-theft system.

+When NATS detects trouble, the security indicator lamp lights

up while ignition switch is in ªONº position.

This lighting up indicates that the anti-theft is not functioning,

so prompt service is required.

+When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs),

CONSULT-II hardware and CONSULT-II NATS software is

necessary.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

+When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner. A

maximum of five key IDs can be registered into NATS.

+When failing to start the engine first time using the key of

NATS, start as follows.

a) Leave the ignition key in ªONº position for approximately 5

seconds.

b) Turn ignition key to ªOFFº or ªLOCKº position and wait approxi-

mately 5 seconds.

c) Repeat step 1 and 2 again.

d) Restart the engine while keeping the key separate from any

others on key-chain.

SGI285

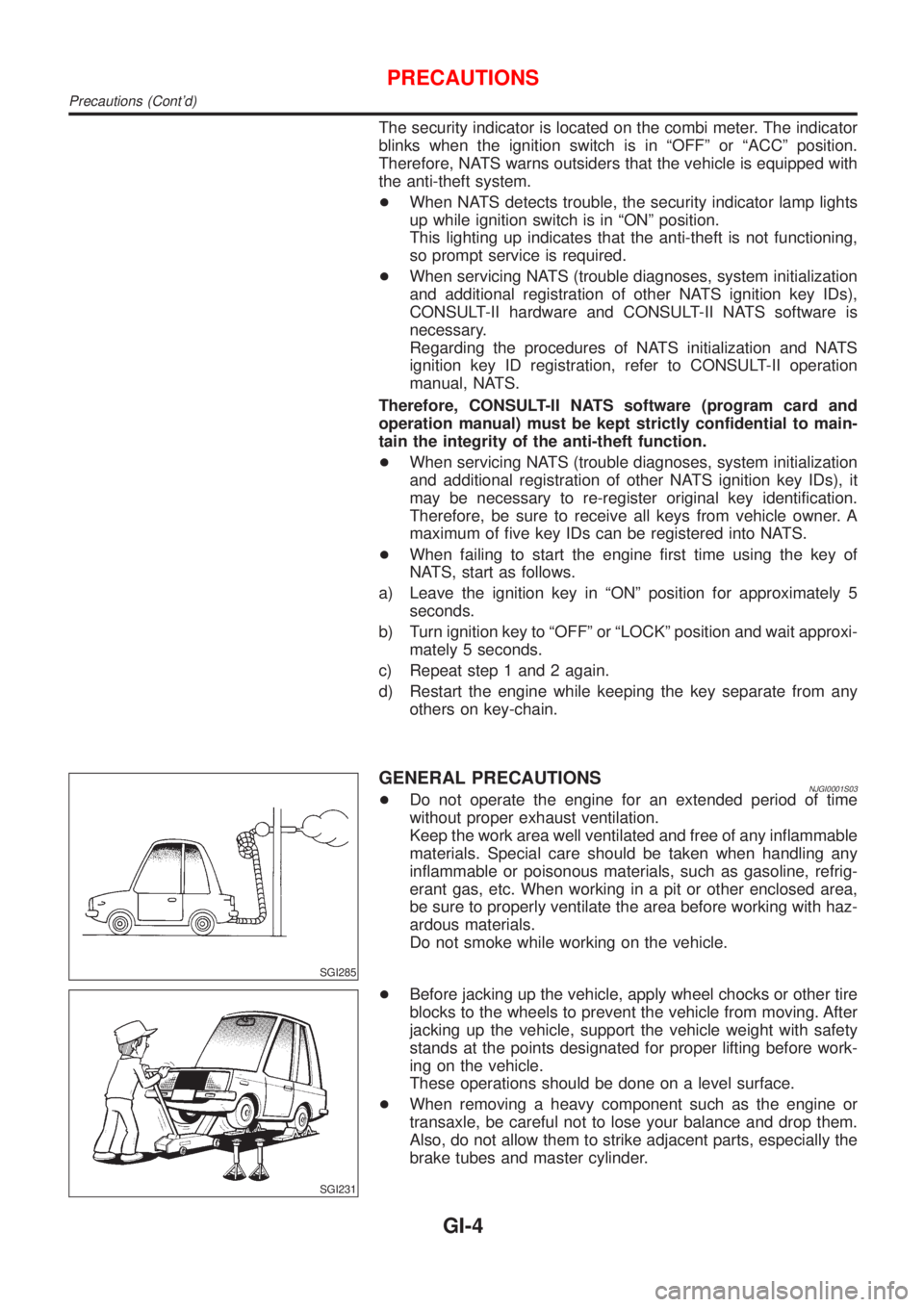

GENERAL PRECAUTIONSNJGI0001S03+Do not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrig-

erant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with haz-

ardous materials.

Do not smoke while working on the vehicle.

