cooling fan wiring diagram NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 662 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-332

[QG (WITH EURO-OBD)]

DTC P1217 ENGINE OVER TEMPERATURE

3. CHECK COOLING FAN MOTORS CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and cool NISSAN ALMERA N16 2003 Electronic Repair Manual EC-332

[QG (WITH EURO-OBD)]

DTC P1217 ENGINE OVER TEMPERATURE

3. CHECK COOLING FAN MOTORS CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and cool](/img/5/57350/w960_57350-661.png)

EC-332

[QG (WITH EURO-OBD)]

DTC P1217 ENGINE OVER TEMPERATURE

3. CHECK COOLING FAN MOTORS CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and cooling

fan motor-2 harness connector.

3. Check harness continuity between cooling fan relay-1 terminal 5

and cooling fan motor-1 terminal 1, cooling fan motor-1 terminal

2 and body ground.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

5. Check harness continuity between cooling fan relay-1 terminal 7

and cooling fan motor-2 terminal 1, cooling fan motor-2 terminal

2 and body ground.

Refer to Wiring Diagram.

6. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4. CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect smart entrance control unit.

2. Check harness continuity between smart entrance control unit

terminal 33 and cooling fan relay-1 terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5. DETECT MALFUNCTIONING PART

Check the following.

●Harness connectors E251, M182 (LHD models)

●Harness connectors E174, M159 (RHD models)

●Harness for open or short between smart entrance control unit and cooling fan relay-1

>> Repair open circuit or short to ground or short to power in harness or connectors.

6. CHECK COOLING FAN RELAY-1

Refer to EC-334, "

Component Inspection" .

OK or NG

OK >> GO TO 7.

NG >> Replace cooling fan relay.Continuity should exist.

Continuity should exist.

MBIB0252E

Continuity should exist.

MBIB0264E

Page 934 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-604

[QG (WITHOUT EURO-OBD)]

DTC P1217 ENGINE OVER TEMPERATURE

3. CHECK COOLING FAN MOTORS CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and c NISSAN ALMERA N16 2003 Electronic Repair Manual EC-604

[QG (WITHOUT EURO-OBD)]

DTC P1217 ENGINE OVER TEMPERATURE

3. CHECK COOLING FAN MOTORS CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and c](/img/5/57350/w960_57350-933.png)

EC-604

[QG (WITHOUT EURO-OBD)]

DTC P1217 ENGINE OVER TEMPERATURE

3. CHECK COOLING FAN MOTORS CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and cooling

fan motor-2 harness connector.

3. Check harness continuity between cooling fan relay-1 terminal 5

and cooling fan motor-1 terminal 1, cooling fan motor-1 terminal

2 and body ground.

Refer to wiring diagram.

4. Also check harness for short to ground and short to power.

5. Check harness continuity between cooling fan relay-1 terminal 7

and cooling fan motor-2 terminal 1, cooling fan motor-2 terminal

2 and body ground.

Refer to wiring diagram.

6. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4. CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect smart entrance control unit.

2. Check harness continuity between smart entrance control unit

terminal 33 and cooling fan relay-1 terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5. DETECT MALFUNCTIONING PART

Check the following.

●Harness connectors E251, M182 (LHD models)

●Harness connectors E174, M159 (RHD models)

●Harness for open or short between smart entrance control unit and cooling fan relay-1

>> Repair open circuit or short to ground or short to power in harness or connectors.

6. CHECK COOLING FAN RELAY-1

Refer to EC-606, "

Component Inspection" .

OK or NG

OK >> GO TO 7.

NG >> Replace cooling fan relay.Continuity should exist.

Continuity should exist.

MBIB0252E

Continuity should exist.

MBIB0264E

Page 1193 of 3189

2 DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E104

10A fuse

40A fusible link

Harness for open or short between cooling fan relay-1 and fuse

Harness for open or short between cooling fan relay-1 and battery

Repair open circuit or short to ground or short to power in harness or connectors.

