open hood NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 59 of 3189

NJMA0004

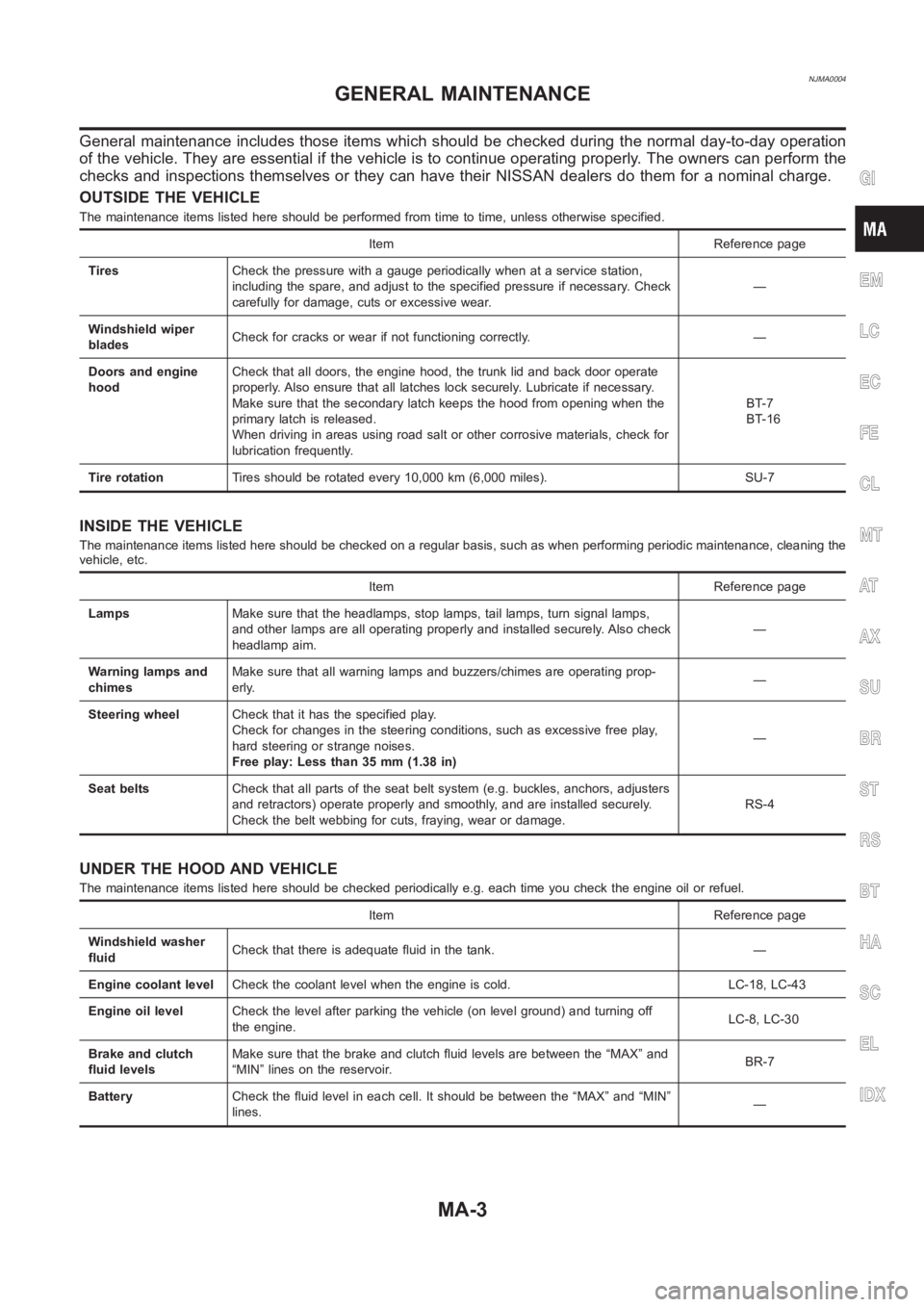

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers dothem for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-16

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-7

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.—

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-4

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold. LC-18, LC-43

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-30

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.BR-7

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

GENERAL MAINTENANCE

MA-3

Page 248 of 3189

crankshaft position sensor (TDC sensor) from the assem-

bly.

Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-43, “Changing Engine Coolant”.

3. Remove the following parts:

Battery

RH and LH front wheels

RH and LH splash covers (combined with undercover)

Auxiliary belts

Alternator

Alternator brackets

Radiator and cooling fan

Engine cover

Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

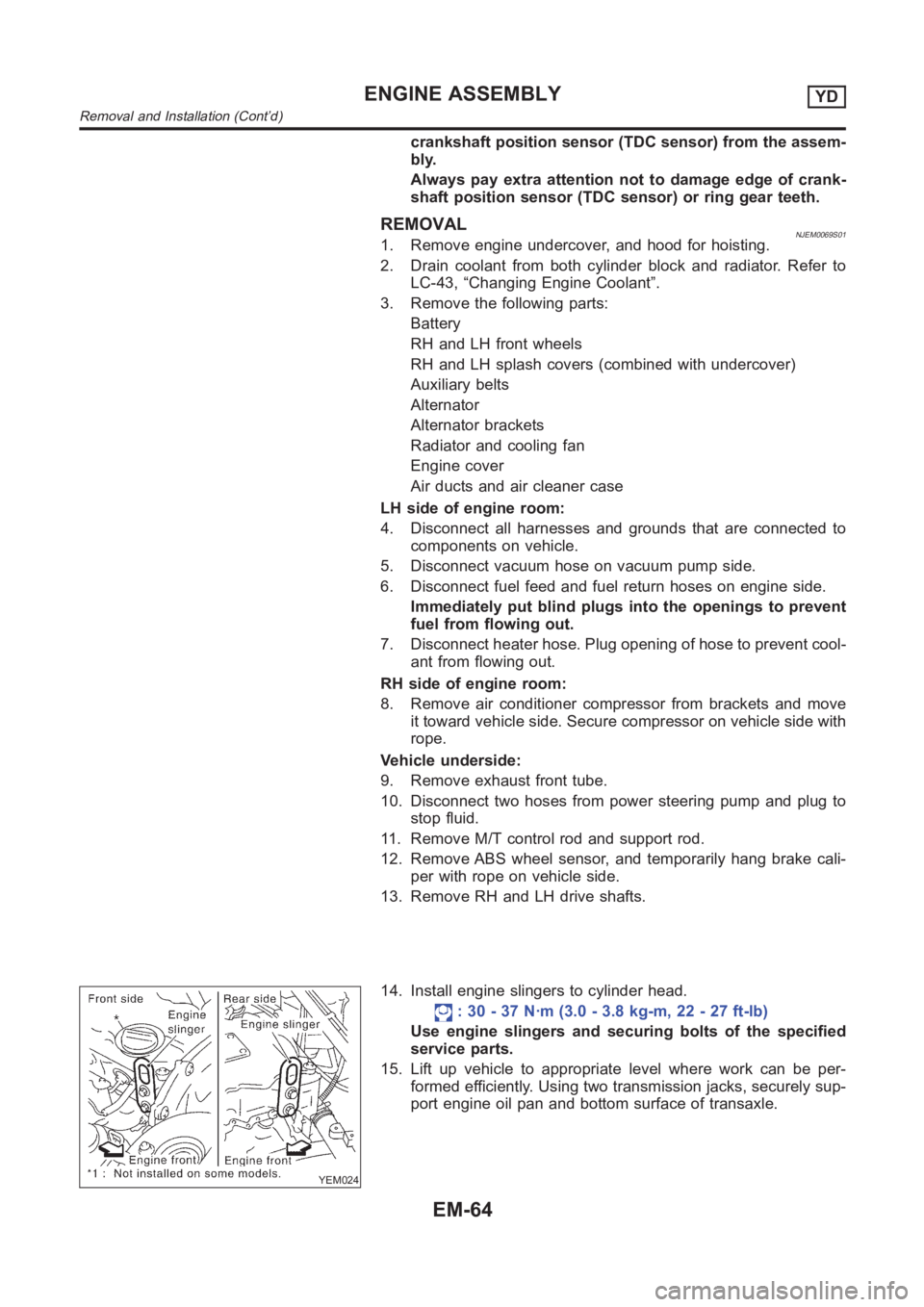

YEM024

14. Install engine slingers to cylinder head.

: 30 - 37 N·m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont’d)

