coolant NISSAN ALMERA TINO 2001 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 444 of 3051

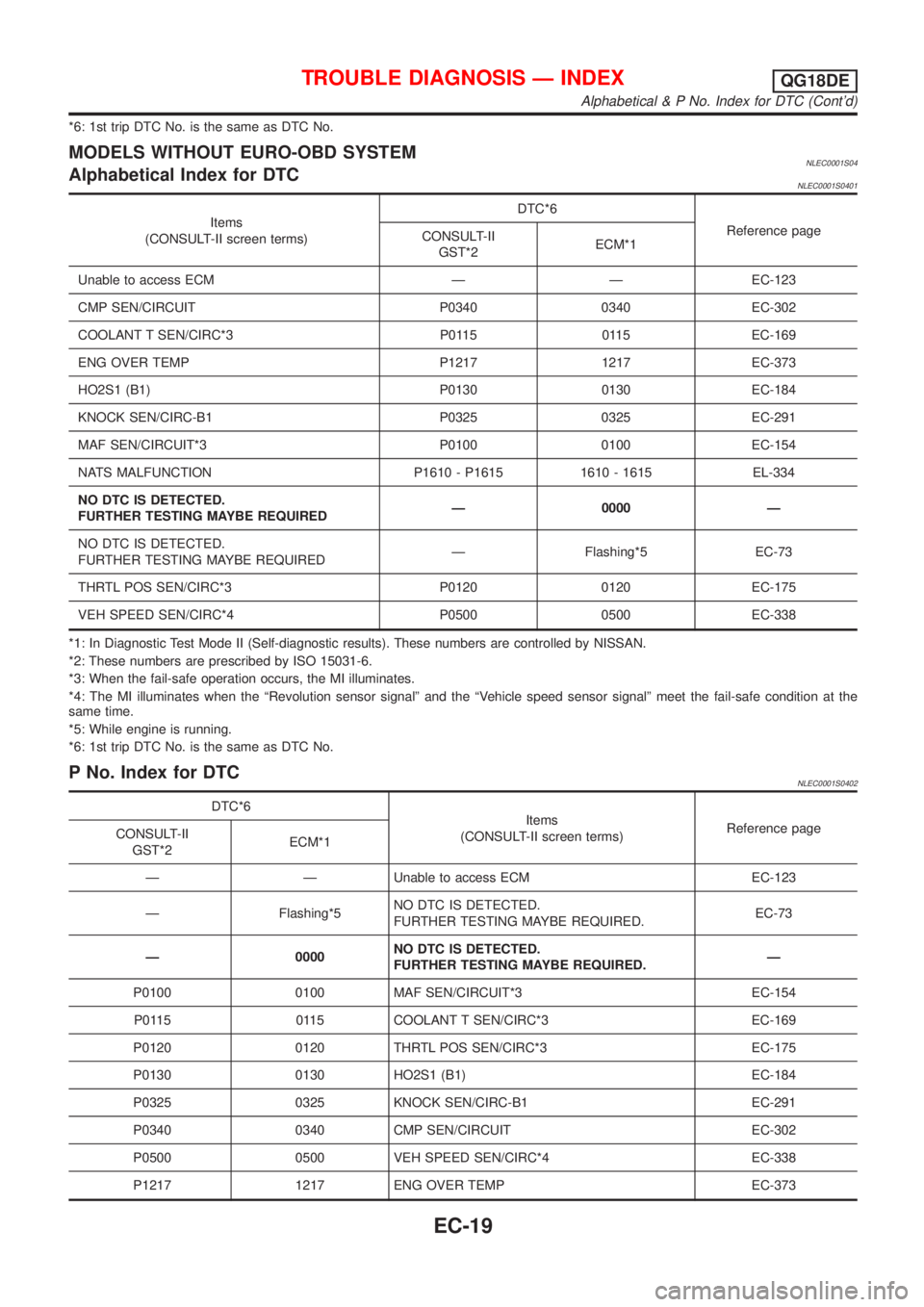

*6: 1st trip DTC No. is the same as DTC No.

MODELS WITHOUT EURO-OBD SYSTEMNLEC0001S04Alphabetical Index for DTCNLEC0001S0401

Items

(CONSULT-II screen terms)DTC*6

Reference page

CONSULT-II

GST*2ECM*1

Unable to access ECM Ð Ð EC-123

CMP SEN/CIRCUIT P0340 0340 EC-302

COOLANT T SEN/CIRC*3 P0115 0115 EC-169

ENG OVER TEMP P1217 1217 EC-373

HO2S1 (B1) P0130 0130 EC-184

KNOCK SEN/CIRC-B1 P0325 0325 EC-291

MAF SEN/CIRCUIT*3 P0100 0100 EC-154

NATS MALFUNCTION P1610 - P1615 1610 - 1615 EL-334

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ 0000 Ð

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ Flashing*5 EC-73

THRTL POS SEN/CIRC*3 P0120 0120 EC-175

VEH SPEED SEN/CIRC*4 P0500 0500 EC-338

*1: In Diagnostic Test Mode II (Self-diagnostic results). These numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO 15031-6.

*3: When the fail-safe operation occurs, the MI illuminates.

*4: The MI illuminates when the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at the

same time.

*5: While engine is running.

*6: 1st trip DTC No. is the same as DTC No.

