ESP NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 9 of 3051

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

EURO-OBD SELF-DIAGNOSISNLAT0004S04+CVT self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the SPORT indicator lamp. Refer to the table on AT-22 for the indicator used to dis-

play each self-diagnostic result.

+The self-diagnostic results indicated by the MI are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure ªHOW TO ERASE DTCº on AT-19 to complete the repair and avoid

unnecessary blinking of the MI.

For details of EURO-OBD, refer to EC section (ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº).

+Certain systems and components, especially those related to EURO-OBD, may use a new style

slide-locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

Wiring Diagrams and Trouble DiagnosesNLAT0005When you read wiring diagrams, refer to the following:

+ªHOW TO READ WIRING DIAGRAMSº in GI section

+ªPOWER SUPPLY ROUTINGº for power distribution circuit in EL section

When you perform trouble diagnoses, refer to the following:

+ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº in GI section

+ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº in GI section

PRECAUTIONS

Service Notice or Precautions (Cont'd)

AT-8

Page 18 of 3051

TCM FUNCTION=NLAT0014S03The function of the TCM is to:

+Receive input signals sent from various switches and sensors.

+Determine required line pressure, shifting point and lock-up operation.

+Send required output signals to the step motor and the respective solenoids.

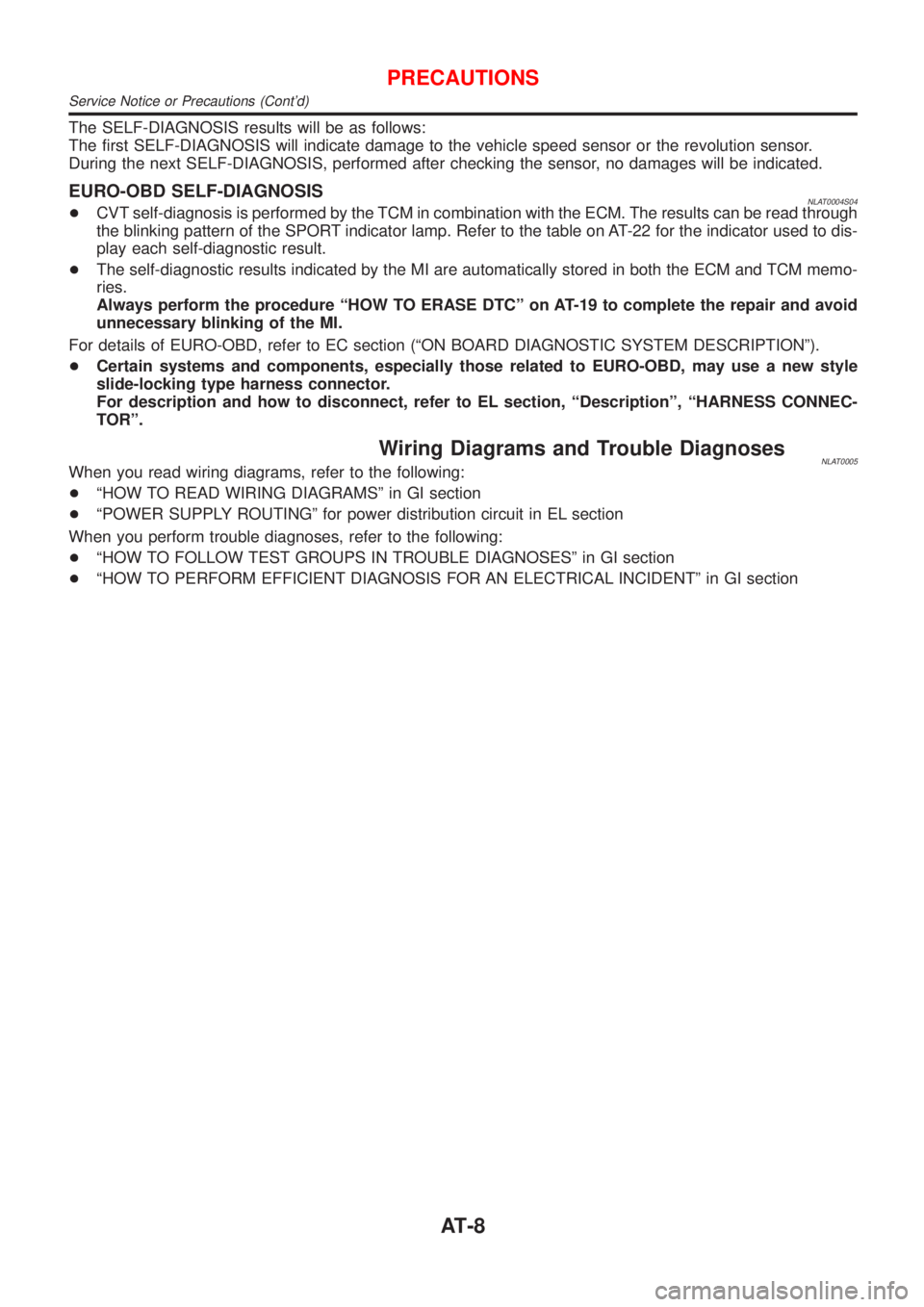

INPUT/OUTPUT SIGNAL OF TCMNLAT0014S04

Switches, sensors and actuators Function

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor Detects throttle valve position and sends a signal to TCM.

Closed throttle position switch Detects throttle valve's fully-closed position and sends a signal to TCM.

Wide open throttle position switchDetects a throttle valve position of greater than 1/2 of full throttle and

sends a signal to TCM.

Engine speed signal From ECM.

CVT fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

CVT fluid pressure sensor Detects transmission fluid pressure and sends a signal to TCM.

Primary speed sensor Detects primary pulley rpm and sends a signal to TCM.

Secondary speed sensor Detects secondary pulley rpm and sends a signal to TCM.

Stop lamp switchSends a signal to the TCM relaying the operation condition of the brake

pedal.

SPORT mode switchSends a signal to the TCM relaying the operation condition of the SPORT

mode switch.