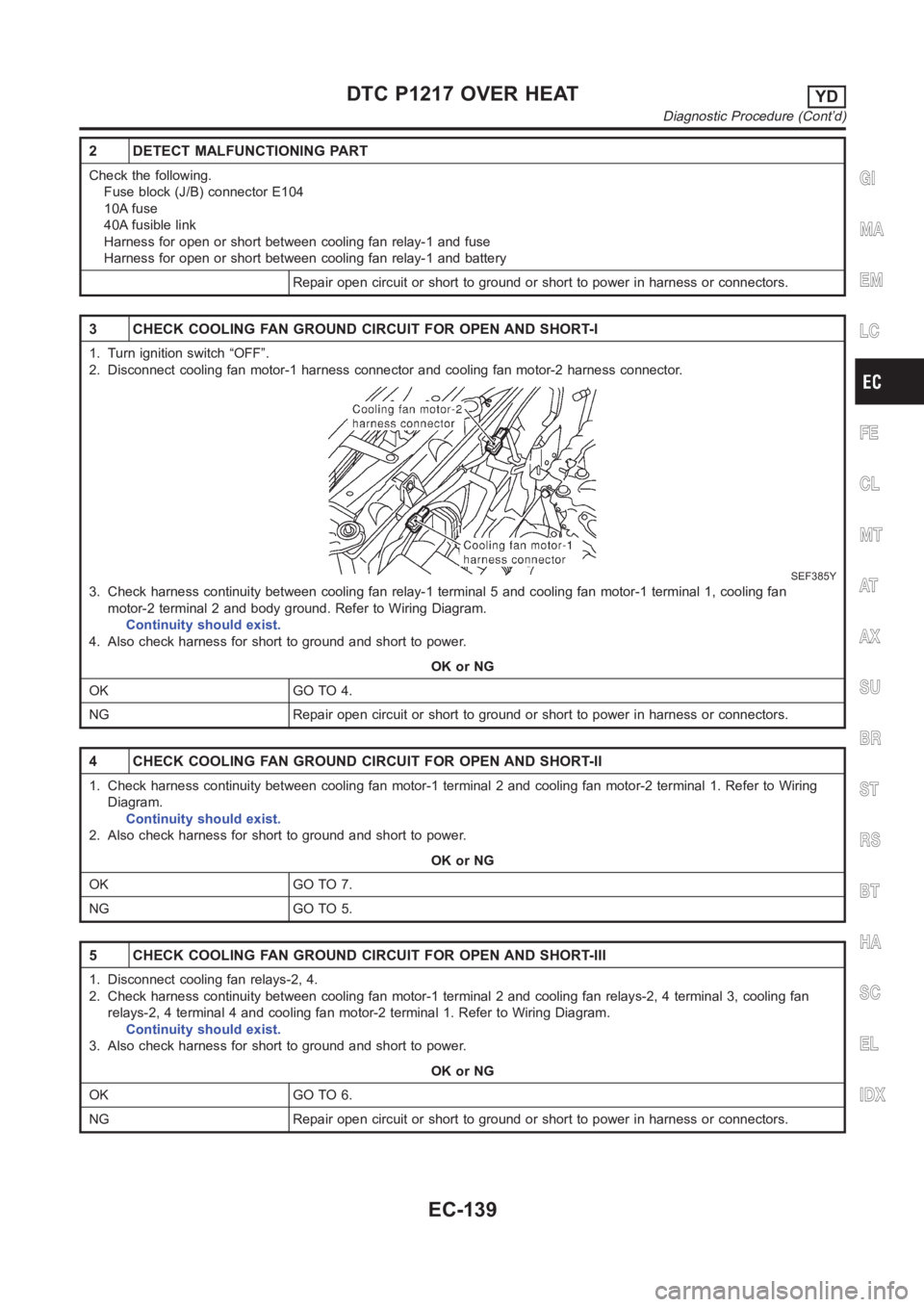

3 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and cooling fan motor-2 harness connector.

SEF385Y

3. Check harness continuity between cooling fan relay-1 terminal 5 and cooling fan motor-1 terminal 1, cooling fan

motor-2 terminal 2 and body ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 4.

NG Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Check harness continuity between cooling fan motor-1 terminal 2 and cooling fan motor-2 terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 7.