EM-64

Page 395 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-65

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00K3O

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfuncti NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-65

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00K3O

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfuncti](/img/5/57350/w960_57350-394.png)

TROUBLE DIAGNOSIS

EC-65

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00K3O

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

–Harness connectors for improper connections

–Wiring harness for improper connections, pinches and cut

–Vacuum hoses for splits, kinks and improper connections

–Hoses and ducts for leaks

–Air cleaner clogging

–Gasket

3. Confirm that electrical or mechanical loads are not applied.

–Headlamp switch is OFF.

–Air conditioner switch is OFF.

–Rear window defogger switch is OFF.

–Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no-

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding “Diagnostic Procedure”.

>> GO TO 3.

SEF983U

SEF976U

SEF977U

Page 576 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-246

[QG (WITH EURO-OBD)]

DTC P0420 THREE WAY CATALYST FUNCTION

DTC P0420 THREE WAY CATALYST FUNCTION

PFP:20905

On Board Diagnosis LogicEBS00K8J

The ECM monitors the switching frequency ratio of hea NISSAN ALMERA N16 2003 Electronic Repair Manual EC-246

[QG (WITH EURO-OBD)]

DTC P0420 THREE WAY CATALYST FUNCTION

DTC P0420 THREE WAY CATALYST FUNCTION

PFP:20905

On Board Diagnosis LogicEBS00K8J

The ECM monitors the switching frequency ratio of hea](/img/5/57350/w960_57350-575.png)

EC-246

[QG (WITH EURO-OBD)]

DTC P0420 THREE WAY CATALYST FUNCTION

DTC P0420 THREE WAY CATALYST FUNCTION

PFP:20905

On Board Diagnosis LogicEBS00K8J

The ECM monitors the switching frequency ratio of heated oxygen

sensors 1 and 2.

A three way catalyst (Manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of heated oxygen sensors 1 and 2

approaches a specified limit value, the three way catalyst (Manifold)

malfunction is diagnosed.

DTC Confirmation ProcedureEBS00K8K

NOTE:

If “DTC Confirmation Procedure” has been previously conducted, always turn ignition switch “OFF” and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

TESTING CONDITION:

●Open engine hood before conducting the following procedure.

●Do not hold engine speed for more than the specified minutes below.

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch ″OFF″ and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least one minute under no

load.

4. Let engine idle for one minute.

5. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUP-

PORT” mode with CONSULT-II.

6. Rev engine up to 2,500 to 3,500 rpm and hold it for 3 consecu-

tive minutes then release the accelerator pedal completely.

If “INCMP” of “CATALYST” changed to “COMPLT”, go to step 9

7. Wait 5 seconds at idle.

SEF484YF

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420

0420Catalyst system efficiency

below threshold

●Three way catalyst (Manifold) does not operate

properly.

●Three way catalyst (Manifold) does not have

enough oxygen storage capacity.

●Three way catalyst (Manifold)

●Exhaust tube

●Intake air leaks

●Fuel injectors

●Fuel injector leaks

●Spark plug

●Improper ignition timing

PBIB0566E

Page 773 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-443

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00KEU

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfu NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-443

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00KEU

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfu](/img/5/57350/w960_57350-772.png)

TROUBLE DIAGNOSIS

EC-443

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Basic InspectionEBS00KEU

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

–Harness connectors for improper connections

–Wiring harness for improper connections, pinches and cut

–Vacuum hoses for splits, kinks and improper connections

–Hoses and ducts for leaks

–Air cleaner clogging

–Gasket

3. Confirm that electrical or mechanical loads are not applied.

–Headlamp switch is OFF.