ABS control unit Sends a signal to the TCM operation condition of the ABS.

OutputStep motor Regulates pulley position in relation to a signal sent from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in

relation to a signal sent from TCM.

SPORT indicator lamp Shows the operation condition of the SPORT mode switch.

OVERALL SYSTEM

Control System (Cont'd)

AT-17

Page 19 of 3051

IntroductionNLAT0017The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (EURO-OBD) performed by the TCM in combi-

nation with the ECM. The malfunction is indicated by the MI (malfunction indicator) and is stored as a DTC in

the ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the CVT indicator (warning) lamp or SPORT indi-

cator lamp. The malfunction is stored in the TCM memory. The detected items are overlapped with EURO-

OBD self-diagnostic items. For detail, refer to AT-28.

EURO-OBD Function for CVT SystemNLAT0018The ECM provides emission-related on board diagnostic (EURO-OBD) functions for the CVT system. One

function is to receive a signal from the TCM used with EURO-OBD-related parts of the CVT system. The sig-

nal is sent to the ECM when a malfunction occurs in the corresponding EURO-OBD-related part. The other

function is to indicate a diagnostic result by means of the MI (malfunction indicator) on the instrument panel.

Sensors, switches and solenoid valves are used as sensing elements.

The MI automatically illuminates in Two Trip Detection Logic when a malfunction is sensed in relation to CVT

system parts.

EURO-OBD Diagnostic Trouble Code (DTC)NLAT0020HOW TO READ DTC AND 1ST TRIP DTCNLAT0020S01DTC and 1st trip DTC can be read by the following methods.

1.(

No Tools)The number of blinks of the malfunction indicator in the Diagnostic Test Mode II (Self-Di-

agnostic Results) Examples: 0705, 0710, 0715, 0720, etc. For details, refer to EC section [ªMalfunction

Indicator (MI)º, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº].

These DTCs are controlled by NISSAN.

2.(

with CONSULT-II orGST)CONSULT-II or GST (Generic Scan Tool) Examples: P0705, P0710,

P0720, P0725, etc.

These DTCs are prescribed by ISO15031-6.

(CONSULT-II also displays the malfunctioning component or system.)

+1st trip DTC No. is the same as DTC No.

+Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction.

However, in case of the Mode II and GST they do not indicate whether the malfunction is still

occurring or occurred in the past and returned to normal.

CONSULT-II can identify them as shown below. Therefore, using CONSULT-II (if available) is rec-

ommended.