NG GO TO 5.

5 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-III

1. Disconnect cooling fan relays-2, 4.

2. Check harness continuity between cooling fan motor-1 terminal 2 and cooling fan relays-2, 4 terminal 3, cooling fan

relays-2, 4 terminal 4 and cooling fan motor-2 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 6.

NG Repair open circuit or short to ground or short to power in harness or connectors.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-139

Page 1194 of 3189

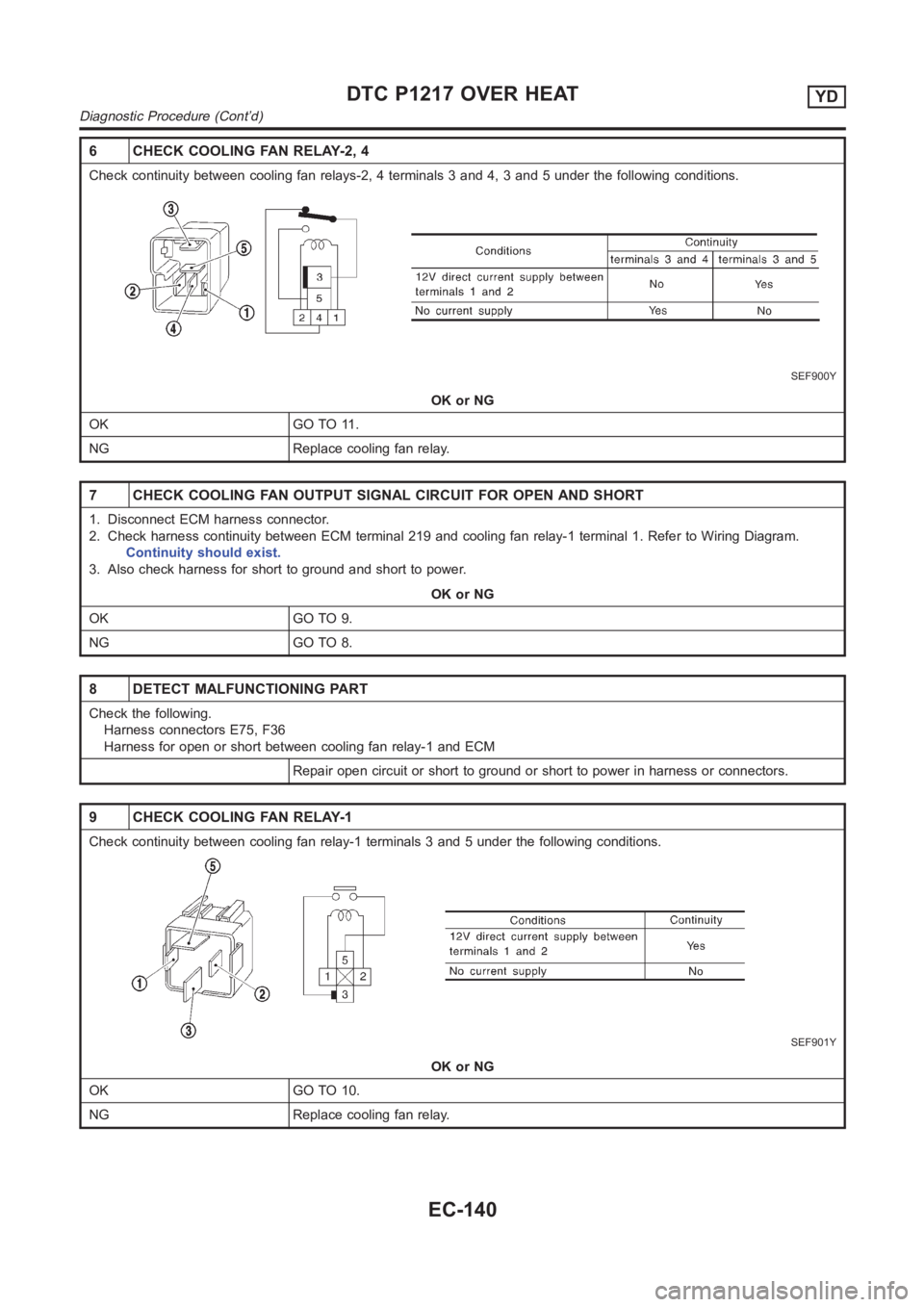

6 CHECK COOLING FAN RELAY-2, 4

Check continuity between cooling fan relays-2, 4 terminals 3 and 4, 3 and 5 under the following conditions.

