fuel cap release NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 349 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual PREPARATION

EC-19

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PREPARATIONPFP:00002

Special Service ToolsEBS00K2Z

Commercial Service ToolsEBS00K30

Tool number

Tool nameDescription

KV10117100

Heated NISSAN ALMERA N16 2003 Electronic Repair Manual PREPARATION

EC-19

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PREPARATIONPFP:00002

Special Service ToolsEBS00K2Z

Commercial Service ToolsEBS00K30

Tool number

Tool nameDescription

KV10117100

Heated](/img/5/57350/w960_57350-348.png)

PREPARATION

EC-19

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PREPARATIONPFP:00002

Special Service ToolsEBS00K2Z

Commercial Service ToolsEBS00K30

Tool number

Tool nameDescription

KV10117100

Heated oxygen

sensor wrenchLoosening or tightening heated oxygen sensors

with 22 mm (0.87 in) hexagon nut

KV10114400

Heated oxygen

sensor wrenchLoosening or tightening heated oxygen sensors

a: 22 mm (0.87 in)

KV109E0010

Break-out boxMeasuring the ECM signals with a circuit tester

KV109E0080

Y-cable adapterMeasuring the ECM signals with a circuit tester

S-NT379

S-NT636

S-NT825

S-NT826

Tool name Description

Quick connector

releaseRemoving fuel tube quick connectors in engine

room

(Available in SEC. 164 of PARTS CATALOG: Part

No. 16441 6N210)

Fuel filler cap adapter Checking fuel tank vacuum relief valve opening

pressure

PBIC0198E

S-NT653

Page 576 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-246

[QG (WITH EURO-OBD)]

DTC P0420 THREE WAY CATALYST FUNCTION

DTC P0420 THREE WAY CATALYST FUNCTION

PFP:20905

On Board Diagnosis LogicEBS00K8J

The ECM monitors the switching frequency ratio of hea NISSAN ALMERA N16 2003 Electronic Repair Manual EC-246

[QG (WITH EURO-OBD)]

DTC P0420 THREE WAY CATALYST FUNCTION

DTC P0420 THREE WAY CATALYST FUNCTION

PFP:20905

On Board Diagnosis LogicEBS00K8J

The ECM monitors the switching frequency ratio of hea](/img/5/57350/w960_57350-575.png)

EC-246

[QG (WITH EURO-OBD)]

DTC P0420 THREE WAY CATALYST FUNCTION

DTC P0420 THREE WAY CATALYST FUNCTION

PFP:20905

On Board Diagnosis LogicEBS00K8J

The ECM monitors the switching frequency ratio of heated oxygen

sensors 1 and 2.

A three way catalyst (Manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of heated oxygen sensors 1 and 2

approaches a specified limit value, the three way catalyst (Manifold)

malfunction is diagnosed.

DTC Confirmation ProcedureEBS00K8K

NOTE:

If “DTC Confirmation Procedure” has been previously conducted, always turn ignition switch “OFF” and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

TESTING CONDITION:

●Open engine hood before conducting the following procedure.

●Do not hold engine speed for more than the specified minutes below.

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch ″OFF″ and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least one minute under no

load.

4. Let engine idle for one minute.

5. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUP-

PORT” mode with CONSULT-II.

6. Rev engine up to 2,500 to 3,500 rpm and hold it for 3 consecu-

tive minutes then release the accelerator pedal completely.

If “INCMP” of “CATALYST” changed to “COMPLT”, go to step 9

7. Wait 5 seconds at idle.

SEF484YF

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420

0420Catalyst system efficiency

below threshold

●Three way catalyst (Manifold) does not operate

properly.

●Three way catalyst (Manifold) does not have

enough oxygen storage capacity.

●Three way catalyst (Manifold)

●Exhaust tube

●Intake air leaks

●Fuel injectors

●Fuel injector leaks

●Spark plug

●Improper ignition timing

PBIB0566E

Page 743 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual PREPARATION

EC-413

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PREPARATIONPFP:00002

Special Service ToolsEBS00KE6

Commercial Service ToolsEBS00KE7

Tool number

Tool nameDescription

KV10117100

Hea NISSAN ALMERA N16 2003 Electronic Repair Manual PREPARATION

EC-413

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PREPARATIONPFP:00002

Special Service ToolsEBS00KE6

Commercial Service ToolsEBS00KE7

Tool number

Tool nameDescription

KV10117100

Hea](/img/5/57350/w960_57350-742.png)

PREPARATION

EC-413

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PREPARATIONPFP:00002

Special Service ToolsEBS00KE6

Commercial Service ToolsEBS00KE7

Tool number

Tool nameDescription

KV10117100

Heated oxygen

sensor wrenchLoosening or tightening heated oxygen sensors

with 22 mm (0.87 in) hexagon nut

KV10114400

Heated oxygen

sensor wrenchLoosening or tightening heated oxygen sensors

a: 22 mm (0.87 in)

