Wiring Diagram NISSAN ALMERA N16 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 23 of 3189

manual.

Fuse block — Junction box (J/B)

Fuse block — Junction box (J/B) connector number is shown in the

Reference Area of the wiring diagram. For connector terminal and

fuse arrangement, refer to the “FUSE BLOCK — Junction Box

(J/B)” electrical reference page at the end of the manual.

Fuse and fusible link box

For fuse arrangement in the fuse and fusible link box, refer to the

“FUSE AND FUSIBLE LINK BOX” electrical reference page at the

end of the manual.

Electrical units

Electrical unit connector symbols are shown in the Connector Area

of the wiring diagram.

However, when there is not enough space to show the connector

terminal arrangement in the Connector Area of the wiring diagram,

the electrical unit connector number is shown in the Reference

Area of the wiring diagram. For electrical unit connector terminal

arrangement, refer to the “ELECTRICAL UNITS” electrical refer-

ence page at the end of the manual. Most of the electrical unit

connectors on this page are shown from the harness side of the

connector.

Joint connector

Joint connector symbols are shown in the connector area of the

wiring diagram. For connector internal wiring layout and joint con-

nector terminal arrangement, refer to the “JOINT CONNECTOR

(J/C)” electrical reference page at the end of the manual.

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

GI-21

Page 26 of 3189

Engine Compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

Connectors not fully seated.

Wiring harness not long enough and is being stressed due to

engine vibrations or rocking.

Wires laying across brackets or moving components.

Loose, dirty or corroded ground wires.

Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection bygently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind The Instrument Panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under Seating Areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