–Air conditioner switch is OFF.

–Rear window defogger switch is OFF.

–Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no-

load.

6. Make sure that no DTC is displayed with CONSULT-II or ECM.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding “Diagnostic Procedure”.

>> GO TO 3.

SEF983U

SEF976U

SEF977U

Page 1102 of 3189

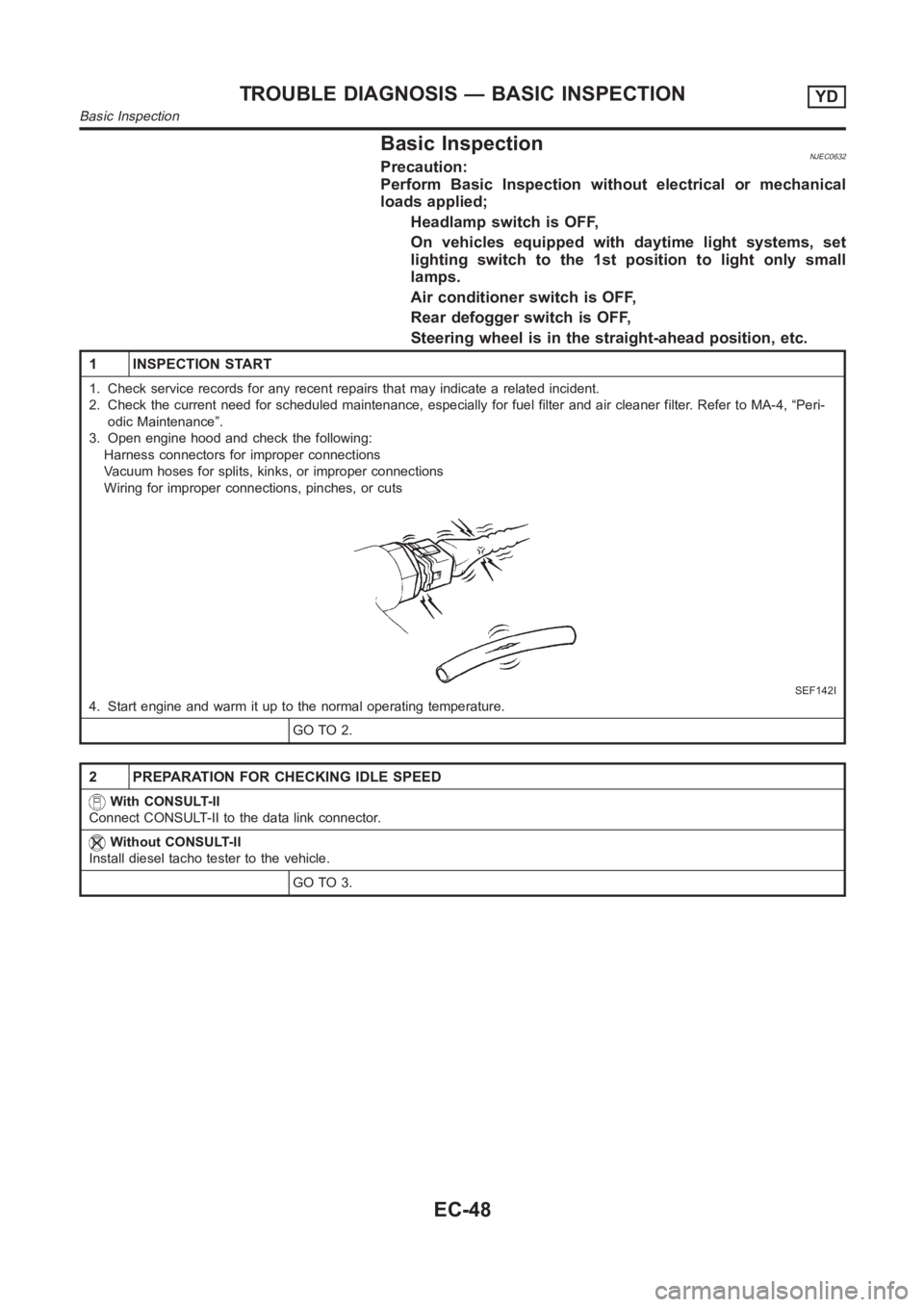

Basic InspectionNJEC0632Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

Headlamp switch is OFF,

On vehicles equipped with daytime light systems, set

lighting switch to the 1st position to light only small

lamps.

Air conditioner switch is OFF,

Rear defogger switch is OFF,

Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a relatedincident.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to MA-4, “Peri-

odic Maintenance”.

3. Open engine hood and check the following:

Harness connectors for improper connections

Vacuum hoses for splits, kinks, or improper connections

Wiring for improper connections, pinches, or cuts

SEF142I

4. Start engine and warm it up to the normal operating temperature.

GO TO 2.

2 PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

Without CONSULT-II

Install diesel tacho tester to the vehicle.

GO TO 3.