SGI231

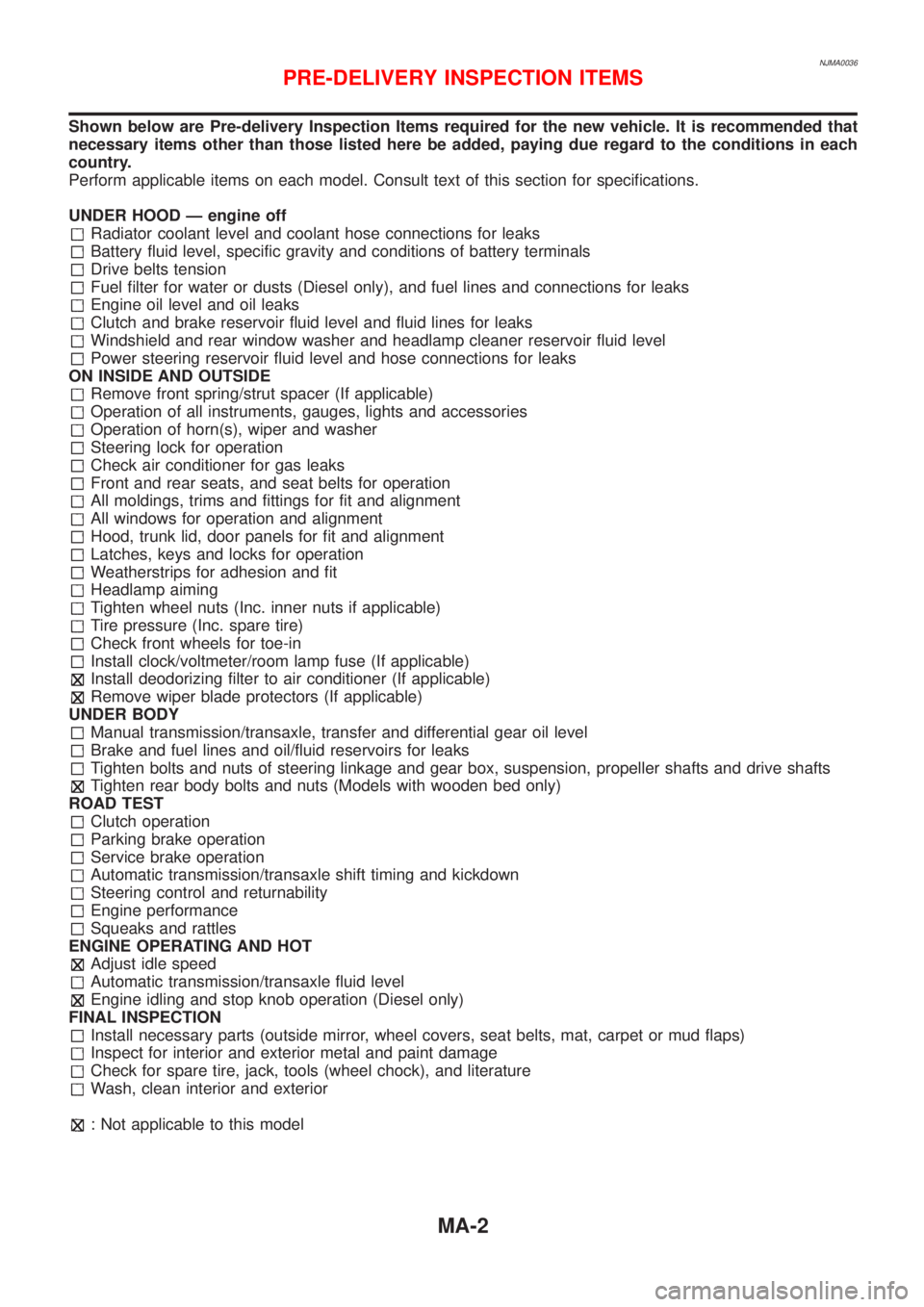

+Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before work-

ing on the vehicle.

These operations should be done on a level surface.

+When removing a heavy component such as the engine or

transaxle, be careful not to lose your balance and drop them.

Also, do not allow them to strike adjacent parts, especially the

brake tubes and master cylinder.

PRECAUTIONS

Precautions (Cont'd)

