POS NISSAN ALMERA N16 2003 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 50 of 3189

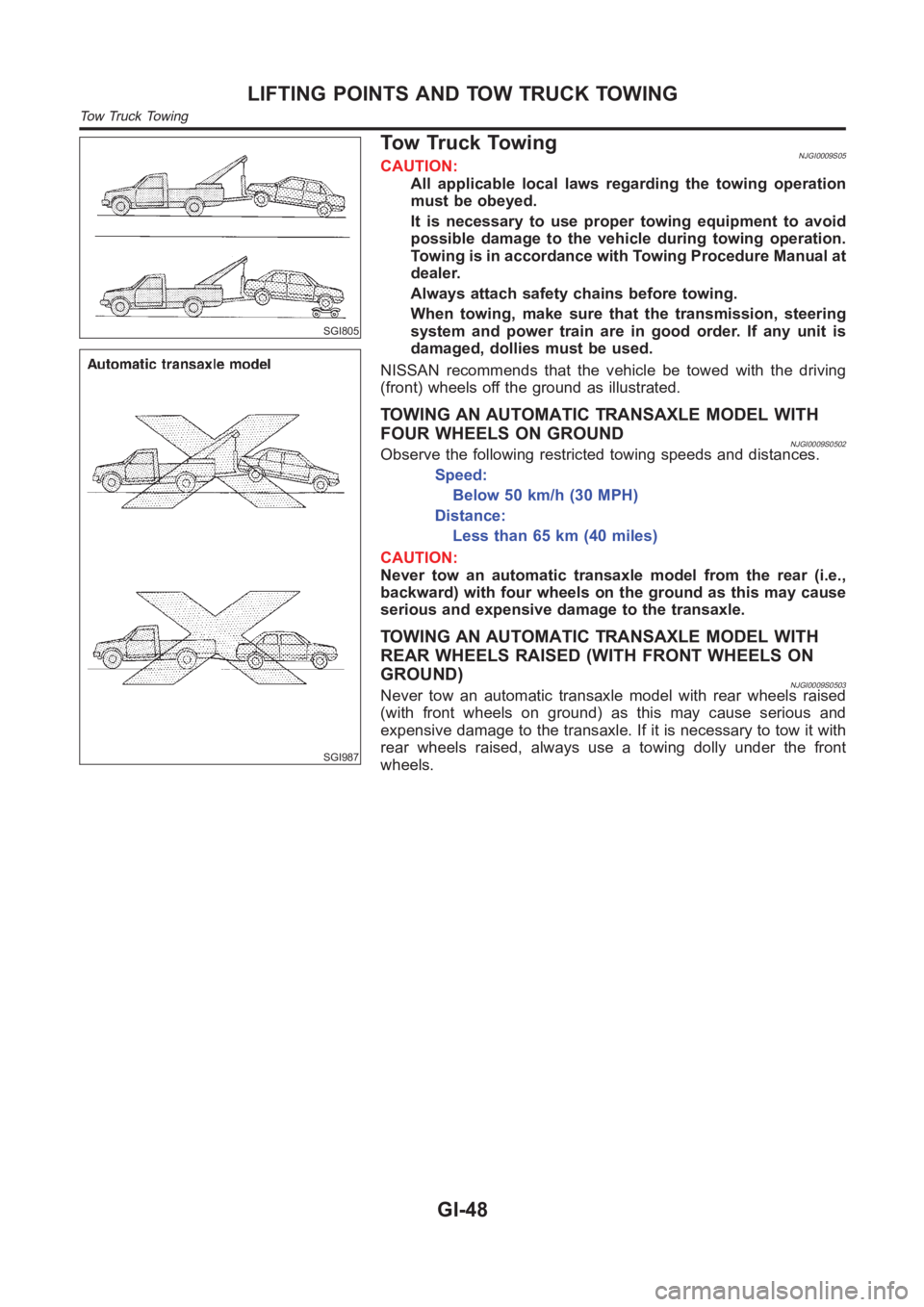

SGI805

SGI987

Tow Truck TowingNJGI0009S05CAUTION:

All applicable local laws regarding the towing operation

must be obeyed.

It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during towing operation.

Towing is in accordance with Towing Procedure Manual at

dealer.

Always attach safety chains before towing.

When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, dollies must be used.

NISSAN recommends that the vehicle be towed with the driving

(front) wheels off the ground as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

FOUR WHEELS ON GROUND

NJGI0009S0502Observe the following restricted towing speeds and distances.

Speed:

Below 50 km/h (30 MPH)

Distance:

Less than 65 km (40 miles)

CAUTION:

Never tow an automatic transaxle model from the rear (i.e.,

backward) with four wheels on the ground as this may cause

serious and expensive damage to the transaxle.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

REAR WHEELS RAISED (WITH FRONT WHEELS ON

GROUND)

NJGI0009S0503Never tow an automatic transaxle model with rear wheels raised

(with front wheels on ground) as this may cause serious and

expensive damage to the transaxle. If it is necessary to tow it with

rear wheels raised, always use a towing dolly under the front

wheels.