TROUBLE DIAGNOSIS — BASIC INSPECTIONYD

Basic Inspection

EC-48

Page 2070 of 3189

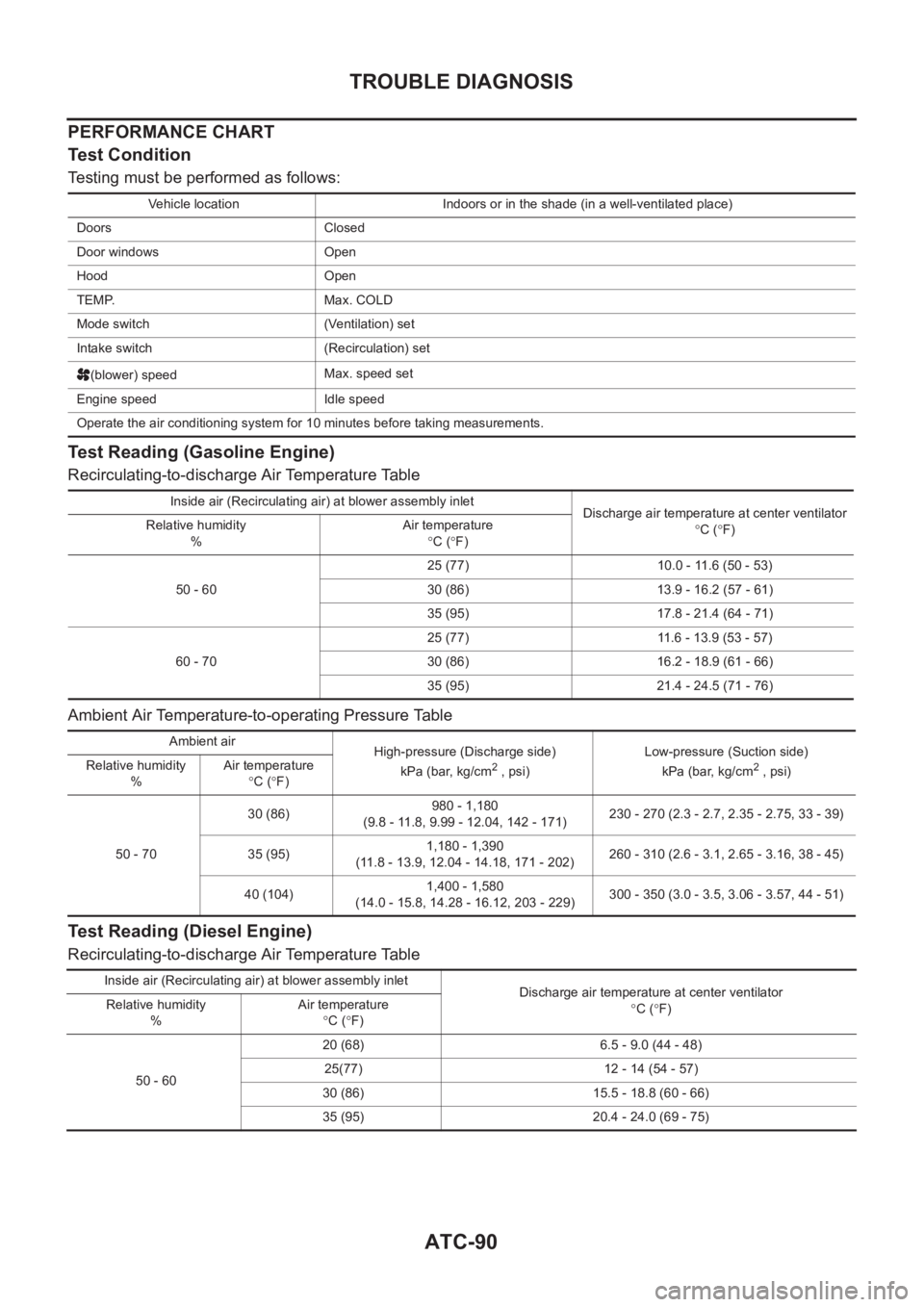

ATC-90

TROUBLE DIAGNOSIS

PERFORMANCE CHART

Test Condition

Testing must be performed as follows:

Test Reading (Gasoline Engine)

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Test Reading (Diesel Engine)

Recirculating-to-discharge Air Temperature Table

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door windows Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Intake switch (Recirculation) set

(blower) speedMax. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C (°F) Relative humidity

%Air temperature

°C (°F)

50 - 6025 (77) 10.0 - 11.6 (50 - 53)

30 (86) 13.9 - 16.2 (57 - 61)

35 (95) 17.8 - 21.4 (64 - 71)

60 - 7025 (77) 11.6 - 13.9 (53 - 57)

30 (86) 16.2 - 18.9 (61 - 66)

35 (95) 21.4 - 24.5 (71 - 76)

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2 , psi)Low-pressure (Suction side)

kPa (bar, kg/cm2 , psi) Relative humidity

%Air temperature

°C (°F)

50 - 7030 (86)980 - 1,180

(9.8 - 11.8, 9.99 - 12.04, 142 - 171)230 - 270 (2.3 - 2.7, 2.35 - 2.75, 33 - 39)

35 (95)1,180 - 1,390

(11.8 - 13.9, 12.04 - 14.18, 171 - 202)260 - 310 (2.6 - 3.1, 2.65 - 3.16, 38 - 45)

40 (104)1,400 - 1,580

(14.0 - 15.8, 14.28 - 16.12, 203 - 229)300 - 350 (3.0 - 3.5, 3.06 - 3.57, 44 - 51)

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C (°F) Relative humidity

%Air temperature

°C (°F)

50 - 6020 (68) 6.5 - 9.0 (44 - 48)

25(77) 12 - 14 (54 - 57)

30 (86) 15.5 - 18.8 (60 - 66)

35 (95) 20.4 - 24.0 (69 - 75)

Page 2264 of 3189

Checking Body CorrosionNJBT0033Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel fillerlid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

