Diagnostic NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 8 of 3189

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically. Continued refueling may cause fuel

overflow, resulting in fuel spray and possibly a fire.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do

not carelessly disconnect the harness connectors which are

related to the engine control system and TCM (Transmission

Control Module) system. The connectors should be discon-

nected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

SGI787

PRECAUTIONS FOR MULTIPORT FUEL INJECTION

SYSTEM OR ENGINE CONTROL SYSTEM

NJGI0001S04Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

Be careful not to jar components such as ECM and mass air

flow sensor.

PRECAUTIONS FOR THREE WAY CATALYSTNJGI0001S05If a large amount of unburned fuel flows into the catalyst, the cata-

lyst temperature will be excessively high. To prevent this, follow the

instructions below:

Use unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

When checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

Do not run engine when the fuel tank level is low, otherwise the

engine may misfire, causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

SMA019D

PRECAUTIONS FOR HOSESNJGI0001S06Hose Removal and InstallationNJGI0001S0601To prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

PRECAUTIONS

Precautions (Cont’d)

GI-6

Page 20 of 3189

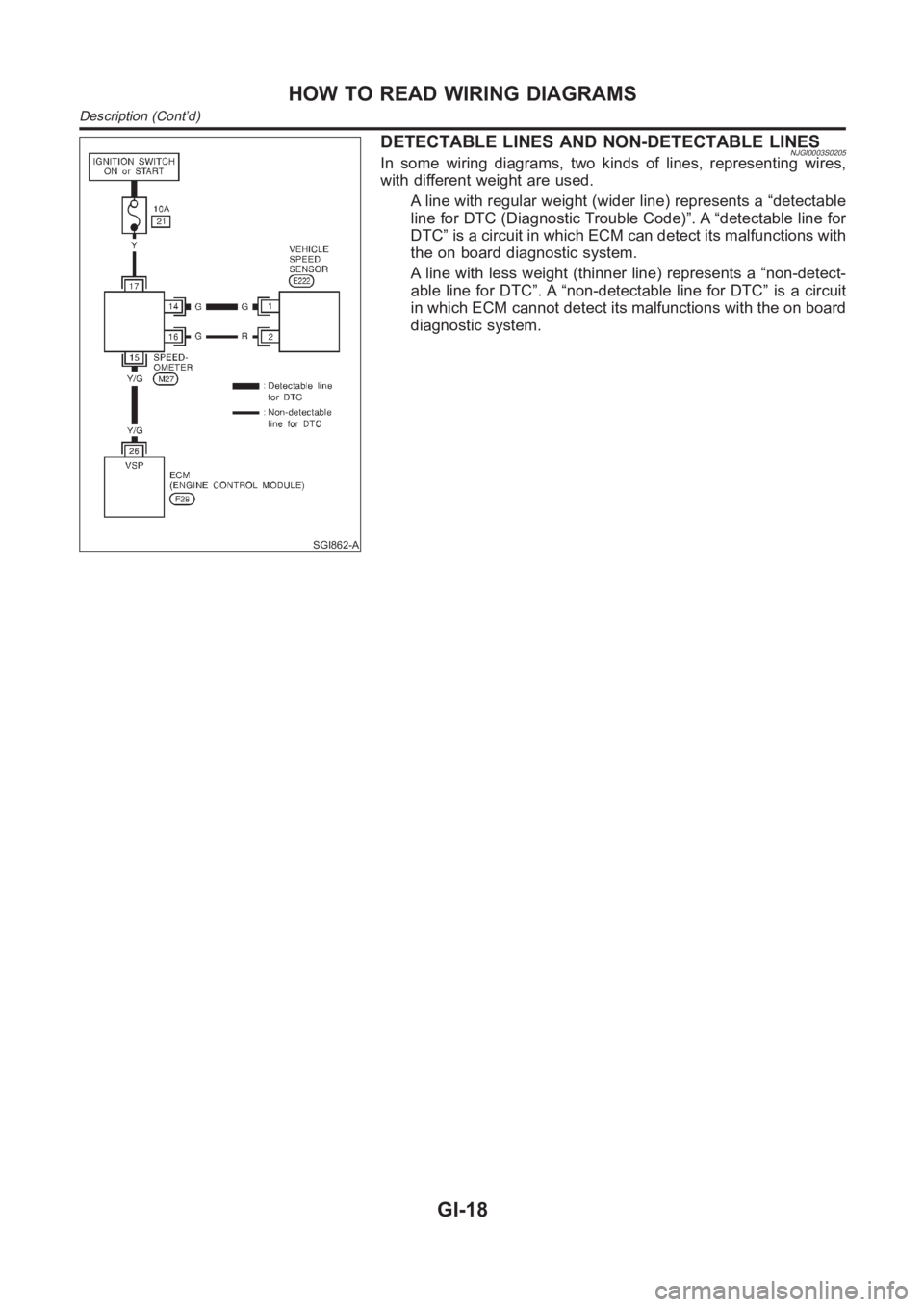

SGI862-A

DETECTABLE LINES AND NON-DETECTABLE LINESNJGI0003S0205In some wiring diagrams, two kinds of lines, representing wires,

with different weight are used.

A line with regular weight (wider line) represents a “detectable

line for DTC (Diagnostic Trouble Code)”. A “detectable line for

DTC” is a circuit in which ECM can detect its malfunctions with

the on board diagnostic system.