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing

GI-48

Page 53 of 3189

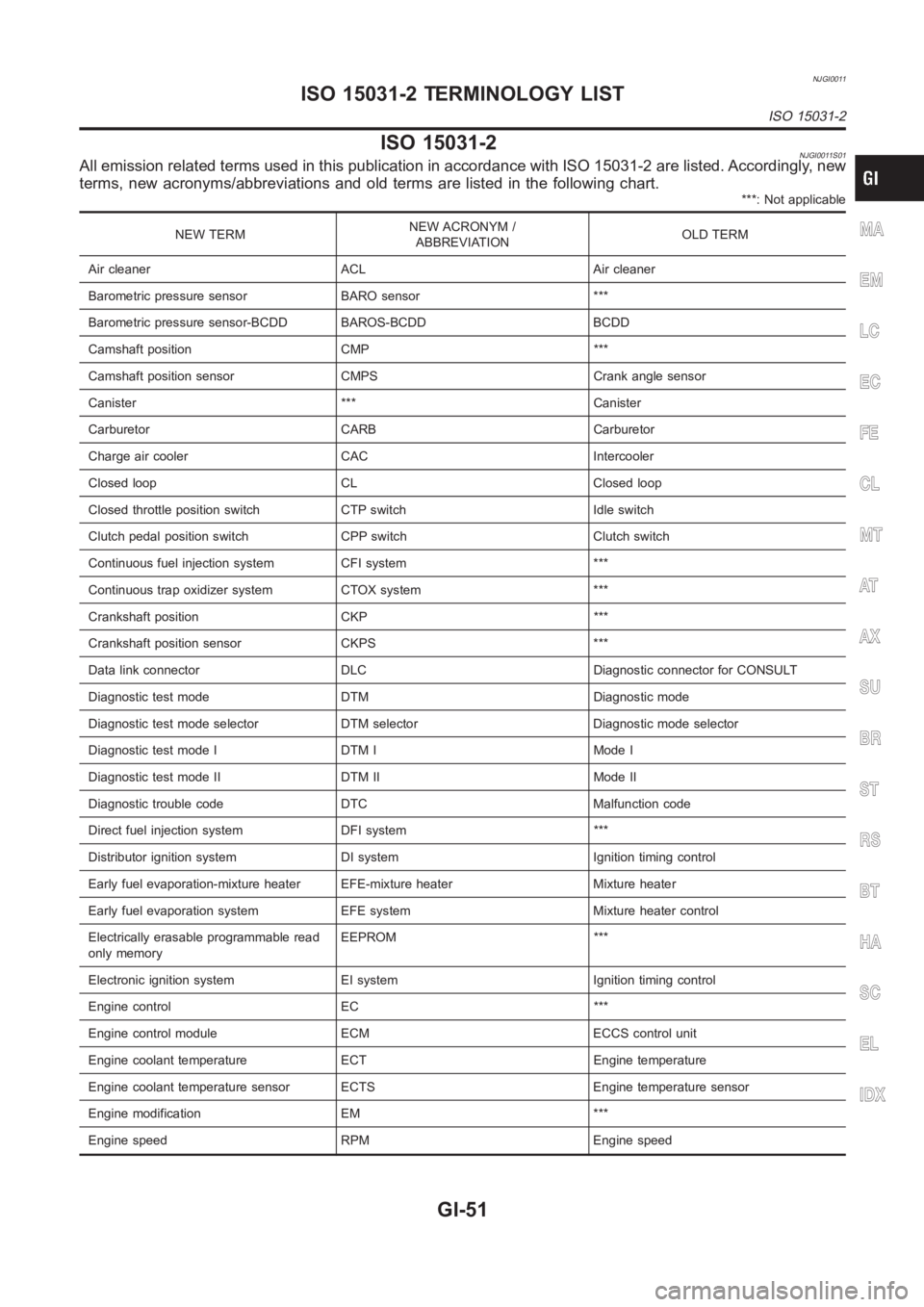

NJGI0011

ISO 15031-2NJGI0011S01All emission related terms used in this publication in accordance with ISO15031-2 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure sensor BARO sensor ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speedMA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2