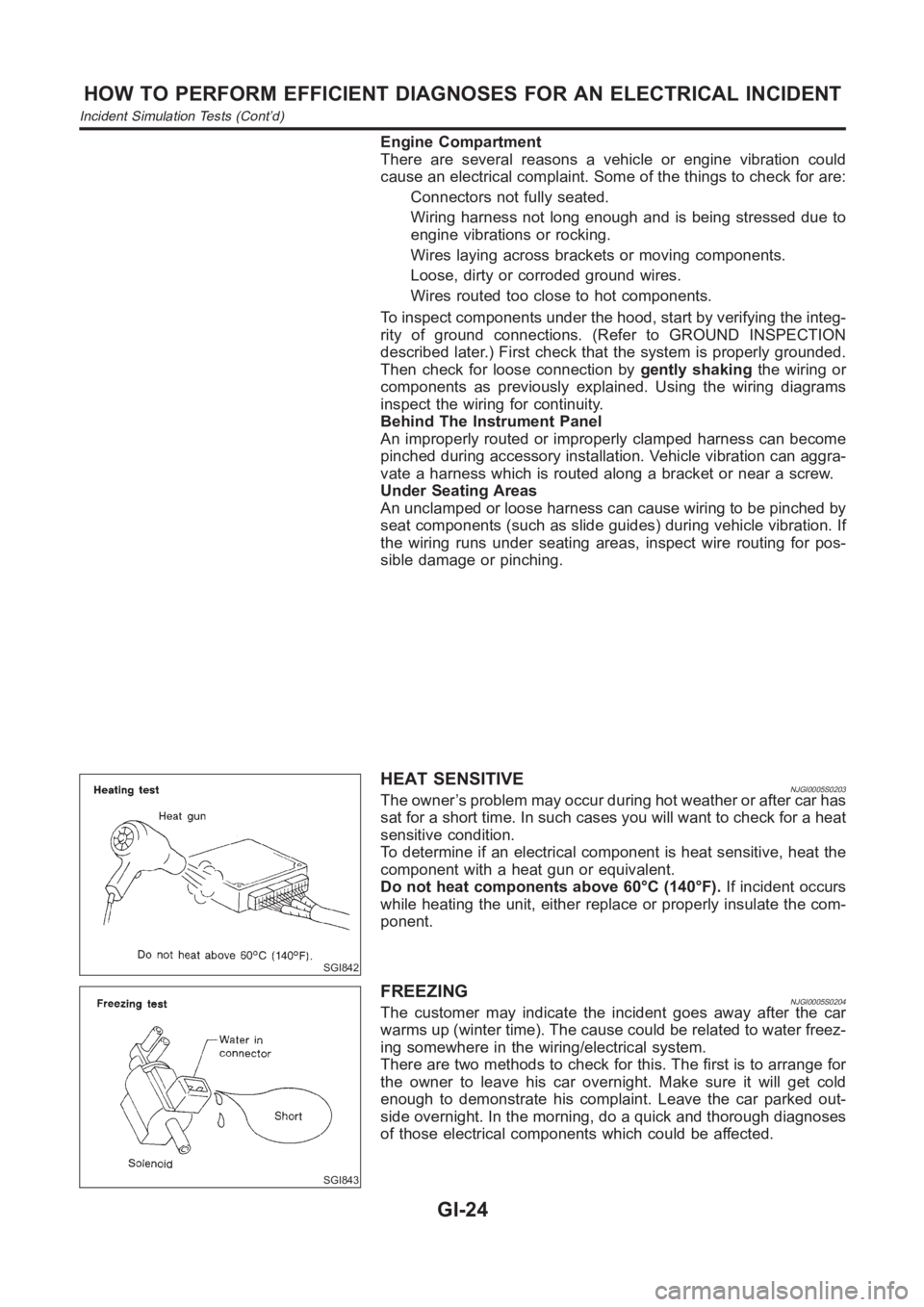

SGI842

HEAT SENSITIVENJGI0005S0203The owner’s problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60°C (140°F).If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI843

FREEZINGNJGI0005S0204The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnoses

of those electrical components which could be affected.

HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont’d)

GI-24

Page 34 of 3189

NJGI0006

NOTICE:

Trouble diagnoses indicate work procedures required to diagnose

problems effectively. Observe the following instructions before

diagnosing.

1)Before performing trouble diagnoses, read the “Prelimi-

nary Check”, the “Symptom Chart” or the “Work Flow”.

2)After repairs, re-check that the problem has been com-

pletely eliminated.

3)Refer to Component Parts and Harness Connector Loca-

tion for the Systems described in each section for

identification/location of components and harness con-

nectors.

4)Refer to the Circuit Diagram for quick pinpoint check.

If you need to check circuit continuity between harness

connectors in more detail, such as when a sub-harness is

used, refer to Wiring Diagram in each individual section

and Harness Layout in EL section for identification of har-

ness connectors.

5)When checking circuit continuity, ignition switch should

be OFF.

6)Before checking voltage at connectors, check battery volt-

age.

7)After accomplishing the Diagnostic Procedures and Elec-

trical Components Inspection, make sure that all harness

connectors are reconnected as they were.