A line with less weight (thinner line) represents a “non-detect-

able line for DTC”. A “non-detectable line for DTC” is a circuit

in which ECM cannot detect its malfunctions with the on board

diagnostic system.

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

GI-18

Page 34 of 3189

NJGI0006

NOTICE:

Trouble diagnoses indicate work procedures required to diagnose

problems effectively. Observe the following instructions before

diagnosing.

1)Before performing trouble diagnoses, read the “Prelimi-

nary Check”, the “Symptom Chart” or the “Work Flow”.

2)After repairs, re-check that the problem has been com-

pletely eliminated.

3)Refer to Component Parts and Harness Connector Loca-

tion for the Systems described in each section for

identification/location of components and harness con-

nectors.

4)Refer to the Circuit Diagram for quick pinpoint check.

If you need to check circuit continuity between harness

connectors in more detail, such as when a sub-harness is

used, refer to Wiring Diagram in each individual section

and Harness Layout in EL section for identification of har-

ness connectors.

5)When checking circuit continuity, ignition switch should

be OFF.

6)Before checking voltage at connectors, check battery volt-

age.

7)After accomplishing the Diagnostic Procedures and Elec-

trical Components Inspection, make sure that all harness

connectors are reconnected as they were.

HOW TO FOLLOW TROUBLE DIAGNOSES

GI-32

Page 35 of 3189

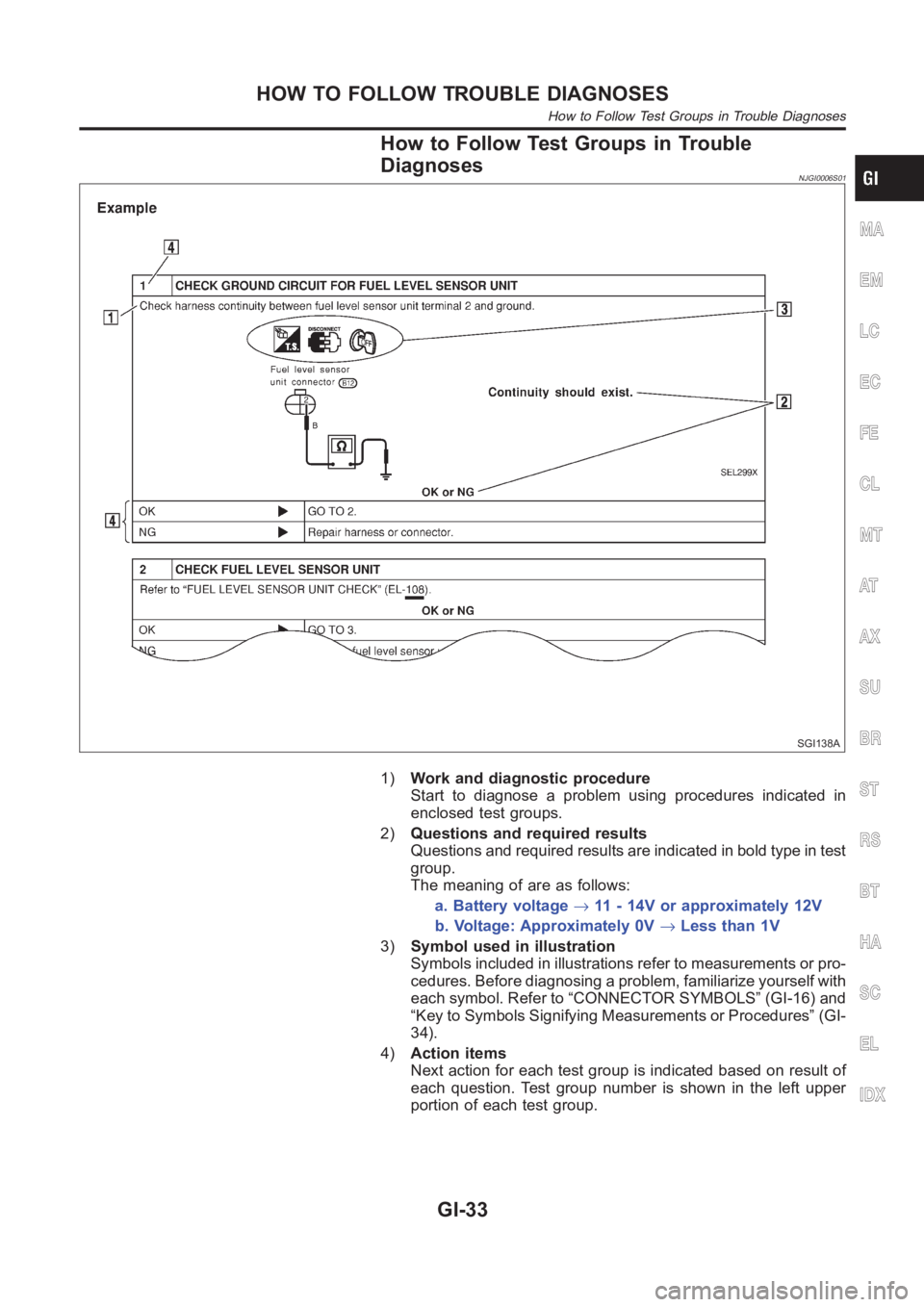

How to Follow Test Groups in Trouble

Diagnoses

NJGI0006S01

SGI138A

1)Work and diagnostic procedure

Start to diagnose a problem using procedures indicated in

enclosed test groups.