GI-51

Page 55 of 3189

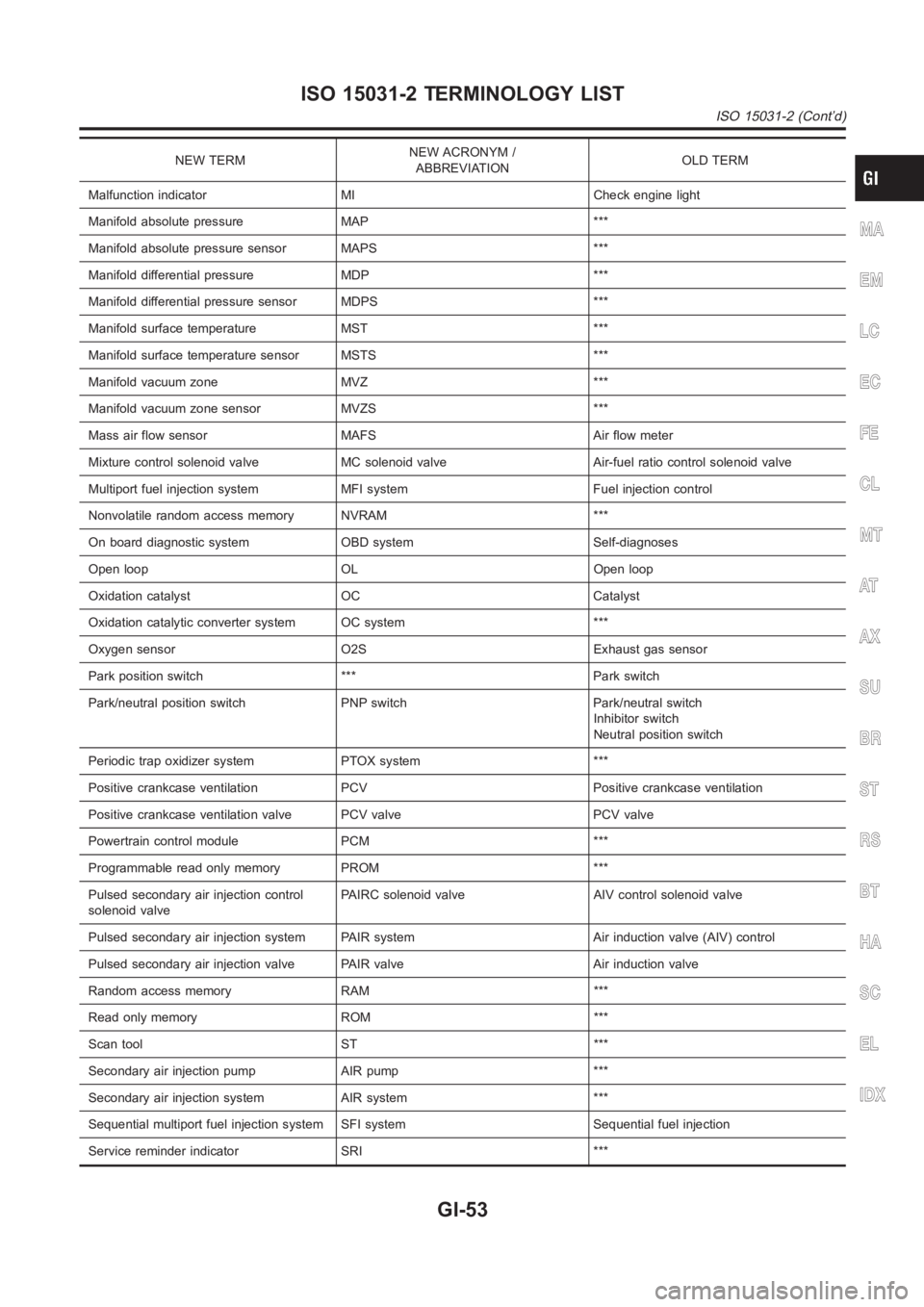

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnoses

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control

solenoid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-53

Page 56 of 3189

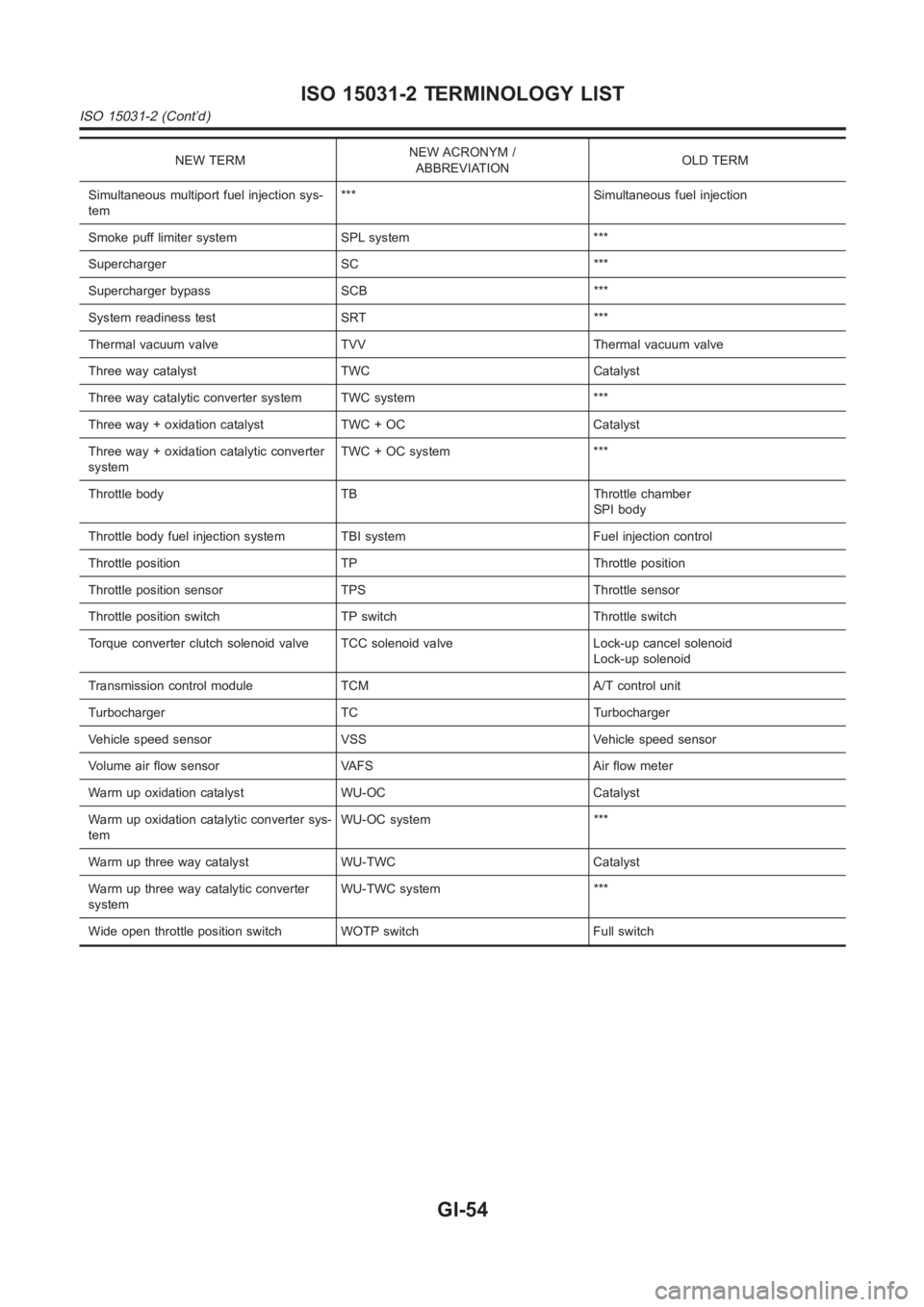

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancelsolenoid

Lock-up solenoid

Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

temWU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter

systemWU-TWC system ***

Wide open throttle position switch WOTP switch Full switch

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-54

Page 60 of 3189

NJMA0005

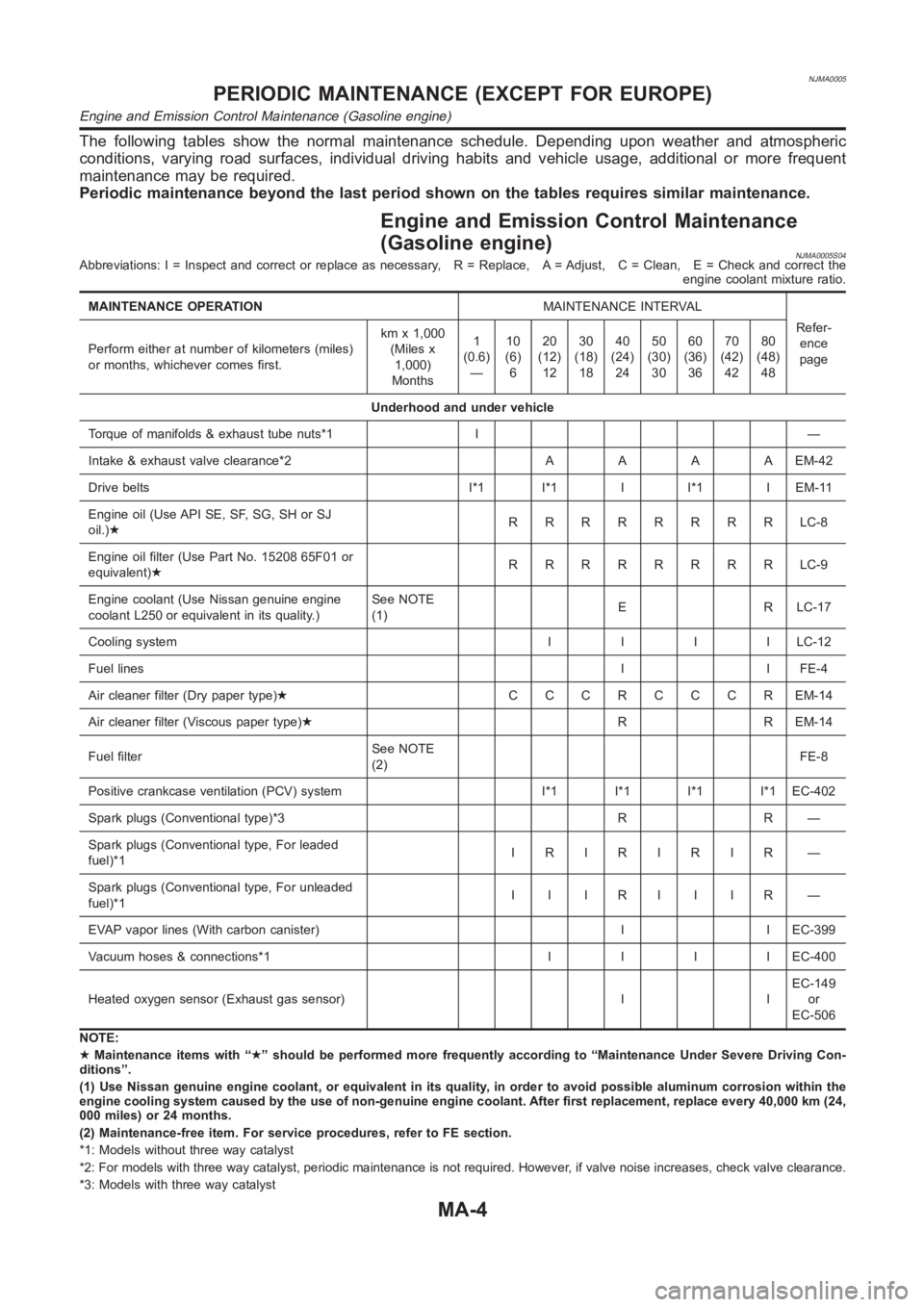

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric

conditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent

maintenance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

Engine and Emission Control Maintenance