GI-4

Page 58 of 2493

NJMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 129 of 2493

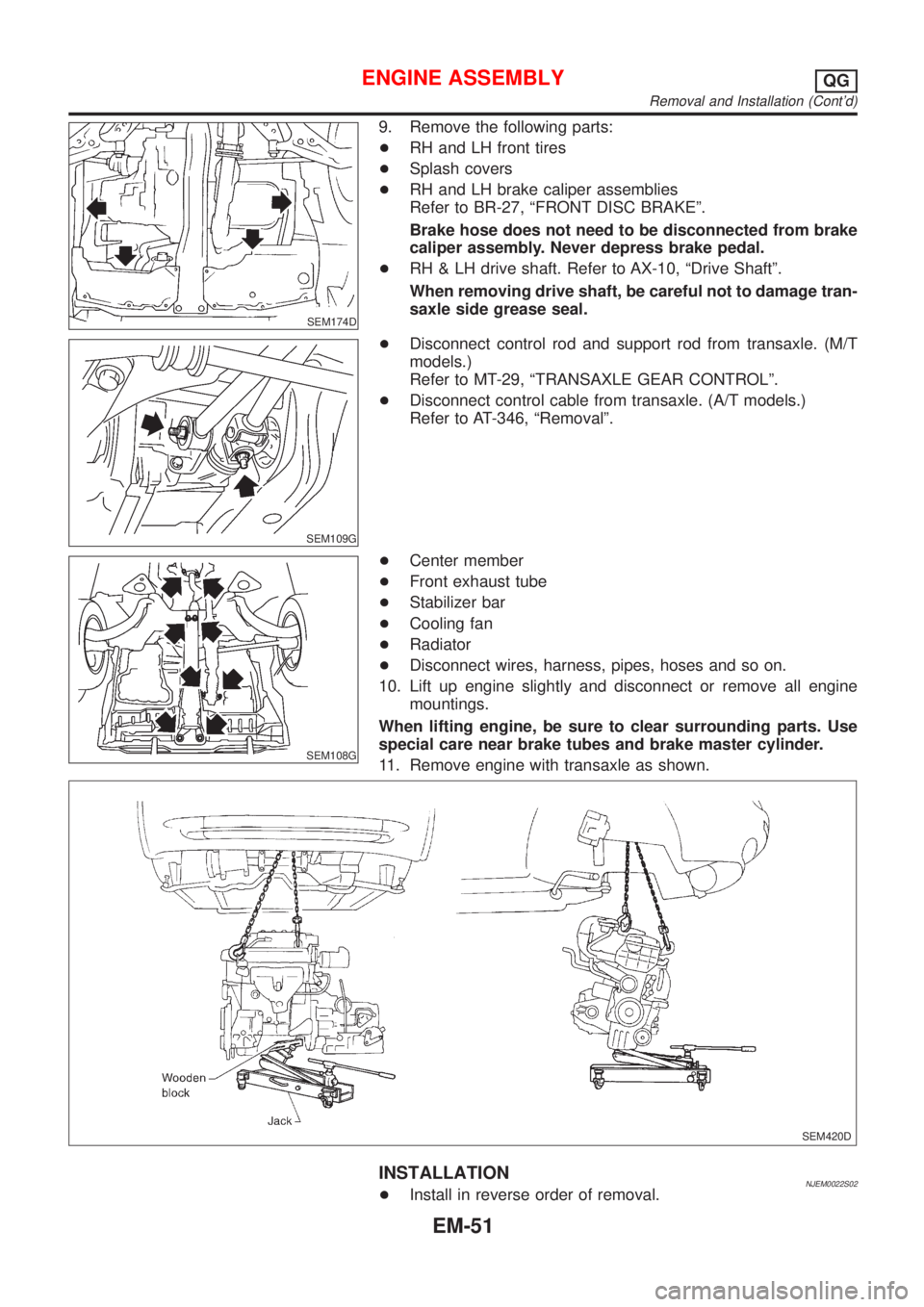

SEM174D

9. Remove the following parts:

+RH and LH front tires

+Splash covers

+RH and LH brake caliper assemblies

Refer to BR-27, ªFRONT DISC BRAKEº.

Brake hose does not need to be disconnected from brake

caliper assembly. Never depress brake pedal.

+RH & LH drive shaft. Refer to AX-10, ªDrive Shaftº.

When removing drive shaft, be careful not to damage tran-

saxle side grease seal.

SEM109G

+Disconnect control rod and support rod from transaxle. (M/T

models.)

Refer to MT-29, ªTRANSAXLE GEAR CONTROLº.

+Disconnect control cable from transaxle. (A/T models.)

Refer to AT-346, ªRemovalº.

SEM108G

+Center member

+Front exhaust tube

+Stabilizer bar

+Cooling fan

+Radiator

+Disconnect wires, harness, pipes, hoses and so on.

10. Lift up engine slightly and disconnect or remove all engine

mountings.

When lifting engine, be sure to clear surrounding parts. Use

special care near brake tubes and brake master cylinder.

11. Remove engine with transaxle as shown.

SEM420D

INSTALLATIONNJEM0022S02+Install in reverse order of removal.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-51