2)Questions and required results

Questions and required results are indicated in bold type in test

group.

The meaning of are as follows:

a. Battery voltage→11 - 14V or approximately 12V

b. Voltage: Approximately 0V→Less than 1V

3)Symbol used in illustration

Symbols included in illustrations refer to measurements or pro-

cedures. Before diagnosing a problem, familiarize yourself with

each symbol. Refer to “CONNECTOR SYMBOLS” (GI-16) and

“Key to Symbols Signifying Measurements or Procedures” (GI-

34).

4)Action items

Next action for each test group is indicated based on result of

each question. Test group number is shown in the left upper

portion of each test group.

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO FOLLOW TROUBLE DIAGNOSES

How to Follow Test Groups in Trouble Diagnoses

GI-33

Page 38 of 3189

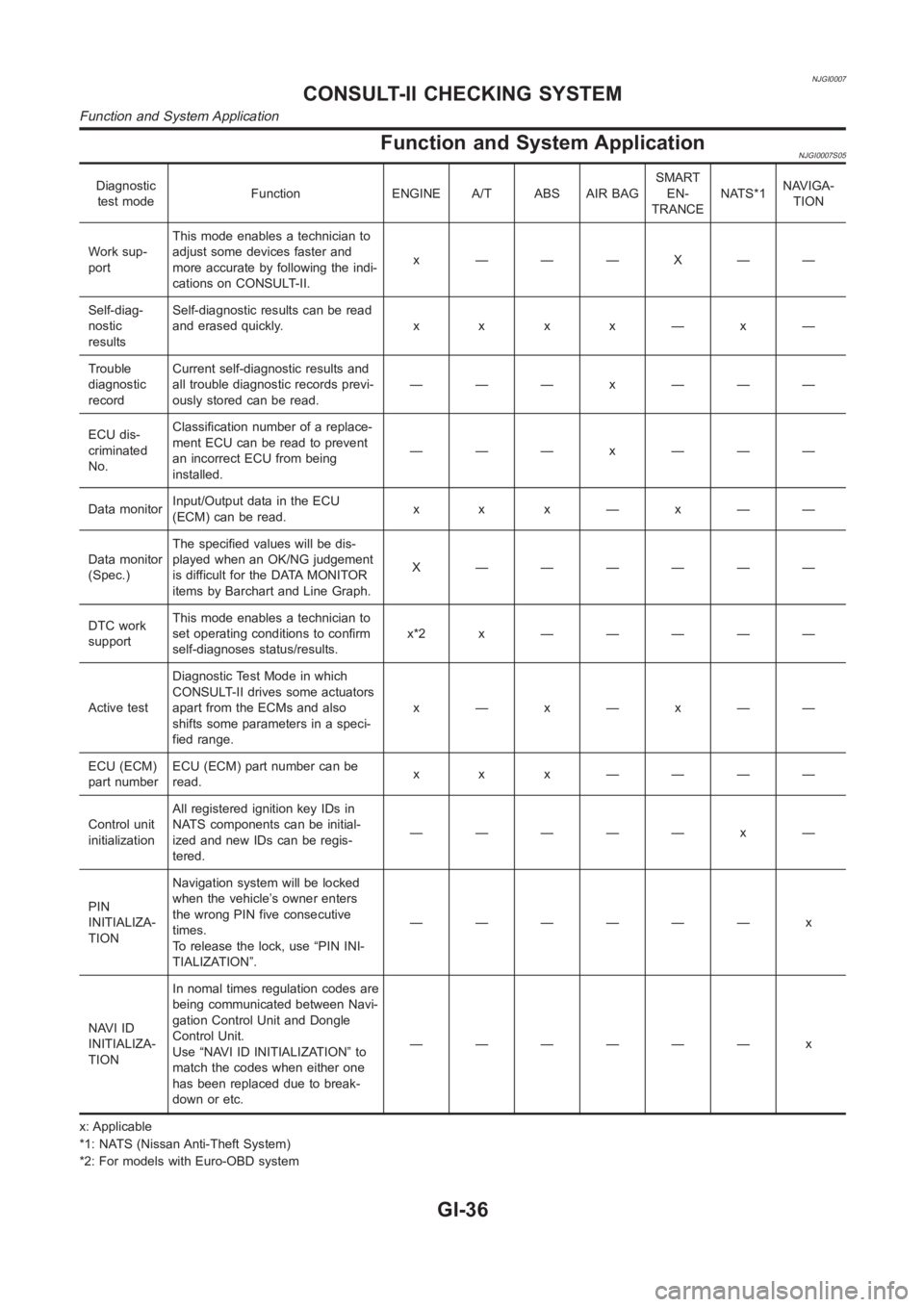

NJGI0007

Function and System ApplicationNJGI0007S05

Diagnostic

test modeFunction ENGINE A/T ABS AIR BAGSMART

EN-

TRANCENATS*1NAVIGA-

TION

Work sup-

portThis mode enables a technician to

adjust some devices faster and

more accurate by following the indi-

cations on CONSULT-II.x ———X——

Self-diag-

nostic

resultsSelf-diagnostic results can be read

anderasedquickly. x x x x—x—

Trouble

diagnostic

recordCurrent self-diagnostic results and

all trouble diagnostic records previ-

ously stored can be read.——— x ———

ECU dis-

criminated

No.Classification number of a replace-

ment ECU can be read to prevent

an incorrect ECU from being

installed.——— x ———

Data monitorInput/Output data in the ECU

(ECM) can be read.x x x—x——

Data monitor

