heating NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 10 of 2493

+Do not use gasoline, kerosine, diesel fuel, gas oil, thinners or

solvents for cleaning skin.

+If skin disorders develop, obtain medical advice without delay.

+Where practicable, degrease components prior to handling.

+Where there is a risk of eye contact, eye protection should be

worn, for example, chemical goggles or face shields; in addi-

tion an eye wash facility should be provided.

Environmental Protection PrecautionsNJGI0001S0702Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt, check with the

appropriate local authority and/or manufacturer of the approved

appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local authority

for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or drains,

or into water courses.

The regulations concerning the pollution vary between

regions.

PRECAUTIONS FOR FUELNJGI0001S08Gasoline EngineNJGI0001S0803Europe

Models with three way catalyst

Unleaded premium gasoline of at least 95 octane (RON)

If premium gasoline is not available, unleaded regular gaso-

line with an octane rating of 91 (RON) may be temporarily

used, but only under the following precautions:

+Have the fuel tank filled only partially with unleaded regu-

lar gasoline, and fill up with premium unleaded gasoline

as soon as possible.

+Avoid full throttle driving and abrupt acceleration.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Except For Europe

Models without three way catalyst

Leaded gasoline of at least 91 octane (RON)

Models with three way catalyst

Unleaded gasoline of above 91 octane (RON)

For improved vehicle performance, Nissan recommends the use of

premium unleaded gasoline above 95 octane (RON).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Diesel Engine*:NJGI0001S0804Diesel fuel of at least 50 cetane

* If two types of diesel fuel are available, use summer or winter

fuel properly according to the following temperature conditions.

+Above þ7ÉC (20ÉF) ... Summer type diesel fuel.

+Below þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

+Do not use home heating oil, gasoline, or other alternate

PRECAUTIONS

Precautions (Cont'd)

GI-8

Page 25 of 2493

Engine Compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

+Connectors not fully seated.

+Wiring harness not long enough and is being stressed due to

engine vibrations or rocking.

+Wires laying across brackets or moving components.

+Loose, dirty or corroded ground wires.

+Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection bygently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind The Instrument Panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under Seating Areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

SGI842

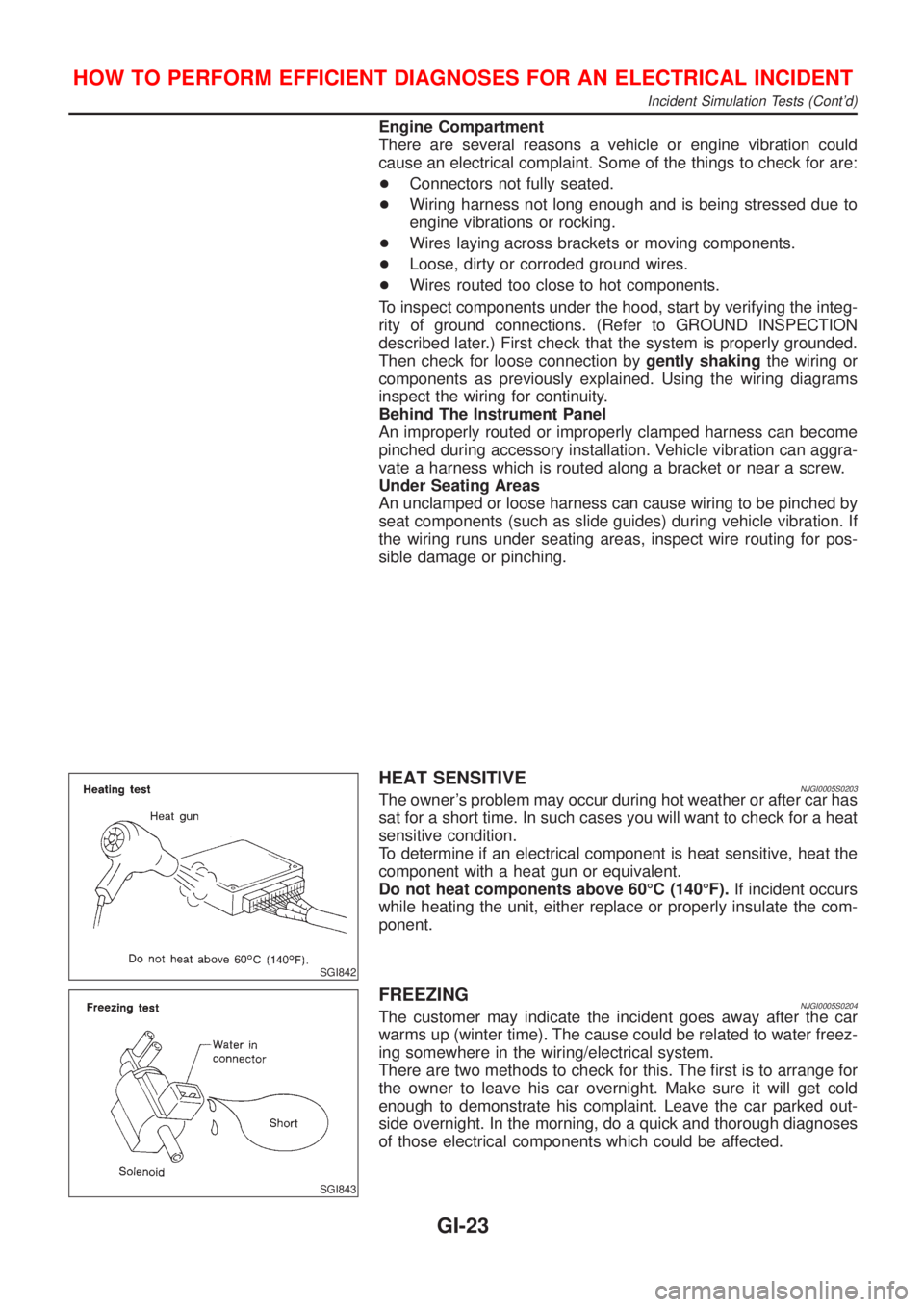

HEAT SENSITIVENJGI0005S0203The owner's problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF).If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI843

FREEZINGNJGI0005S0204The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnoses

of those electrical components which could be affected.

HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-23

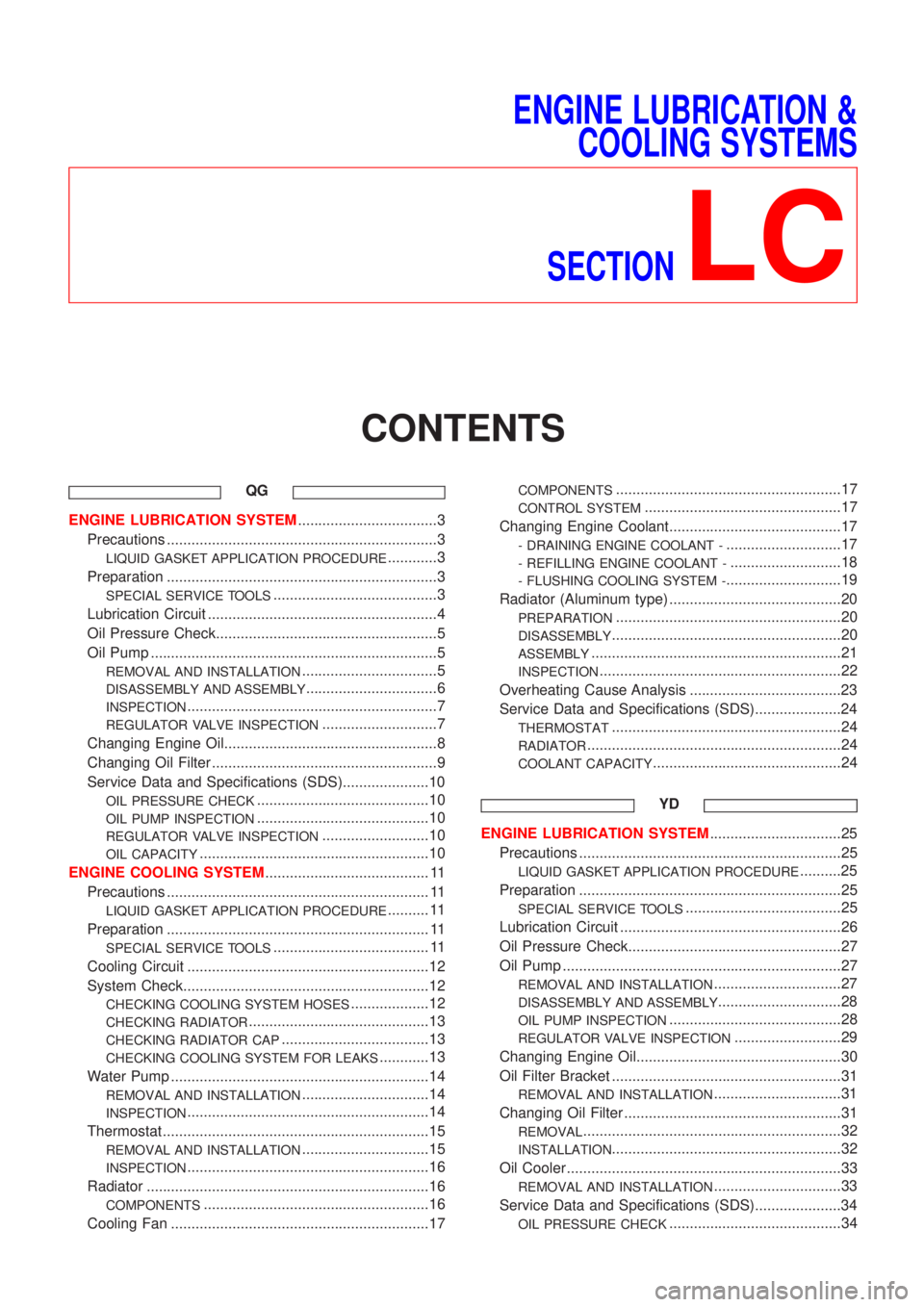

Page 249 of 2493

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

QG

ENGINE LUBRICATION SYSTEM..................................3

Precautions ..................................................................3

LIQUID GASKET APPLICATION PROCEDURE............3

Preparation ..................................................................3

SPECIAL SERVICE TOOLS........................................3

Lubrication Circuit ........................................................4

Oil Pressure Check......................................................5

Oil Pump ......................................................................5

REMOVAL AND INSTALLATION.................................5

DISASSEMBLY AND ASSEMBLY................................6

INSPECTION.............................................................7

REGULATOR VALVE INSPECTION............................7

Changing Engine Oil....................................................8

Changing Oil Filter .......................................................9

Service Data and Specifications (SDS).....................10

OIL PRESSURE CHECK..........................................10

OIL PUMP INSPECTION..........................................10

REGULATOR VALVE INSPECTION..........................10

OIL CAPACITY........................................................10

ENGINE COOLING SYSTEM........................................ 11

Precautions ................................................................ 11

LIQUID GASKET APPLICATION PROCEDURE.......... 11

Preparation ................................................................ 11

SPECIAL SERVICE TOOLS...................................... 11

Cooling Circuit ...........................................................12

System Check............................................................12

CHECKING COOLING SYSTEM HOSES...................12

CHECKING RADIATOR............................................13

CHECKING RADIATOR CAP....................................13

CHECKING COOLING SYSTEM FOR LEAKS............13

Water Pump ...............................................................14

REMOVAL AND INSTALLATION...............................14

INSPECTION...........................................................14

Thermostat .................................................................15

REMOVAL AND INSTALLATION...............................15

INSPECTION...........................................................16

Radiator .....................................................................16

COMPONENTS.......................................................16

Cooling Fan ...............................................................17

COMPONENTS.......................................................17

CONTROL SYSTEM................................................17

Changing Engine Coolant..........................................17

- DRAINING ENGINE COOLANT -............................17

- REFILLING ENGINE COOLANT -...........................18

- FLUSHING COOLING SYSTEM -............................19

Radiator (Aluminum type) ..........................................20

PREPARATION.......................................................20

DISASSEMBLY........................................................20

ASSEMBLY.............................................................21

INSPECTION...........................................................22

Overheating Cause Analysis .....................................23

Service Data and Specifications (SDS).....................24

THERMOSTAT........................................................24

RADIATOR..............................................................24

COOLANT CAPACITY..............................................24

YD

ENGINE LUBRICATION SYSTEM................................25