Page 847 of 2493

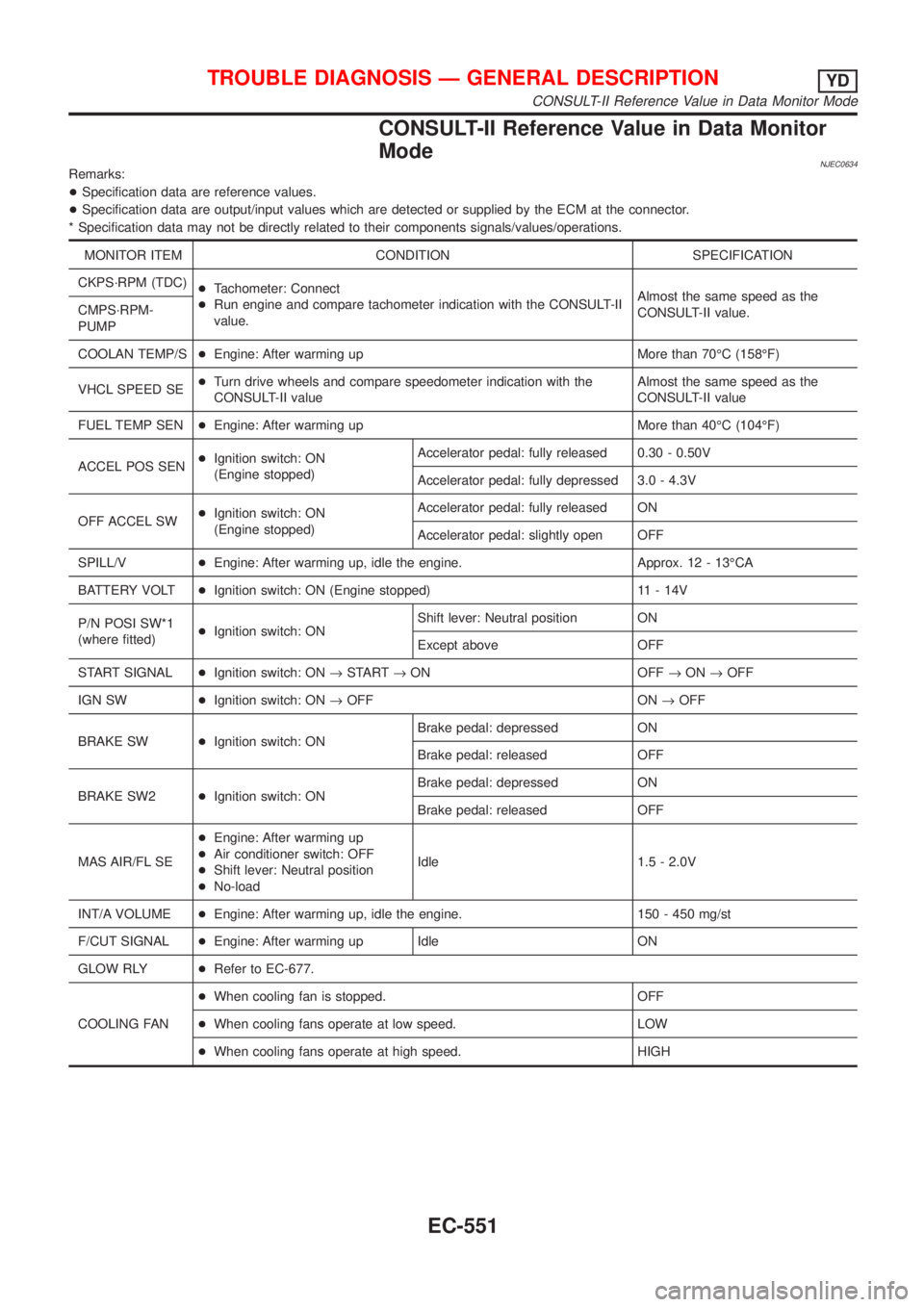

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0634Remarks:

+Specification data are reference values.

+Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (TDC)

+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value. CMPS´RPM-

PUMP

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the

CONSULT-II valueAlmost the same speed as the

CONSULT-II value

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.30 - 0.50V

Accelerator pedal: fully depressed 3.0 - 4.3V

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SPILL/V+Engine: After warming up, idle the engine. Approx. 12 - 13ÉCA

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW*1

(where fitted)+Ignition switch: ONShift lever: Neutral position ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

IGN SW+Ignition switch: ON®OFF ON®OFF

BRAKE SW+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

BRAKE SW2+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

MAS AIR/FL SE+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: Neutral position

+No-loadIdle 1.5 - 2.0V

INT/A VOLUME+Engine: After warming up, idle the engine. 150 - 450 mg/st

F/CUT SIGNAL+Engine: After warming up Idle ON

GLOW RLY+Refer to EC-677.

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fans operate at low speed. LOW

+When cooling fans operate at high speed. HIGH

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

CONSULT-II Reference Value in Data Monitor Mode

EC-551

Page 1189 of 2493

Diagnostic Procedure ..............................................253

Component Inspection .............................................255

DTC P1705 THROTTLE POSITION SENSOR...........256

Description ...............................................................256

Wiring Diagram - AT - TPS ......................................259

Diagnostic Procedure ..............................................260

Component Inspection .............................................264

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE..........................................................................265

Description ...............................................................265

Wiring Diagram - AT - OVRCSV..............................267

Diagnostic Procedure ..............................................268

Component Inspection .............................................270

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....271

Description ...............................................................271

Wiring Diagram - AT - BA/FTS ................................273

Diagnostic Procedure ..............................................274

Component Inspection .............................................277

DTC VHCL SPEED SEN.MTR VEHICLE SPEED......278

Description ...............................................................278

Wiring Diagram - AT - VSSMTR ..............................280

Diagnostic Procedure ..............................................281

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM)...........................................................................282

Description ...............................................................282

Diagnostic Procedure ..............................................282

DTC CONTROL UNIT (EEP ROM).............................284

Description ...............................................................284

Diagnostic Procedure ..............................................285

TROUBLE DIAGNOSES FOR SYMPTOMS...............286

Wiring Diagram - AT - NONDTC .............................286

1. O/D OFF Indicator Lamp Does Not Come On....288

2. Engine Cannot Be Started In²P²and²N²

Position ....................................................................291

3. In²P²Position, Vehicle Moves Forward Or

Backward When Pushed .........................................292

4. In²N²Position, Vehicle Moves ...........................293

5. Large Shock.²N²->²R²Position .......................295

6. Vehicle Does Not Creep Backward In²R²

Position ....................................................................297

7. Vehicle Does Not Creep Forward In²D²,²2²

Or²1²Position .........................................................300

8. Vehicle Cannot Be Started From D

1...................303

9. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................306

10. A/T Does Not Shift: D

2-> D3.............................309

11. A/T Does Not Shift: D

3-> D4.............................312

12. A/T Does Not Perform Lock-up .........................315

13. A/T Does Not Hold Lock-up Condition ..............31714. Lock-up Is Not Released ...................................319

15. Engine Speed Does Not Return To Idle (Light

Braking D

4-> D3).....................................................320

16. Vehicle Does Not Start From D

1.......................322

17. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch²ON²->²OFF²...............323