Checking Body Corrosion

BT-6

Page 2265 of 3189

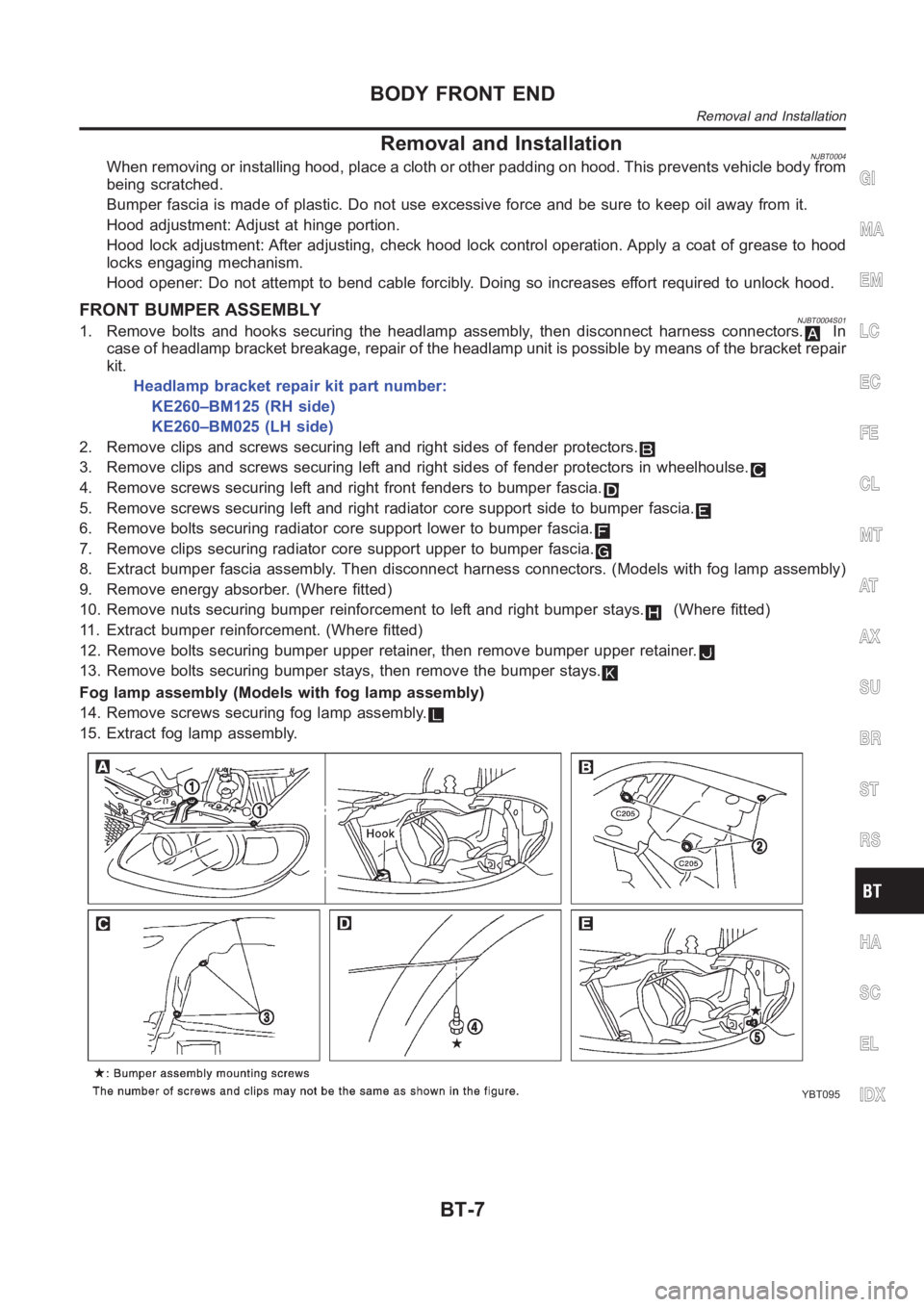

Removal and InstallationNJBT0004When removing or installing hood, place a cloth or other padding on hood. This prevents vehicle body from

being scratched.

Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

Hood adjustment: Adjust at hinge portion.

Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

FRONT BUMPER ASSEMBLYNJBT0004S011. Remove bolts and hooks securing the headlamp assembly, then disconnectharness connectors.In

case of headlamp bracket breakage, repair of the headlamp unit is possibleby means of the bracket repair

kit.