(Gasoline engine)

NJMA0005S04Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, A = Adjust, C = Clean, E = Check and correct the

engine coolant mixture ratio.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform either at number of kilometers (miles)

or months, whichever comes first.kmx1,000

(Miles x

1,000)

Months1

(0.6)

—10

(6)

620

(12)

1230

(18)

1840

(24)

2450

(30)

3060

(36)

3670

(42)

4280

(48)

48

Underhood and under vehicle

Torque of manifolds & exhaust tube nuts*1 I —

Intake & exhaust valve clearance*2AAAAEM-42

Drive belts I*1 I*1 I I*1 I EM-11

Engine oil (Use API SE, SF, SG, SH or SJ

oil.)★RRRRRRRRLC-8

Engine oil filter (Use Part No. 15208 65F01 or

equivalent)★RRRRRRRRLC-9

Engine coolant (Use Nissan genuine engine

coolant L250 or equivalent in its quality.)See NOTE

(1)E R LC-17

Cooling systemIIIILC-12

Fuel linesI I FE-4

Air cleaner filter (Dry paper type)★CCCRCCCREM-14

Air cleaner filter (Viscous paper type)★R R EM-14

Fuel filterSee NOTE

(2)FE-8

Positive crankcase ventilation (PCV) system I*1 I*1 I*1 I*1 EC-402

Spark plugs (Conventional type)*3 R R —

Spark plugs (Conventional type, For leaded

fuel)*1IRIRIRIR —

Spark plugs (Conventional type, For unleaded

fuel)*1IIIRIIIR —

EVAP vapor lines (With carbon canister) I I EC-399

Vacuum hoses & connections*1IIIIEC-400

Heated oxygen sensor (Exhaust gas sensor) I IEC-149

or

EC-506

NOTE:

★Maintenance items with “★” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) Use Nissan genuine engine coolant, or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant. After first replacement, replace every 40,000 km (24,

000 miles) or 24 months.

(2) Maintenance-free item. For service procedures, refer to FE section.

*1: Models without three way catalyst

*2: For models with three way catalyst, periodic maintenance is not requir

ed. However, if valve noise increases, check valve clearance.