HOW TO FOLLOW TROUBLE DIAGNOSES

GI-32

Page 40 of 3189

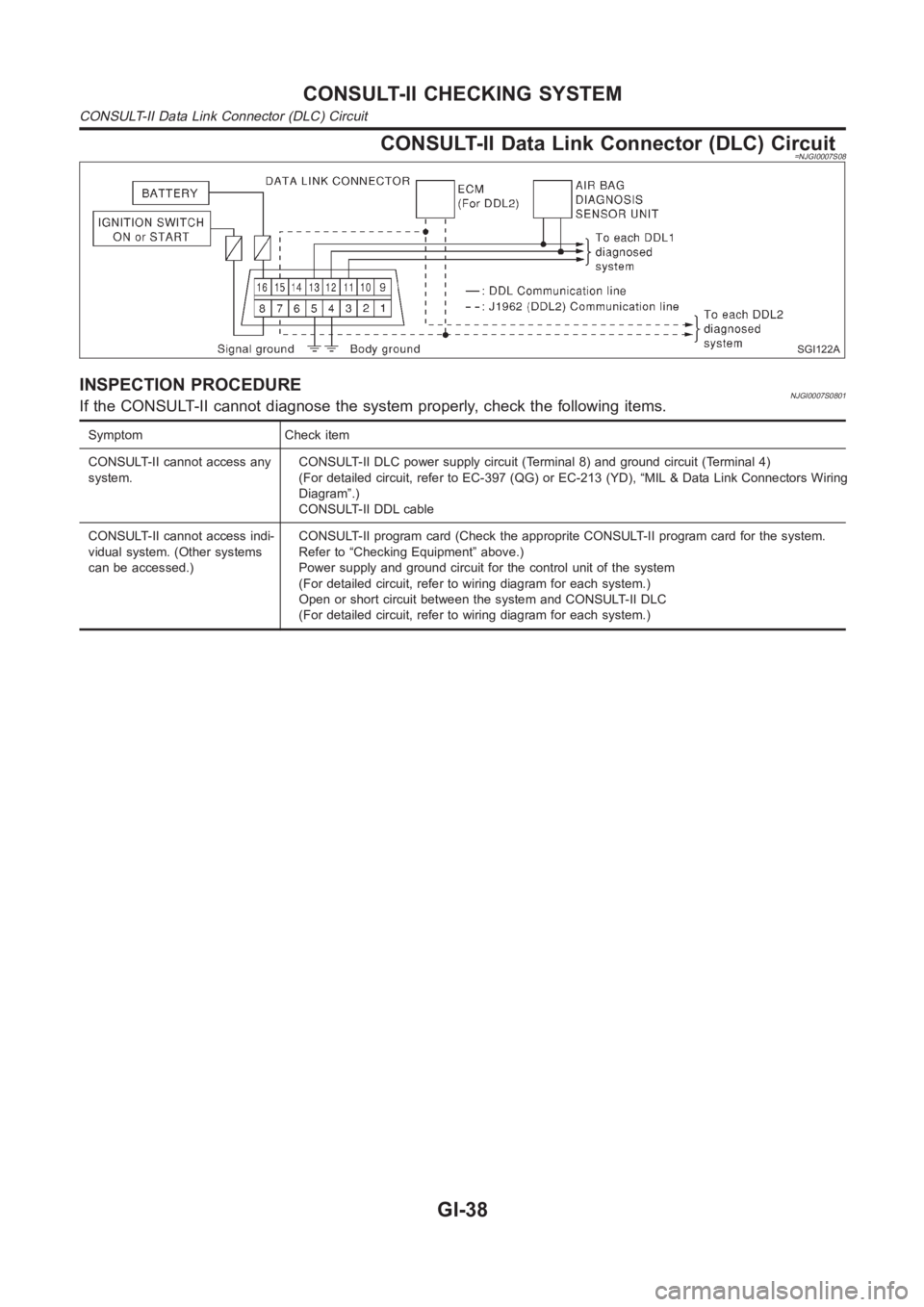

CONSULT-II Data Link Connector (DLC) Circuit=NJGI0007S08

SGI122A

INSPECTION PROCEDURENJGI0007S0801If the CONSULT-II cannot diagnose the system properly, check the following items.

Symptom Check item

CONSULT-II cannot access any

system.CONSULT-II DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4)

(For detailed circuit, refer to EC-397 (QG) or EC-213 (YD), “MIL & Data LinkConnectors Wiring

Diagram”.)

CONSULT-II DDL cable

CONSULT-II cannot access indi-

vidual system. (Other systems

can be accessed.)CONSULT-II program card (Check the approprite CONSULT-II program card for the system.

Refer to “Checking Equipment” above.)

Power supply and ground circuit for the control unit of the system

(For detailed circuit, refer to wiring diagram for each system.)

Open or short circuit between the system and CONSULT-II DLC

(For detailed circuit, refer to wiring diagram for each system.)

CONSULT-II CHECKING SYSTEM

CONSULT-II Data Link Connector (DLC) Circuit

GI-38

Page 331 of 3189

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QG (WITH EURO-OBD)

INDEX FOR DTC ...................................................... 10

Alphabetical Index .................................................. 10

DTC No. Index ....................................................... 12

PRECAUTIONS ........................................................ 15

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 15

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 15

Precaution .............................................................. 15

Wiring Diagrams and Trouble Diagnosis ................ 18

PREPARATION ......................................................... 19

Special Service Tools ............................................. 19

Commercial Service Tools ...................................... 19

ENGINE CONTROL SYSTEM .................................. 21

System Diagram ..................................................... 21

Vacuum Hose Drawing ........................................... 22

System Chart ......................................................... 23

Multiport Fuel Injection (MFI) System .................... 23

Electronic Ignition (EI) System ............................... 25

Air Conditioning Cut Control ................................... 26

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 27

CAN Communication .............................................. 27

BASIC SERVICE PROCEDURE .............................. 30

Idle Speed and Ignition Timing Check .................... 30

Accelerator Pedal Released Position Learning ...... 31

Throttle Valve Closed Position Learning ................ 31

Idle Air Volume Learning ........................................ 31

Fuel Pressure Check .............................................. 34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 36

Introduction ............................................................ 36

Two Trip Detection Logic ........................................ 36

Emission-related Diagnostic Information ................ 37

NATS (Nissan Anti-theft System) ........................... 49

Malfunction Indicator (MI) ....................................... 49

OBD System Operation Chart ................................ 52

TROUBLE DIAGNOSIS ............................................ 58

Trouble Diagnosis Introduction ............................... 58DTC Inspection Priority Chart ................................. 62

Fail-safe Chart ........................................................ 63

Basic Inspection ..................................................... 65

Symptom Matrix Chart ............................................ 70

Engine Control Component Parts Location ............ 74

Circuit Diagram ....................................................... 78

ECM Harness Connector Terminal Layout ............. 80

ECM Terminals and Reference Value ..................