P No. Index for DTCNLEC0001S0402

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1

Ð Ð Unable to access ECM EC-123

Ð Flashing*5NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.EC-73

Ð 0000NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.Ð

P0100 0100 MAF SEN/CIRCUIT*3 EC-154

P0115 0115 COOLANT T SEN/CIRC*3 EC-169

P0120 0120 THRTL POS SEN/CIRC*3 EC-175

P0130 0130 HO2S1 (B1) EC-184

P0325 0325 KNOCK SEN/CIRC-B1 EC-291

P0340 0340 CMP SEN/CIRCUIT EC-302

P0500 0500 VEH SPEED SEN/CIRC*4 EC-338

P1217 1217 ENG OVER TEMP EC-373

TROUBLE DIAGNOSIS Ð INDEXQG18DE

Alphabetical & P No. Index for DTC (Cont'd)

EC-19

Page 459 of 3051

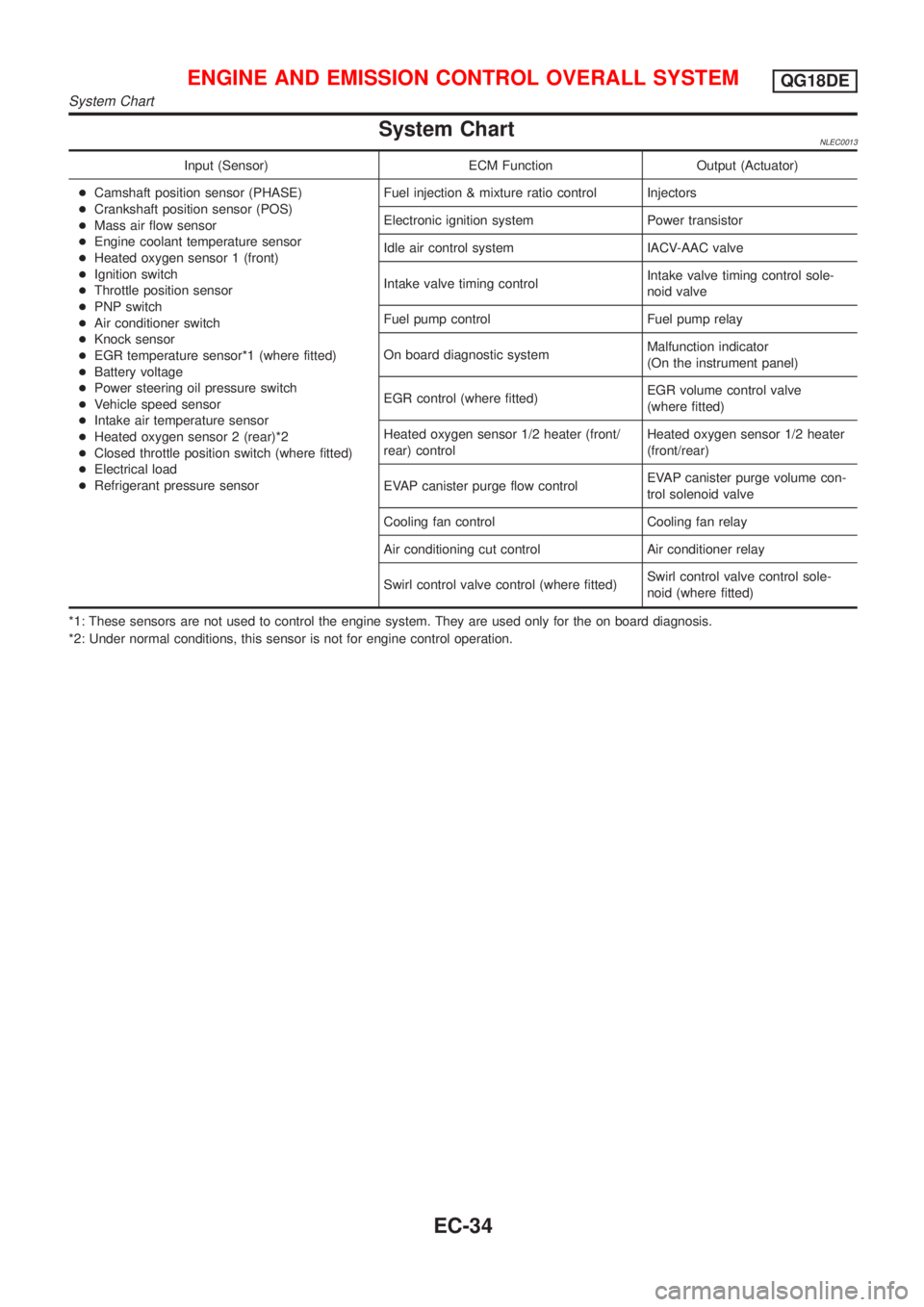

System ChartNLEC0013

Input (Sensor) ECM Function Output (Actuator)

+Camshaft position sensor (PHASE)

+Crankshaft position sensor (POS)

+Mass air flow sensor

+Engine coolant temperature sensor

+Heated oxygen sensor 1 (front)

+Ignition switch

+Throttle position sensor

+PNP switch

+Air conditioner switch

+Knock sensor

+EGR temperature sensor*1 (where fitted)

+Battery voltage

+Power steering oil pressure switch

+Vehicle speed sensor

+Intake air temperature sensor

+Heated oxygen sensor 2 (rear)*2

+Closed throttle position switch (where fitted)

+Electrical load

+Refrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Intake valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

On board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control (where fitted)EGR volume control valve

(where fitted)

Heated oxygen sensor 1/2 heater (front/

rear) controlHeated oxygen sensor 1/2 heater

(front/rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Swirl control valve control (where fitted)Swirl control valve control sole-

noid (where fitted)

