rims NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 58 of 3189

NJMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard tothe conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 201 of 3189

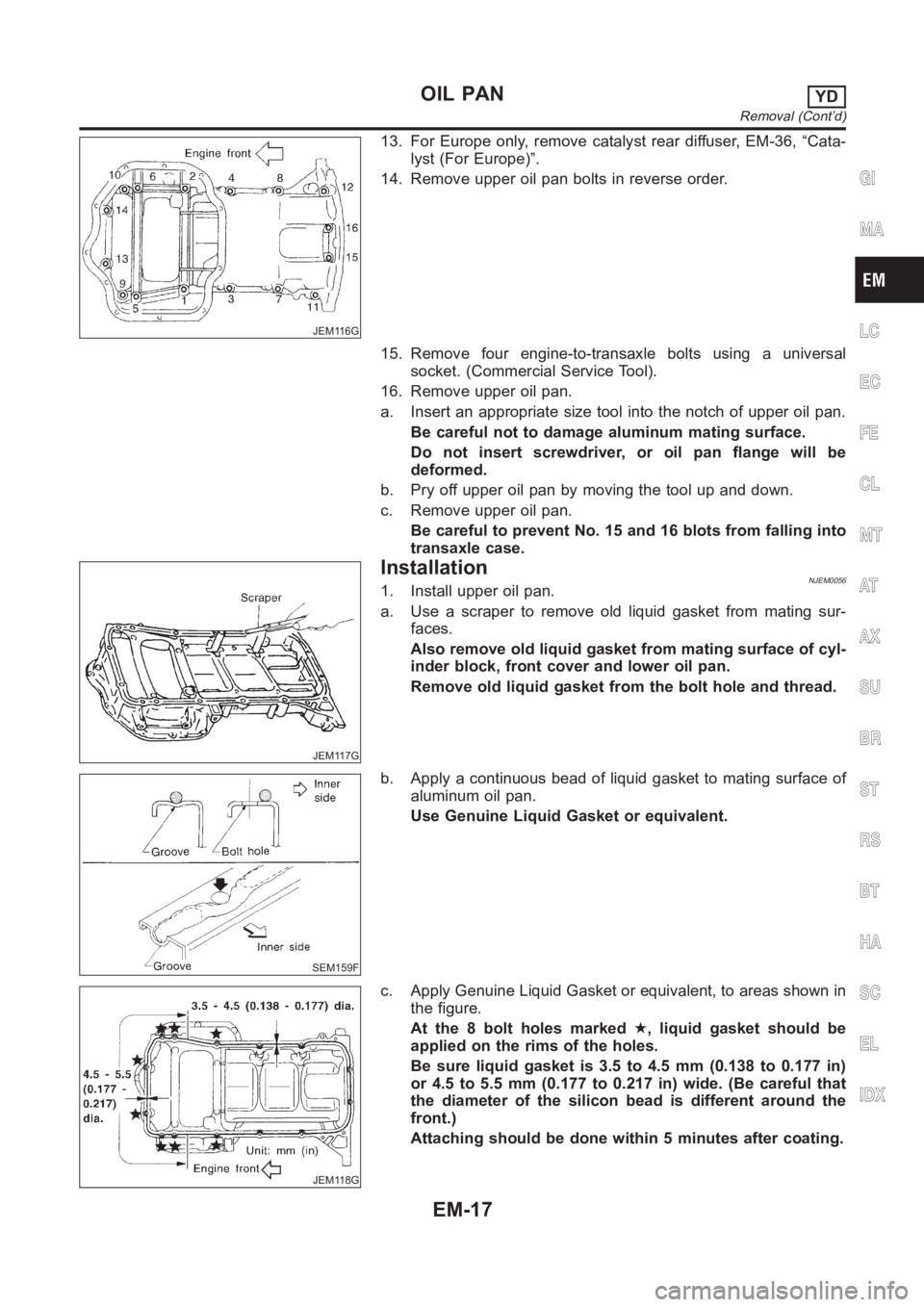

JEM116G

13. For Europe only, remove catalyst rear diffuser, EM-36, “Cata-

lyst (For Europe)”.

14. Remove upper oil pan bolts in reverse order.

15. Remove four engine-to-transaxle bolts using a universal

socket. (Commercial Service Tool).

16. Remove upper oil pan.

a. Insert an appropriate size tool into the notch of upper oil pan.

Be careful not to damage aluminum mating surface.

Do not insert screwdriver, or oil pan flange will be

deformed.

b. Pry off upper oil pan by moving the tool up and down.

c. Remove upper oil pan.

Be careful to prevent No. 15 and 16 blots from falling into

transaxle case.

JEM117G

InstallationNJEM00561. Install upper oil pan.

a. Use a scraper to remove old liquid gasket from mating sur-

faces.

Also remove old liquid gasket from mating surface of cyl-

inder block, front cover and lower oil pan.

Remove old liquid gasket from the bolt hole and thread.

SEM159F

b. Apply a continuous bead of liquid gasket to mating surface of

aluminum oil pan.

Use Genuine Liquid Gasket or equivalent.

JEM118G

c. Apply Genuine Liquid Gasket or equivalent, to areas shown in

the figure.

At the 8 bolt holes marked★, liquid gasket should be

applied on the rims of the holes.

Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in)

or 4.5 to 5.5 mm (0.177 to 0.217 in) wide. (Be careful that

the diameter of the silicon bead is different around the

front.)

Attaching should be done within 5 minutes after coating.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PANYD

Removal (Cont’d)

EM-17