Precautions ................................................................25

LIQUID GASKET APPLICATION PROCEDURE..........25

Preparation ................................................................25

SPECIAL SERVICE TOOLS......................................25

Lubrication Circuit ......................................................26

Oil Pressure Check....................................................27

Oil Pump ....................................................................27

REMOVAL AND INSTALLATION...............................27

DISASSEMBLY AND ASSEMBLY..............................28

OIL PUMP INSPECTION..........................................28

REGULATOR VALVE INSPECTION..........................29

Changing Engine Oil..................................................30

Oil Filter Bracket ........................................................31

REMOVAL AND INSTALLATION...............................31

Changing Oil Filter .....................................................31

REMOVAL...............................................................32

INSTALLATION........................................................32

Oil Cooler ...................................................................33

REMOVAL AND INSTALLATION...............................33

Service Data and Specifications (SDS).....................34

OIL PRESSURE CHECK..........................................34

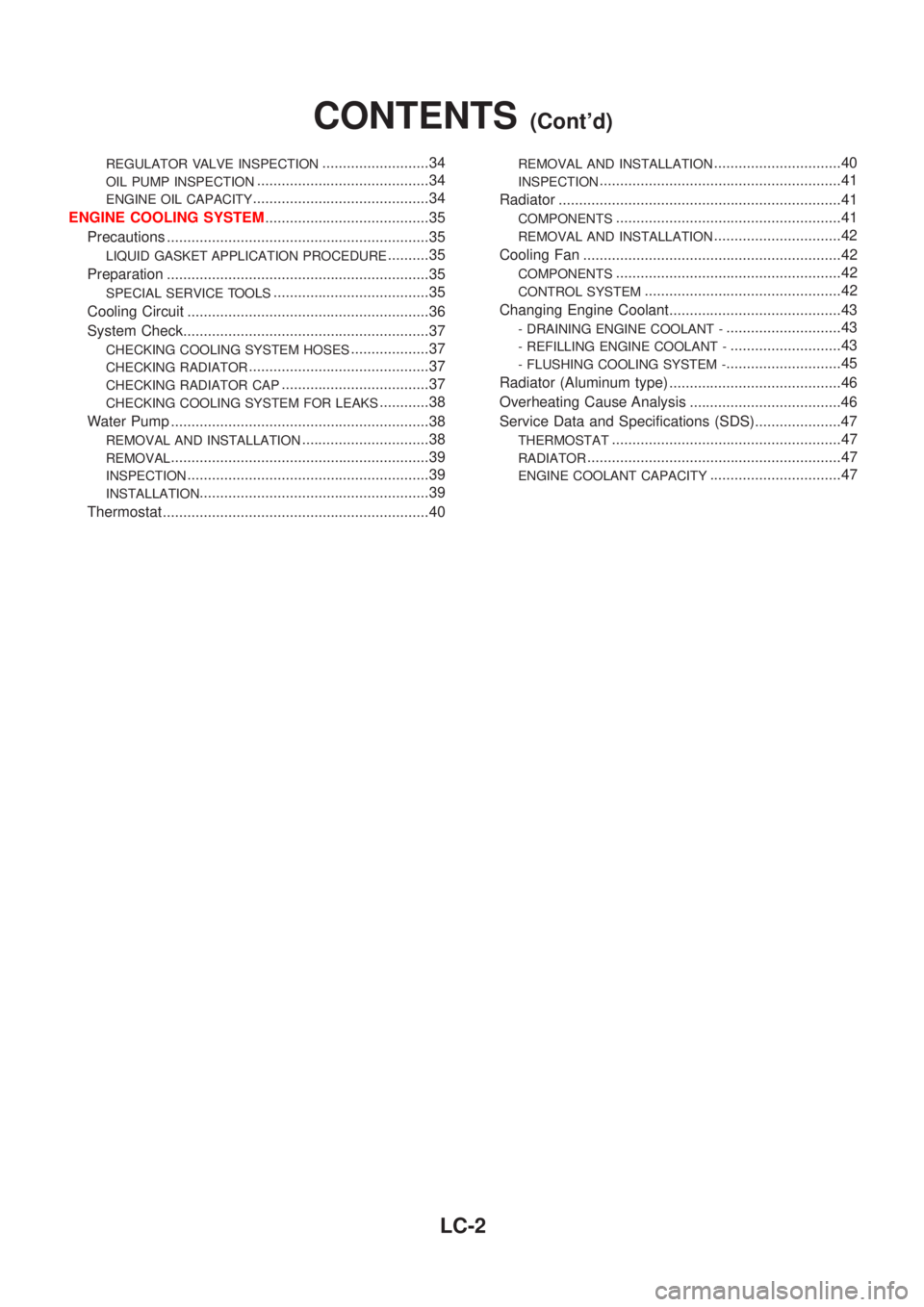

Page 250 of 2493

REGULATOR VALVE INSPECTION..........................34

OIL PUMP INSPECTION..........................................34

ENGINE OIL CAPACITY...........................................34

ENGINE COOLING SYSTEM........................................35

Precautions ................................................................35

LIQUID GASKET APPLICATION PROCEDURE..........35

Preparation ................................................................35

SPECIAL SERVICE TOOLS......................................35

Cooling Circuit ...........................................................36

System Check............................................................37

CHECKING COOLING SYSTEM HOSES...................37

CHECKING RADIATOR............................................37

CHECKING RADIATOR CAP....................................37

CHECKING COOLING SYSTEM FOR LEAKS............38

Water Pump ...............................................................38

REMOVAL AND INSTALLATION...............................38

REMOVAL...............................................................39

INSPECTION...........................................................39

INSTALLATION........................................................39

Thermostat .................................................................40

REMOVAL AND INSTALLATION...............................40

INSPECTION...........................................................41

Radiator .....................................................................41

COMPONENTS.......................................................41

REMOVAL AND INSTALLATION...............................42

Cooling Fan ...............................................................42

COMPONENTS.......................................................42

CONTROL SYSTEM................................................42

Changing Engine Coolant..........................................43

- DRAINING ENGINE COOLANT -............................43

- REFILLING ENGINE COOLANT -...........................43

- FLUSHING COOLING SYSTEM -............................45

Radiator (Aluminum type) ..........................................46

Overheating Cause Analysis .....................................46

Service Data and Specifications (SDS).....................47

THERMOSTAT........................................................47

RADIATOR..............................................................47

ENGINE COOLANT CAPACITY................................47

CONTENTS(Cont'd)