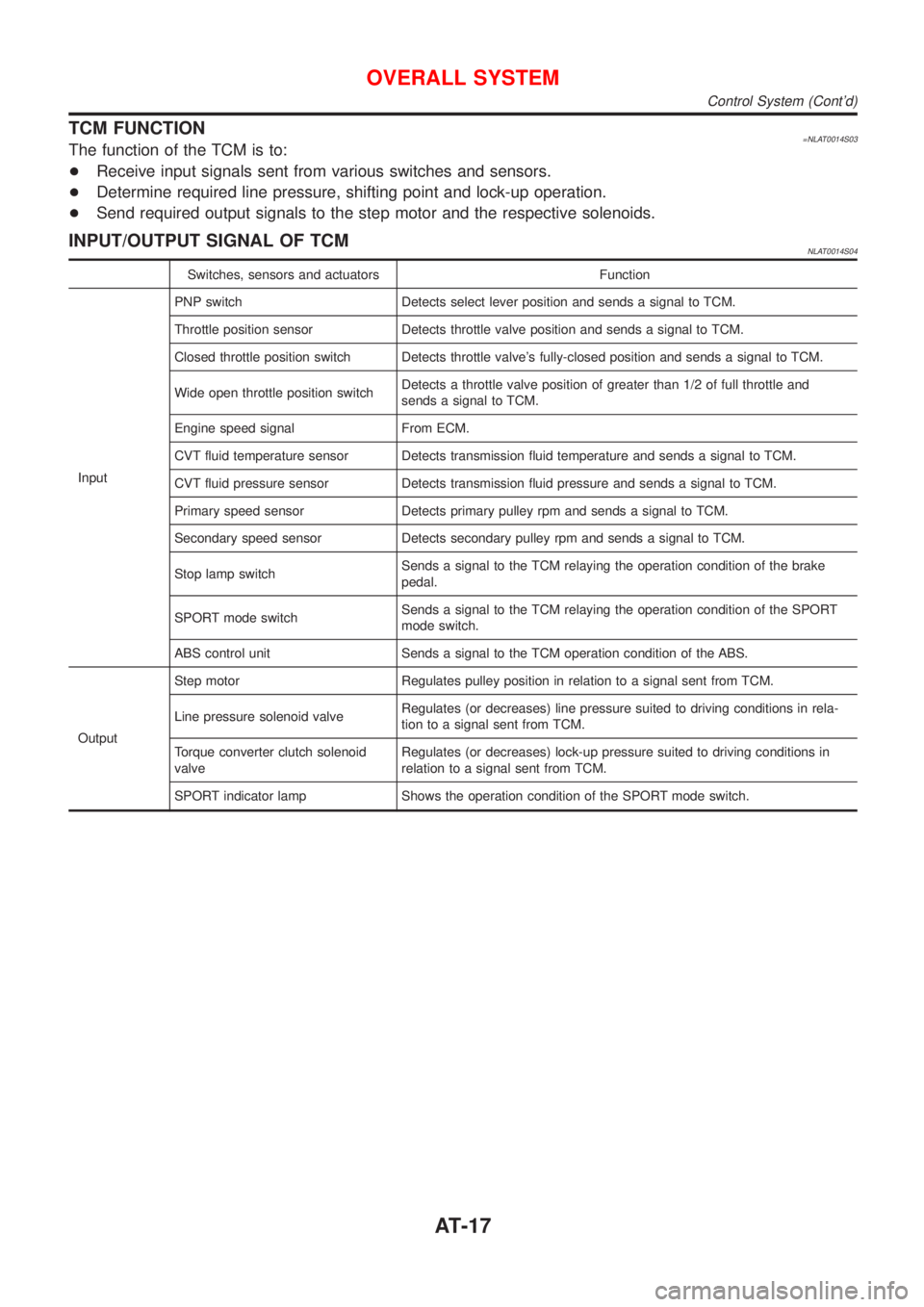

A sample of CONSULT-II display for DTC is shown at left. DTC or 1st trip DTC of a malfunction is displayed

in SELF-DIAGNOSTIC RESULTS mode for ªENGINEº with CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

SAT250K

If the DTC is being detected currently, the time data will be ª0º.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONEURO-OBD