(Spec.)The specified values will be dis-

played when an OK/NG judgement

is difficult for the DATA MONITOR

items by Barchart and Line Graph.X ——————

DTC work

supportThis mode enables a technician to

set operating conditions to confirm

self-diagnoses status/results.x*2x —————

Active testDiagnostic Test Mode in which

CONSULT-II drives some actuators

apart from the ECMs and also

shifts some parameters in a speci-

fied range.x—x—x——

ECU (ECM)

part numberECU (ECM) part number can be

read.x x x ————

Control unit

initializationAll registered ignition key IDs in

NATS components can be initial-

ized and new IDs can be regis-

tered.————— x —

PIN

INITIALIZA-

TIONNavigation system will be locked

when the vehicle’s owner enters

the wrong PIN five consecutive

times.

To release the lock, use “PIN INI-

TIALIZATION”.—————— x

NAVI ID

INITIALIZA-

TIONIn nomal times regulation codes are

being communicated between Navi-

gation Control Unit and Dongle

Control Unit.

Use “NAVI ID INITIALIZATION” to

match the codes when either one

has been replaced due to break-

down or etc.—————— x

x: Applicable

*1: NATS (Nissan Anti-Theft System)

*2: For models with Euro-OBD system

CONSULT-II CHECKING SYSTEM

Function and System Application

GI-36

Page 53 of 3189

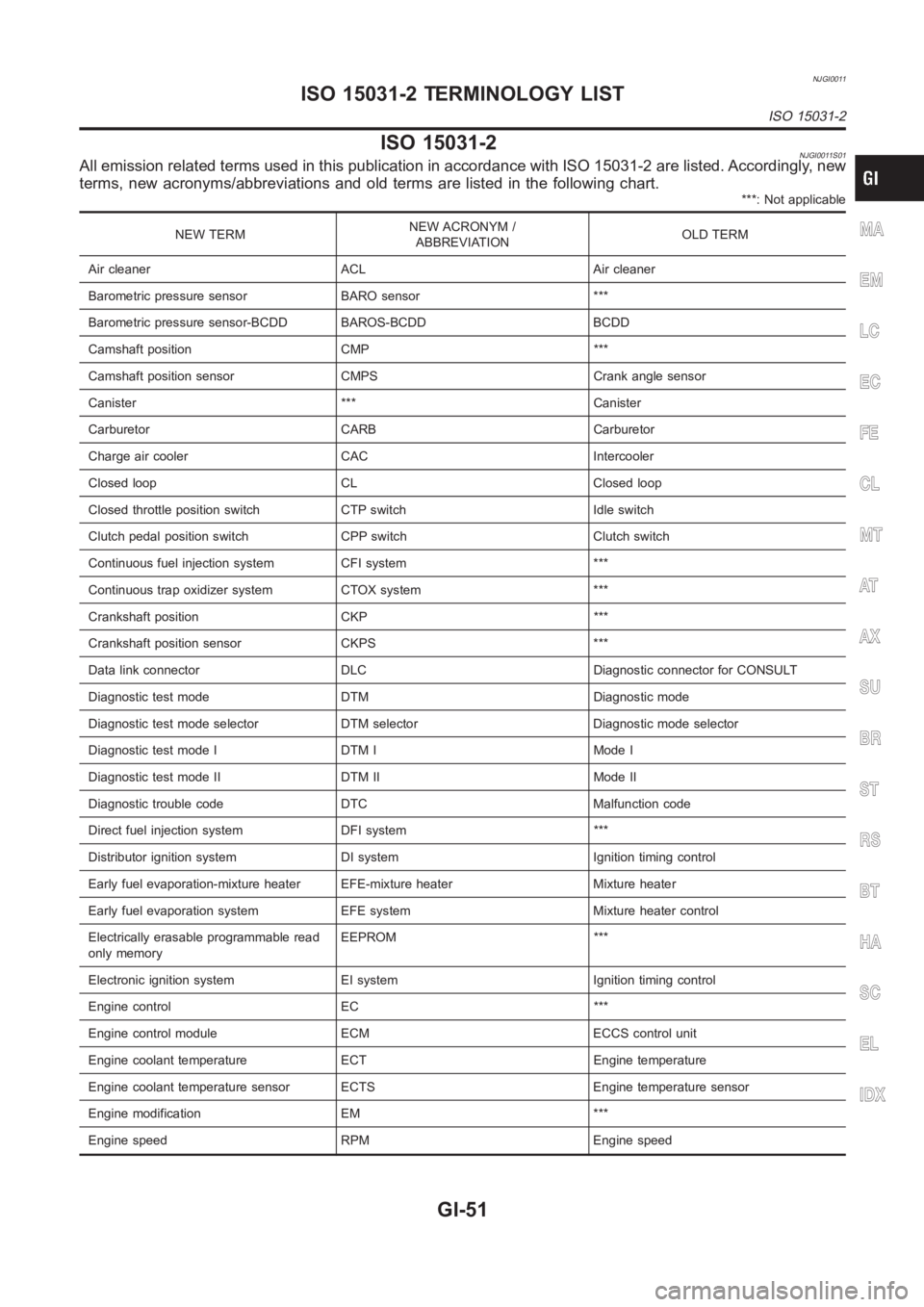

NJGI0011

ISO 15031-2NJGI0011S01All emission related terms used in this publication in accordance with ISO15031-2 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure sensor BARO sensor ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speedMA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2