18. A/T Does Not Shift: D

3-> 22, When Selector

Lever²D²->²2²Position.........................................324

19. A/T Does Not Shift: 2

2-> 11, When Selector

Lever²2²->²1²Position .........................................325

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................326

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................326

A/T SHIFT LOCK SYSTEM.........................................335

Description ...............................................................335

Shift Lock System Electrical Parts Location............335

Wiring Diagram - SHIFT -........................................336

Diagnostic Procedure ..............................................337

KEY INTERLOCK CABLE..........................................341

Components.............................................................341

Removal ...................................................................341

Installation ................................................................342

ON-VEHICLE SERVICE..............................................343

Control Valve Assembly and Accumulators .............343

Control Cable Adjustment ........................................344

Park/Neutral Position (PNP) Switch Adjustment .....344

Differential Side Oil Seal Replacement ...................345

Revolution Sensor Replacement .............................345

REMOVAL AND INSTALLATION...............................346

Removal ...................................................................346

Installation ................................................................347

OVERHAUL.................................................................349

Components-1 .........................................................349

Components-2 .........................................................350

Components-3 .........................................................351

Oil Channel ..............................................................352

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ............................353

DISASSEMBLY............................................................354

REPAIR FOR COMPONENT PARTS.........................368

Manual Shaft............................................................368

Oil Pump ..................................................................371

Control Valve Assembly ...........................................375

Control Valve Upper Body .......................................384

Control Valve Lower Body .......................................388

Reverse Clutch ........................................................390

High Clutch ..............................................................394

Forward Clutch and Overrun Clutch........................399

Low & Reverse Brake..............................................406

CONTENTS(Cont'd)

AT-3

Page 1256 of 2493

4. 4-3. Cruise testAT-90

AT-93

Part-1

N8. Vehicle Cannot Be Started From D

1, AT-303.

N9. A/T Does Not Shift: D

1®D2Or Does Not Kickdown: D4®D2, AT-306.

N10. A/T Does Not Shift: D

2®D3, AT-309.

N11. A/T Does Not Shift: D

3®D4, AT-312.

N12. A/T Does Not Perform Lock-up, AT-315.

N13. A/T Does Not Hold Lock-up Condition, AT-317.

N14. Lock-up Is Not Released, AT-319.

N15. Engine Speed Does Not Return To Idle (Light Braking D

4®D3), AT-320.

Part-2AT-97

N16. Vehicle Does Not Start From D

1, AT-322.

N9. A/T Does Not Shift: D

1®D2Or Does Not Kickdown: D4®D2, AT-306.

N10. A/T Does Not Shift: D

2®D3, AT-309.

N11. A/T Does Not Shift: D

3®D4, AT-312.

Part-3AT-99

N17. A/T Does Not Shift: D

4®D3When Overdrive Control Switch ªONº®ªOFFº, AT-323

N15. Engine Speed Does Not Return To Idle (Engine Brake In D

3), AT-320.

N18. A/T Does Not Shift: D

3®22, When Selector Lever ªDº®ª2º Position, AT-324.

N15. Engine Speed Does Not Return To Idle (Engine Brake In 2

2), AT-320.

N19. A/T Does Not Shift: 2

2®11, When Selector Lever ª2º®ª1º Position, AT-325.

N20. Vehicle Does Not Decelerate By Engine Brake, AT-326.

N21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches

Circuit Checks), AT-326.

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NVehicle speed sensor´A/T (Revolution sensor), AT-124.

NVehicle speed sensor´MTR, AT-129.

NThrottle position sensor, AT-132.

NShift solenoid valve A, AT-140.

NShift solenoid valve B, AT-146.

NOverrun clutch solenoid valve, AT-152.

NTorque converter clutch solenoid valve, AT-157.

NA/T fluid temperature sensor and TCM power source, AT-163.

NEngine speed signal, AT-170.

NLine pressure solenoid valve, AT-174.

NControl unit (RAM), control unit (ROM), AT-282.

NControl unit (EEP ROM), AT-284.

NPNP, overdrive control and throttle position switches, AT-326.

NBattery

NOthers

5.NFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-38

6.NPerform all ROAD TEST and re-mark required procedures. AT-83

7.NPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible

symptoms and the component inspection orders.)AT-116

AT-103

8.NErase self-diagnosis code from TCM memories. AT-41

AT-47

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

Introduction (Cont'd)

AT-70

Page 1261 of 2493

4. 4-3. Cruise testAT-90

AT-93

Part-1

N8. Vehicle Cannot Be Started From D

1, AT-303.

N9. A/T Does Not Shift: D

1®D2Or Does Not Kickdown: D4®D2, AT-306.

N10. A/T Does Not Shift: D

2®D3, AT-309.

N11. A/T Does Not Shift: D

3®D4, AT-312.

N12. A/T Does Not Perform Lock-up, AT-315.

N13. A/T Does Not Hold Lock-up Condition, AT-317.

N14. Lock-up Is Not Released, AT-319.

N15. Engine Speed Does Not Return To Idle (Light Braking D

4®D3), AT-320.

Part-2AT-97

N16. Vehicle Does Not Start From D

1, AT-322.

N9. A/T Does Not Shift: D

1®D2Or Does Not Kickdown: D4®D2, AT-306.

N10. A/T Does Not Shift: D

2®D3, AT-309.