... 80

CONSULT-II Function ............................................. 87

Generic Scan Tool (GST) Function ......................... 97

CONSULT-II Reference Value in Data Monitor Mode

... 99

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................102

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .105

Description ............................................................105

Testing Condition ..................................................105

Inspection Procedure ............................................105

Diagnostic Procedure ...........................................106

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................109

Description ............................................................109

Diagnostic Procedure ...........................................109

POWER SUPPLY CIRCUIT FOR ECM ...................110

Wiring Diagram .....................................................110

Diagnostic Procedure ............................................111

Component Inspection ..........................................115

DTC U1000, U1001 CAN COMMUNICATION LINE .116

Description ............................................................116

On Board Diagnosis Logic ....................................116

DTC Confirmation Procedure ...............................116

Wiring Diagram .....................................................117

Diagnostic Procedure ...........................................118

DTC P0011 IVT CONTROL .....................................119

Description ............................................................119

CONSULT-II Reference Value in Data Monitor Mode

.119

On Board Diagnosis Logic ....................................120

DTC Confirmation Procedure ...............................120

Diagnostic Procedure ...........................................121

Page 332 of 3189

EC-2

DTC P0031, P0032 HO2S1 HEATER .....................122

Description ............................................................122

CONSULT-II Reference Value in Data Monitor Mode

.122

On Board Diagnosis Logic ....................................122

DTC Confirmation Procedure ...............................122

Wiring Diagram .....................................................124

Diagnostic Procedure ...........................................125

Component Inspection ..........................................127

Removal and Installation ......................................127

DTC P0037, P0038 HO2S2 HEATER .....................128

Description ............................................................128

CONSULT-II Reference Value in Data Monitor Mode

.128

On Board Diagnosis Logic ....................................128

DTC Confirmation Procedure ...............................128

Wiring Diagram .....................................................130

Diagnostic Procedure ...........................................131

Component Inspection ..........................................133

Removal and Installation ......................................133

DTC P0102, P0103 MAF SENSOR .........................134

Component Description ........................................134

CONSULT-II Reference Value in Data Monitor Mode

.134

On Board Diagnosis Logic ....................................134

DTC Confirmation Procedure ...............................135

Wiring Diagram .....................................................136

Diagnostic Procedure ...........................................137

Component Inspection ..........................................139

Removal and Installation ......................................139

DTC P0112, P0113 IAT SENSOR ...........................140

Component Description ........................................140

On Board Diagnosis Logic ....................................140

DTC Confirmation Procedure ...............................140

Wiring Diagram .....................................................141

Diagnostic Procedure ...........................................142

Component Inspection ..........................................143

Removal and Installation ......................................143

DTC P0117, P0118 ECT SENSOR ..........................144

Component Description ........................................144

On Board Diagnosis Logic ....................................144

DTC Confirmation Procedure ...............................145

Wiring Diagram .....................................................146

Diagnostic Procedure ...........................................147

Component Inspection ..........................................148

Removal and Installation ......................................148

DTC P0132 HO2S1 .................................................149

Component Description ........................................149

CONSULT-II Reference Value in Data Monitor Mode

.149

On Board Diagnosis Logic ...................................

.149

DTC Confirmation Procedure ...............................150

Wiring Diagram .....................................................151

Diagnostic Procedure ...........................................152

Component Inspection ..........................................153

Removal and Installation ......................................154

DTC P0133 HO2S1 .................................................155

Component Description ........................................155

CONSULT-II Reference Value in Data Monitor Mode .155

On Board Diagnosis Logic ....................................155

DTC Confirmation Procedure ................................156

Overall Function Check .........................................157

Wiring Diagram .....................................................158

Diagnostic Procedure ............................................159

Component Inspection ..........................................162

Removal and Installation .......................................164

DTC P0134 HO2S1 ................................................ .165

Component Description ........................................165

CONSULT-II Reference Value in Data Monitor Mode

.165

On Board Diagnosis Logic ....................................165

DTC Confirmation Procedure ................................166

Overall Function Check .........................................166

Wiring Diagram .....................................................168

Diagnostic Procedure ............................................169

Component Inspection ..........................................170

Removal and Installation .......................................171

DTC P0138 HO2S2 ................................................ .172

Component Description ........................................172

CONSULT-II Reference Value in Data Monitor Mode

.172

On Board Diagnosis Logic ....................................172

DTC Confirmation Procedure ................................173

Wiring Diagram .....................................................174

Diagnostic Procedure ............................................175

Component Inspection ..........................................176

Removal and Installation .......................................177

DTC P0139 HO2S2 ................................................ .178

Component Description ........................................178

CONSULT-II Reference Value in Data Monitor Mode

.178

On Board Diagnosis Logic ....................................178

DTC Confirmation Procedure ................................179

Overall Function Check .........................................180

Wiring Diagram .....................................................181

Diagnostic Procedure ............................................182

Component Inspection ..........................................184

Removal and Installation ......................................