SEF900Y

OK or NG

OK GO TO 11.

NG Replace cooling fan relay.

7 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 219 and cooling fan relay-1 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 9.

NG GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E75, F36

Harness for open or short between cooling fan relay-1 and ECM

Repair open circuit or short to ground or short to power in harness or connectors.

9 CHECK COOLING FAN RELAY-1

Check continuity between cooling fan relay-1 terminals 3 and 5 under the following conditions.

SEF901Y

OK or NG

OK GO TO 10.

NG Replace cooling fan relay.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-140

Page 1196 of 3189

2 DETECT MALFUNCTIONING PART

Check the following.

30A fusible link

10A fuse

Harness for open or short between cooling fan relays-2, 3, 4 and fuse

Harness for open or short between cooling fan relay-3 and fusible link

Repair harness or connectors.

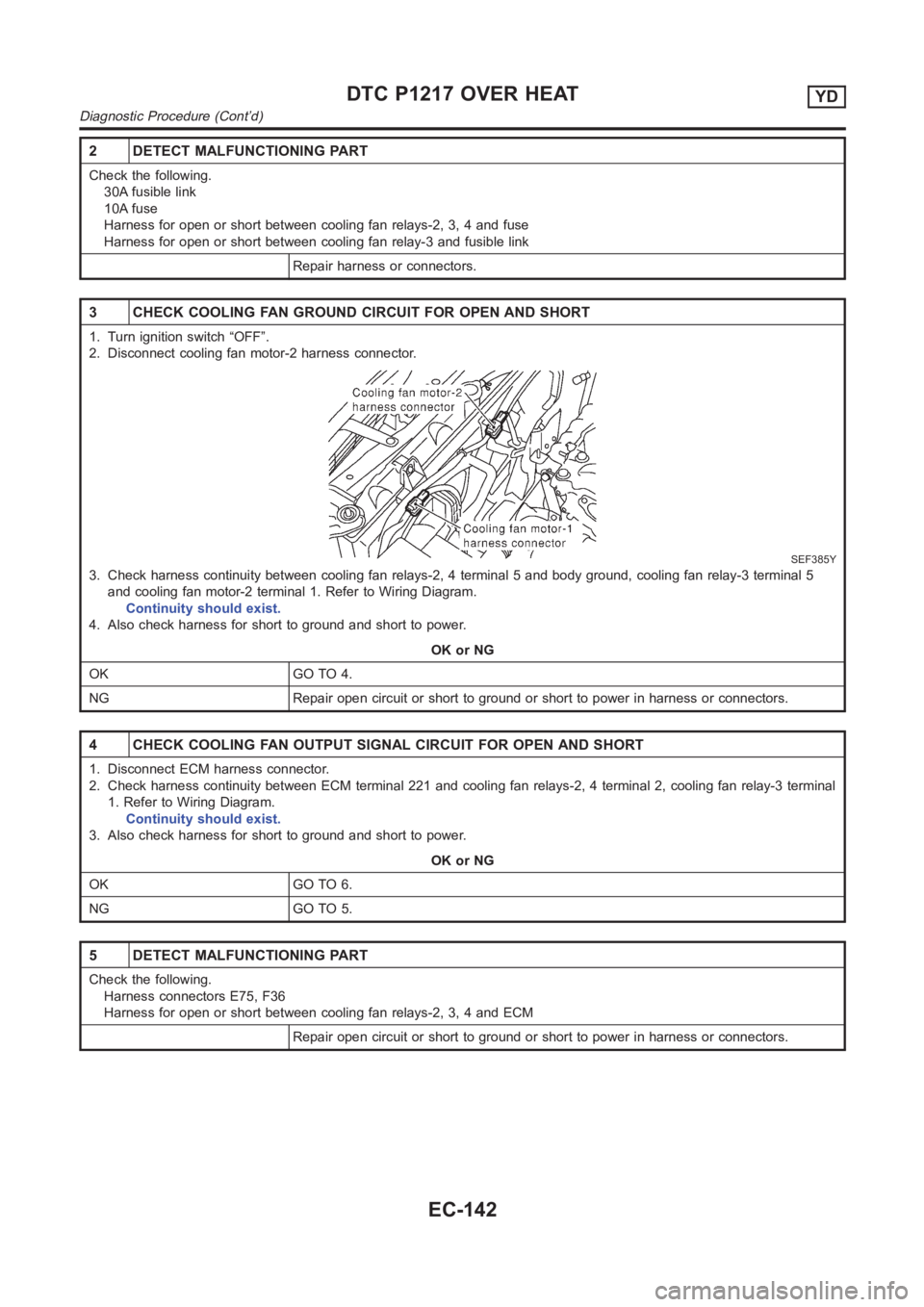

3 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-2 harness connector.

SEF385Y

3. Check harness continuity between cooling fan relays-2, 4 terminal 5 andbody ground, cooling fan relay-3 terminal 5

and cooling fan motor-2 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 4.

NG Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 221 and cooling fan relays-2, 4 terminal 2, cooling fan relay-3 terminal

1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 6.