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG18DE

System Chart

EC-34

Page 460 of 3051

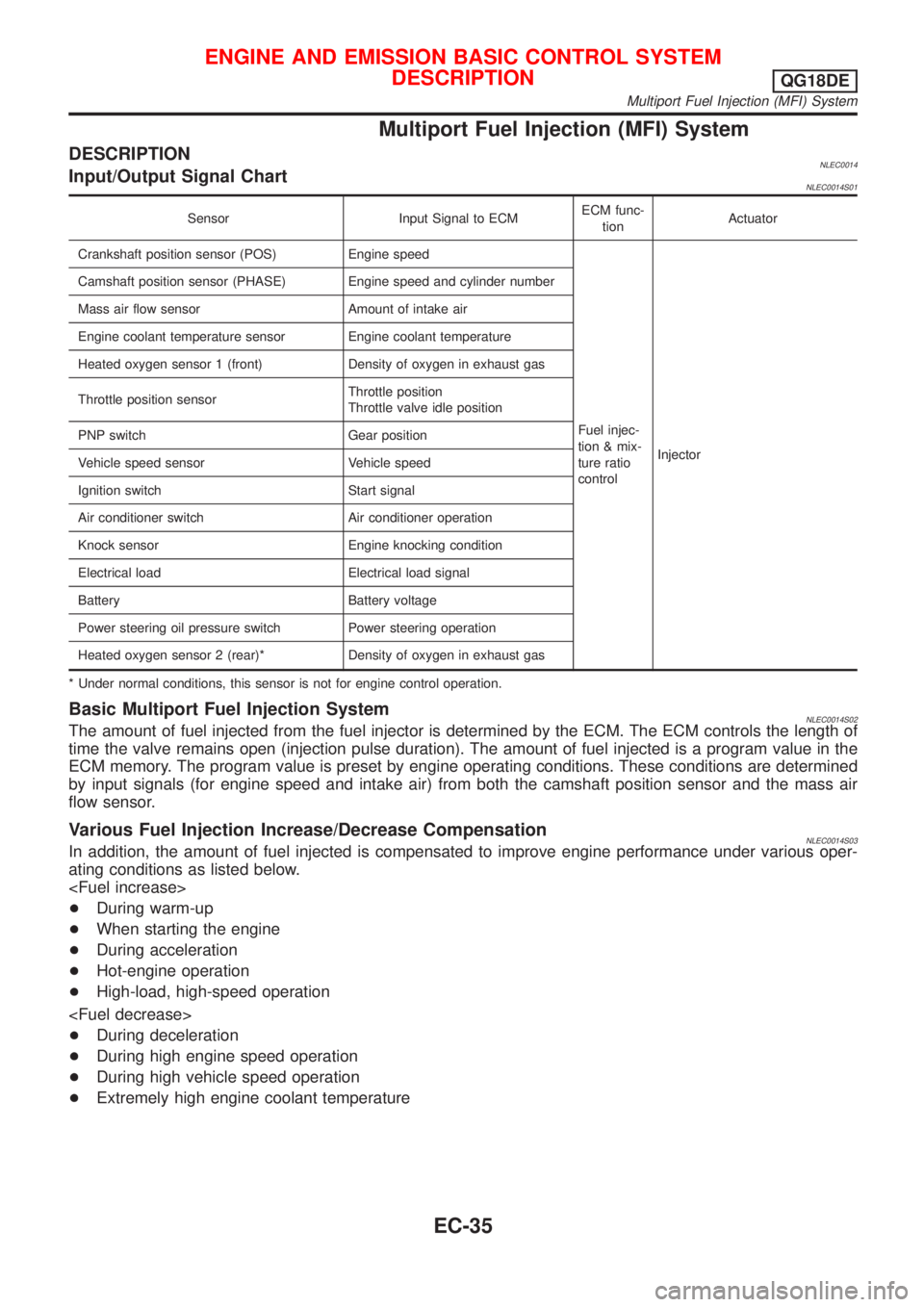

Multiport Fuel Injection (MFI) System

DESCRIPTIONNLEC0014Input/Output Signal ChartNLEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Fuel injec-

tion & mix-

ture ratio

controlInjector Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 (front) Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

PNP switch Gear position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Electrical load Electrical load signal

Battery Battery voltage

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2 (rear)* Density of oxygen in exhaust gas

* Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNLEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the camshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNLEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

+During warm-up

+When starting the engine

+During acceleration

+Hot-engine operation

+High-load, high-speed operation

+During deceleration

+During high engine speed operation

+During high vehicle speed operation

+Extremely high engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Multiport Fuel Injection (MFI) System