GI-51

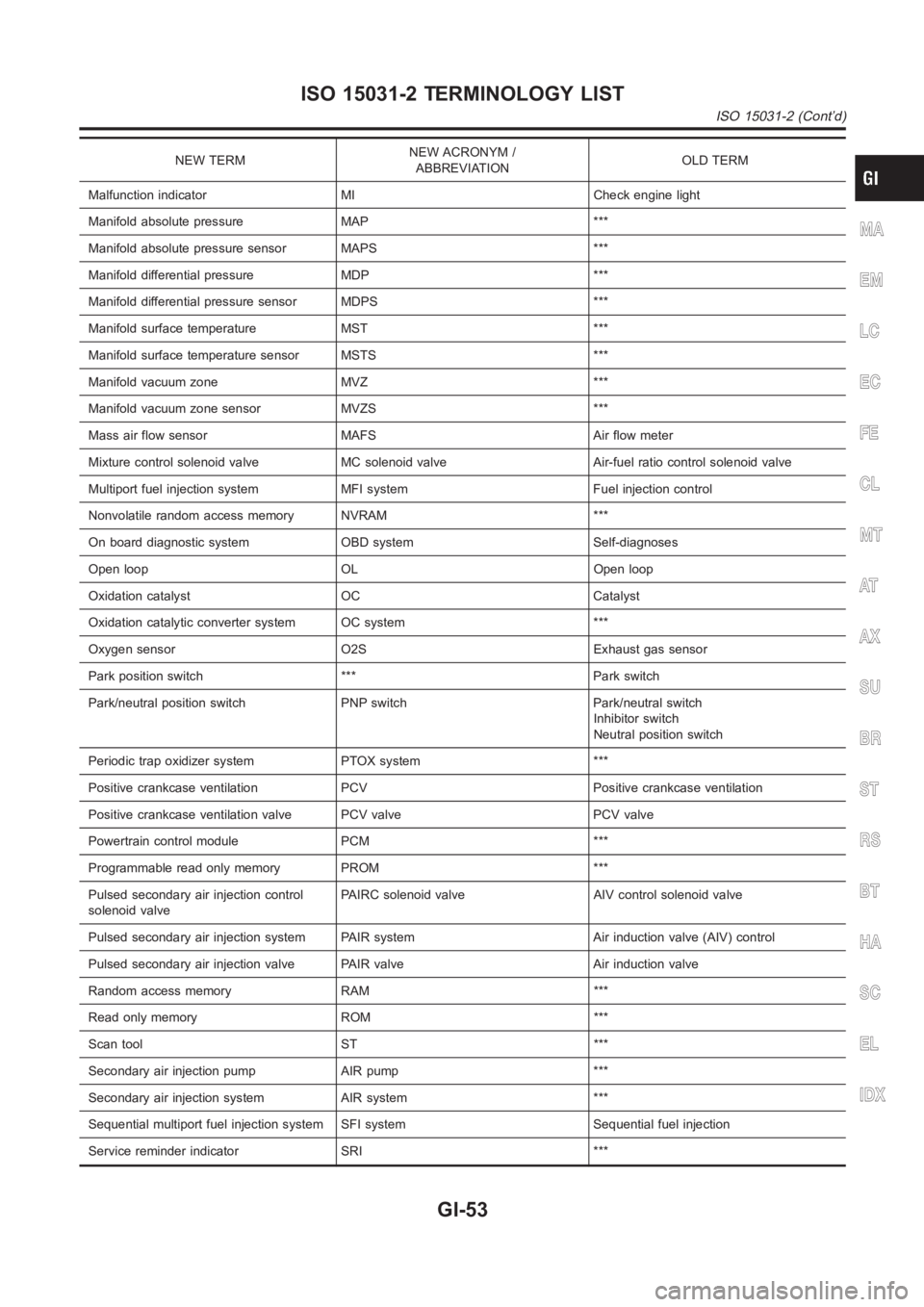

Page 55 of 3189

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnoses

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control

solenoid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-53

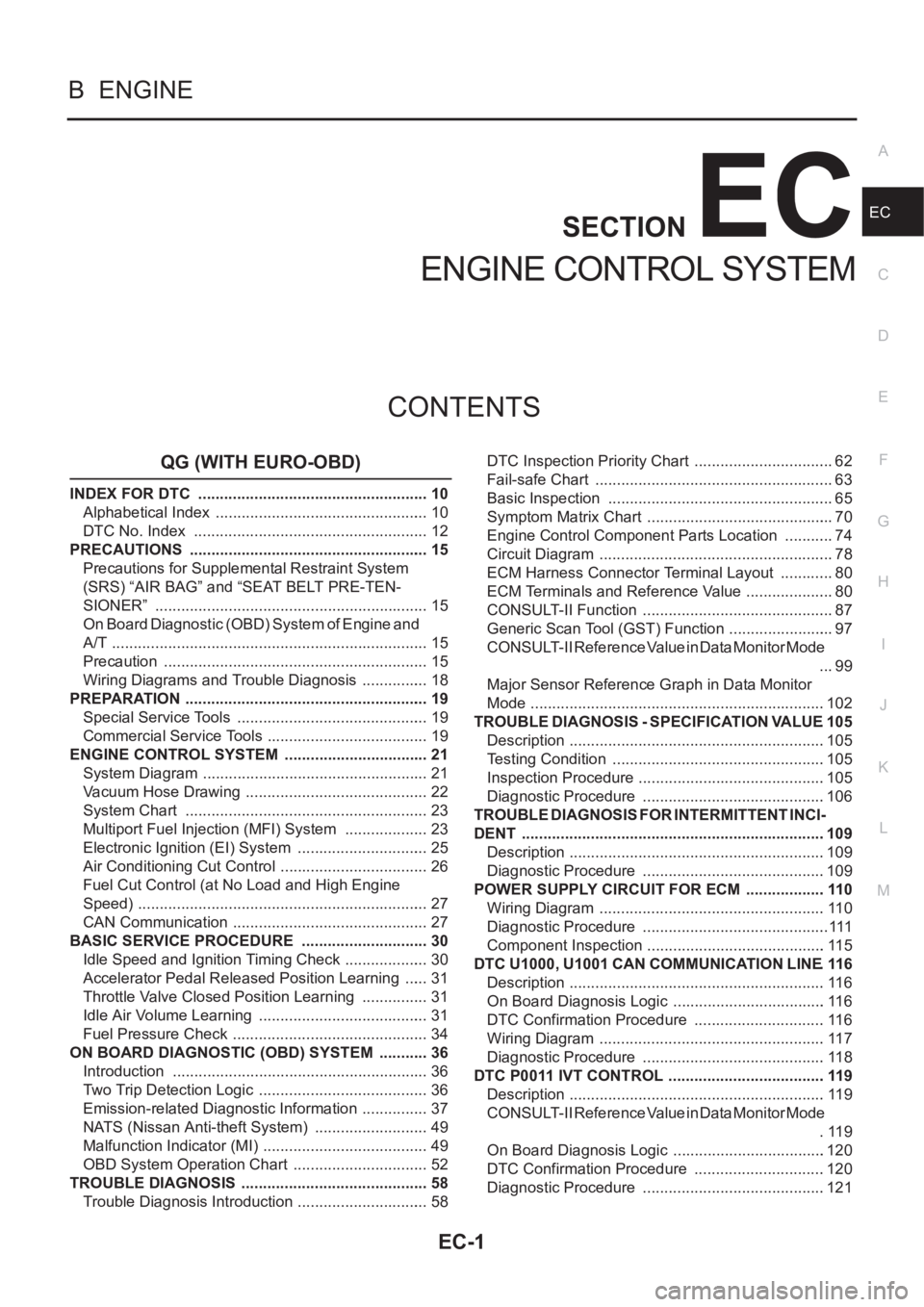

Page 331 of 3189

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QG (WITH EURO-OBD)

INDEX FOR DTC ...................................................... 10

Alphabetical Index .................................................. 10

DTC No. Index ....................................................... 12

PRECAUTIONS ........................................................ 15

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 15

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 15

Precaution .............................................................. 15

Wiring Diagrams and Trouble Diagnosis ................ 18

PREPARATION ......................................................... 19

Special Service Tools ............................................. 19

Commercial Service Tools ...................................... 19

ENGINE CONTROL SYSTEM .................................. 21

System Diagram ..................................................... 21

Vacuum Hose Drawing ........................................... 22

System Chart ......................................................... 23

Multiport Fuel Injection (MFI) System .................... 23

Electronic Ignition (EI) System ............................... 25

Air Conditioning Cut Control ................................... 26

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 27

CAN Communication .............................................. 27

BASIC SERVICE PROCEDURE .............................. 30

Idle Speed and Ignition Timing Check .................... 30

Accelerator Pedal Released Position Learning ...... 31

Throttle Valve Closed Position Learning ................ 31

Idle Air Volume Learning ........................................ 31

Fuel Pressure Check .............................................. 34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 36

Introduction ............................................................ 36

Two Trip Detection Logic ........................................ 36

Emission-related Diagnostic Information ................ 37

NATS (Nissan Anti-theft System) ........................... 49

Malfunction Indicator (MI) ....................................... 49

OBD System Operation Chart ................................ 52

TROUBLE DIAGNOSIS ............................................ 58

Trouble Diagnosis Introduction ............................... 58DTC Inspection Priority Chart ................................. 62

Fail-safe Chart ........................................................ 63

Basic Inspection ..................................................... 65

Symptom Matrix Chart ............................................ 70

Engine Control Component Parts Location ............ 74

Circuit Diagram ....................................................... 78

ECM Harness Connector Terminal Layout ............. 80

ECM Terminals and Reference Value ..................