.185

DTC P0171 FUEL INJECTION SYSTEM FUNCTION .186

On Board Diagnosis Logic ....................................186

DTC Confirmation Procedure ................................186

Wiring Diagram .....................................................188

Diagnostic Procedure ............................................189

DTC P0172 FUEL INJECTION SYSTEM FUNCTION .193

On Board Diagnosis Logic ....................................193

DTC Confirmation Procedure ................................193

Wiring Diagram .....................................................195

Diagnostic Procedure ............................................196

DTC P0221 TP SENSOR ........................................199

Component Description ........................................199

CONSULT-II Reference Value in Data Monitor Mode

.199

On Board Diagnosis Logic ....................................199

DTC Confirmation Procedure ................................199

Wiring Diagram .....................................................201

Diagnostic Procedure ............................................202

Page 333 of 3189

EC-3

C

D

E

F

G

H

I

J

K

L

M

ECA Component Inspection ......................................... 204

Removal and Installation ...................................... 204

DTC P0222, P0223 TP SENSOR ........................... 205

Component Description ........................................ 205

CONSULT-II Reference Value in Data Monitor Mode

. 205

On Board Diagnosis Logic ................................... 205

DTC Confirmation Procedure ............................... 205

Wiring Diagram .................................................... 207

Diagnostic Procedure ........................................... 208

Component Inspection ......................................... 210

Removal and Installation ...................................... 210

DTC P0226 APP SENSOR ......................................211

Component Description ......................................... 211

CONSULT-II Reference Value in Data Monitor Mode

.. 211

On Board Diagnosis Logic .................................... 211

DTC Confirmation Procedure ................................ 211

Wiring Diagram .................................................... 213

Diagnostic Procedure ........................................... 214

Component Inspection ......................................... 216

Removal and Installation ...................................... 217

DTC P0227, P0228 APP SENSOR ........................ 218

Component Description ........................................ 218

CONSULT-II Reference Value in Data Monitor Mode

. 218

On Board Diagnosis Logic ................................... 218

DTC Confirmation Procedure ............................... 218

Wiring Diagram .................................................... 220

Diagnostic Procedure ........................................... 221

Component Inspection ......................................... 223

Removal and Installation ...................................... 224

DTC P0300 - P0304 MULTIPLE CYLINDER MIS-

FIRE, NO. 1 - 4 CYLINDER MISFIRE ..................... 225

On Board Diagnosis Logic ................................... 225

DTC Confirmation Procedure ............................... 225

Diagnostic Procedure ........................................... 226

DTC P0327, P0328 KS ........................................... 230

Component Description ........................................ 230

On Board Diagnosis Logic ................................... 230

DTC Confirmation Procedure ............................... 230

Wiring Diagram .................................................... 231

Diagnostic Procedure ........................................... 232

Component Inspection ......................................... 233

Removal and Installation ...................................... 233

DTC P0335 CKP SENSOR (POS) .......................... 234

Component Description ........................................ 234

CONSULT-II Reference Value in Data Monitor Mode

. 234

On Board Diagnosis Logic ................................... 234

DTC Confirmation Procedure ............................... 234

Wiring Diagram ...................................................

. 235

Diagnostic Procedure ........................................... 236

Component Inspection ......................................... 238

Removal and Installation ...................................... 239

DTC P0340 CMP SENSOR (PHASE) ..................... 240

Component Description ........................................ 240

On Board Diagnosis Logic ................................... 240

DTC Confirmation Procedure ............................... 240Wiring Diagram .....................................................241

Diagnostic Procedure ...........................................242

Component Inspection ..........................................244

Removal and Installation ......................................245

DTC P0420 THREE WAY CATALYST FUNCTION . 246

On Board Diagnosis Logic ....................................246

DTC Confirmation Procedure ...............................246

Overall Function Check ........................................247

Diagnostic Procedure ...........................................248

DTC P0444 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE ...............................251

Description ............................................................251

CONSULT-II Reference Value in Data Monitor Mode

.251

On Board Diagnosis Logic ....................................252

DTC Confirmation Procedure ...............................252

Wiring Diagram .....................................................253

Diagnostic Procedure ...........................................254

Component Inspection ..........................................256

Removal and Installation ......................................256

DTC P0500 VSS ......................................................257

Description ............................................................257

On Board Diagnosis Logic ....................................257

DTC Confirmation Procedure ...............................257

Overall Function Check ........................................258

Diagnostic Procedure ...........................................259

DTC P0550 PSP SENSOR .....................................260

Component Description ........................................260

CONSULT-II Reference Value in Data Monitor Mode

.260

On Board Diagnosis Logic ....................................260

DTC Confirmation Procedure ...............................260

Wiring Diagram .....................................................261

Diagnostic Procedure ...........................................262

Component Inspection ..........................................264

DTC P0605 ECM .....................................................265

Component Description ........................................265

On Board Diagnosis Logic ....................................265

DTC Confirmation Procedure ...............................265

Diagnostic Procedure ...........................................266

DTC P1065 ECM POWER SUPPLY .......................268

Component Description ........................................268

On Board Diagnosis Logic ....................................268

DTC Confirmation Procedure ...............................268

Wiring Diagram .....................................................269

Diagnostic Procedure ...........................................270

DTC P1111 IVT CONTROL SOLENOID VALVE .....272

Component Description ........................................272

CONSULT-II Reference Value in Data Monitor Mode

.272

On Board Diagnosis Logic ....................................272

DTC Confirmation Procedure ...............................272

Wiring Diagram .....................................................273

Diagnostic Procedure ...........................................274

Component Inspection ..........................................275

Removal and Installation ......................................275

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR .............................................................276