*3: Models with three way catalyst

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Engine and Emission Control Maintenance (Gasoline engine)

MA-4

Page 75 of 3189

NJMA0006

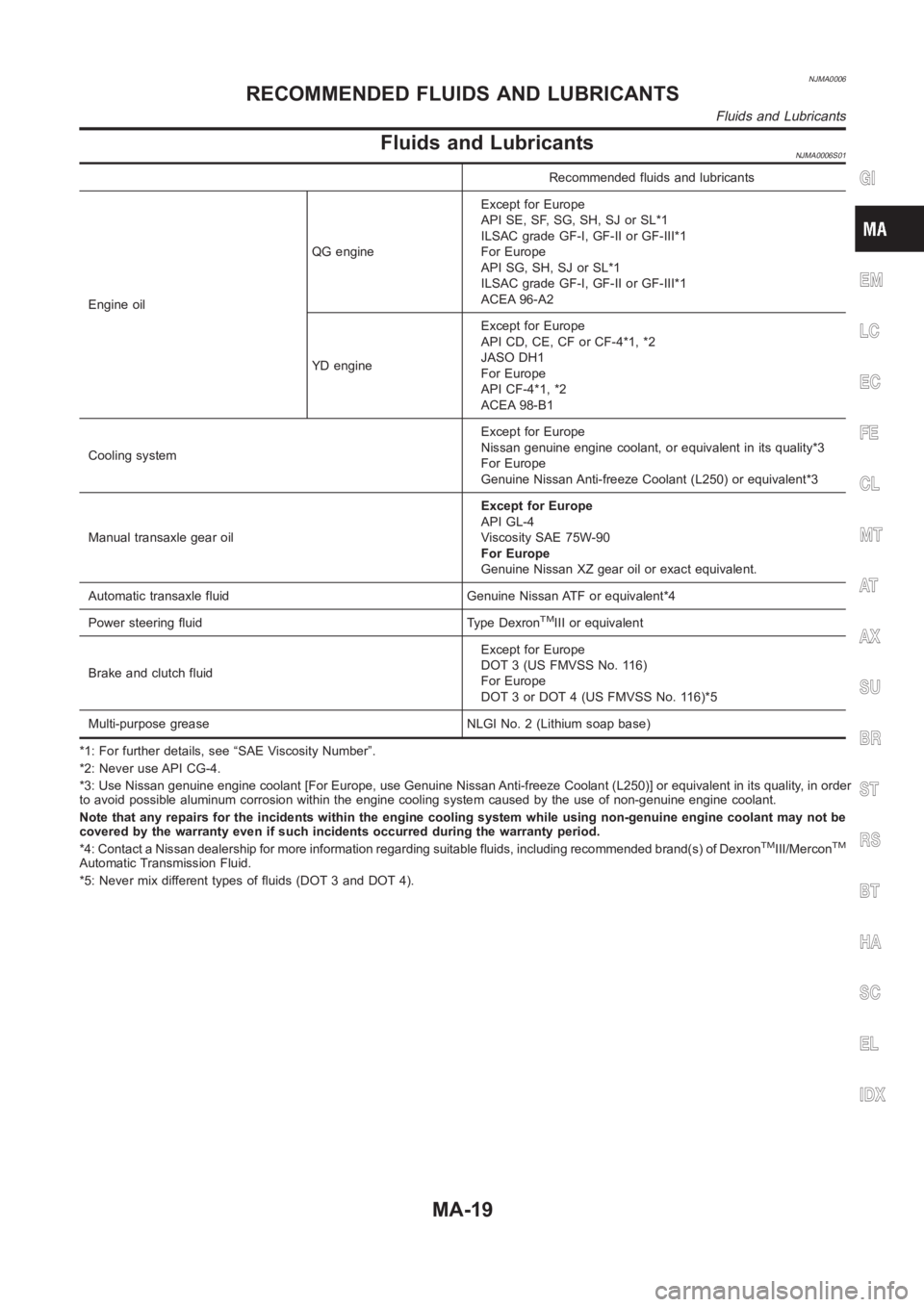

Fluids and LubricantsNJMA0006S01

Recommended fluids and lubricants

Engine oilQG engineExcept for Europe

API SE, SF, SG, SH, SJ or SL*1

ILSAC grade GF-I, GF-II or GF-III*1

For Europe

API SG, SH, SJ or SL*1

ILSAC grade GF-I, GF-II or GF-III*1

ACEA 96-A2

YD engineExcept for Europe

API CD, CE, CF or CF-4*1, *2

JASO DH1

For Europe

API CF-4*1, *2

ACEA 98-B1

Cooling systemExcept for Europe

Nissan genuine engine coolant, or equivalent in its quality*3

For Europe

Genuine Nissan Anti-freeze Coolant (L250) or equivalent*3

Manual transaxle gear oilExcept for Europe

API GL-4

Viscosity SAE 75W-90

For Europe

Genuine Nissan XZ gear oil or exact equivalent.

Automatic transaxle fluid Genuine Nissan ATF or equivalent*4

Power steering fluid Type Dexron

TMIII or equivalent

Brake and clutch fluidExcept for Europe

DOT 3 (US FMVSS No. 116)

For Europe

DOT 3 or DOT 4 (US FMVSS No. 116)*5

Multi-purpose grease NLGI No. 2 (Lithium soap base)

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Nissan genuine engine coolant [For Europe, use Genuine Nissan Anti-freeze Coolant (L250)] or equivalent in its quality, in order

to avoid possible aluminum corrosion within the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of Dexron

TMIII/MerconTM

Automatic Transmission Fluid.