KV109E0010

Break-out boxMeasuring ECM signals with a circuit tester

KV109E0080

Y-cable adapterMeasuring ECM signals with a circuit tester

S-NT379

S-NT636

S-NT825

S-NT826

Tool name Description

Quick connector

releaseRemoving fuel tube quick connectors in engine

room

(Available in SEC. 164 of PARTS CATALOG: Part

No. 16441 6N210)

Fuel filler cap adapter Checking fuel tank vacuum relief valve opening

pressure

PBIC0198E

S-NT653

Page 1273 of 3189

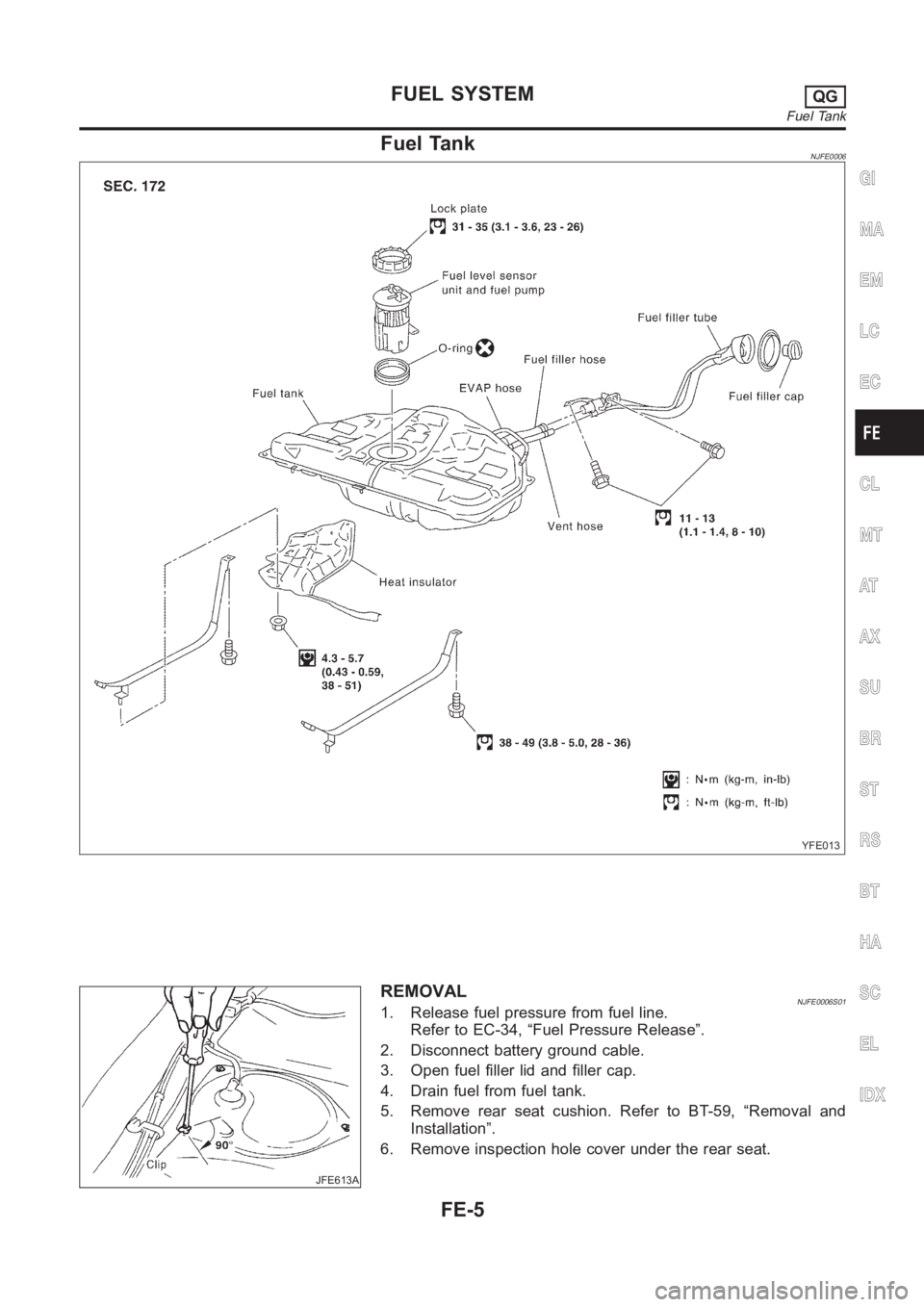

Fuel TankNJFE0006

YFE013

JFE613A

REMOVALNJFE0006S011. Release fuel pressure from fuel line.

Refer to EC-34, “Fuel Pressure Release”.

2. Disconnect battery ground cable.

3. Open fuel filler lid and filler cap.

4. Drain fuel from fuel tank.

5. Remove rear seat cushion. Refer to BT-59, “Removal and

Installation”.