EC-35

Page 461 of 3051

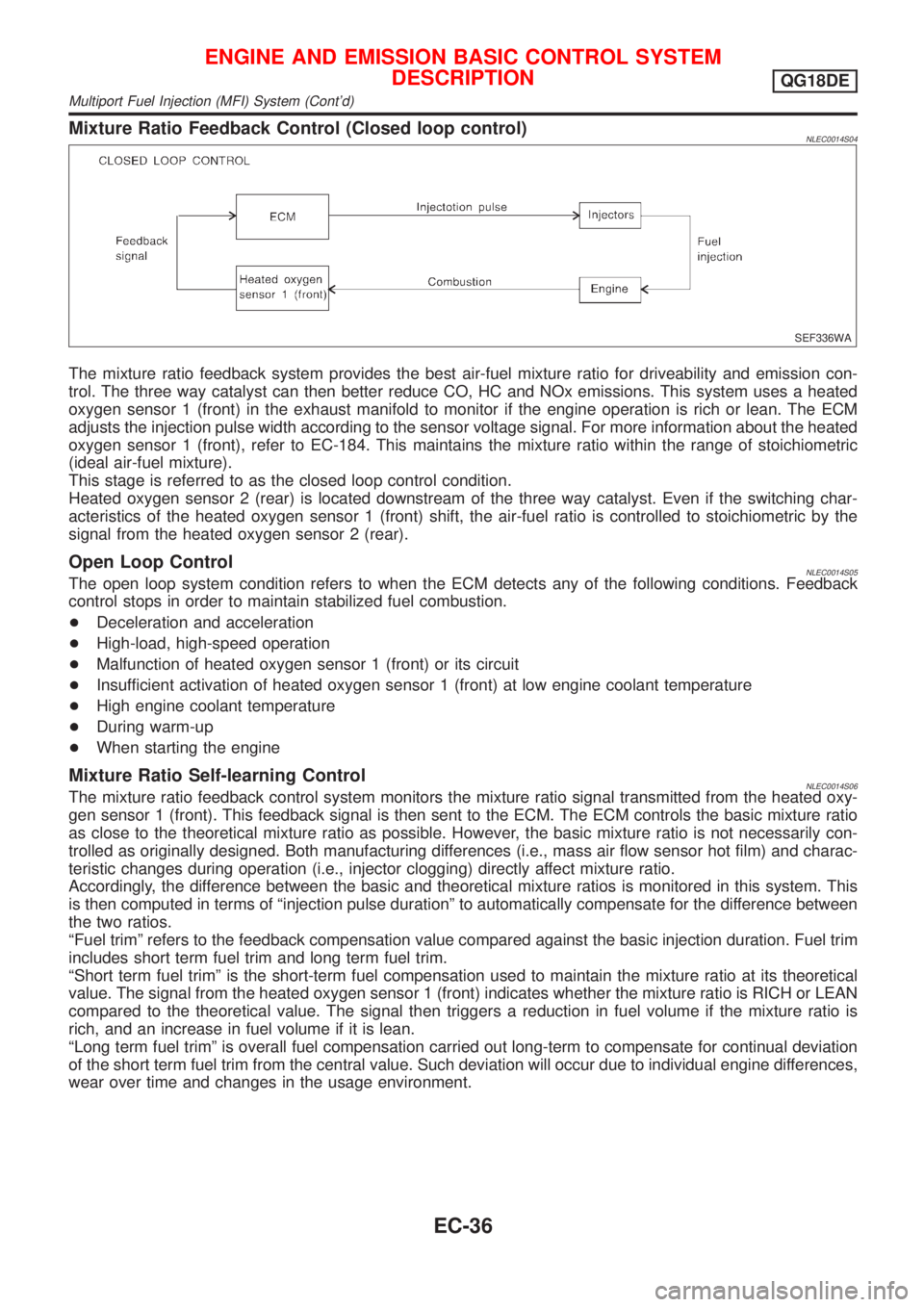

Mixture Ratio Feedback Control (Closed loop control)NLEC0014S04

SEF336WA

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission con-

trol. The three way catalyst can then better reduce CO, HC and NOx emissions. This system uses a heated

oxygen sensor 1 (front) in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about the heated

oxygen sensor 1 (front), refer to EC-184. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 (rear) is located downstream of the three way catalyst. Even if the switching char-

acteristics of the heated oxygen sensor 1 (front) shift, the air-fuel ratio is controlled to stoichiometric by the

signal from the heated oxygen sensor 2 (rear).

Open Loop ControlNLEC0014S05The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

+Deceleration and acceleration

+High-load, high-speed operation

+Malfunction of heated oxygen sensor 1 (front) or its circuit

+Insufficient activation of heated oxygen sensor 1 (front) at low engine coolant temperature

+High engine coolant temperature

+During warm-up

+When starting the engine

Mixture Ratio Self-learning ControlNLEC0014S06The mixture ratio feedback control system monitors the mixture ratio signal transmitted from the heated oxy-

gen sensor 1 (front). This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio

as close to the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily con-

trolled as originally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and charac-

teristic changes during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This

is then computed in terms of ªinjection pulse durationº to automatically compensate for the difference between

the two ratios.

ªFuel trimº refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

ªShort term fuel trimº is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from the heated oxygen sensor 1 (front) indicates whether the mixture ratio is RICH or LEAN

compared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is

rich, and an increase in fuel volume if it is lean.

ªLong term fuel trimº is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Multiport Fuel Injection (MFI) System (Cont'd)