Headlamp bracket repair kit part number:

KE260–BM125 (RH side)

KE260–BM025 (LH side)

2. Remove clips and screws securing left and right sides of fender protectors.

3. Remove clips and screws securing left and right sides of fender protectors in wheelhoulse.

4. Remove screws securing left and right front fenders to bumper fascia.

5. Remove screws securing left and right radiator core support side to bumper fascia.

6. Remove bolts securing radiator core support lower to bumper fascia.

7. Remove clips securing radiator core support upper to bumper fascia.

8. Extract bumper fascia assembly. Then disconnect harness connectors. (Models with fog lamp assembly)

9. Remove energy absorber. (Where fitted)

10. Remove nuts securing bumper reinforcement to left and right bumper stays.

(Where fitted)

11. Extract bumper reinforcement. (Where fitted)

12. Remove bolts securing bumper upper retainer, then remove bumper upperretainer.

13. Remove bolts securing bumper stays, then remove the bumper stays.

Fog lamp assembly (Models with fog lamp assembly)

14. Remove screws securing fog lamp assembly.

15. Extract fog lamp assembly.

YBT095

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY FRONT END

Removal and Installation

BT-7

Page 2704 of 3189

DescriptionNJEL0583The Smart Entrance Control Unit is applied for QG engine models and YD engine models with common rail.

OUTLINENJEL0583S01The smart entrance control unit totally controls the following body electrical system operations.

Warning chime, refer to EL-136, “WARNING CHIME”.

Rear defogger and door mirror defogger, refer to EL-173, “REAR WINDOW DEFOGGER”.

Power door lock, refer to EL-261, “POWER DOOR LOCK SYSTEM”.

Power door lock - Super lock - (RHD models), refer to EL-301, “POWER DOOR LOCK — SUPER LOCK

—”.

Multi-remote control system, refer to EL-352, “MULTI-REMOTE CONTROL SYSTEM”.

NATS (Nissan Anti-Theft system), refer to EL-386, “NATS (NISSAN ANTI-THEFT SYSTEM)”.

Interior lamp, refer to EL-80, “INTERIOR ROOM LAMP”.

Also, smart entrance control unit has the “sleep/wake-up control” function. Smart entrance control unit puts

itself (the whole smart entrance control unit) to sleep under certain conditions to prevent unnecessary power

consumption. Then, when a certain input is detected, the system wakes itself up. For more detailed

information, refer to EL-368, “SLEEP/WAKE-UP CONTROL”.

INTERIOR LAMP/SPOT LAMP/VANITY MIRROR ILLUMINATIONNJEL0583S02The lamps turn off automatically when the interior lamp, spot lamp or/and vanity mirror illumination are illumi-

nated with the ignition key in the OFF position, if the lamp remains lit by the door switch open signal or if the

lamp switch is in the ON position for more than 30 minutes.

After lamps are turned off by the smart entrance control unit, the lamps illuminate again when:

Driver’s door is locked or unlocked with remote controller, door lock/unlock switch or door key cylinder.

Ignition switch is turned to ON.

Door is opened or closed,

Key is inserted into ignition key cylinder.

REAR WINDOW DEFOGGER/DOOR MIRROR DEFOGGERNJEL0583S03Rear window defogger is turned off in approximately 15 minutes after the rear window defogger switch is turned

on.

SLEEP/WAKE-UP CONTROLNJEL0583S04Sleep ControlNJEL0583S0401“Sleep” control prevents unnecessary power consumption. After the following conditions are met, the smart

entrance control unit suspends the operation. The whole smart entrance control unit is set in the “sleep” mode.

Ignition switch “OFF”

All electrical loads (in the smart entrance control unit) “OFF”

Timer “OFF”

Each switch do not input

Wake-up ControlNJEL0583S0402When the smart entrance control unit detects a “wake-up” signal, it wakes up the whole system and starts

operating again. When any one of the following switches are turned ON, the “sleep” mode is canceled:

Ignition switch

Hazard switch

Headlamp switch

Hood switch

Trunk room lamp switch (sedan models)

Back door switch (hatchback or wagon models)

Each door switch

Trunk release switch (sedan models)

Back door release switch (hatchback or wagon models)

External trunk release switch (sedan models)

External back door release switch (hatchback or wagon models)

SMART ENTRANCE CONTROL SYSTEM

Description

EL-368