Introduction

AT-18

Page 42 of 3051

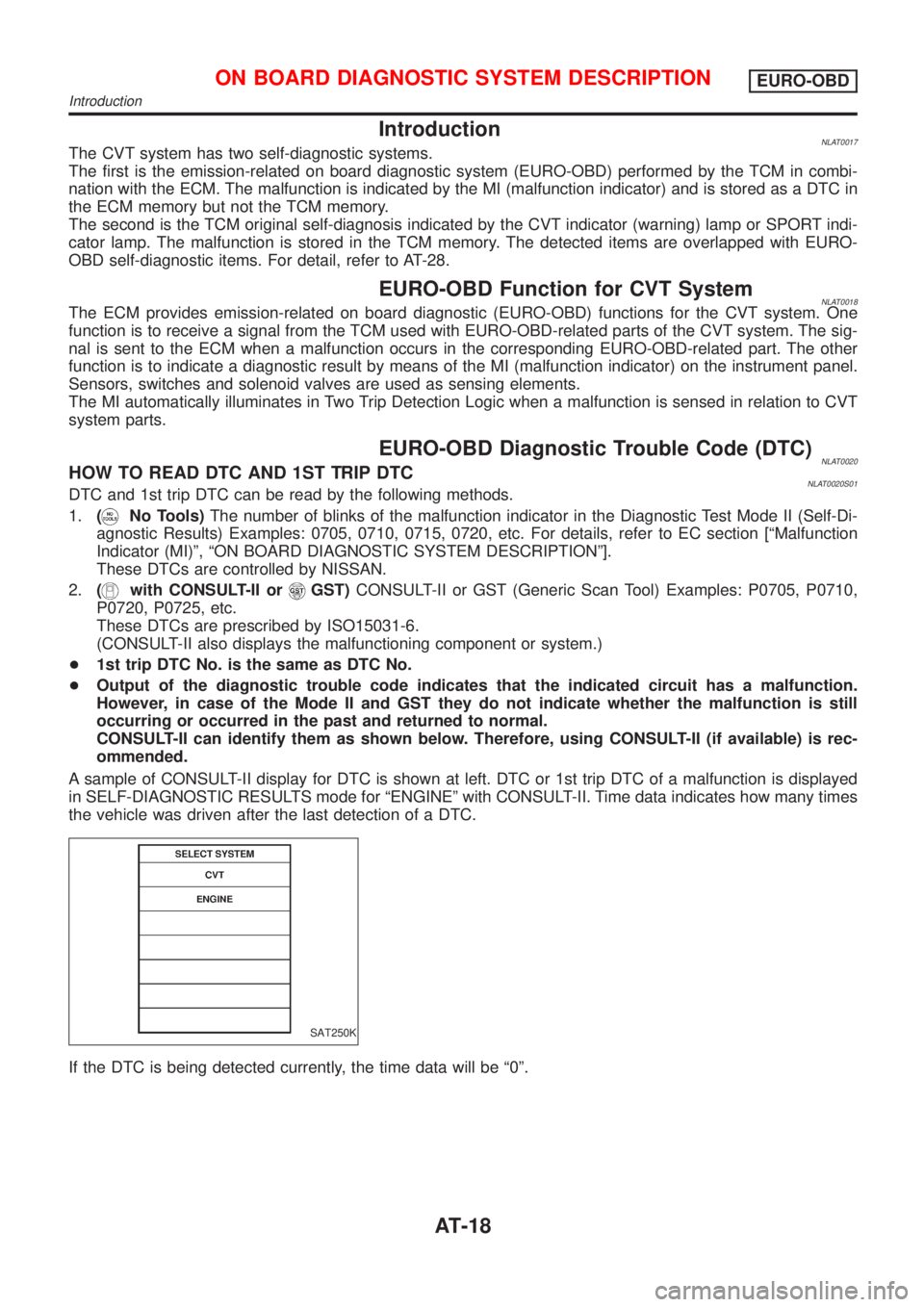

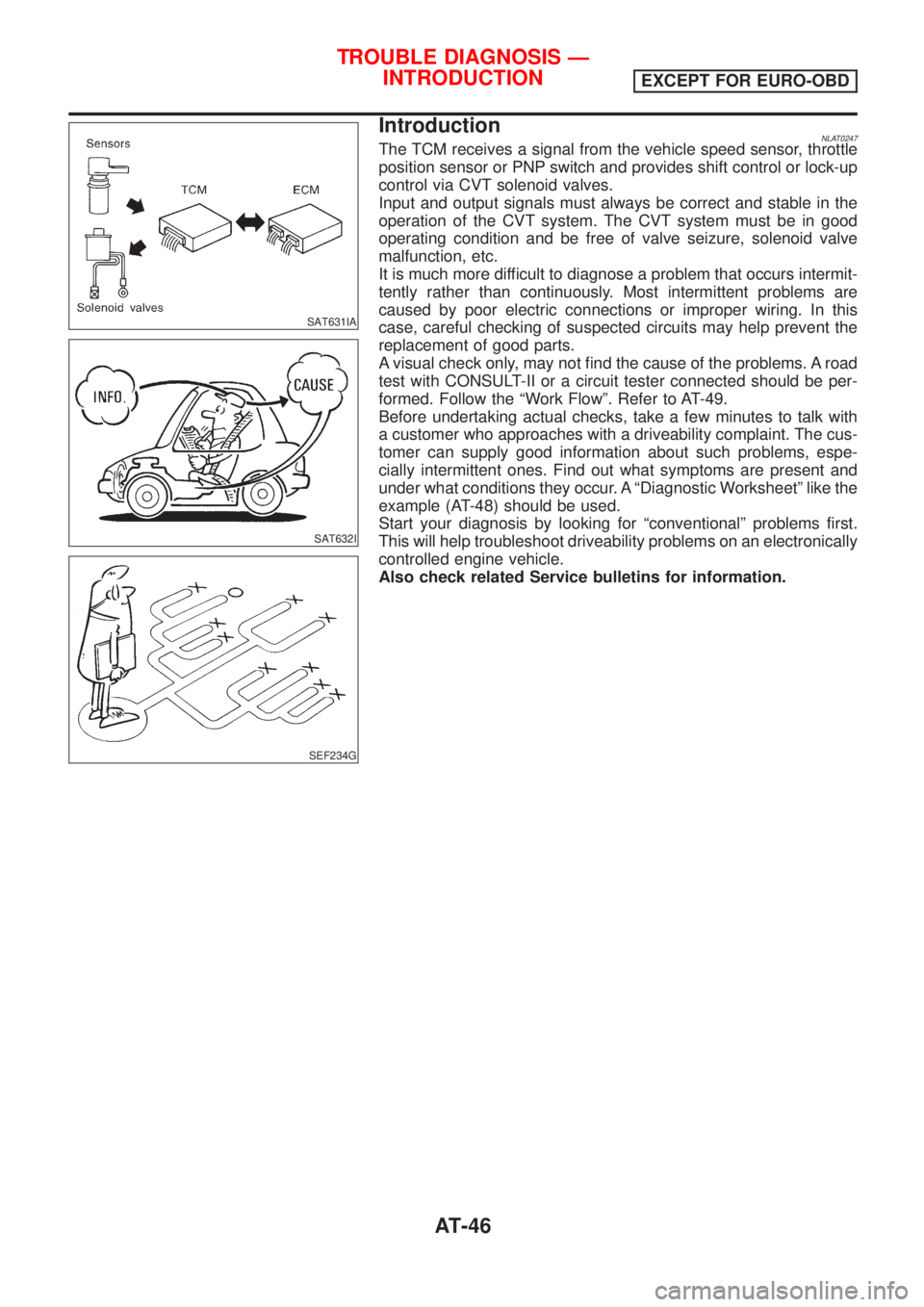

SAT631IA

SAT632I

SEF234G

IntroductionNLAT0023The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via step motor and CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the EURO-OBD-related

parts of the CVT system for malfunction-diagnostic purposes. The

TCM is capable of diagnosing malfunctioning parts while the ECM

can store malfunctions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº. Refer to AT-44.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-43) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

AT-41

Page 47 of 3051

SAT631IA

SAT632I

SEF234G

IntroductionNLAT0247The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow the ªWork Flowº. Refer to AT-49.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-48) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

AT-46

Page 54 of 3051

3. Install pressure gauge to corresponding line pressure port.

SAT513G

4. Set parking brake and block wheels.

+Continue to depress brake pedal fully while line pressure

test is being performed at stall speed.

SAT493G

5. Start engine and measure line pressure at idle and stall speed.

+When measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure: Refer to SDS, AT-210.

SAT692J

Road TestNLAT0028DESCRIPTIONNLAT0028S01+The purpose of the test is to determine overall performance of

CVT and analyze causes of problems.

+The road test consists of the following three parts:

1. Check before engine is started

2. Cruise test

SAT496G

+Before road test, familiarize yourself with all test procedures

and items to check.

+Conduct tests on all items until specified symptom is found.

Troubleshoot items which check out No Good after road test.

Refer to ªON BOARD DIAGNOSTIC SYSTEM

DESCRIPTIONº, AT-18 to AT-28 (EURO-OBD)/AT-31 to AT-38

(Except for EURO-OBD).