LC-2

Page 271 of 2493

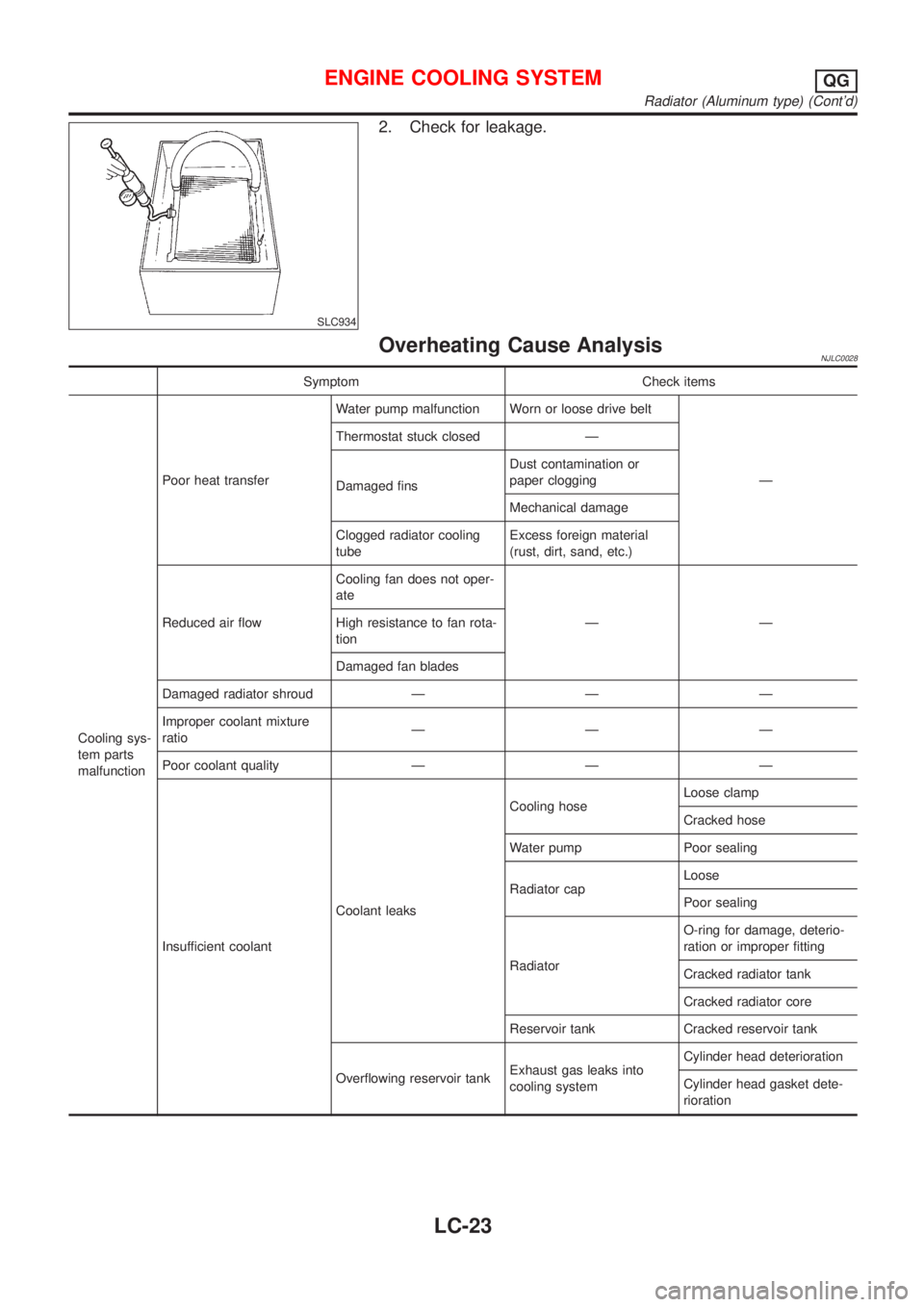

SLC934

2. Check for leakage.

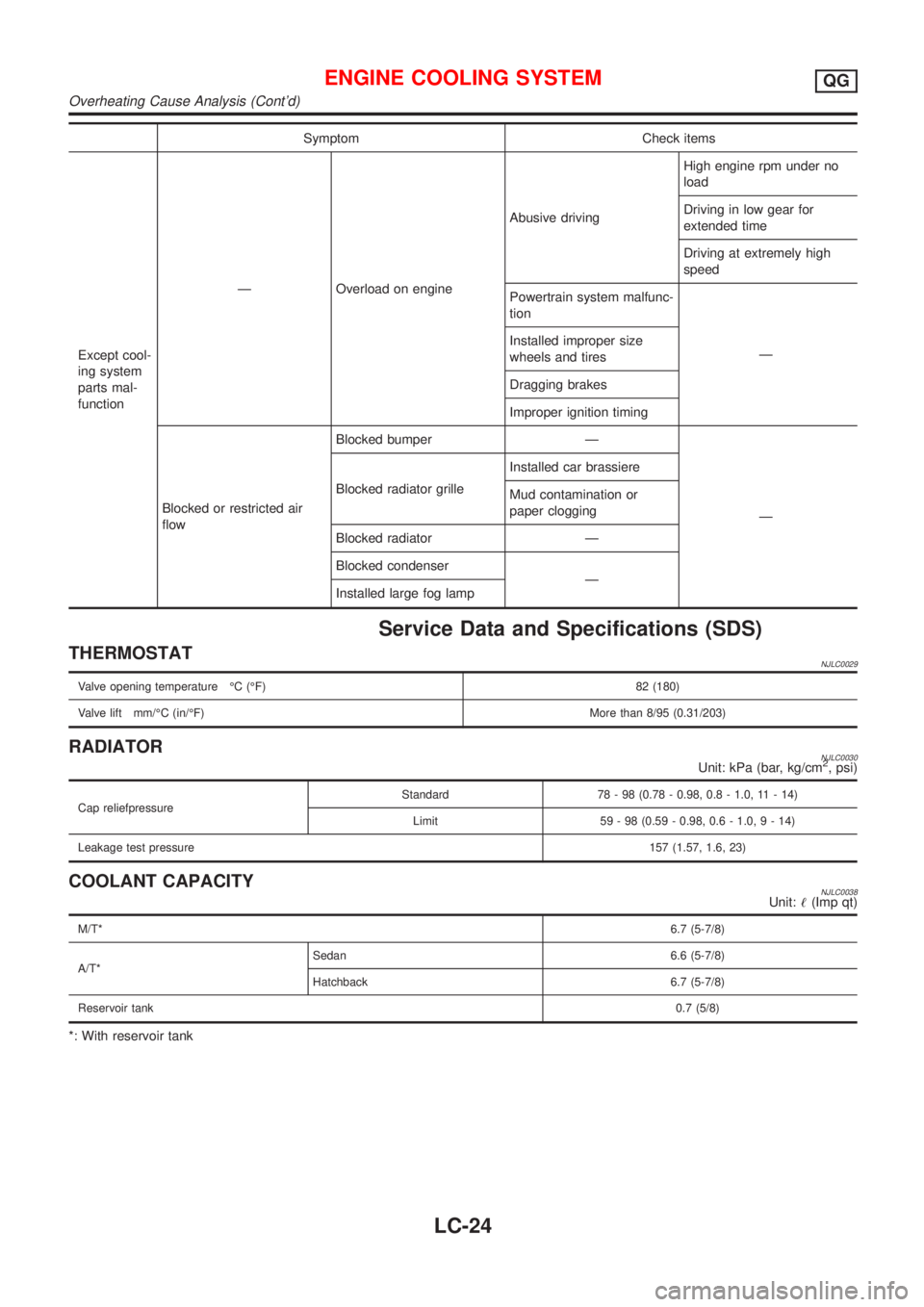

Overheating Cause AnalysisNJLC0028

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

ÐÐ High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

ENGINE COOLING SYSTEMQG

Radiator (Aluminum type) (Cont'd)

LC-23

Page 272 of 2493

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0029

Valve opening temperature ÉC (ÉF) 82 (180)

Valve lift mm/ÉC (in/ÉF)More than 8/95 (0.31/203)

RADIATORNJLC0030Unit: kPa (bar, kg/cm2, psi)

Cap reliefpressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

COOLANT CAPACITYNJLC0038Unit:!(Imp qt)

