brake sensor NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 68 of 2493

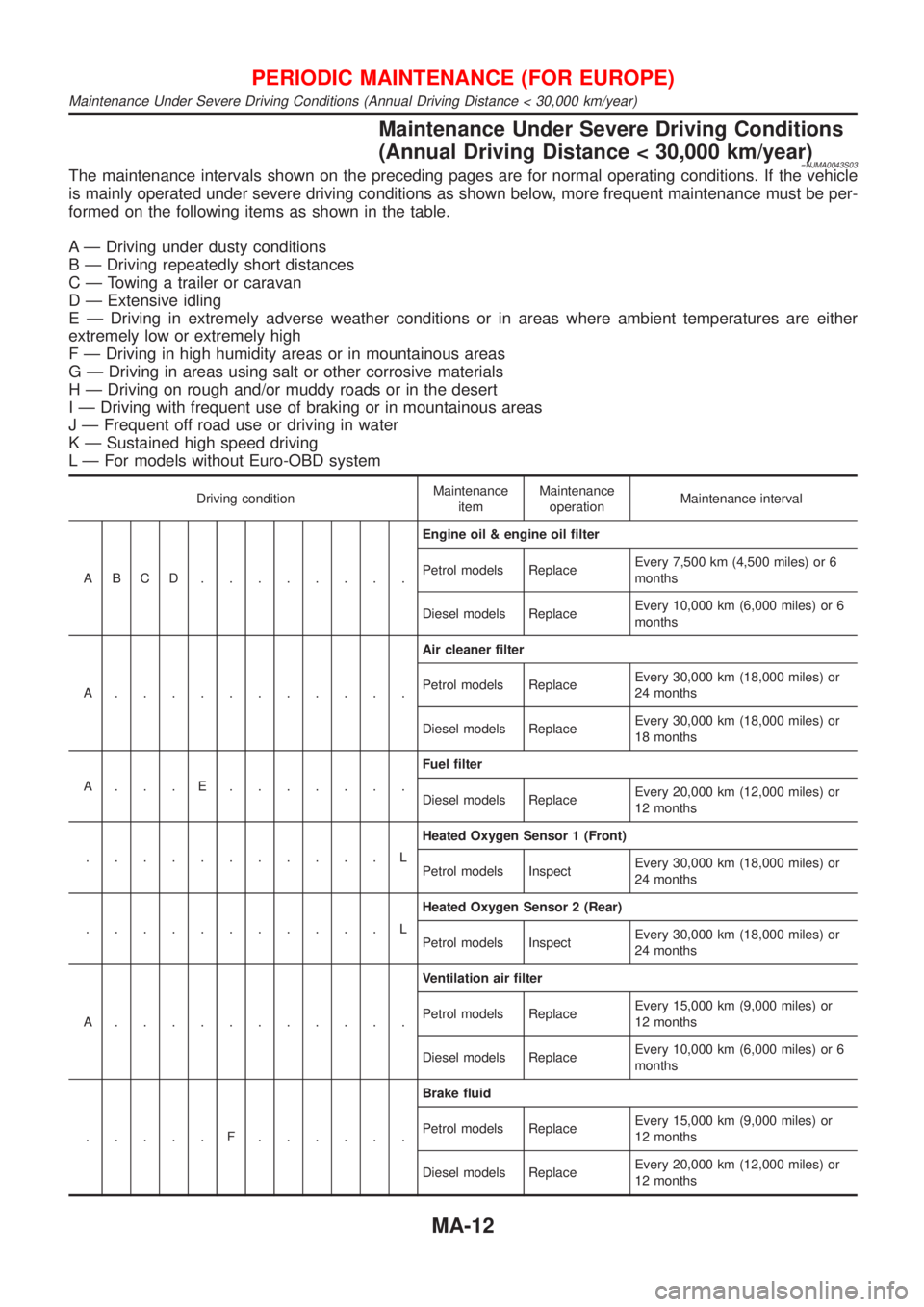

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)

=NJMA0043S03The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

K Ð Sustained high speed driving

L Ð For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models ReplaceEvery 7,500 km (4,500 miles) or 6

months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or 6

months

A...........Air cleaner filter

Petrol models ReplaceEvery 30,000 km (18,000 miles) or

24 months

Diesel models ReplaceEvery 30,000 km (18,000 miles) or

18 months

A...E.......Fuel filter

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

...........LHeated Oxygen Sensor 1 (Front)

Petrol models InspectEvery 30,000 km (18,000 miles) or

24 months

...........LHeated Oxygen Sensor 2 (Rear)

Petrol models InspectEvery 30,000 km (18,000 miles) or

24 months

A...........Ventilation air filter

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or 6

months

.....F......Brake fluid

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance < 30,000 km/year)