*5: Never mix different types of fluids (DOT 3 and DOT 4).

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-19

Page 76 of 3189

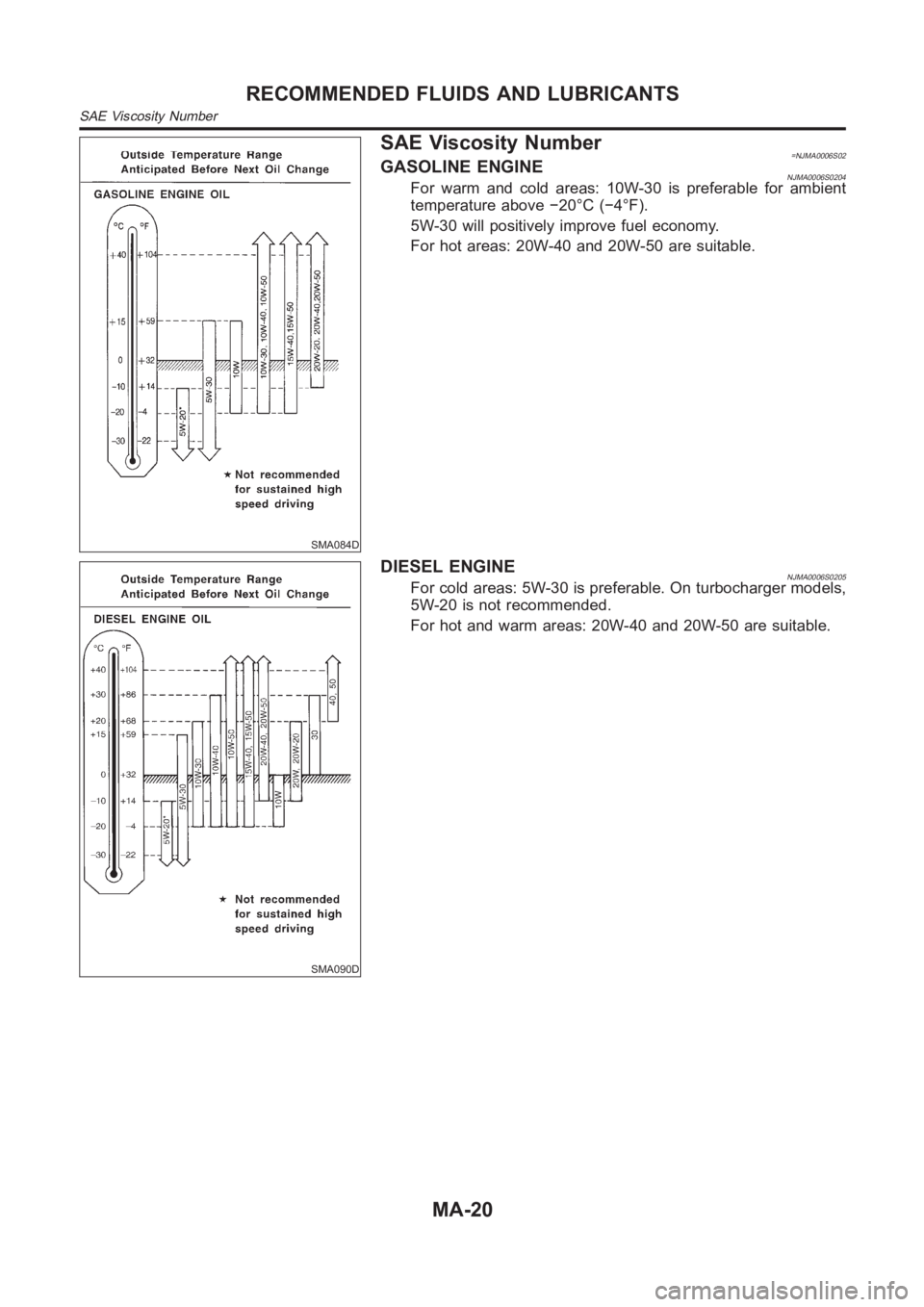

SMA084D

SAE Viscosity Number=NJMA0006S02GASOLINE ENGINENJMA0006S0204For warm and cold areas: 10W-30 is preferable for ambient

temperature above −20°C (−4°F).

5W-30 will positively improve fuel economy.

For hot areas: 20W-40 and 20W-50 are suitable.

SMA090D

DIESEL ENGINENJMA0006S0205For cold areas: 5W-30 is preferable. On turbocharger models,

5W-20 is not recommended.