N11. A/T Does Not Shift: D

3®D4, AT-312.

Part-3AT-99

N17. A/T Does Not Shift: D

4®D3When Overdrive Control Switch ªONº®ªOFFº, AT-323

N15. Engine Speed Does Not Return To Idle (Engine Brake In D

3), AT-320.

N18. A/T Does Not Shift: D

3®22, When Selector Lever ªDº®ª2º Position, AT-324.

N15. Engine Speed Does Not Return To Idle (Engine Brake In 2

2), AT-320.

N19. A/T Does Not Shift: 2

2®11, When Selector Lever ª2º®ª1º Position, AT-325.

N20. Vehicle Does Not Decelerate By Engine Brake, AT-326.

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NPNP switch, AT-181.

NA/T fluid temperature sensor, AT-187.

NVehicle speed sensor´A/T (Revolution sensor), AT-193.

NEngine speed signal, AT-198.

NTorque converter clutch solenoid valve, AT-231.

NLine pressure solenoid valve, AT-237.

NShift solenoid valve A, AT-244.

NShift solenoid valve B, AT-250.

NThrottle position sensor, AT-256.

NOverrun clutch solenoid valve, AT-265.

NPNP, overdrive control and throttle position switches, AT-326.

NA/T fluid temperature sensor and TCM power source, AT-271.

NVehicle speed sensor´MTR, AT-278.

NControl unit (RAM), control unit (ROM), AT-282.

NControl unit (EEP ROM), AT-284.

NBattery

NOthers

5.NFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-53

6.NPerform all ROAD TEST and re-mark required procedures. AT-83

7.NPerform DTC CONFIRMATION PROCEDURE for following MIL indicating items and check out NG items.

Refer to EC-58, ªEmission-related Diagnostic Informationº.EC section

NDTC (P0731) A/T 1st gear function, AT-202.

NDTC (P0732) A/T 2nd gear function, AT-209.

NDTC (P0733) A/T 3rd gear function, AT-215.

NDTC (P0734) A/T 4th gear function, AT-221.

8.NPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible

symptoms and the component inspection orders.)AT-103

AT-116

9.NErase DTC from TCM and ECM memories. AT-50

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Introduction (Cont'd)