M/T*6.7 (5-7/8)

A/T*Sedan 6.6 (5-7/8)

Hatchback 6.7 (5-7/8)

Reservoir tank0.7 (5/8)

*: With reservoir tank

ENGINE COOLING SYSTEMQG

Overheating Cause Analysis (Cont'd)

LC-24

Page 294 of 2493

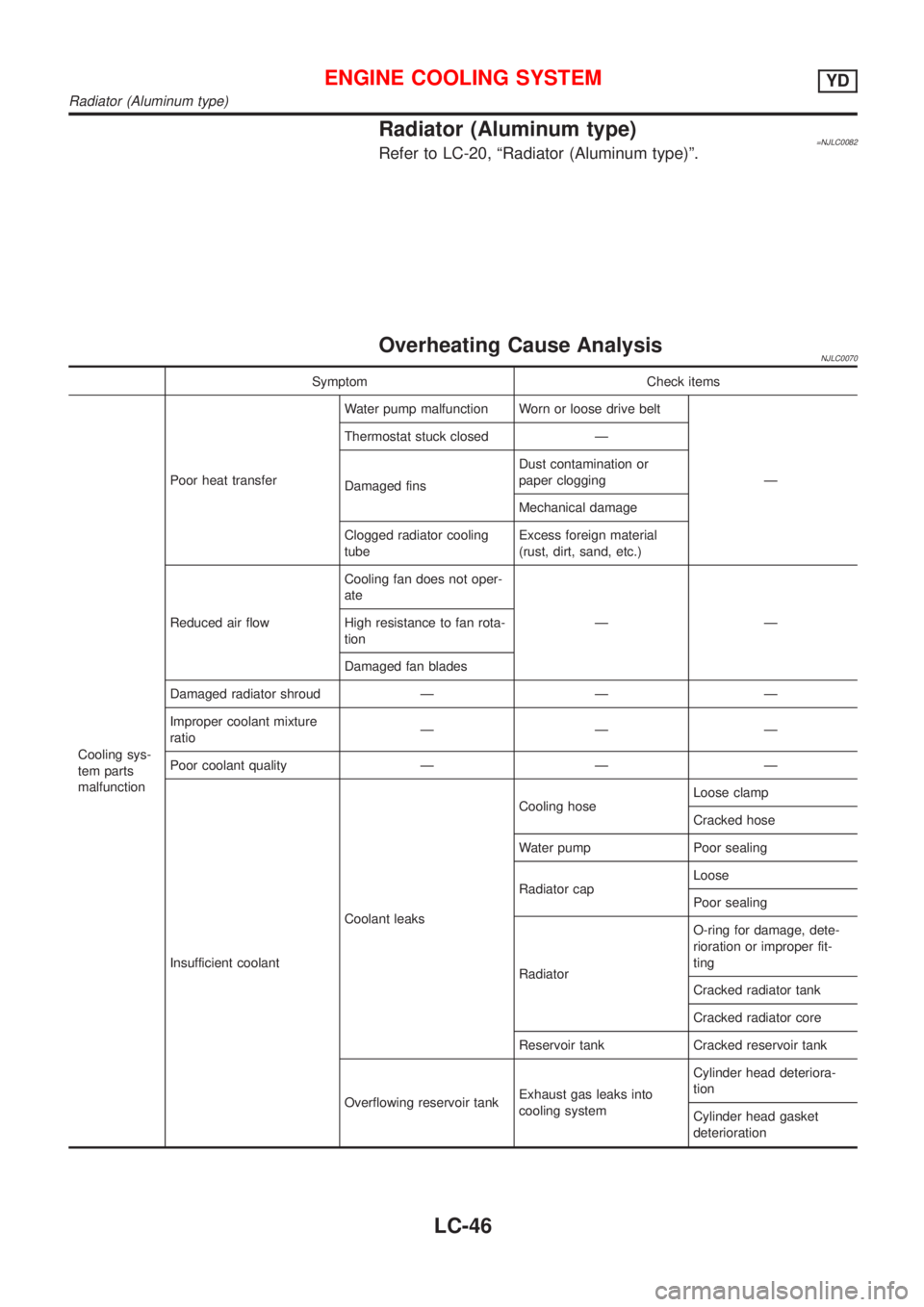

Radiator (Aluminum type)=NJLC0082Refer to LC-20, ªRadiator (Aluminum type)º.

Overheating Cause AnalysisNJLC0070

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

ÐÐ High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, dete-

rioration or improper fit-

ting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deteriora-

tion

Cylinder head gasket

deterioration

ENGINE COOLING SYSTEMYD

Radiator (Aluminum type)