Component Description ........................................276

Page 334 of 3189

EC-4

On Board Diagnosis Logic ....................................276

DTC Confirmation Procedure ...............................276

Diagnostic Procedure ...........................................277

Removal and Installation ......................................277

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION ..............................................................278

Description ............................................................278

On Board Diagnosis Logic ....................................278

DTC Confirmation Procedure ...............................278

Wiring Diagram .....................................................279

Diagnostic Procedure ...........................................280

Component Inspection ..........................................284

Removal and Installation ......................................284

DTC P1124, P1126 THROTTLE CONTROL MOTOR

RELAY .....................................................................285

Component Description ........................................285

CONSULT-II Reference Value in Data Monitor Mode

.285

On Board Diagnosis Logic ....................................285

DTC Confirmation Procedure ...............................285

Wiring Diagram .....................................................287

Diagnostic Procedure ...........................................288

Component Inspection ..........................................289

DTC P1128 THROTTLE CONTROL MOTOR .........291

Component Description ........................................291

On Board Diagnosis Logic ....................................291

DTC Confirmation Procedure ...............................291

Wiring Diagram .....................................................292

Diagnostic Procedure ...........................................293

Component Inspection ..........................................294

Removal and Installation ......................................295

DTC P1143 HO2S1 .................................................296

Component Description ........................................296

CONSULT-II Reference Value in Data Monitor Mode

.296

On Board Diagnosis Logic ....................................296

DTC Confirmation Procedure ...............................297

Overall Function Check ........................................298

Diagnostic Procedure ...........................................298

Component Inspection ..........................................300

Removal and Installation ......................................301

DTC P1144 HO2S1 .................................................302

Component Description ........................................302

CONSULT-II Reference Value in Data Monitor Mode

.302

On Board Diagnosis Logic ....................................302

DTC Confirmation Procedure ...............................303

Overall Function Check ........................................304

Diagnostic Procedure ...........................................304

Component Inspection ..........................................306

Removal and Installation ......................................307

DTC P1146 HO2S2 ...............................................

..308

Component Description ........................................308

CONSULT-II Reference Value in Data Monitor Mode

.308

On Board Diagnosis Logic ....................................308

DTC Confirmation Procedure ...............................308

Overall Function Check ........................................310

Wiring Diagram .....................................................311Diagnostic Procedure ............................................312

Component Inspection ..........................................314

Removal and Installation .......................................315

DTC P1147 HO2S2 ..................................................316

Component Description ........................................316

CONSULT-II Reference Value in Data Monitor Mode

.316

On Board Diagnosis Logic ....................................316

DTC Confirmation Procedure ................................317

Overall Function Check .........................................318

Wiring Diagram .....................................................319

Diagnostic Procedure ............................................320

Component Inspection ..........................................322

Removal and Installation .......................................323

DTC P1217 ENGINE OVER TEMPERATURE ........324

System Description ...............................................324

CONSULT-II Reference Value in Data Monitor Mode

.324

On Board Diagnosis Logic ....................................325

Overall Function Check .........................................325

Wiring Diagram .....................................................327

Diagnostic Procedure ............................................328

Main 12 Causes of Overheating ...........................333

Component Inspection ..........................................334

DTC P1223, P1224 TP SENSOR ............................335

Component Description ........................................335

CONSULT-II Reference Value in Data Monitor Mode

.335

On Board Diagnosis Logic ....................................335

DTC Confirmation Procedure ................................335

Wiring Diagram .....................................................337

Diagnostic Procedure ............................................338

Component Inspection ..........................................340

Removal and Installation .......................................340

DTC P1225 TP SENSOR ........................................341

Component Description ........................................341

On Board Diagnosis Logic ....................................341

DTC Confirmation Procedure ................................341

Diagnostic Procedure ............................................342

Removal and Installation .......................................342

DTC P1226 TP SENSOR ........................................343

Component Description ........................................343

On Board Diagnosis Logic ....................................343

DTC Confirmation Procedure ................................343

Diagnostic Procedure ............................................344

Removal and Installation .......................................344

DTC P1227, P1228 APP SENSOR .........................345

Component Description ........................................345

CONSULT-II Reference Value in Data Monitor Mode

.345

On Board Diagnosis Logic ....................................345

DTC Confirmation Procedure ................................345

Wiring Diagram .....................................................347

Diagnostic Procedure ............................................348

Component Inspection ..........................................350

Removal and Installation .......................................351

DTC P1229 SENSOR POWER SUPPLY ................352

On Board Diagnosis Logic ....................................352

DTC Confirmation Procedure ................................352

Page 335 of 3189

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA Wiring Diagram .................................................... 353