AT-75

Page 1264 of 2493

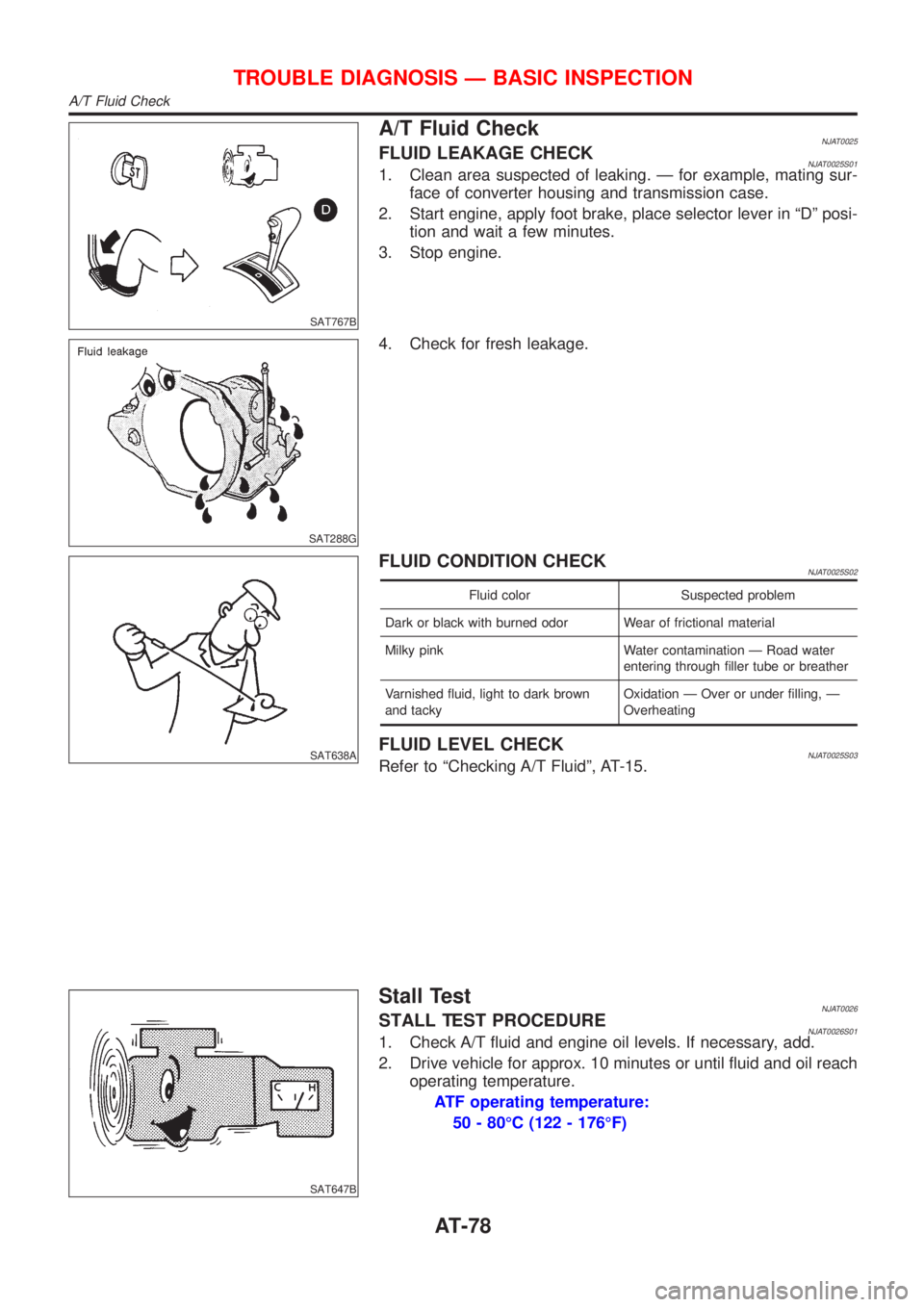

SAT767B

A/T Fluid CheckNJAT0025FLUID LEAKAGE CHECKNJAT0025S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

SAT288G

4. Check for fresh leakage.

SAT638A

FLUID CONDITION CHECKNJAT0025S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNJAT0025S03Refer to ªChecking A/T Fluidº, AT-15.

SAT647B

Stall TestNJAT0026STALL TEST PROCEDURENJAT0026S011. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

A/T Fluid Check

AT-78

Page 1282 of 2493

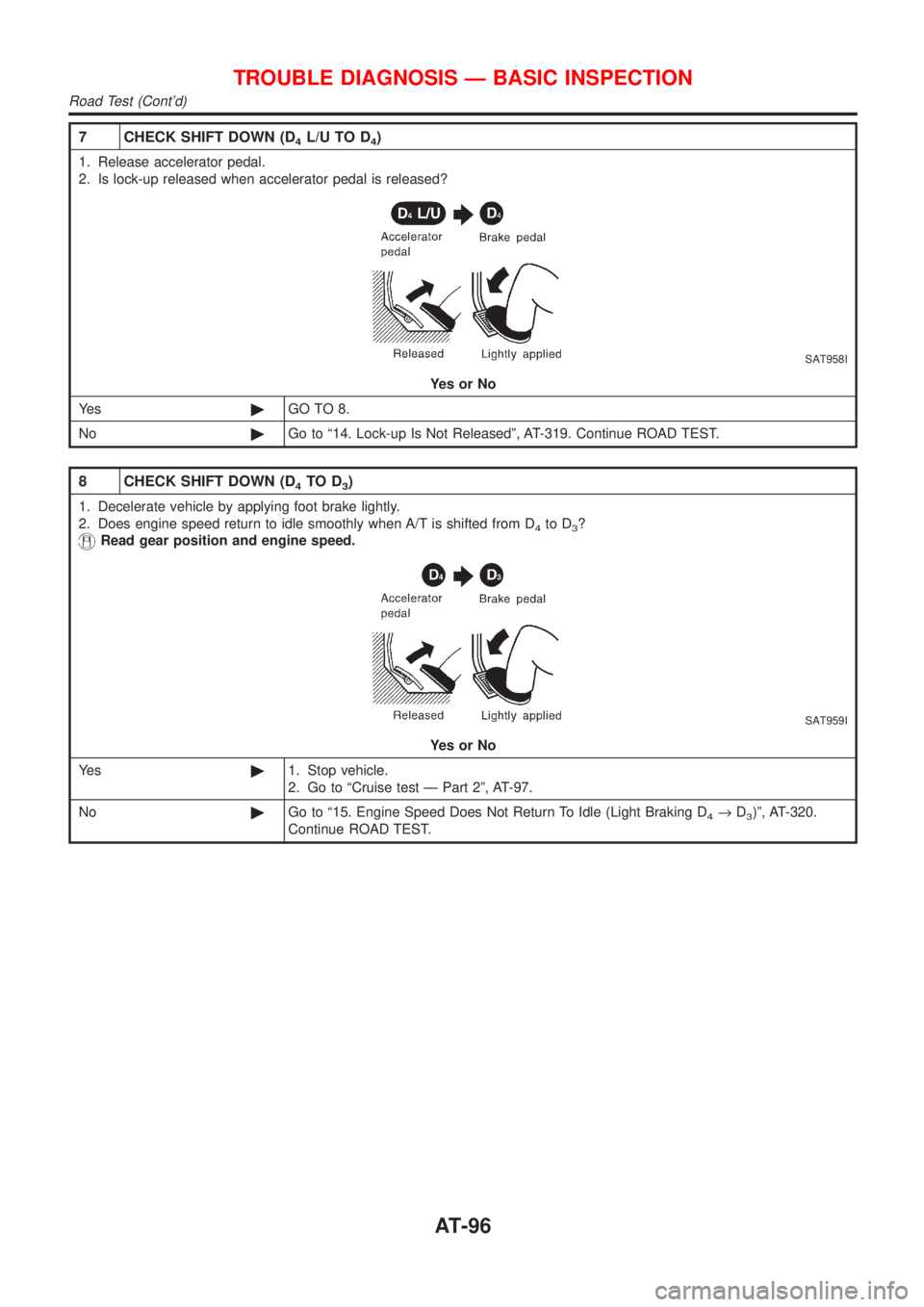

7 CHECK SHIFT DOWN (D4L/U TO D4)

1. Release accelerator pedal.

2. Is lock-up released when accelerator pedal is released?

SAT958I

YesorNo

Ye s©GO TO 8.