6. Remove inspection hole cover under the rear seat.

GI

MA

EM

LC

EC

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FUEL SYSTEMQG

Fuel Tank

FE-5

Page 1276 of 3189

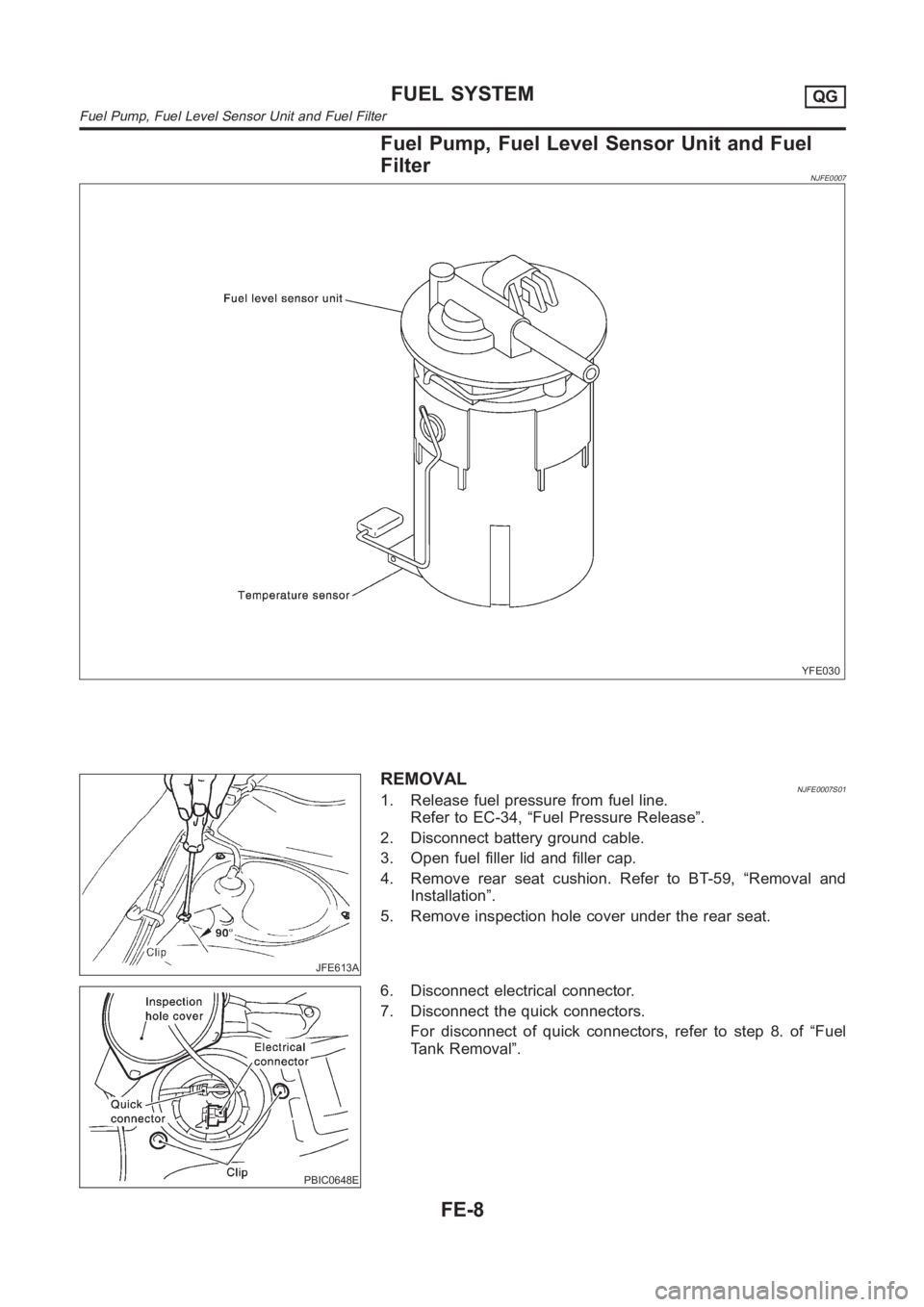

Fuel Pump, Fuel Level Sensor Unit and Fuel

Filter

NJFE0007

YFE030

JFE613A

REMOVALNJFE0007S011. Release fuel pressure from fuel line.

Refer to EC-34, “Fuel Pressure Release”.

2. Disconnect battery ground cable.

3. Open fuel filler lid and filler cap.

4. Remove rear seat cushion. Refer to BT-59, “Removal and

Installation”.

5. Remove inspection hole cover under the rear seat.

PBIC0648E

6. Disconnect electrical connector.

7. Disconnect the quick connectors.

For disconnect of quick connectors, refer to step 8. of “Fuel

Tank Removal”.

FUEL SYSTEMQG

Fuel Pump, Fuel Level Sensor Unit and Fuel Filter

FE-8