EC-36

Page 462 of 3051

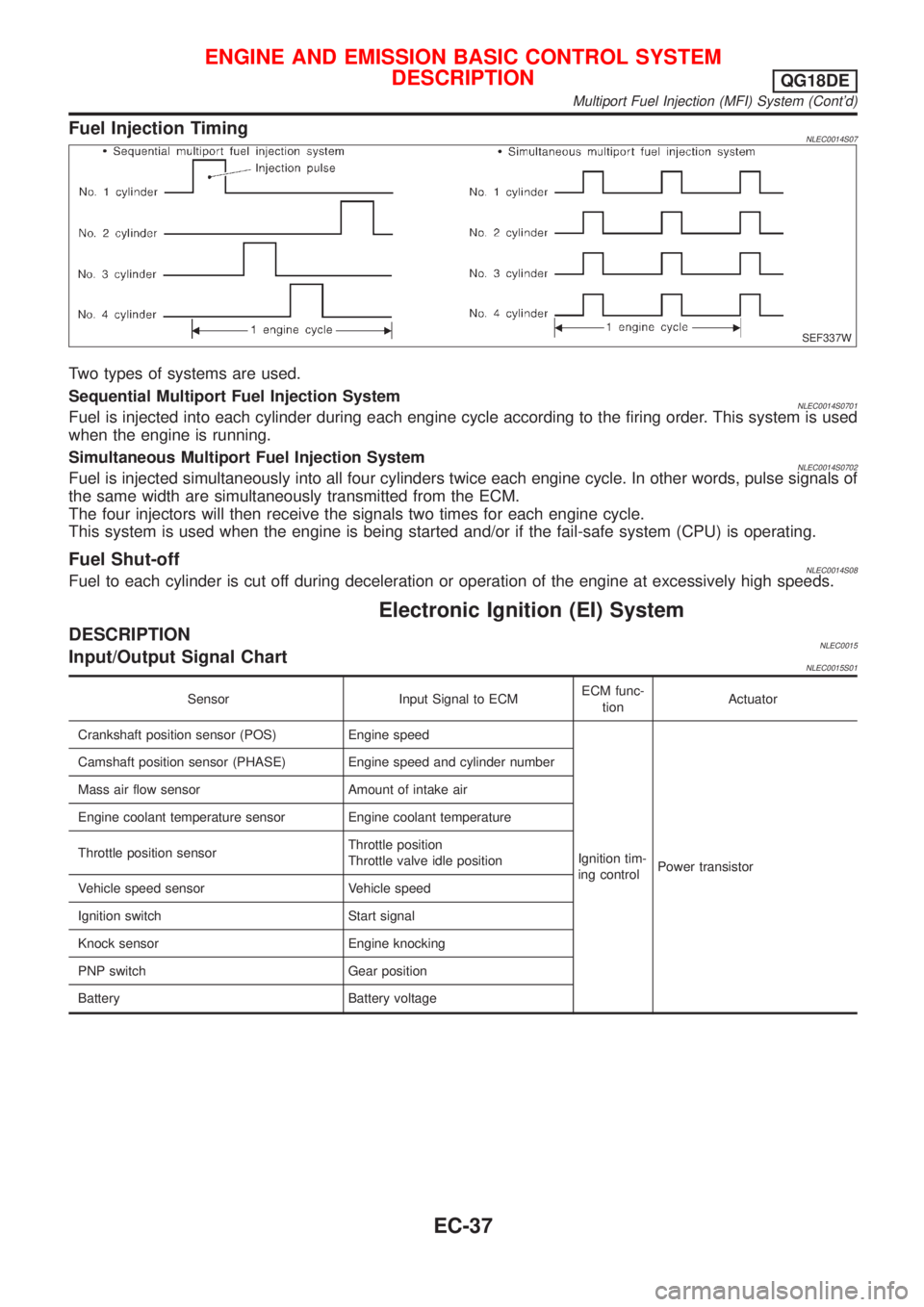

Fuel Injection TimingNLEC0014S07

SEF337W

Two types of systems are used.

Sequential Multiport Fuel Injection System

NLEC0014S0701Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

NLEC0014S0702Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

Fuel Shut-offNLEC0014S08Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Electronic Ignition (EI) System

DESCRIPTIONNLEC0015Input/Output Signal ChartNLEC0015S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Ignition tim-

ing controlPower transistor Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensorThrottle position

Throttle valve idle position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Knock sensor Engine knocking

PNP switch Gear position

Battery Battery voltage

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Multiport Fuel Injection (MFI) System (Cont'd)

EC-37

Page 463 of 3051

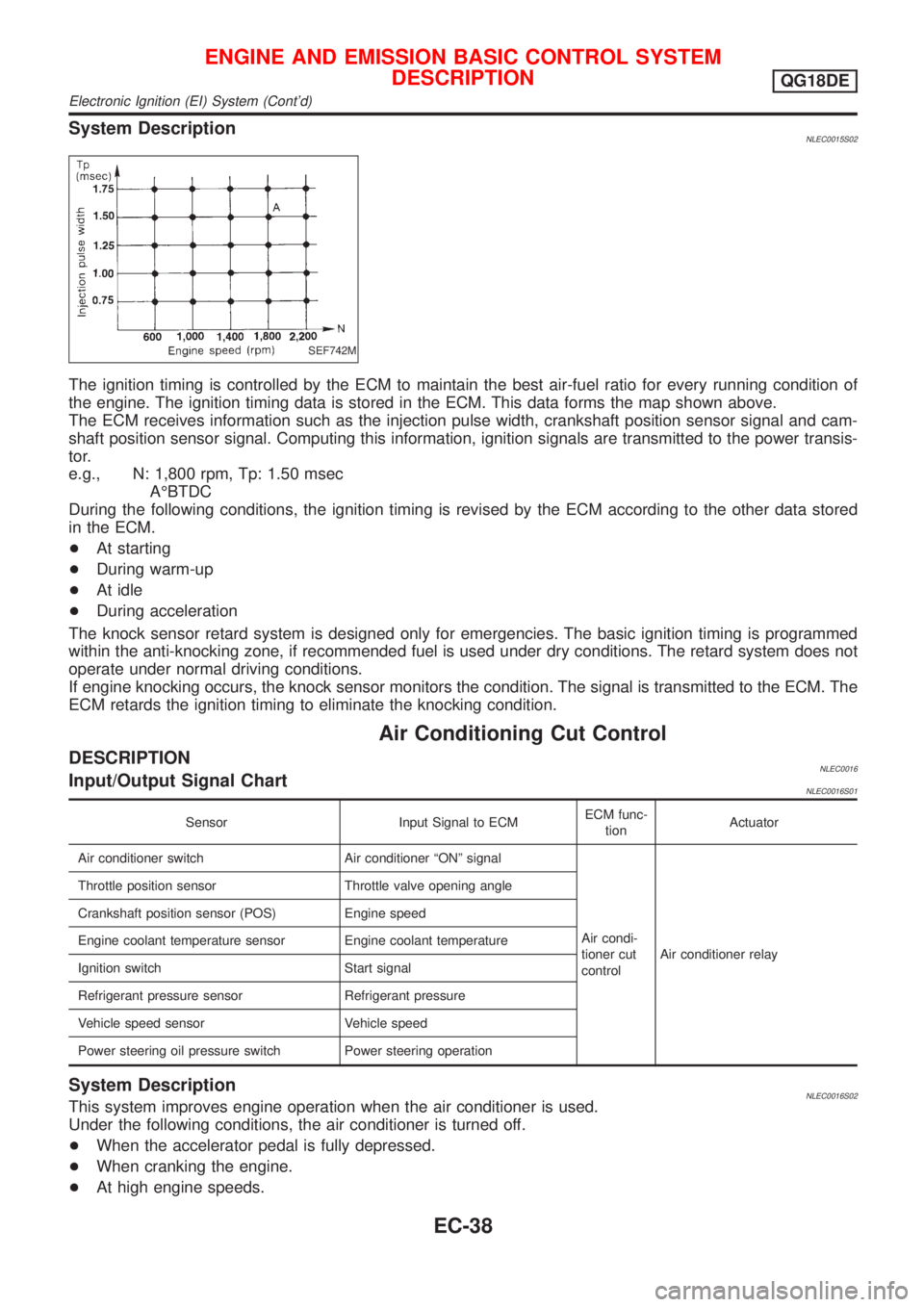

System DescriptionNLEC0015S02

SEF742M

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width, crankshaft position sensor signal and cam-