No©Go to ª14. Lock-up Is Not Releasedº, AT-319. Continue ROAD TEST.

8 CHECK SHIFT DOWN (D4TO D3)

1. Decelerate vehicle by applying foot brake lightly.

2. Does engine speed return to idle smoothly when A/T is shifted from D

4to D3?

Read gear position and engine speed.

SAT959I

YesorNo

Ye s©1. Stop vehicle.

2. Go to ªCruise test Ð Part 2º, AT-97.

No©Go to ª15. Engine Speed Does Not Return To Idle (Light Braking D

4®D3)º, AT-320.

Continue ROAD TEST.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-96

Page 1286 of 2493

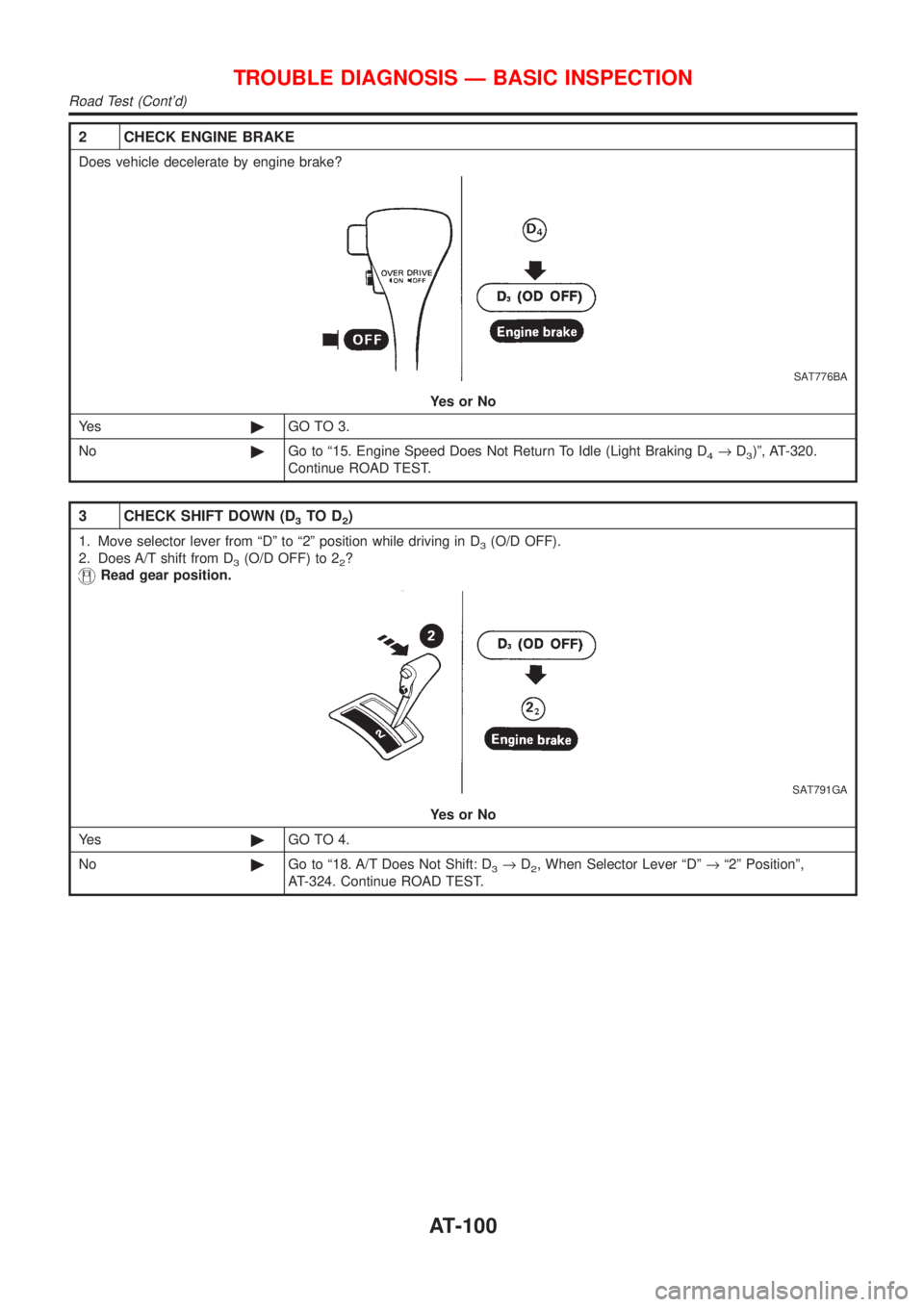

2 CHECK ENGINE BRAKE

Does vehicle decelerate by engine brake?

SAT776BA

YesorNo

Ye s©GO TO 3.

No©Go to ª15. Engine Speed Does Not Return To Idle (Light Braking D

4®D3)º, AT-320.

Continue ROAD TEST.

3 CHECK SHIFT DOWN (D3TO D2)

1. Move selector lever from ªDº to ª2º position while driving in D3(O/D OFF).

2. Does A/T shift from D

3(O/D OFF) to 22?

Read gear position.

SAT791GA

YesorNo

Ye s©GO TO 4.

No©Go to ª18. A/T Does Not Shift: D

3®D2, When Selector Lever ªDº®ª2º Positionº,

AT-324. Continue ROAD TEST.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-100