LC-46

Page 295 of 2493

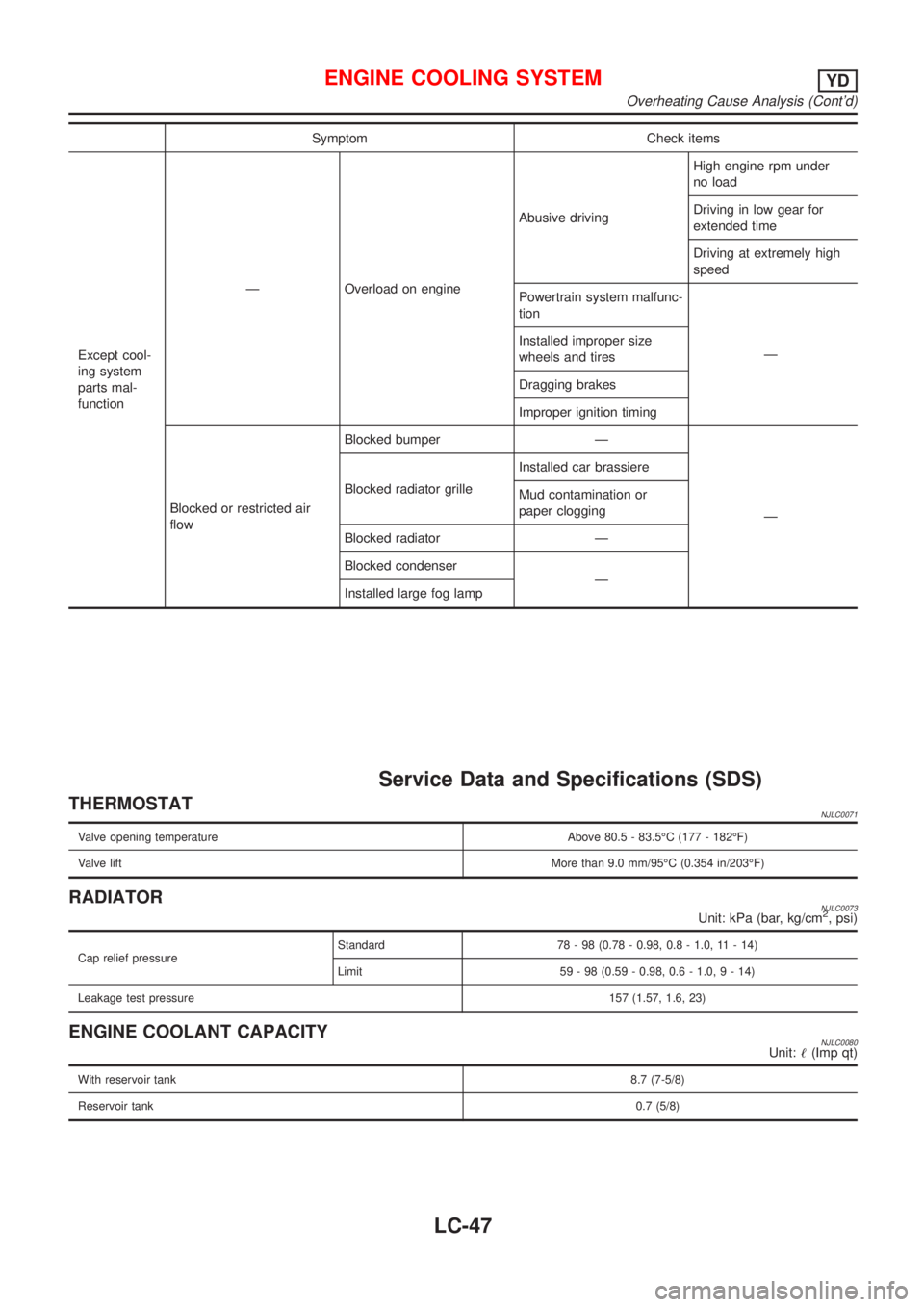

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0071

Valve opening temperature Above 80.5 - 83.5ÉC (177 - 182ÉF)

Valve liftMore than 9.0 mm/95ÉC (0.354 in/203ÉF)

RADIATORNJLC0073Unit: kPa (bar, kg/cm2, psi)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

ENGINE COOLANT CAPACITYNJLC0080Unit:!(Imp qt)

With reservoir tank8.7 (7-5/8)

Reservoir tank0.7 (5/8)

ENGINE COOLING SYSTEMYD

Overheating Cause Analysis (Cont'd)

LC-47

Page 300 of 2493

Diagnostic Procedure ..............................................281

Component Inspection .............................................284

DTC P0400 EGR FUNCTION (CLOSED) (WHERE

FITTED)........................................................................285

Description ...............................................................285

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................286

ECM Terminals and Reference Value .....................286

On Board Diagnosis Logic.......................................286

DTC Confirmation Procedure ..................................287

Wiring Diagram ........................................................289

Diagnostic Procedure ..............................................290

Component Inspection .............................................292

DTC P0403 EGR VOLUME CONTROL VALVE

(CIRCUIT).....................................................................293

Description ...............................................................293

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................294

ECM Terminals and Reference Value .....................294

On Board Diagnosis Logic.......................................294

DTC Confirmation Procedure ..................................294

Wiring Diagram ........................................................296

Diagnostic Procedure ..............................................297

Component Inspection .............................................298

DTC P0420 THREE WAY CATALYST FUNCTION...299

On Board Diagnosis Logic.......................................299

DTC Confirmation Procedure ..................................299

Overall Function Check ...........................................300

Diagnostic Procedure ..............................................300

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................304

Description ...............................................................304

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................304

ECM Terminals and Reference Value .....................305

On Board Diagnosis Logic.......................................305

DTC Confirmation Procedure ..................................305

Wiring Diagram ........................................................306

Diagnostic Procedure ..............................................307

Component Inspection .............................................308

DTC P0500 VEHICLE SPEED SENSOR (VSS).........309

Component Description ...........................................309

ECM Terminals and Reference Value .....................309

On Board Diagnosis Logic.......................................309

DTC Confirmation Procedure ..................................309

Wiring Diagram ........................................................ 311

Diagnostic Procedure ..............................................312

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............313

Description ...............................................................313

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................314ECM Terminals and Reference Value .....................314

