wiper blades NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 59 of 3189

NJMA0004

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers dothem for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-16

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-7

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.—

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-4

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold. LC-18, LC-43

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-30

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.BR-7

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

GENERAL MAINTENANCE

MA-3

Page 2498 of 3189

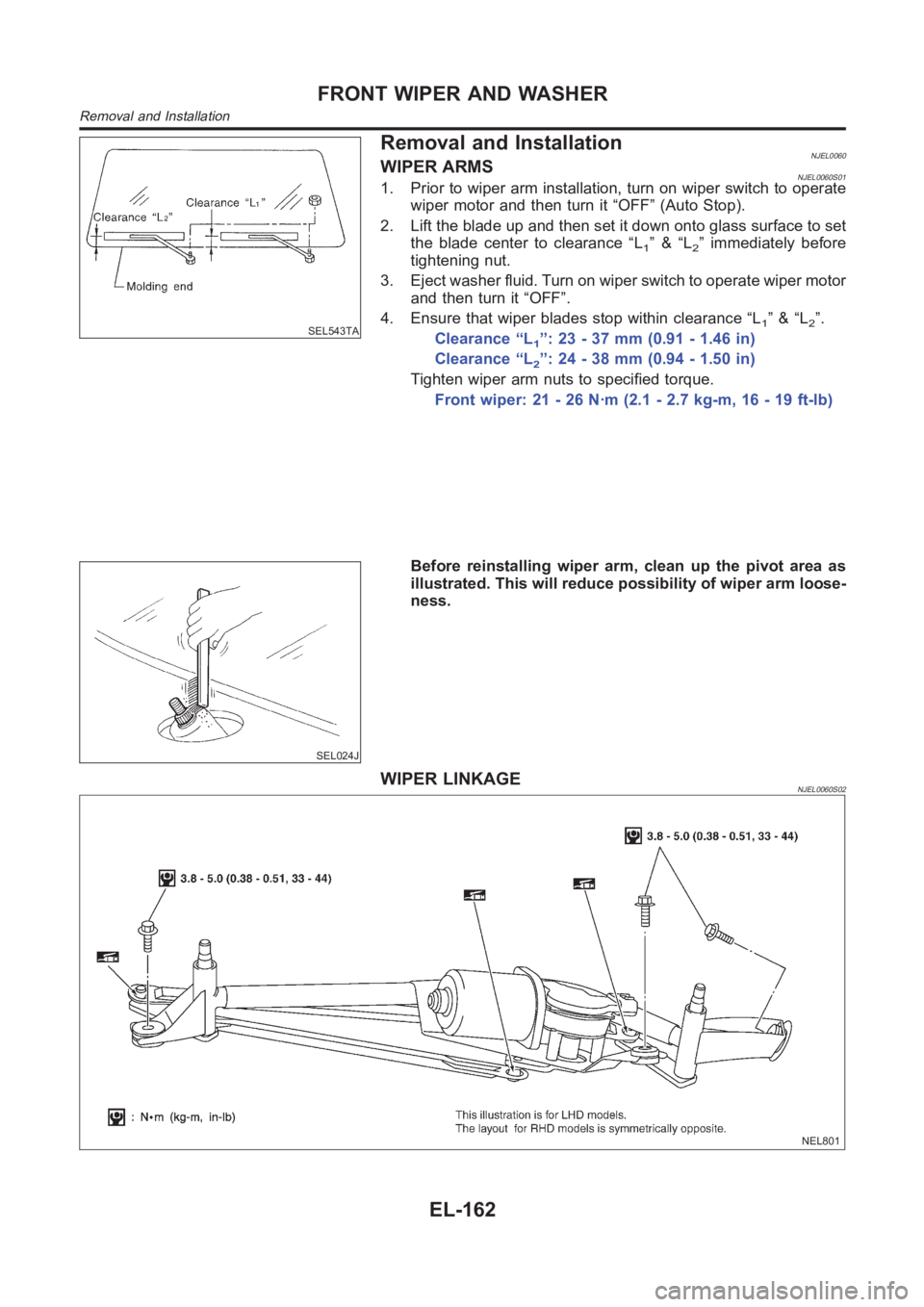

SEL543TA

Removal and InstallationNJEL0060WIPER ARMSNJEL0060S011. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it “OFF” (Auto Stop).

2. Lift the blade up and then set it down onto glass surface to set

the blade center to clearance “L

1”&“L2” immediately before

tightening nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it “OFF”.

4. Ensure that wiper blades stop within clearance “L

1”&“L2”.

Clearance “L1”:23-37mm(0.91-1.46in)

Clearance “L

2”:24-38mm(0.94-1.50in)

Tighten wiper arm nuts to specified torque.