NG GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E75, F36

Harness for open or short between cooling fan relays-2, 3, 4 and ECM

Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-142

Page 2935 of 3189

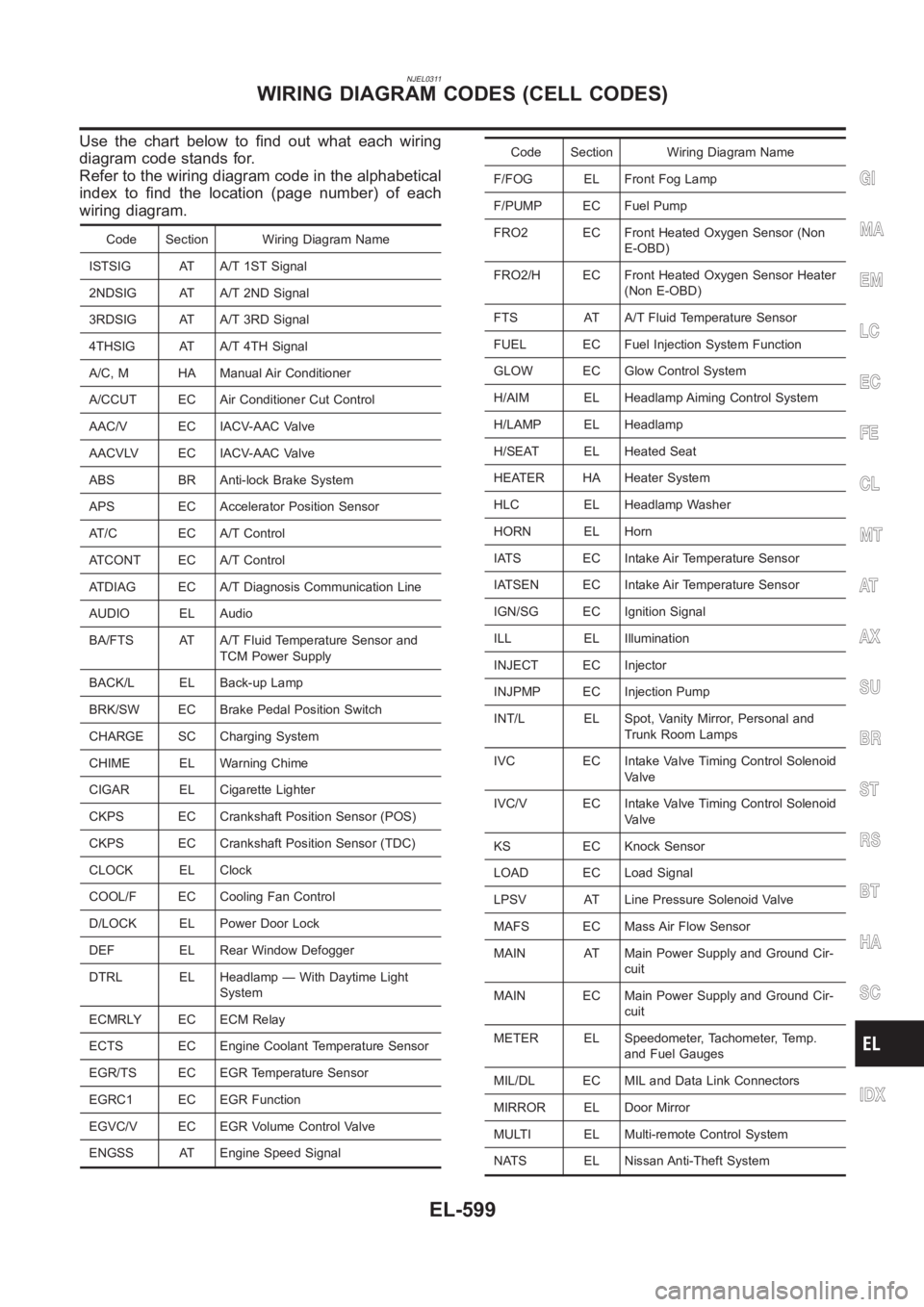

NJEL0311

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

ISTSIG AT A/T 1ST Signal

2NDSIG AT A/T 2ND Signal

3RDSIG AT A/T 3RD Signal

4THSIG AT A/T 4TH Signal

A/C, M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Cut Control

AAC/V EC IACV-AAC Valve

AACVLV EC IACV-AAC Valve

ABS BR Anti-lock Brake System

APS EC Accelerator Position Sensor

AT/C EC A/T Control

ATCONT EC A/T Control

ATDIAG EC A/T Diagnosis Communication Line

AUDIO EL Audio

BA/FTS AT A/T Fluid Temperature Sensor and

TCM Power Supply

BACK/L EL Back-up Lamp

BRK/SW EC Brake Pedal Position Switch

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor (POS)

CKPS EC Crankshaft Position Sensor (TDC)

CLOCK EL Clock

COOL/F EC Cooling Fan Control

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DTRL EL Headlamp — With Daytime Light

System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGR/TS EC EGR Temperature Sensor

EGRC1 EC EGR Function

EGVC/V EC EGR Volume Control Valve

ENGSS AT Engine Speed Signal

Code Section Wiring Diagram Name

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FRO2 EC Front Heated Oxygen Sensor (Non

E-OBD)

FRO2/H EC Front Heated Oxygen Sensor Heater

(Non E-OBD)

FTS AT A/T Fluid Temperature Sensor

FUEL EC Fuel Injection System Function

GLOW EC Glow Control System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

H/SEAT EL Heated Seat

HEATER HA Heater System

HLC EL Headlamp Washer

HORN EL Horn

IATS EC Intake Air Temperature Sensor

IATSEN EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP EC Injection Pump

INT/L EL Spot, Vanity Mirror, Personal and

Trunk Room Lamps

IVC EC Intake Valve Timing Control Solenoid

Valve

IVC/V EC Intake Valve Timing Control Solenoid

Valve

KS EC Knock Sensor

LOAD EC Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Cir-

cuit

MAIN EC Main Power Supply and Ground Cir-

cuit

METER EL Speedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WIRING DIAGRAM CODES (CELL CODES)