... 80

CONSULT-II Function ............................................. 87

Generic Scan Tool (GST) Function ......................... 97

CONSULT-II Reference Value in Data Monitor Mode

... 99

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................102

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .105

Description ............................................................105

Testing Condition ..................................................105

Inspection Procedure ............................................105

Diagnostic Procedure ...........................................106

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................109

Description ............................................................109

Diagnostic Procedure ...........................................109

POWER SUPPLY CIRCUIT FOR ECM ...................110

Wiring Diagram .....................................................110

Diagnostic Procedure ............................................111

Component Inspection ..........................................115

DTC U1000, U1001 CAN COMMUNICATION LINE .116

Description ............................................................116

On Board Diagnosis Logic ....................................116

DTC Confirmation Procedure ...............................116

Wiring Diagram .....................................................117

Diagnostic Procedure ...........................................118

DTC P0011 IVT CONTROL .....................................119

Description ............................................................119

CONSULT-II Reference Value in Data Monitor Mode

.119

On Board Diagnosis Logic ....................................120

DTC Confirmation Procedure ...............................120

Diagnostic Procedure ...........................................121

Page 332 of 3189

EC-2

DTC P0031, P0032 HO2S1 HEATER .....................122

Description ............................................................122

CONSULT-II Reference Value in Data Monitor Mode

.122

On Board Diagnosis Logic ....................................122

DTC Confirmation Procedure ...............................122

Wiring Diagram .....................................................124

Diagnostic Procedure ...........................................125

Component Inspection ..........................................127

Removal and Installation ......................................127

DTC P0037, P0038 HO2S2 HEATER .....................128

Description ............................................................128

CONSULT-II Reference Value in Data Monitor Mode

.128

On Board Diagnosis Logic ....................................128

DTC Confirmation Procedure ...............................128

Wiring Diagram .....................................................130

Diagnostic Procedure ...........................................131

Component Inspection ..........................................133

Removal and Installation ......................................133

DTC P0102, P0103 MAF SENSOR .........................134

Component Description ........................................134

CONSULT-II Reference Value in Data Monitor Mode

.134

On Board Diagnosis Logic ....................................134

DTC Confirmation Procedure ...............................135

Wiring Diagram .....................................................136

Diagnostic Procedure ...........................................137

Component Inspection ..........................................139

Removal and Installation ......................................139

DTC P0112, P0113 IAT SENSOR ...........................140

Component Description ........................................140

On Board Diagnosis Logic ....................................140

DTC Confirmation Procedure ...............................140

Wiring Diagram .....................................................141

Diagnostic Procedure ...........................................142

Component Inspection ..........................................143

Removal and Installation ......................................143

DTC P0117, P0118 ECT SENSOR ..........................144

Component Description ........................................144

On Board Diagnosis Logic ....................................144

DTC Confirmation Procedure ...............................145

Wiring Diagram .....................................................146

Diagnostic Procedure ...........................................147

Component Inspection ..........................................148

Removal and Installation ......................................148

DTC P0132 HO2S1 .................................................149

Component Description ........................................149

CONSULT-II Reference Value in Data Monitor Mode

.149

On Board Diagnosis Logic ...................................

.149

DTC Confirmation Procedure ...............................150

Wiring Diagram .....................................................151

Diagnostic Procedure ...........................................152

Component Inspection ..........................................153

Removal and Installation ......................................154

DTC P0133 HO2S1 .................................................155

Component Description ........................................155

CONSULT-II Reference Value in Data Monitor Mode .155

On Board Diagnosis Logic ....................................155

DTC Confirmation Procedure ................................156

Overall Function Check .........................................157

Wiring Diagram .....................................................158

Diagnostic Procedure ............................................159

Component Inspection ..........................................162

Removal and Installation .......................................164

DTC P0134 HO2S1 ................................................ .165

Component Description ........................................165

CONSULT-II Reference Value in Data Monitor Mode

.165

On Board Diagnosis Logic ....................................165

DTC Confirmation Procedure ................................166

Overall Function Check .........................................166

Wiring Diagram .....................................................168

Diagnostic Procedure ............................................169

Component Inspection ..........................................170

Removal and Installation .......................................171

DTC P0138 HO2S2 ................................................ .172

Component Description ........................................172

CONSULT-II Reference Value in Data Monitor Mode

.172

On Board Diagnosis Logic ....................................172

DTC Confirmation Procedure ................................173

Wiring Diagram .....................................................174

Diagnostic Procedure ............................................175

Component Inspection ..........................................176

Removal and Installation .......................................177

DTC P0139 HO2S2 ................................................ .178

Component Description ........................................178

CONSULT-II Reference Value in Data Monitor Mode

.178

On Board Diagnosis Logic ....................................178

DTC Confirmation Procedure ................................179

Overall Function Check .........................................180

Wiring Diagram .....................................................181

Diagnostic Procedure ............................................182

Component Inspection ..........................................184

Removal and Installation ......................................