shaft position sensor signal. Computing this information, ignition signals are transmitted to the power transis-

tor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

+At starting

+During warm-up

+At idle

+During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut Control

DESCRIPTIONNLEC0016Input/Output Signal ChartNLEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Crankshaft position sensor (POS) Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Vehicle speed sensor Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNLEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

+When the accelerator pedal is fully depressed.

+When cranking the engine.

+At high engine speeds.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Electronic Ignition (EI) System (Cont'd)

EC-38

Page 464 of 3051

+When the engine coolant temperature becomes excessively high.

+When operating power steering during low engine speed or low vehicle speed.

+When engine speed is excessively low.

+When the refrigerant pressure is excessively high or low.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTIONNLEC0017Input/Output Signal ChartNLEC0017S01

Sensor Input Signal to ECMECM func-

tionActuator

Vehicle speed sensor Vehicle speed

Fuel cut

controlInjectors PNP switch Neutral position

Throttle position sensor Throttle position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS) Engine speed

Camshaft position sensor (PHASE) Engine speed and cylinder number

If the engine speed is above 3,950 rpm with no load, (for example, in Neutral and engine speed over 4,000

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,150 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªMultiport Fuel Injection (MFI) Systemº,

EC-35.

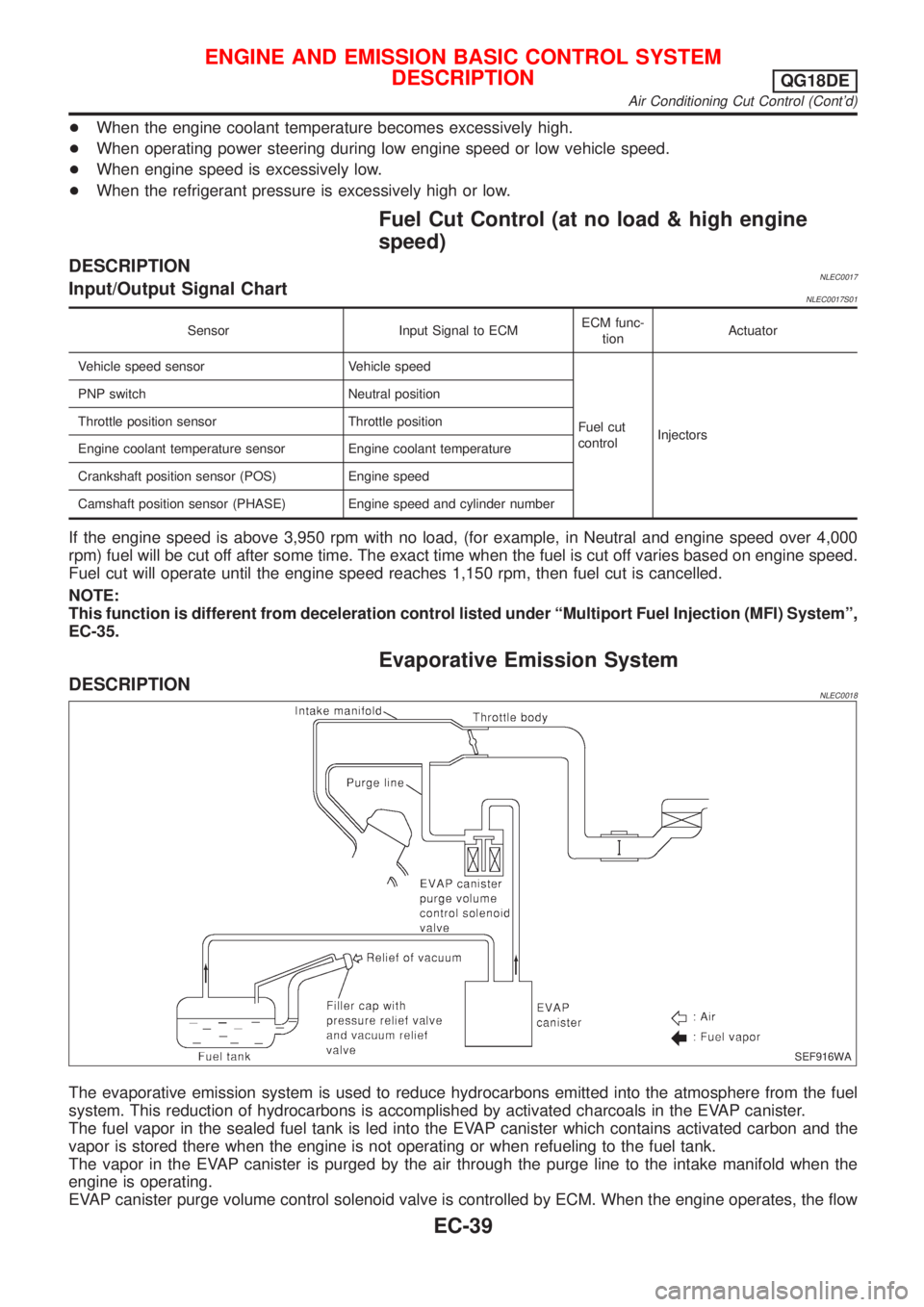

Evaporative Emission System

DESCRIPTIONNLEC0018

SEF916WA

The evaporative emission system is used to reduce hydrocarbons emitted into the atmosphere from the fuel

system. This reduction of hydrocarbons is accomplished by activated charcoals in the EVAP canister.