MA-12

Page 74 of 2493

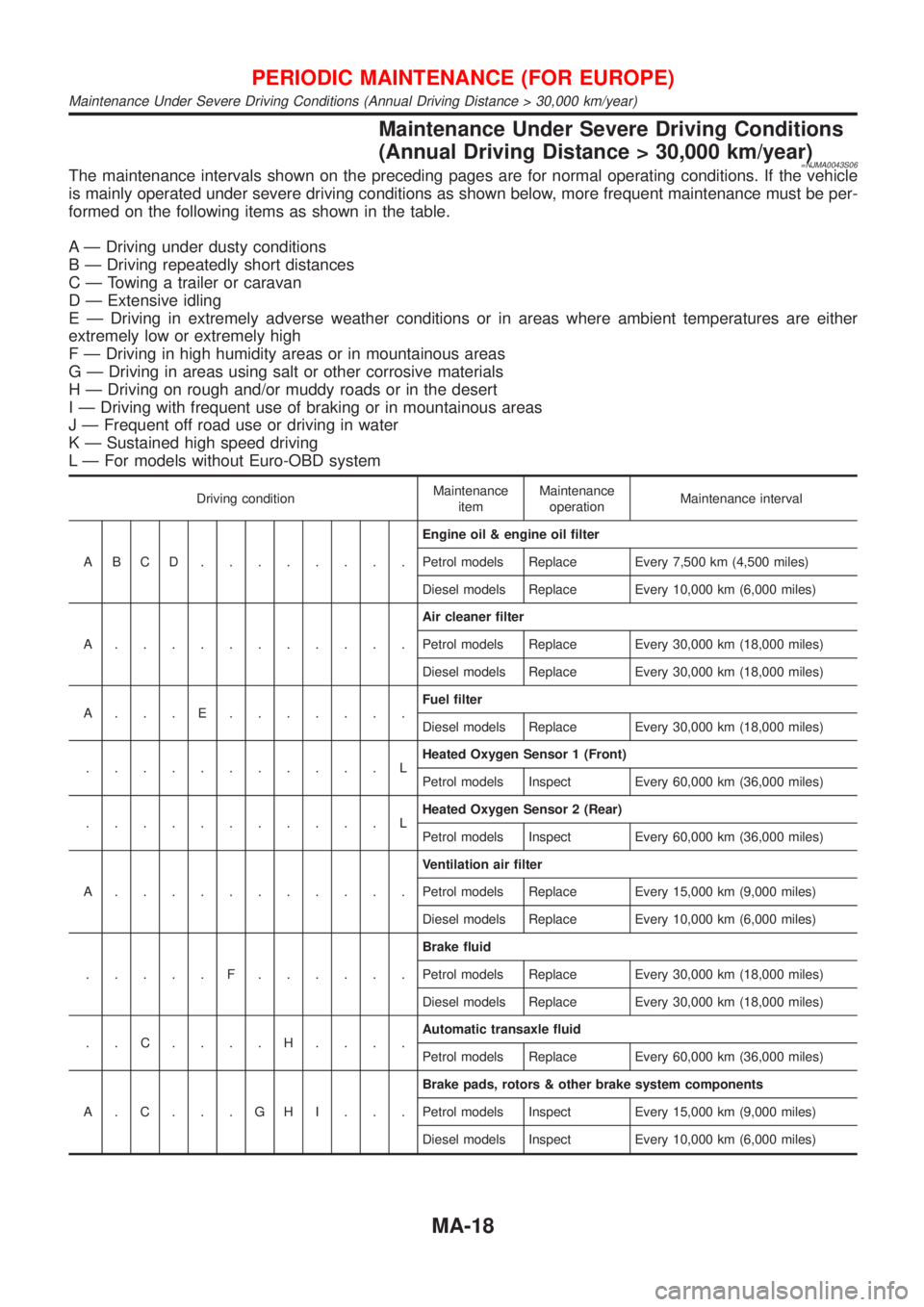

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km/year)

=NJMA0043S06The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

K Ð Sustained high speed driving

L Ð For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models Replace Every 7,500 km (4,500 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

A...........Air cleaner filter

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

A...E.......Fuel filter

Diesel models Replace Every 30,000 km (18,000 miles)

...........LHeated Oxygen Sensor 1 (Front)

Petrol models Inspect Every 60,000 km (36,000 miles)

...........LHeated Oxygen Sensor 2 (Rear)

Petrol models Inspect Every 60,000 km (36,000 miles)

A...........Ventilation air filter

Petrol models Replace Every 15,000 km (9,000 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

.....F......Brake fluid

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

..C....H....Automatic transaxle fluid

Petrol models Replace Every 60,000 km (36,000 miles)

A.C...GHI...Brake pads, rotors & other brake system components

Petrol models Inspect Every 15,000 km (9,000 miles)

Diesel models Inspect Every 10,000 km (6,000 miles)

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance > 30,000 km/year)

MA-18

Page 128 of 2493

WARNING:

+Position vehicle on a flat and solid surface.

+Place chocks at front and back of rear wheels.

+Do not remove engine until exhaust system has com-

pletely cooled off, otherwise, you may burn yourself

and/or fire may break out in fuel line.

+Before disconnecting fuel hose, release pressure.

Refer to EC-38, ªFuel Pressure Releaseº.

+Be sure to lift engine and transaxle in a safe manner.

+For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

+When lifting engine, be sure to clear surrounding parts.

Use special care near accelerator wire casing, brake lines

and brake master cylinder.

+When lifting the engine, always use engine slingers in a

safe manner.

+When removing drive shaft, be careful not to damage

grease seal of transaxle.

+Before separating engine and transaxle, remove crank-

shaft position sensor (POS) from the cylinder block

assembly.

+Always be extra careful not to damage edge of crankshaft

position sensor (POS), or signal plate teeth.

Engine cannot be removed separately from transaxle. Remove

engine with transaxle as an assembly.

REMOVALNJEM0022S011. Drain coolant from radiator and cylinder block. Refer to LC-17,

ªChanging Engine Coolantº.

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from

engine.

8. Remove power steering oil pump from engine and position

aside.