EL-599

Page 3178 of 3189

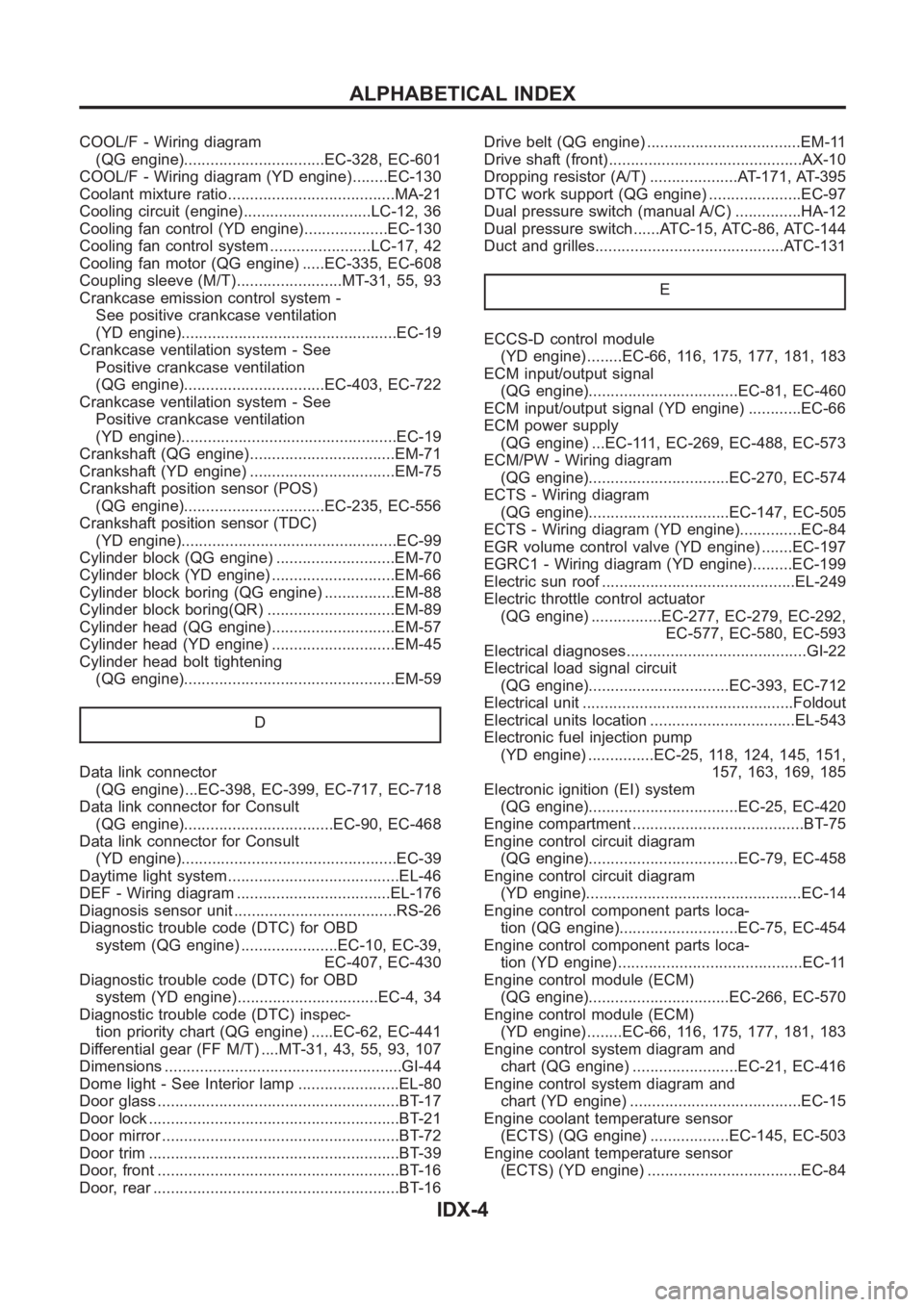

COOL/F - Wiring diagram

(QG engine)................................EC-328, EC-601

COOL/F - Wiring diagram (YD engine) ........EC-130

Coolant mixture ratio......................................MA-21

Cooling circuit (engine).............................LC-12, 36

Cooling fan control (YD engine)...................EC-130

Cooling fan control system .......................LC-17, 42

Cooling fan motor (QG engine) .....EC-335, EC-608

Coupling sleeve (M/T)........................MT-31, 55, 93

Crankcase emission control system -

See positive crankcase ventilation

(YD engine).................................................EC-19

Crankcase ventilation system - See

Positive crankcase ventilation

(QG engine)................................EC-403, EC-722

Crankcase ventilation system - See

Positive crankcase ventilation

(YD engine).................................................EC-19

Crankshaft (QG engine).................................EM-71

Crankshaft (YD engine) .................................EM-75

Crankshaft position sensor (POS)