The fuel vapor in the sealed fuel tank is led into the EVAP canister which contains activated carbon and the

vapor is stored there when the engine is not operating or when refueling to the fuel tank.

The vapor in the EVAP canister is purged by the air through the purge line to the intake manifold when the

engine is operating.

EVAP canister purge volume control solenoid valve is controlled by ECM. When the engine operates, the flow

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Air Conditioning Cut Control (Cont'd)

EC-39

Page 472 of 3051

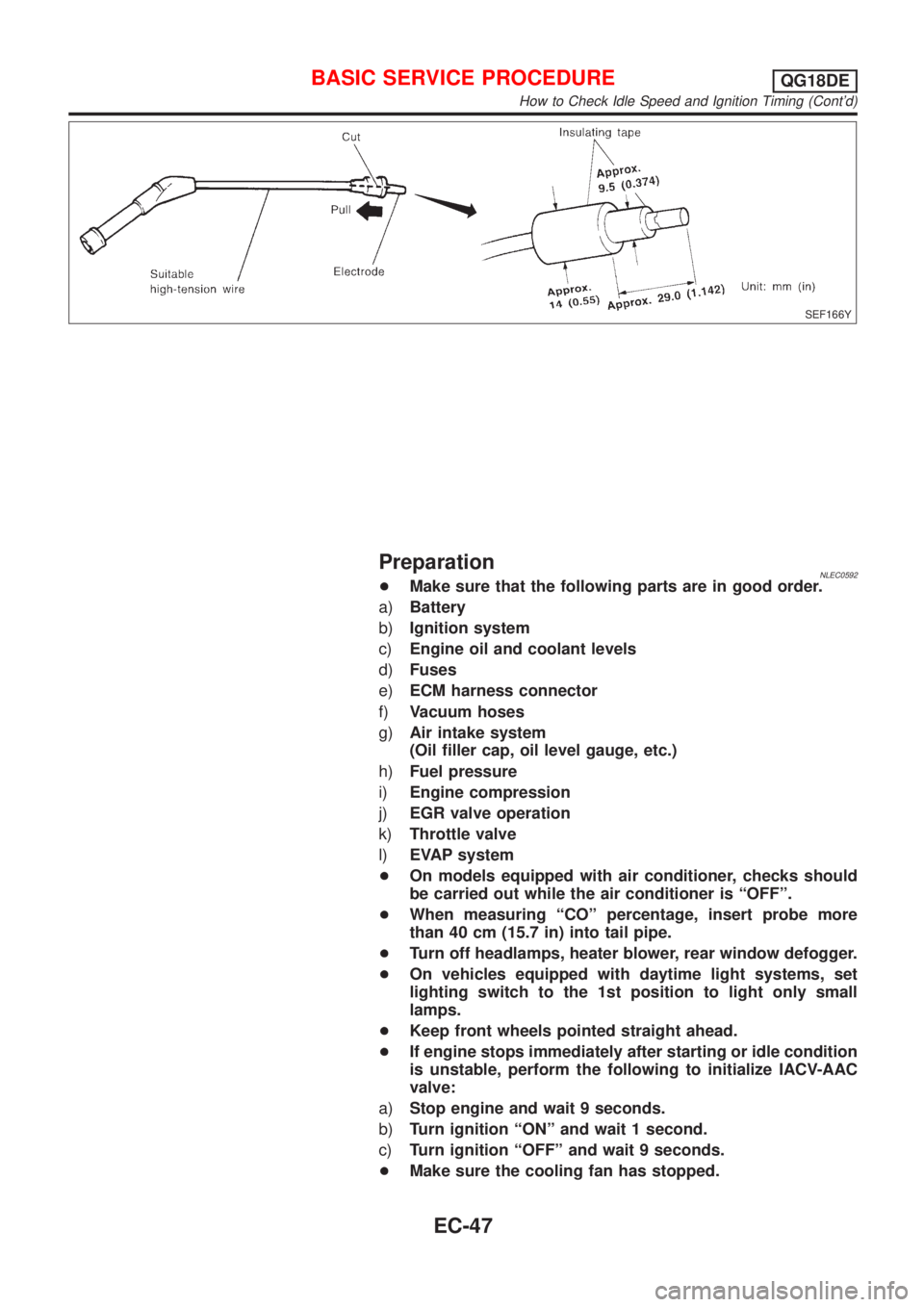

SEF166Y

PreparationNLEC0592+Make sure that the following parts are in good order.

a)Battery

b)Ignition system

c)Engine oil and coolant levels

d)Fuses

e)ECM harness connector

f)Vacuum hoses

g)Air intake system

(Oil filler cap, oil level gauge, etc.)

h)Fuel pressure

i)Engine compression

j)EGR valve operation

k)Throttle valve

l)EVAP system

+On models equipped with air conditioner, checks should

be carried out while the air conditioner is ªOFFº.

+When measuring ªCOº percentage, insert probe more

than 40 cm (15.7 in) into tail pipe.

+Turn off headlamps, heater blower, rear window defogger.

+On vehicles equipped with daytime light systems, set

lighting switch to the 1st position to light only small

lamps.

+Keep front wheels pointed straight ahead.

+If engine stops immediately after starting or idle condition

is unstable, perform the following to initialize IACV-AAC

valve:

a)Stop engine and wait 9 seconds.

b)Turn ignition ªONº and wait 1 second.

c)Turn ignition ªOFFº and wait 9 seconds.

+Make sure the cooling fan has stopped.