.185

DTC P0171 FUEL INJECTION SYSTEM FUNCTION .186

On Board Diagnosis Logic ....................................186

DTC Confirmation Procedure ................................186

Wiring Diagram .....................................................188

Diagnostic Procedure ............................................189

DTC P0172 FUEL INJECTION SYSTEM FUNCTION .193

On Board Diagnosis Logic ....................................193

DTC Confirmation Procedure ................................193

Wiring Diagram .....................................................195

Diagnostic Procedure ............................................196

DTC P0221 TP SENSOR ........................................199

Component Description ........................................199

CONSULT-II Reference Value in Data Monitor Mode

.199

On Board Diagnosis Logic ....................................199

DTC Confirmation Procedure ................................199

Wiring Diagram .....................................................201

Diagnostic Procedure ............................................202

Page 333 of 3189

EC-3

C

D

E

F

G

H

I

J

K

L

M

ECA Component Inspection ......................................... 204

Removal and Installation ...................................... 204

DTC P0222, P0223 TP SENSOR ........................... 205

Component Description ........................................ 205

CONSULT-II Reference Value in Data Monitor Mode

. 205

On Board Diagnosis Logic ................................... 205

DTC Confirmation Procedure ............................... 205

Wiring Diagram .................................................... 207

Diagnostic Procedure ........................................... 208

Component Inspection ......................................... 210

Removal and Installation ...................................... 210

DTC P0226 APP SENSOR ......................................211

Component Description ......................................... 211

CONSULT-II Reference Value in Data Monitor Mode

.. 211

On Board Diagnosis Logic .................................... 211

DTC Confirmation Procedure ................................ 211

Wiring Diagram .................................................... 213

Diagnostic Procedure ........................................... 214

Component Inspection ......................................... 216

Removal and Installation ...................................... 217

DTC P0227, P0228 APP SENSOR ........................ 218

Component Description ........................................ 218

CONSULT-II Reference Value in Data Monitor Mode

. 218

On Board Diagnosis Logic ................................... 218

DTC Confirmation Procedure ............................... 218

Wiring Diagram .................................................... 220

Diagnostic Procedure ........................................... 221

Component Inspection ......................................... 223

Removal and Installation ...................................... 224

DTC P0300 - P0304 MULTIPLE CYLINDER MIS-

FIRE, NO. 1 - 4 CYLINDER MISFIRE ..................... 225

On Board Diagnosis Logic ................................... 225

DTC Confirmation Procedure ............................... 225

Diagnostic Procedure ........................................... 226

DTC P0327, P0328 KS ........................................... 230

Component Description ........................................ 230

On Board Diagnosis Logic ................................... 230

DTC Confirmation Procedure ............................... 230

Wiring Diagram .................................................... 231

Diagnostic Procedure ........................................... 232

Component Inspection ......................................... 233

Removal and Installation ...................................... 233

DTC P0335 CKP SENSOR (POS) .......................... 234

Component Description ........................................ 234

CONSULT-II Reference Value in Data Monitor Mode

. 234

On Board Diagnosis Logic ................................... 234

DTC Confirmation Procedure ............................... 234

Wiring Diagram ...................................................

. 235

Diagnostic Procedure ........................................... 236

Component Inspection ......................................... 238

Removal and Installation ...................................... 239

DTC P0340 CMP SENSOR (PHASE) ..................... 240

Component Description ........................................ 240

On Board Diagnosis Logic ................................... 240

DTC Confirmation Procedure ............................... 240Wiring Diagram .....................................................241

Diagnostic Procedure ...........................................242

Component Inspection ..........................................244

Removal and Installation ......................................245

DTC P0420 THREE WAY CATALYST FUNCTION . 246

On Board Diagnosis Logic ....................................246

DTC Confirmation Procedure ...............................246

Overall Function Check ........................................247

Diagnostic Procedure ...........................................248

DTC P0444 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE ...............................251

Description ............................................................251

CONSULT-II Reference Value in Data Monitor Mode

.251

On Board Diagnosis Logic ....................................252

DTC Confirmation Procedure ...............................252

Wiring Diagram .....................................................253

Diagnostic Procedure ...........................................254

Component Inspection ..........................................256

Removal and Installation ......................................256

DTC P0500 VSS ......................................................257

Description ............................................................257

On Board Diagnosis Logic ....................................257

DTC Confirmation Procedure ...............................257

Overall Function Check ........................................258

Diagnostic Procedure ...........................................259

DTC P0550 PSP SENSOR .....................................260

Component Description ........................................260

CONSULT-II Reference Value in Data Monitor Mode

.260

On Board Diagnosis Logic ....................................260

DTC Confirmation Procedure ...............................260

Wiring Diagram .....................................................261

Diagnostic Procedure ...........................................262

Component Inspection ..........................................264

DTC P0605 ECM .....................................................265

Component Description ........................................265

On Board Diagnosis Logic ....................................265

DTC Confirmation Procedure ...............................265

Diagnostic Procedure ...........................................266

DTC P1065 ECM POWER SUPPLY .......................268

Component Description ........................................268

On Board Diagnosis Logic ....................................268

DTC Confirmation Procedure ...............................268

Wiring Diagram .....................................................269

Diagnostic Procedure ...........................................270

DTC P1111 IVT CONTROL SOLENOID VALVE .....272

Component Description ........................................272

CONSULT-II Reference Value in Data Monitor Mode

.272

On Board Diagnosis Logic ....................................272

DTC Confirmation Procedure ...............................272

Wiring Diagram .....................................................273

Diagnostic Procedure ...........................................274

Component Inspection ..........................................275

Removal and Installation ......................................275

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR .............................................................276

Component Description ........................................276