Front wiper: 21 - 26 N·m (2.1 - 2.7 kg-m, 16 - 19 ft-lb)

SEL024J

Before reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

WIPER LINKAGENJEL0060S02

NEL801

FRONT WIPER AND WASHER

Removal and Installation

EL-162

Page 2502 of 3189

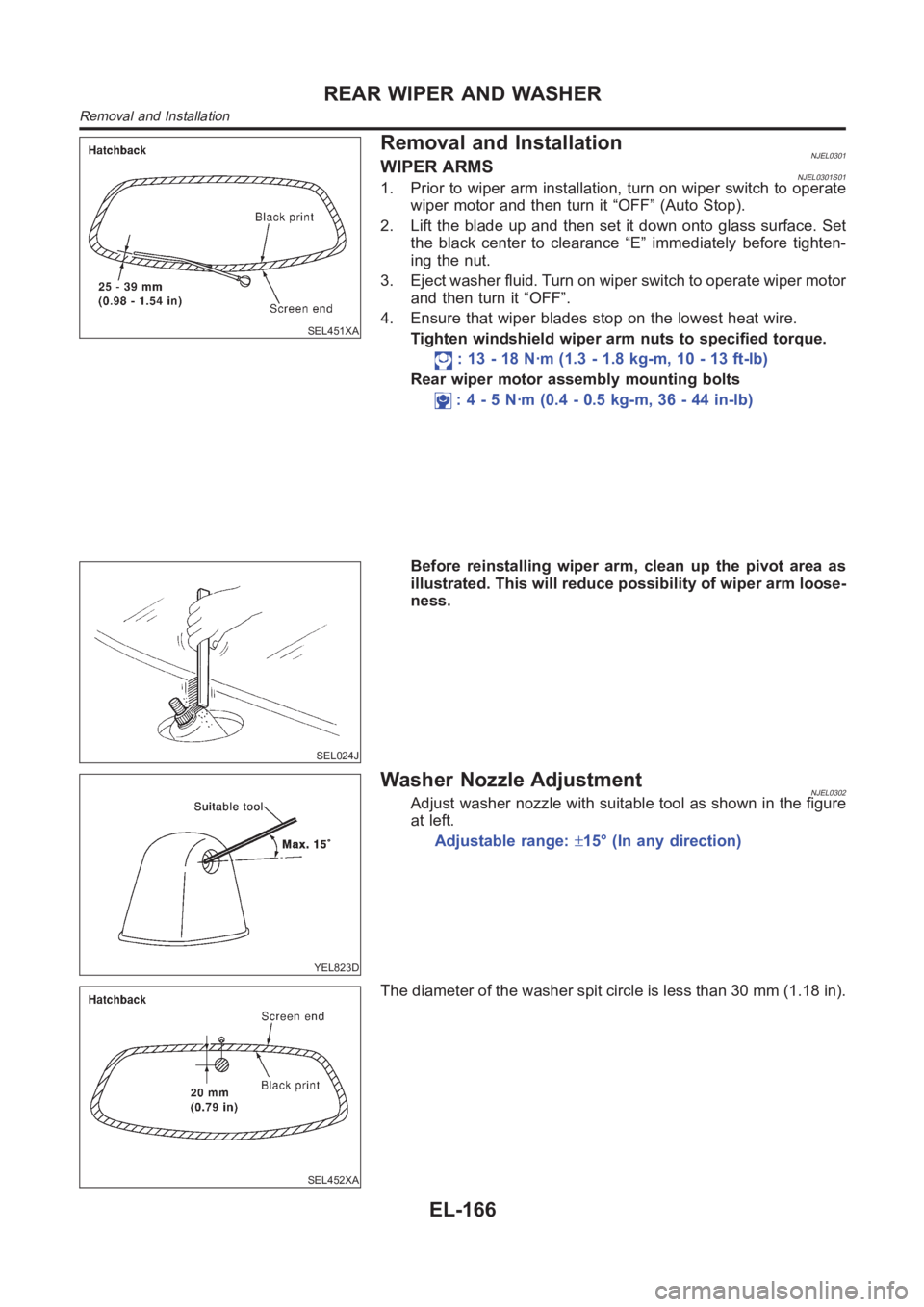

SEL451XA

Removal and InstallationNJEL0301WIPER ARMSNJEL0301S011. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it “OFF” (Auto Stop).

2. Lift the blade up and then set it down onto glass surface. Set

the black center to clearance “E” immediately before tighten-

ing the nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it “OFF”.

4. Ensure that wiper blades stop on the lowest heat wire.

Tighten windshield wiper arm nuts to specified torque.

: 13 - 18 N·m (1.3 - 1.8 kg-m, 10 - 13 ft-lb)

Rear wiper motor assembly mounting bolts

: 4 - 5 N·m (0.4 - 0.5 kg-m, 36 - 44 in-lb)

SEL024J

Before reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm loose-

ness.

YEL823D

Washer Nozzle AdjustmentNJEL0302Adjust washer nozzle with suitable tool as shown in the figure

at left.

Adjustable range:±15° (In any direction)

SEL452XA

The diameter of the washer spit circle is less than 30 mm (1.18 in).

REAR WIPER AND WASHER

Removal and Installation

EL-166