Diagnostic Procedure ........................................... 354

DTC P1706 PNP SWITCH ...................................... 356

Component Description ........................................ 356

CONSULT-II Reference Value in Data Monitor Mode

. 356

On Board Diagnosis Logic ................................... 356

DTC Confirmation Procedure ............................... 356

Overall Function Check ........................................ 357

Wiring Diagram .................................................... 358

Diagnostic Procedure ........................................... 359

DTC P1805 BRAKE SWITCH ................................ 360

Description ........................................................... 360

CONSULT-II Reference Value in Data Monitor Mode

. 360

On Board Diagnosis Logic ................................... 360

DTC Confirmation Procedure ............................... 360

Wiring Diagram .................................................... 361

Diagnostic Procedure ........................................... 362

Component Inspection ......................................... 364

IGNITION SIGNAL .................................................. 365

Component Description ........................................ 365

Wiring Diagram .................................................... 366

Diagnostic Procedure ........................................... 369

Component Inspection ......................................... 373

Removal and Installation ...................................... 374

INJECTOR CIRCUIT ............................................... 375

Component Description ........................................ 375

CONSULT-II Reference Value in Data Monitor Mode

. 375

Wiring Diagram .................................................... 376

Diagnostic Procedure ........................................... 377

Component Inspection ......................................... 380

Removal and Installation ...................................... 380

FUEL PUMP CIRCUIT ............................................ 381

Description ........................................................... 381

CONSULT-II Reference Value in Data Monitor Mode

. 381

Wiring Diagram .................................................... 382

Diagnostic Procedure ........................................... 383

Component Inspection ......................................... 385

Removal and Installation ...................................... 386

REFRIGERANT PRESSURE SENSOR ................. 387

Component Description ........................................ 387

Wiring Diagram .................................................... 388

Diagnostic Procedure ........................................... 389

Removal and Installation ...................................... 391

ELECTRICAL LOAD SIGNAL ................................ 392

Description ...................................................

........ 392

CONSULT-II Reference Value in Data Monitor Mode

. 392

Wiring Diagram .................................................... 393

Diagnostic Procedure ........................................... 394

MI & DATA LINK CONNECTORS .......................... 397

Wiring Diagram—LHD Models ............................. 397

Wiring Diagram—RHD Models ............................ 398

EVAPORATIVE EMISSION SYSTEM ..................... 399

Description ........................................................... 399

Component Inspection ......................................... 401POSITIVE CRANKCASE VENTILATION ...............402