Power steering oil pump does not need to be disconnected

from power steering tubes.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-50

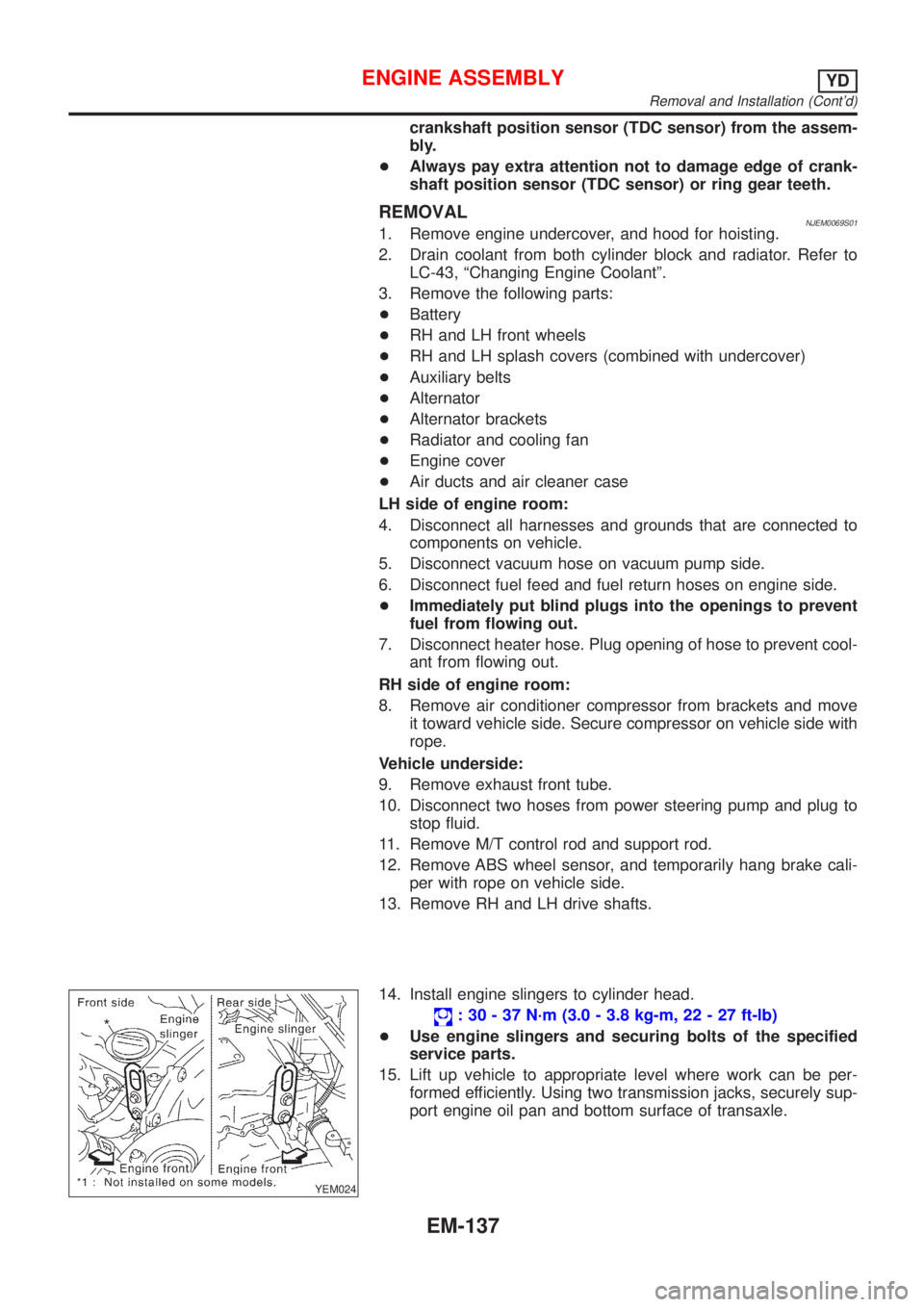

Page 215 of 2493

crankshaft position sensor (TDC sensor) from the assem-

bly.

+Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-43, ªChanging Engine Coolantº.

3. Remove the following parts:

+Battery

+RH and LH front wheels

+RH and LH splash covers (combined with undercover)

+Auxiliary belts

+Alternator

+Alternator brackets

+Radiator and cooling fan

+Engine cover

+Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

+Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

YEM024

14. Install engine slingers to cylinder head.

: 30 - 37 N´m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

+Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont'd)