(QG engine)................................EC-235, EC-556

Crankshaft position sensor (TDC)

(YD engine).................................................EC-99

Cylinder block (QG engine) ...........................EM-70

Cylinder block (YD engine) ............................EM-66

Cylinder block boring (QG engine) ................EM-88

Cylinder block boring(QR) .............................EM-89

Cylinder head (QG engine)............................EM-57

Cylinder head (YD engine) ............................EM-45

Cylinder head bolt tightening

(QG engine)................................................EM-59

D

Data link connector

(QG engine) ...EC-398, EC-399, EC-717, EC-718

Data link connector for Consult

(QG engine)..................................EC-90, EC-468

Data link connector for Consult

(YD engine).................................................EC-39

Daytime light system.......................................EL-46

DEF - Wiring diagram ...................................EL-176

Diagnosis sensor unit .....................................RS-26

Diagnostic trouble code (DTC) for OBD

system (QG engine) ......................EC-10, EC-39,

EC-407, EC-430

Diagnostic trouble code (DTC) for OBD

system (YD engine) ................................EC-4, 34

Diagnostic trouble code (DTC) inspec-

tion priority chart (QG engine) .....EC-62, EC-441

Differential gear (FF M/T) ....MT-31, 43, 55, 93, 107

Dimensions <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.GI-44

Dome light - See Interior lamp .......................EL-80

Door glass <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[.BT-17

Door lock <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[..BT-21

Door mirror <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.BT-72

Door trim <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[..BT-39

Door, front <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[..BT-16

Door, rear <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..BT-16Drive belt (QG engine) ...................................EM-11

Drive shaft (front)............................................AX-10

Dropping resistor (A/T) ....................AT-171, AT-395

DTC work support (QG engine) .....................EC-97

Dual pressure switch (manual A/C) ...............HA-12

Dual pressure switch ......ATC-15, ATC-86, ATC-144

Duct and grilles...........................................ATC-131

E

ECCS-D control module

(YD engine) ........EC-66, 116, 175, 177, 181, 183

ECM input/output signal

(QG engine)..................................EC-81, EC-460

ECM input/output signal (YD engine) ............EC-66

ECM power supply

(QG engine) ...EC-111, EC-269, EC-488, EC-573

ECM/PW - Wiring diagram

(QG engine)................................EC-270, EC-574

ECTS - Wiring diagram

(QG engine)................................EC-147, EC-505

ECTS - Wiring diagram (YD engine)..............EC-84

EGR volume control valve (YD engine) .......EC-197

EGRC1 - Wiring diagram (YD engine) .........EC-199

Electric sun roof ............................................EL-249

Electric throttle control actuator

(QG engine) ................EC-277, EC-279, EC-292,

EC-577, EC-580, EC-593

Electrical diagnoses.........................................GI-22

Electrical load signal circuit

(QG engine)................................EC-393, EC-712

Electrical unit ................................................Foldout

Electrical units location .................................EL-543

Electronic fuel injection pump

(YD engine) ...............EC-25, 118, 124, 145, 151,

157, 163, 169, 185

Electronic ignition (EI) system

(QG engine)..................................EC-25, EC-420

Engine compartment .......................................BT-75

Engine control circuit diagram

(QG engine)..................................EC-79, EC-458

Engine control circuit diagram

(YD engine).................................................EC-14

Engine control component parts loca-

tion (QG engine)...........................EC-75, EC-454

Engine control component parts loca-

tion (YD engine) ..........................................EC-11

Engine control module (ECM)

(QG engine)................................EC-266, EC-570

Engine control module (ECM)

(YD engine) ........EC-66, 116, 175, 177, 181, 183

Engine control system diagram and

chart (QG engine) ........................EC-21, EC-416

Engine control system diagram and

chart (YD engine) .......................................EC-15

Engine coolant temperature sensor

(ECTS) (QG engine) ..................EC-145, EC-503

Engine coolant temperature sensor

(ECTS) (YD engine) ...................................EC-84

ALPHABETICAL INDEX

IDX-4