For hot and warm areas: 20W-40 and 20W-50 are suitable.

RECOMMENDED FLUIDS AND LUBRICANTS

SAE Viscosity Number

MA-20

Page 101 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.

NISSAN ALMERA N16 2003 Electronic Owners Manual OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.](/img/5/57350/w960_57350-100.png)

OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.

Remove oil pan.

8. Remove oil strainer.

INSTALLATION

1. Install oil strainer.

NOTE:

Gasket and O-ring are not used for sealed area with oil pump.

2. Install oil pan drain plug.

●Referring to “Components”, install drain plug washer.

3. Apply a continuous bead of liquid gasket to position shown in figure.

Use Genuine Liquid Gasket or equivalent.

4. Tighten mounting nuts and bolts in order shown in figure.

●Install mounting nuts and bolts as follows.

5. Install center member.

Refer to ENGINE ASSEMBLY, EM-67, "

Removal and Installa-

tion" .

6. Install remaining parts in the reverse order of removal.

INSPECTION AFTER INSTALLATION

●Check for leakage of engine oil when engine is warmed.

●Pour engine oil or start engine at least 30 minutes after oil pan is installed.

SEM365EA

PBIC0549E

Mounting bolt:

[Shank length under

head 10 mm (0.39 in)]: Nos. 1 - 10, 13, 14

[Shank length under

head 12 mm (0.47 in)]: Nos. 11, 12

SEM072F

Page 107 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual ROCKER COVER

EM-29

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

ROCKER COVERPFP:13264

Removal and InstallationEBS00LQA

CAUTION:

Apply new engine oil when installing the parts that specified to do so in the figure.

NISSAN ALMERA N16 2003 Electronic Owners Manual ROCKER COVER

EM-29

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

ROCKER COVERPFP:13264

Removal and InstallationEBS00LQA

CAUTION:

Apply new engine oil when installing the parts that specified to do so in the figure.](/img/5/57350/w960_57350-106.png)

ROCKER COVER

EM-29

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

ROCKER COVERPFP:13264

Removal and InstallationEBS00LQA

CAUTION:

Apply new engine oil when installing the parts that specified to do so in the figure.

REMOVAL

1. Move harnesses on top surface and right side of rocker cover, and move them aside.

2. Remove ignition coil. Refer to EM-24, "

Removal and Installation" .

3. Disconnect PCV hoses on rocker cover side.

4. If necessary, remove PCV control valve.

5. If necessary, remove intake valve timing control solenoid valve and camshaft position sensor (PHASE).

CAUTION:

●Do not shock it.

●Do not disassemble it.

●Tip of camshaft position sensor (PHASE) generates strong magnetic fields. Keep it away from

metal particles or objects affected by magnetic fields.

KBIA1375E

1. PCV hose 2. Rocker cover 3. Grommet

4. PCV control valve 5. PCV hose 6.Intake valve timing control solenoid

valve

7. O-ring 8. Oil filter cap 9. Gasket

10. Gasket 11. Rocker cover oil seal 12. Gasket

13. O-ring 14. Camshaft position sensor (PHASE)

Page 108 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual EM-30

[QG]

ROCKER COVER

6. Loosen bolts in reverse order shown in the figure.

7. If replacement is necessary, remove rocker cover oil seal using flat-head screwdriver.

CAUTION:

Be careful not to damag NISSAN ALMERA N16 2003 Electronic Owners Manual EM-30

[QG]

ROCKER COVER

6. Loosen bolts in reverse order shown in the figure.

7. If replacement is necessary, remove rocker cover oil seal using flat-head screwdriver.

CAUTION:

Be careful not to damag](/img/5/57350/w960_57350-107.png)

EM-30

[QG]

ROCKER COVER

6. Loosen bolts in reverse order shown in the figure.

7. If replacement is necessary, remove rocker cover oil seal using flat-head screwdriver.

CAUTION:

Be careful not to damage rocker cover.

INSTALLATION

1. Install rocker cover oil seal.

●Using drift with outer diameter 97 mm (3.82 in) and inner

diameter 83 mm (3.27 in) to 88 mm (3.46 in) (commercial ser-

vice tool), press oil seal in.

NOTE:

There are 2 types of oil seal. If oil seal with flat bottom surface is

pressed in, drift with any inner diameter can be used.

●Press oil seal in until it is flush with installation surface.

2. Install rocker cover in following steps.

a. Install gasket on top of No. 1 camshaft bracket.

●Position gasket aligning its shape with camshaft bracket side.

Align positioning stopper pin with hole on gasket, and install.

b. Install gasket (for circumference, square type) to installation

groove of rocker cover.

c. Apply liquid gasket to positions shown in figure, then install

rocker cover.

KBIA1376E

KBIA1377E

KBIA1379E

PBIC0555E