EM-137

Page 303 of 2493

YD

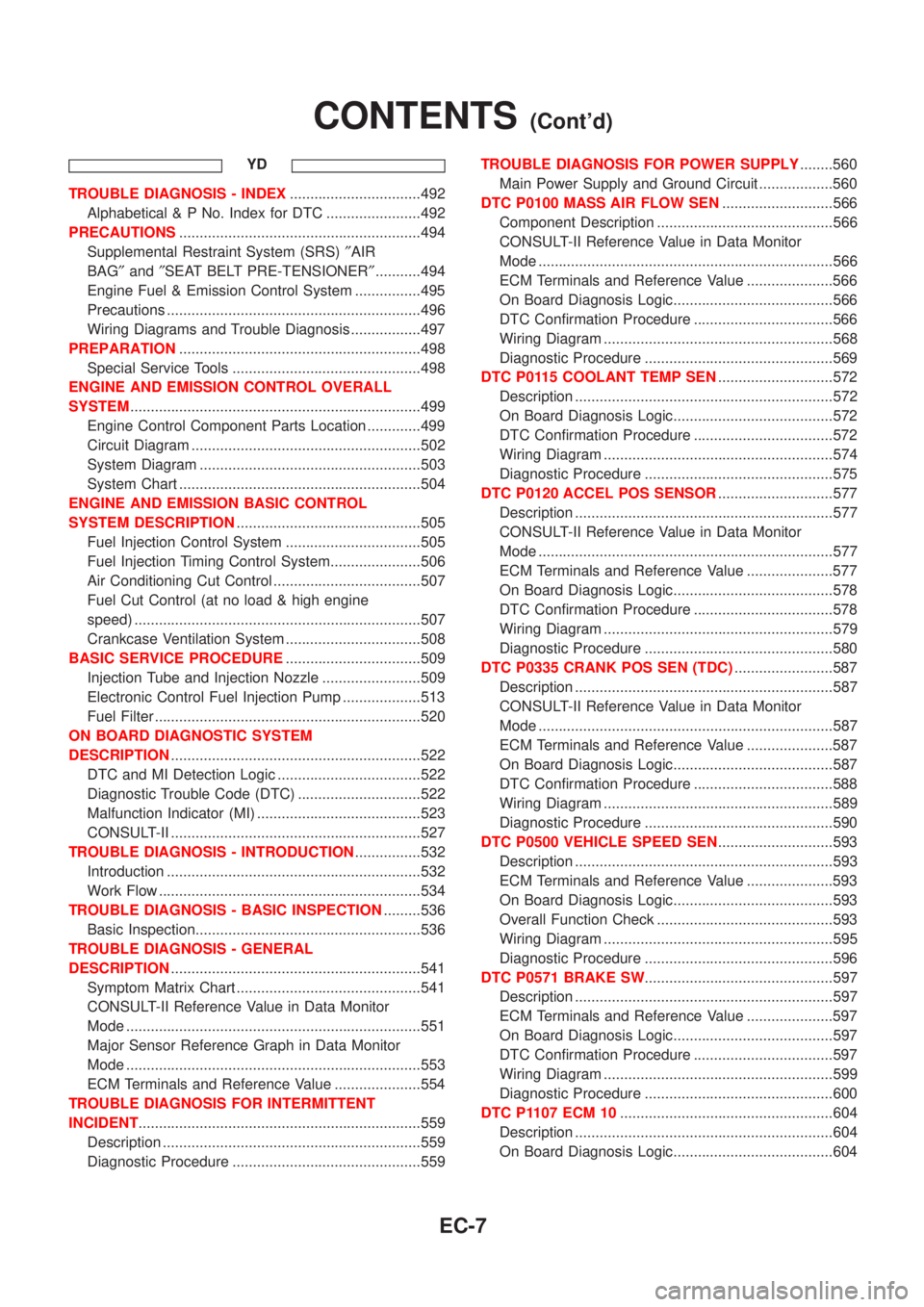

TROUBLE DIAGNOSIS - INDEX................................492

Alphabetical & P No. Index for DTC .......................492

PRECAUTIONS...........................................................494

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...........494

Engine Fuel & Emission Control System ................495

Precautions ..............................................................496

Wiring Diagrams and Trouble Diagnosis .................497

PREPARATION...........................................................498

Special Service Tools ..............................................498

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.......................................................................499

Engine Control Component Parts Location .............499

Circuit Diagram ........................................................502

System Diagram ......................................................503

System Chart ...........................................................504

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION.............................................505

Fuel Injection Control System .................................505

Fuel Injection Timing Control System......................506

Air Conditioning Cut Control ....................................507

Fuel Cut Control (at no load & high engine

speed) ......................................................................507

Crankcase Ventilation System .................................508

BASIC SERVICE PROCEDURE.................................509

Injection Tube and Injection Nozzle ........................509

Electronic Control Fuel Injection Pump ...................513

Fuel Filter .................................................................520

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION.............................................................522

DTC and MI Detection Logic ...................................522

Diagnostic Trouble Code (DTC) ..............................522

Malfunction Indicator (MI) ........................................523

CONSULT-II .............................................................527

TROUBLE DIAGNOSIS - INTRODUCTION................532

Introduction ..............................................................532

Work Flow ................................................................534

TROUBLE DIAGNOSIS - BASIC INSPECTION.........536

Basic Inspection.......................................................536

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................541

Symptom Matrix Chart .............................................541

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................551

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................553

ECM Terminals and Reference Value .....................554

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................559

Description ...............................................................559

Diagnostic Procedure ..............................................559TROUBLE DIAGNOSIS FOR POWER SUPPLY........560