On Board Diagnosis Logic.......................................314

DTC Confirmation Procedure ..................................314

Wiring Diagram ........................................................315

Diagnostic Procedure ..............................................316

Component Inspection .............................................320

DTC P0510 CLOSED THROTTLE POSITION

SWITCH (WHERE FITTED).........................................321

Component Description ...........................................321

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................321

ECM Terminals and Reference Value .....................321

On Board Diagnosis Logic.......................................321

DTC Confirmation Procedure ..................................321

Overall Function Check ...........................................322

Wiring Diagram ........................................................323

Diagnostic Procedure ..............................................324

Component Inspection .............................................325

DTC P0605 ECM.........................................................327

Component Description ...........................................327

On Board Diagnosis Logic.......................................327

DTC Confirmation Procedure ..................................327

Diagnostic Procedure ..............................................328

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE......................................................329

Component Description ...........................................329

Operation .................................................................329

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................329

ECM Terminals and Reference Value .....................329

On Board Diagnosis Logic.......................................329

DTC Confirmation Procedure ..................................330

Wiring Diagram ........................................................331

Diagnostic Procedure ..............................................332

Component Inspection .............................................333

DTC P1217 OVERHEAT (COOLING SYSTEM).........334

System Description ..................................................334

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................334

ECM Terminals and Reference Value .....................335

On Board Diagnosis Logic.......................................335

Overall Function Check ...........................................336

Wiring Diagram ........................................................337

Diagnostic Procedure ..............................................339

Main 12 Causes of Overheating..............................345

Component Inspection .............................................345

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................347

Component Description ...........................................347

On Board Diagnosis Logic.......................................347

DTC Confirmation Procedure ..................................347

Wiring Diagram ........................................................350

CONTENTS(Cont'd)

EC-4

Page 304 of 2493

DTC Confirmation Procedure ..................................604

Diagnostic Procedure ..............................................605

DTC P1180 P9.FUEL TEMP SEN...............................606

Description ...............................................................606

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................606

ECM Terminals and Reference Value .....................607

On Board Diagnosis Logic.......................................607

DTC Confirmation Procedure ..................................607

Wiring Diagram ........................................................609

Diagnostic Procedure ..............................................610

DTC P1202 FUEL CUT SYSTEM2.............................612

Description ...............................................................612

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................612

ECM Terminals and Reference Value .....................613

On Board Diagnosis Logic.......................................613

DTC Confirmation Procedure ..................................613

Wiring Diagram ........................................................615

Diagnostic Procedure ..............................................616

DTC P1217 OVER HEAT............................................618

Description ...............................................................618

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................618

ECM Terminals and Reference Value .....................618

On Board Diagnosis Logic.......................................619

Overall Function Check ...........................................620

Wiring Diagram ........................................................621

Diagnostic Procedure ..............................................622

Main 12 Causes of Overheating..............................633

DTC P1241 P7.F/INJ TIMG FB...................................634

Description ...............................................................634

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................634

ECM Terminals and Reference Value .....................635

On Board Diagnosis Logic.......................................635

DTC Confirmation Procedure ..................................635

Wiring Diagram ........................................................637

Diagnostic Procedure ..............................................638

DTC P1251 P4.SPILL/V CIRC....................................640

Description ...............................................................640

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................640

ECM Terminals and Reference Value .....................641

On Board Diagnosis Logic.......................................641

DTC Confirmation Procedure ..................................641

Wiring Diagram ........................................................643

Diagnostic Procedure ..............................................644

DTC P1337 P2.DTC PULSE SIG................................646

Description ...............................................................646

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................646ECM Terminals and Reference Value .....................647

On Board Diagnosis Logic.......................................647

DTC Confirmation Procedure ..................................647

Wiring Diagram ........................................................649

Diagnostic Procedure ..............................................650

DTC P1341 P1.CAM POS SEN..................................652

Description ...............................................................652

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................652

ECM Terminals and Reference Value .....................653

On Board Diagnosis Logic.......................................653

DTC Confirmation Procedure ..................................653

Wiring Diagram ........................................................655

Diagnostic Procedure ..............................................656

DTC P1600 P3.PUMP COMM LINE............................658

Description ...............................................................658

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................658

ECM Terminals and Reference Value .....................659

On Board Diagnosis Logic.......................................659

DTC Confirmation Procedure ..................................659

Wiring Diagram ........................................................661

Diagnostic Procedure ..............................................662

DTC P1603 ECM 12, DTC P1607 ECM 2...................664

Description ...............................................................664

On Board Diagnosis Logic.......................................664

DTC Confirmation Procedure ..................................664

Diagnostic Procedure ..............................................665

DTC P1620 ECM RLY.................................................666

ECM Terminals and Reference Value .....................666

On Board Diagnosis Logic.......................................666

DTC Confirmation Procedure ..................................666

Wiring Diagram ........................................................667

Diagnostic Procedure ..............................................668

DTC P1621 ECM 15....................................................670

Description ...............................................................670

On Board Diagnosis Logic.......................................670

DTC Confirmation Procedure ..................................670

Diagnostic Procedure ..............................................671

DTC P1660 BATTERY VOLTAGE..............................672

On Board Diagnosis Logic.......................................672

DTC Confirmation Procedure ..................................672

Diagnostic Procedure ..............................................672

DTC P1690 P5.PUMP C/MODULE.............................674

Description ...............................................................674

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................674

ECM Terminals and Reference Value .....................675

On Board Diagnosis Logic.......................................675

DTC Confirmation Procedure ..................................675

Diagnostic Procedure ..............................................676

CONTENTS(Cont'd)

EC-8