BASIC SERVICE PROCEDUREQG18DE

How to Check Idle Speed and Ignition Timing (Cont'd)

EC-47

Page 474 of 3051

Inspection ProcedureNLEC0593

1 INSPECTION START

1. Visually check the following:

+Air cleaner clogging

+Hoses and ducts for leaks

+EGR valve operation

+Electrical connectors

+Gasket

+Throttle valve and throttle position sensor operation

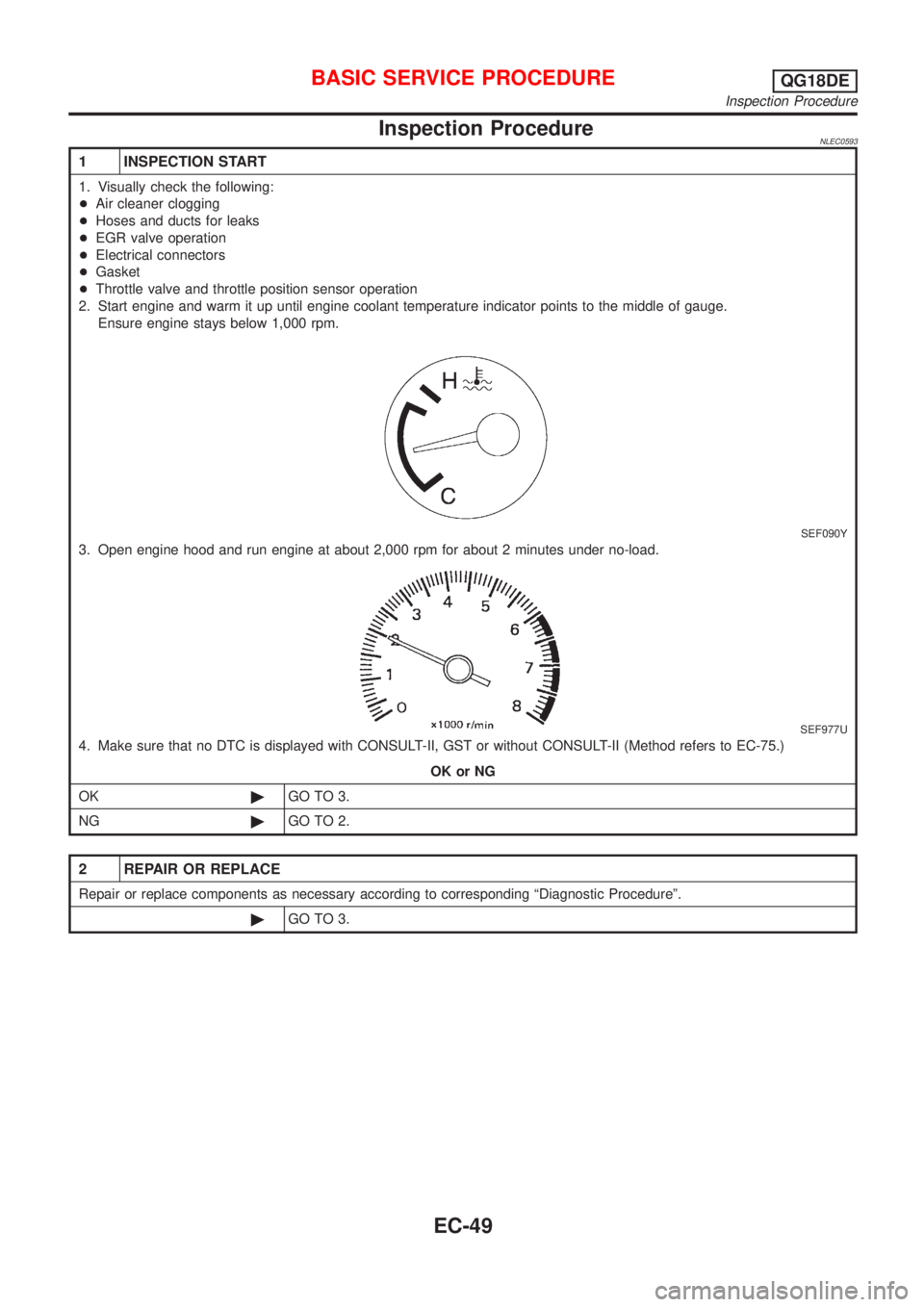

2. Start engine and warm it up until engine coolant temperature indicator points to the middle of gauge.

Ensure engine stays below 1,000 rpm.

SEF090Y

3. Open engine hood and run engine at about 2,000 rpm for about 2 minutes under no-load.

SEF977U

4. Make sure that no DTC is displayed with CONSULT-II, GST or without CONSULT-II (Method refers to EC-75.)

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding ªDiagnostic Procedureº.

©GO TO 3.

BASIC SERVICE PROCEDUREQG18DE

Inspection Procedure

EC-49

Page 478 of 3051

10 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

6. Running engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Set ªHeated oxygen sensor 1 monitor (front)º in the Diagnostic Test Mode II. Refer to EC-73.

4. Run engine at about 2,000 rpm for about 2 minutes under no-load.

5. Maintain engine at 2,000 rpm under no-load and check that MI goes on more than five times within 10 seconds.

OK or NG

OK©INSPECTION END

NG©GO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

1. Check fuel pressure regulator. Refer to EC-44.

2. Check mass air flow sensor and its circuit. Refer to EC-154.

3. Check injector and its circuit. Refer to EC-494.

Clean or replace if necessary.

4. Check engine coolant temperature sensor and its circuit. Refer to EC-169.

5. Check ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

12 CHECK HEATED OXYGEN SENSOR 1 (FRONT) HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) harness connector.

4. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 1.

Refer to Wiring Diagram, EC-184.

Continuity should exist.

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 REPAIR OR REPLACE

Repair or replace harness between ECM and heated oxygen sensor 1 (front).

©GO TO 5.

BASIC SERVICE PROCEDUREQG18DE

Inspection Procedure (Cont'd)

EC-53