Main Power Supply and Ground Circuit ..................560

DTC P0100 MASS AIR FLOW SEN...........................566

Component Description ...........................................566

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................566

ECM Terminals and Reference Value .....................566

On Board Diagnosis Logic.......................................566

DTC Confirmation Procedure ..................................566

Wiring Diagram ........................................................568

Diagnostic Procedure ..............................................569

DTC P0115 COOLANT TEMP SEN............................572

Description ...............................................................572

On Board Diagnosis Logic.......................................572

DTC Confirmation Procedure ..................................572

Wiring Diagram ........................................................574

Diagnostic Procedure ..............................................575

DTC P0120 ACCEL POS SENSOR............................577

Description ...............................................................577

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................577

ECM Terminals and Reference Value .....................577

On Board Diagnosis Logic.......................................578

DTC Confirmation Procedure ..................................578

Wiring Diagram ........................................................579

Diagnostic Procedure ..............................................580

DTC P0335 CRANK POS SEN (TDC)........................587

Description ...............................................................587

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................587

ECM Terminals and Reference Value .....................587

On Board Diagnosis Logic.......................................587

DTC Confirmation Procedure ..................................588

Wiring Diagram ........................................................589

Diagnostic Procedure ..............................................590

DTC P0500 VEHICLE SPEED SEN............................593

Description ...............................................................593

ECM Terminals and Reference Value .....................593

On Board Diagnosis Logic.......................................593

Overall Function Check ...........................................593

Wiring Diagram ........................................................595

Diagnostic Procedure ..............................................596

DTC P0571 BRAKE SW..............................................597

Description ...............................................................597

ECM Terminals and Reference Value .....................597

On Board Diagnosis Logic.......................................597

DTC Confirmation Procedure ..................................597

Wiring Diagram ........................................................599

Diagnostic Procedure ..............................................600

DTC P1107 ECM 10....................................................604

Description ...............................................................604

On Board Diagnosis Logic.......................................604

CONTENTS(Cont'd)

EC-7

Page 788 of 2493

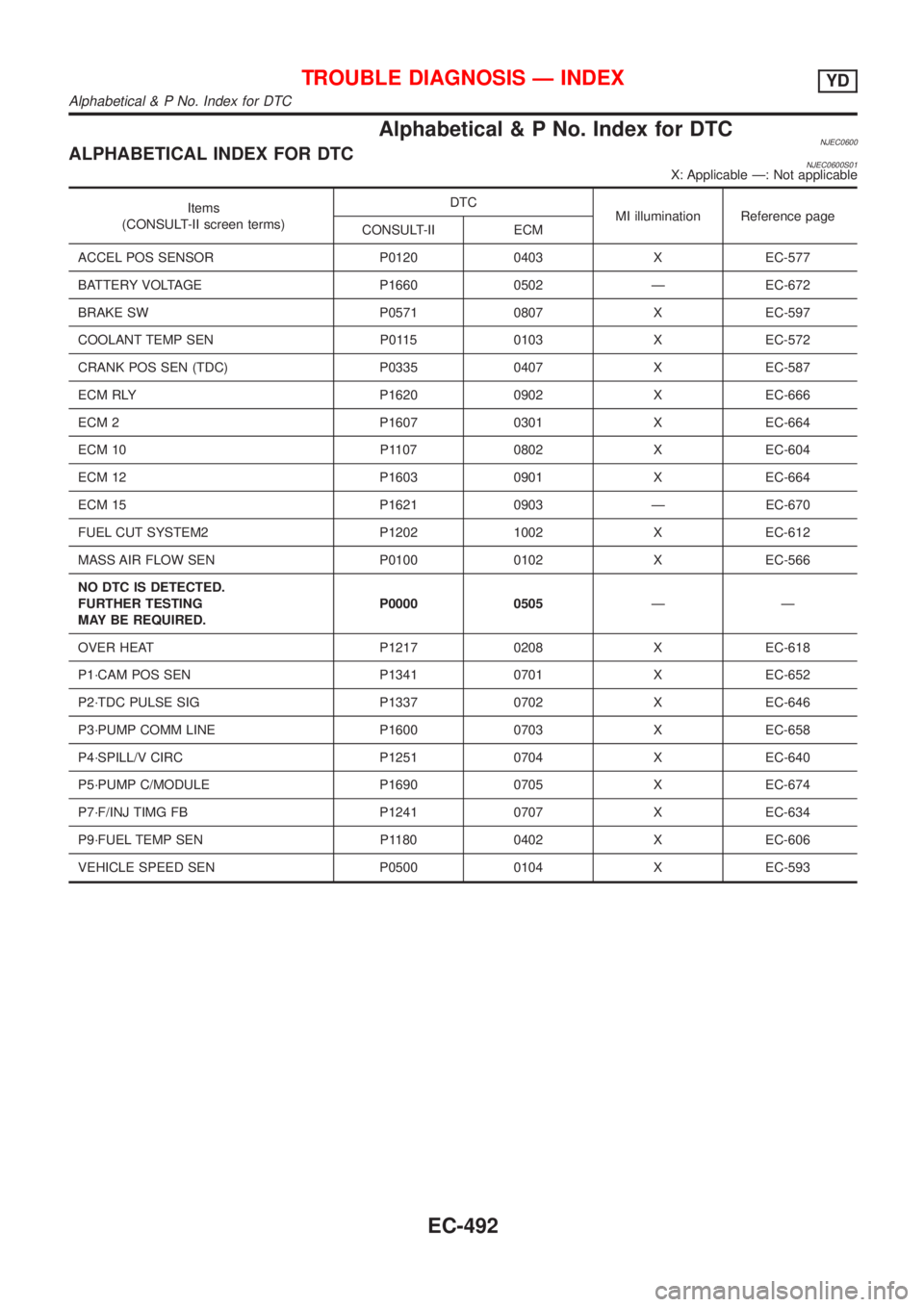

Alphabetical & P No. Index for DTCNJEC0600ALPHABETICAL INDEX FOR DTCNJEC0600S01X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC

MI illumination Reference page

CONSULT-II ECM

ACCEL POS SENSOR P0120 0403 X EC-577

BATTERY VOLTAGE P1660 0502 Ð EC-672

BRAKE SW P0571 0807 X EC-597

COOLANT TEMP SEN P0115 0103 X EC-572

CRANK POS SEN (TDC) P0335 0407 X EC-587

ECM RLY P1620 0902 X EC-666

ECM 2 P1607 0301 X EC-664

ECM 10 P1107 0802 X EC-604

ECM 12 P1603 0901 X EC-664

ECM 15 P1621 0903 Ð EC-670

FUEL CUT SYSTEM2 P1202 1002 X EC-612

MASS AIR FLOW SEN P0100 0102 X EC-566

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 0505ÐÐ

OVER HEAT P1217 0208 X EC-618

P1´CAM POS SEN P1341 0701 X EC-652

P2´TDC PULSE SIG P1337 0702 X EC-646

P3´PUMP COMM LINE P1600 0703 X EC-658

P4´SPILL/V CIRC P1251 0704 X EC-640

P5´PUMP C/MODULE P1690 0705 X EC-674

P7´F/INJ TIMG FB P1241 0707 X EC-634

P9´FUEL TEMP SEN P1180 0402 X EC-606

VEHICLE SPEED SEN P0500 0104 X EC-593

TROUBLE DIAGNOSIS Ð INDEXYD

Alphabetical & P No. Index for DTC

EC-492

Page 789 of 2493

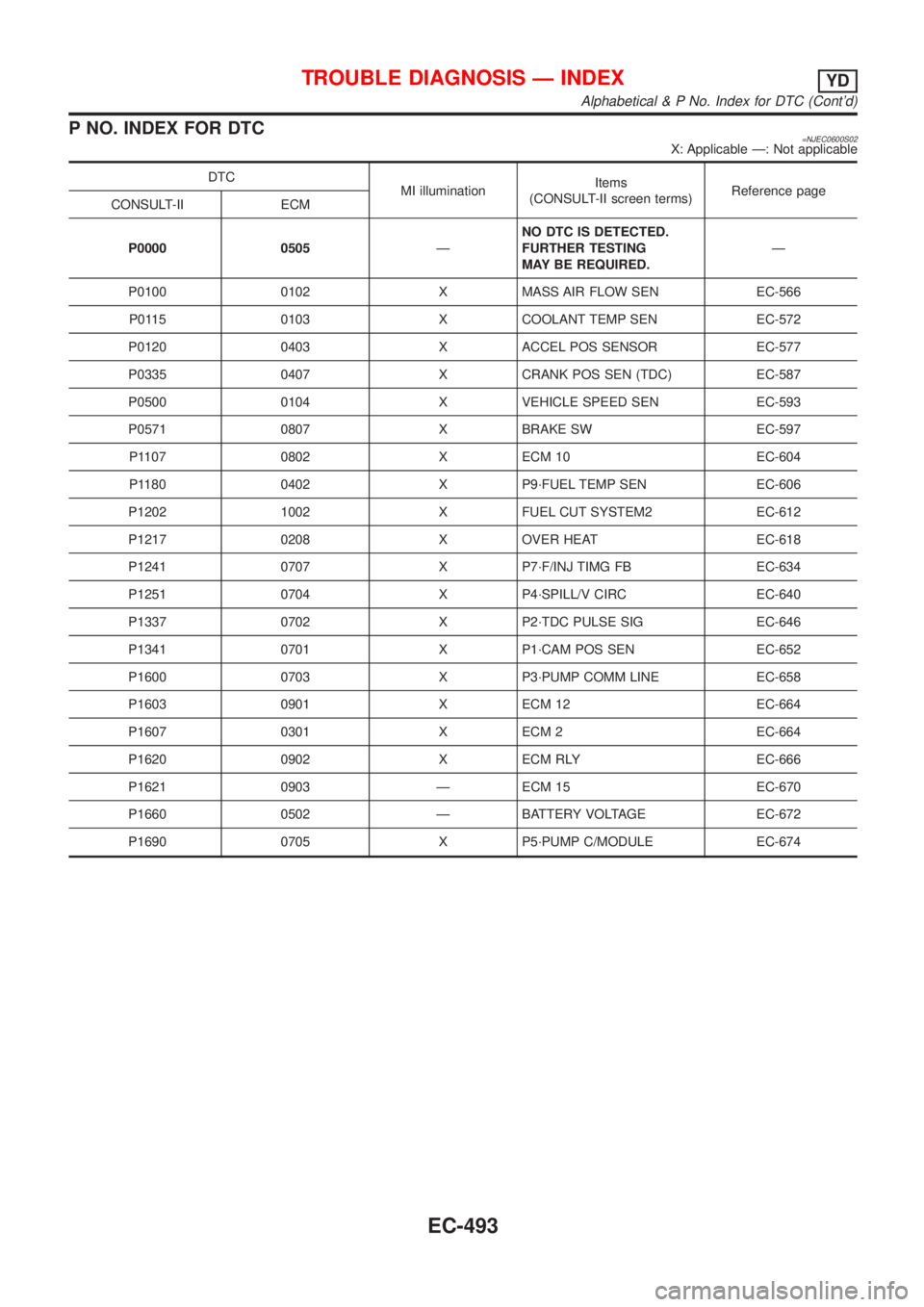

P NO. INDEX FOR DTC=NJEC0600S02X: Applicable Ð: Not applicable

DTC

MI illuminationItems

(CONSULT-II screen terms)Reference page