Description ............................................................402

Component Inspection ..........................................402

SERVICE DATA AND SPECIFICATIONS (SDS) ....404

Fuel Pressure .......................................................404

Idle Speed and Ignition Timing .............................404

Calculated Load Value ..........................................404

Mass Air Flow Sensor ...........................................404

Intake Air Temperature Sensor .............................404

Engine Coolant Temperature Sensor ...................404

Heated Oxygen Sensor 1 Heater .........................404

Heated Oxygen sensor 2 Heater ..........................404

Crankshaft Position Sensor (POS) .......................404

Camshaft Position Sensor (PHASE) ....................404

Throttle Control Motor ...........................................405

Injector ..................................................................405

Fuel Pump ............................................................405

QG (WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................406

Alphabetical Index ................................................406

DTC No. Index ......................................................407

PRECAUTIONS ......................................................409

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................409

On Board Diagnostic (OBD) System of Engine ....409

Precaution ............................................................409

Wiring Diagrams and Trouble Diagnosis ..............412

PREPARATION .......................................................413

Special Service Tools ...........................................413

Commercial Service Tools ....................................413

ENGINE CONTROL SYSTEM ................................415

System Diagram ...................................................415

Vacuum Hose Drawing .........................................416

System Chart ........................................................417

Multiport Fuel Injection (MFI) System ...................417

Electronic Ignition (EI) System .............................419

Air Conditioning Cut Control .................................420

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................421

CAN Communication ............................................421

BASIC SERVICE PROCEDURE .............................424

Idle Speed and Ignition Timing Check ..................424

Accelerator Pedal Released Position Learning ....425

Throttle Valve Closed Position Learning ...............425

Idle Air Volume Learning ......................................425

Fuel Pressure Check ............................................427

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........429

Introduction ...........................................................429

Two Trip Detection Logic ......................................429

Emission-related Diagnostic Information ..............429

NATS (Nissan Anti-theft System) .........................431

Malfunction Indicator (MI) .....................................432

TROUBLE DIAGNOSIS ..........................................436

Trouble Diagnosis Introduction .............................436

DTC Inspection Priority Chart ...............................440

Fail-safe Chart ......................................................441

Page 336 of 3189

EC-6

Basic Inspection ...................................................443

Symptom Matrix Chart ..........................................448

Engine Control Component Parts Location ..........452

Circuit Diagram .....................................................456

ECM Harness Connector Terminal Layout ...........458

ECM Terminals and Reference Value ...................458

CONSULT-II Function ...........................................465

CONSULT-II Reference Value in Data Monitor Mode

.475

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................479

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .481

Description ............................................................481

Testing Condition ..................................................481

Inspection Procedure ............................................481

Diagnostic Procedure ...........................................482

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................485

Description ............................................................485

Diagnostic Procedure ...........................................485

POWER SUPPLY CIRCUIT FOR ECM ...................486

Wiring Diagram .....................................................486

Diagnostic Procedure ...........................................487

Component Inspection ..........................................491

DTC U1000, U1001 CAN COMMUNICATION LINE .492

Description ............................................................492

On Board Diagnosis Logic ....................................492

DTC Confirmation Procedure ...............................492

Wiring Diagram .....................................................493

Diagnostic Procedure ...........................................494

DTC P0102, P0103 MAF SENSOR .........................495

Component Description ........................................495

CONSULT-II Reference Value in Data Monitor Mode

.495

On Board Diagnosis Logic ....................................495

DTC Confirmation Procedure ...............................496

Wiring Diagram .....................................................497

Diagnostic Procedure ...........................................498

Component Inspection ..........................................500

Removal and Installation ......................................500

DTC P0117, P0118 ECT SENSOR ..........................501

Component Description ........................................501

On Board Diagnosis Logic ....................................501

DTC Confirmation Procedure ...............................502

Wiring Diagram .....................................................503

Diagnostic Procedure ...........................................504

Component Inspection ..........................................505

Removal and Installation ......................................505

DTC P0132 HO2S1 .................................................506

Component Description ........................................506

CONSULT-II Reference Value in Data Monitor Mode

.506

On Board Diagnosis Logic ....................................506

DTC Confirmation Procedure ...............................507

Wiring Diagram .....................................................508

Diagnostic Procedure ...........................................509

Component Inspection ..........................................510

Removal and Installation ......................................511DTC P0134 HO2S1 ................................................ .512

Component Description ........................................512

CONSULT-II Reference Value in Data Monitor Mode

.512

On Board Diagnosis Logic ....................................512

Overall Function Check .........................................513

Wiring Diagram .....................................................514

Diagnostic Procedure ............................................515

Component Inspection ..........................................516

Removal and Installation .......................................517

DTC P0138 HO2S2 ................................................ .518

Component Description ........................................518

CONSULT-II Reference Value in Data Monitor Mode

.518

On Board Diagnosis Logic ....................................518

DTC Confirmation Procedure ................................518

Wiring Diagram .....................................................520

Diagnostic Procedure ............................................521

Component Inspection ..........................................522

Removal and Installation .......................................523

DTC P0221 TP SENSOR ........................................524

Component Description ........................................524

CONSULT-II Reference Value in Data Monitor Mode

.524

On Board Diagnosis Logic ....................................524

DTC Confirmation Procedure ................................524

Wiring Diagram .....................................................526

Diagnostic Procedure ............................................527

Component Inspection ..........................................529

Removal and Installation .......................................529

DTC P0222, P0223 TP SENSOR ............................530

Component Description ........................................530

CONSULT-II Reference Value in Data Monitor Mode

.530

On Board Diagnosis Logic ....................................530

DTC Confirmation Procedure ................................530

Wiring Diagram .....................................................532

Diagnostic Procedure ............................................533

Component Inspection ..........................................535

Removal and Installation ......................................

.535

DTC P0226 APP SENSOR ......................................536

Component Description ........................................536

CONSULT-II Reference Value in Data Monitor Mode

.536

On Board Diagnosis Logic ....................................536

DTC Confirmation Procedure ................................536

Wiring Diagram .....................................................538

Diagnostic Procedure ............................................539

Component Inspection ..........................................541

Removal and Installation .......................................542

DTC P0227, P0228 APP SENSOR .........................543

Component Description ........................................543

CONSULT-II Reference Value in Data Monitor Mode

.543

On Board Diagnosis Logic ....................................543

DTC Confirmation Procedure ................................543

Wiring Diagram .....................................................545

Diagnostic Procedure ............................................546