CONSULT-II ECM

P0000 0505ÐNO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.Ð

P0100 0102 X MASS AIR FLOW SEN EC-566

P0115 0103 X COOLANT TEMP SEN EC-572

P0120 0403 X ACCEL POS SENSOR EC-577

P0335 0407 X CRANK POS SEN (TDC) EC-587

P0500 0104 X VEHICLE SPEED SEN EC-593

P0571 0807 X BRAKE SW EC-597

P1107 0802 X ECM 10 EC-604

P1180 0402 X P9´FUEL TEMP SEN EC-606

P1202 1002 X FUEL CUT SYSTEM2 EC-612

P1217 0208 X OVER HEAT EC-618

P1241 0707 X P7´F/INJ TIMG FB EC-634

P1251 0704 X P4´SPILL/V CIRC EC-640

P1337 0702 X P2´TDC PULSE SIG EC-646

P1341 0701 X P1´CAM POS SEN EC-652

P1600 0703 X P3´PUMP COMM LINE EC-658

P1603 0901 X ECM 12 EC-664

P1607 0301 X ECM 2 EC-664

P1620 0902 X ECM RLY EC-666

P1621 0903 Ð ECM 15 EC-670

P1660 0502 Ð BATTERY VOLTAGE EC-672

P1690 0705 X P5´PUMP C/MODULE EC-674

TROUBLE DIAGNOSIS Ð INDEXYD

Alphabetical & P No. Index for DTC (Cont'd)

EC-493

Page 816 of 2493

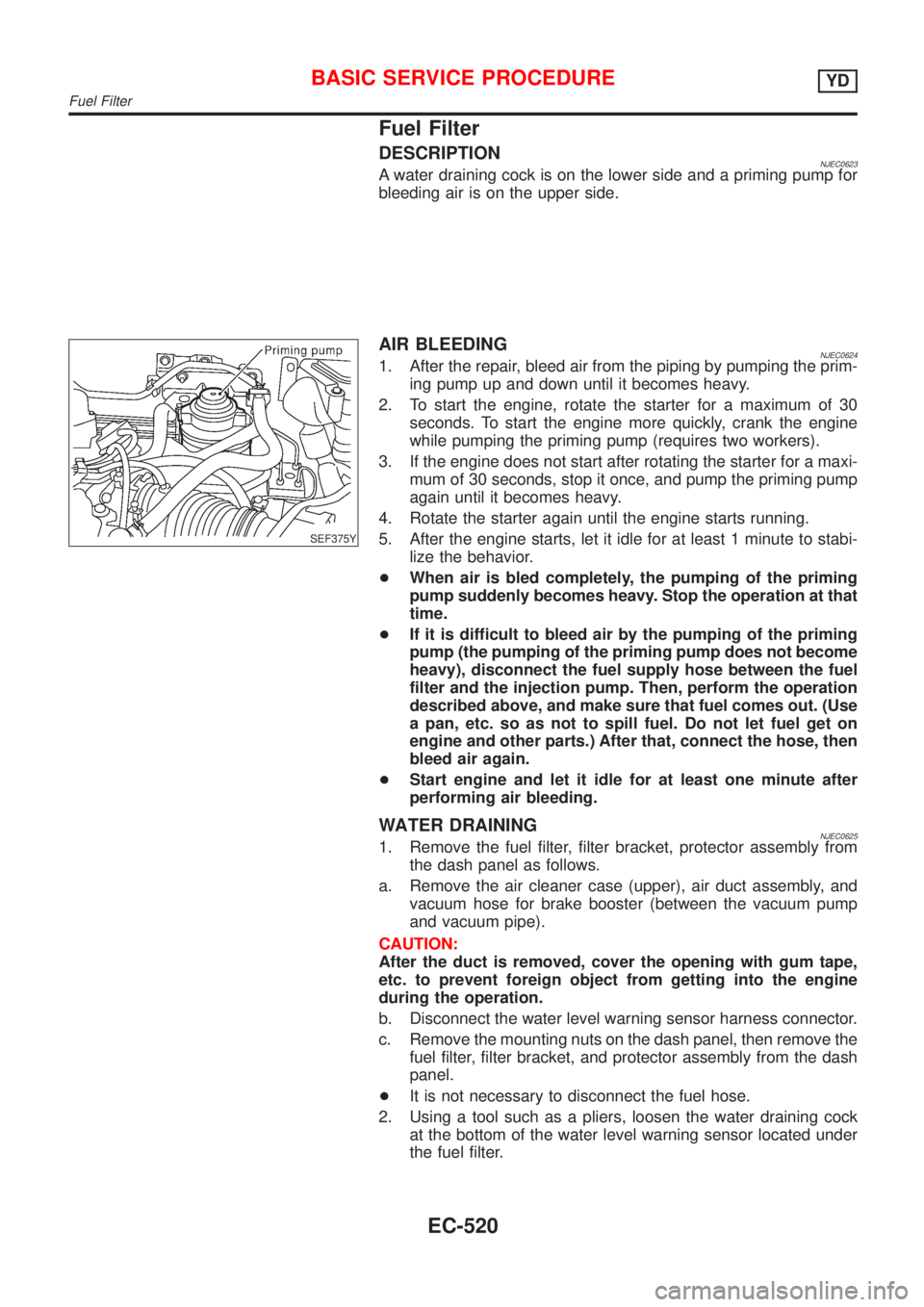

Fuel Filter

DESCRIPTIONNJEC0623A water draining cock is on the lower side and a priming pump for

bleeding air is on the upper side.

SEF375Y

AIR BLEEDINGNJEC06241. After the repair, bleed air from the piping by pumping the prim-

ing pump up and down until it becomes heavy.

2. To start the engine, rotate the starter for a maximum of 30

seconds. To start the engine more quickly, crank the engine

while pumping the priming pump (requires two workers).

3. If the engine does not start after rotating the starter for a maxi-

mum of 30 seconds, stop it once, and pump the priming pump

again until it becomes heavy.

4. Rotate the starter again until the engine starts running.

5. After the engine starts, let it idle for at least 1 minute to stabi-

lize the behavior.

+When air is bled completely, the pumping of the priming

pump suddenly becomes heavy. Stop the operation at that

time.

+If it is difficult to bleed air by the pumping of the priming

pump (the pumping of the priming pump does not become

heavy), disconnect the fuel supply hose between the fuel

filter and the injection pump. Then, perform the operation

described above, and make sure that fuel comes out. (Use

a pan, etc. so as not to spill fuel. Do not let fuel get on

engine and other parts.) After that, connect the hose, then

bleed air again.

+Start engine and let it idle for at least one minute after

performing air bleeding.

WATER DRAININGNJEC06251. Remove the fuel filter, filter bracket, protector assembly from

the dash panel as follows.

a. Remove the air cleaner case (upper), air duct assembly, and

vacuum hose for brake booster (between the vacuum pump

and vacuum pipe).

CAUTION:

After the duct is removed, cover the opening with gum tape,

etc. to prevent foreign object from getting into the engine

during the operation.

b. Disconnect the water level warning sensor harness connector.

c. Remove the mounting nuts on the dash panel, then remove the

fuel filter, filter bracket, and protector assembly from the dash

panel.

+It is not necessary to disconnect the fuel hose.

2. Using a tool such as a pliers, loosen the water draining cock

at the bottom of the water level warning sensor located under

the fuel filter.

BASIC SERVICE PROCEDUREYD

Fuel Filter

EC-520

Page 825 of 2493

![NISSAN ALMERA N16 2001 Electronic Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT NISSAN ALMERA N16 2001 Electronic Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT](/img/5/57351/w960_57351-824.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V]

jj+The power supply voltage of ECM is

displayed.

P/N POSI SW*1

[ON/OFF] (where

fitted)jj+Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the

starter signal.+After starting the engine, [OFF] is dis-

played regardless of the starter signal.

BRAKE SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

stop lamp switch signal.

BRAKE SW2

[ON/OFF]jj+Indicates [ON/OFF] condition from the

brake pedal position switch signal.

IGN SW

[ON/OFF]jj+Indicates [ON/OFF] condition from igni-

tion switch signal.

MAS AIR/FL SE [V]

jj+The signal voltage of the mass air flow

sensor is displayed.+When the engine is stopped, a certain

value is indicated.

INT/A VOLUME [mg/]+The intake air volume computed from

the mass air flow sensor signal is dis-

played.

F/CUT SIGNAL

[ON/OFF]

j+The [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

OFF´´´Fuel is cut off.

ON´´´Fuel is not cut off.

GLOW RLY

[ON/OFF]j+The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[LOW/HI/OFF]

j+Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

+LOW ... Operates at low speed.

HI ... Operates at high speed.

OFF ... Stopped.

BARO SEN [kPa]

jj+The barometric pressure (determined

by the signal voltage from the baromet-

ric pressure sensor built into the ECM)

is displayed.

EGR VOL CON/V

[step]

j+Indicates the EGR volume control value

computed by the ECM according to the

input signals.

+The opening becomes larger as the

value increases.

*1: On models not equipped with park/neutral position (PNP) switch, ªOFFº is always displayed regardless of gear shift position.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

CONSULT-II (Cont'd)

EC-529

Page 852 of 2493

![NISSAN ALMERA N16 2001 Electronic Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

337

338

350

351W/L

PU/W

GY

OR/BEGR volume control

valve[Engine is running]

+Warm-up condition

+Idle speed0.1 - 14V

(Voltage sig NISSAN ALMERA N16 2001 Electronic Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

337

338

350

351W/L

PU/W

GY

OR/BEGR volume control

valve[Engine is running]

+Warm-up condition

+Idle speed0.1 - 14V

(Voltage sig](/img/5/57351/w960_57351-851.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

337

338

350

351W/L

PU/W

GY

OR/BEGR volume control

valve[Engine is running]

+Warm-up condition

+Idle speed0.1 - 14V

(Voltage signals of each ECM

terminals differ according to the

control position of EGR volume

control valve.)

344 WCrankshaft position sen-

sor (TDC)[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

SEF333Y

[Engine is running]

+Warm-up condition

+Engine speed is 2,000 rpmApproximately 0V

SEF334Y

347 L/BEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant temperature

403 R/L Air conditioner switch[Engine is running]

+Air conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Both air conditioner switch and blower fan

switch are ªONº

(Compressor is operating)Approximately 0.1V

405 R/G Stop lamp switch[Ignition switch ªONº]

+Brake pedal fully releasedApproximately 0V

[Ignition switch ªONº]

+Brake pedal depressedBATTERY VOLTAGE

(11 - 14V)

416 Y/BBrake pedal position

switch[Ignition switch ªONº]

+Brake pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Brake pedal depressedApproximately 0V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

ECM Terminals and Reference Value (Cont'd)

EC-556