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test (Cont'd)

AT-53

Page 62 of 3051

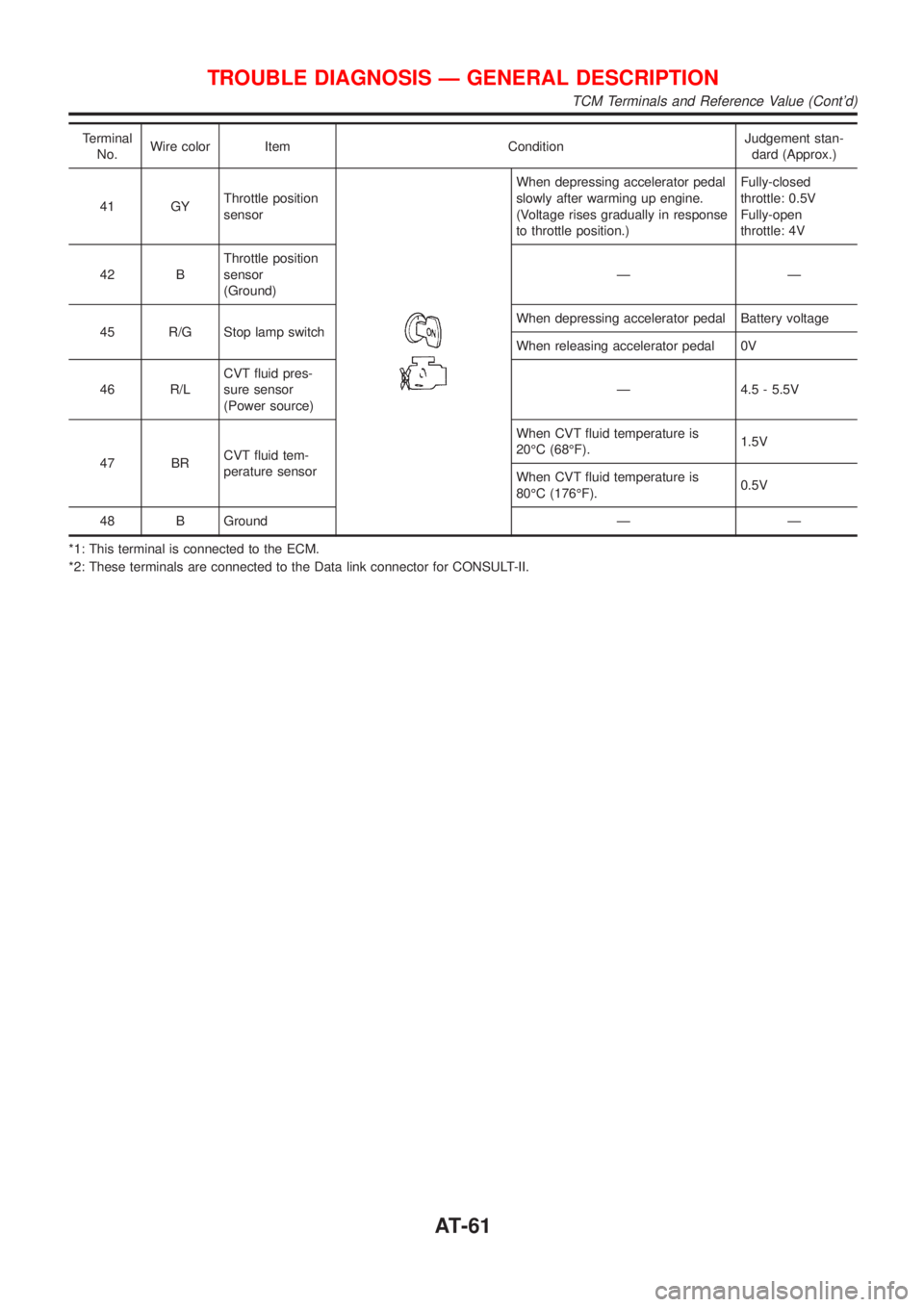

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

41 GYThrottle position

sensor

When depressing accelerator pedal

slowly after warming up engine.

(Voltage rises gradually in response

to throttle position.)Fully-closed

throttle: 0.5V

Fully-open

throttle: 4V

42 BThrottle position

sensor

(Ground)ÐÐ

45 R/G Stop lamp switchWhen depressing accelerator pedal Battery voltage

When releasing accelerator pedal 0V

46 R/LCVT fluid pres-

sure sensor

(Power source)Ð 4.5 - 5.5V

47 BRCVT fluid tem-

perature sensorWhen CVT fluid temperature is

20ÉC (68ÉF).1.5V

When CVT fluid temperature is

80ÉC (176ÉF).0.5V

48 B Ground Ð Ð

*1: This terminal is connected to the ECM.

*2: These terminals are connected to the Data link connector for CONSULT-II.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

TCM Terminals and Reference Value (Cont'd)

AT-61

Page 95 of 3051

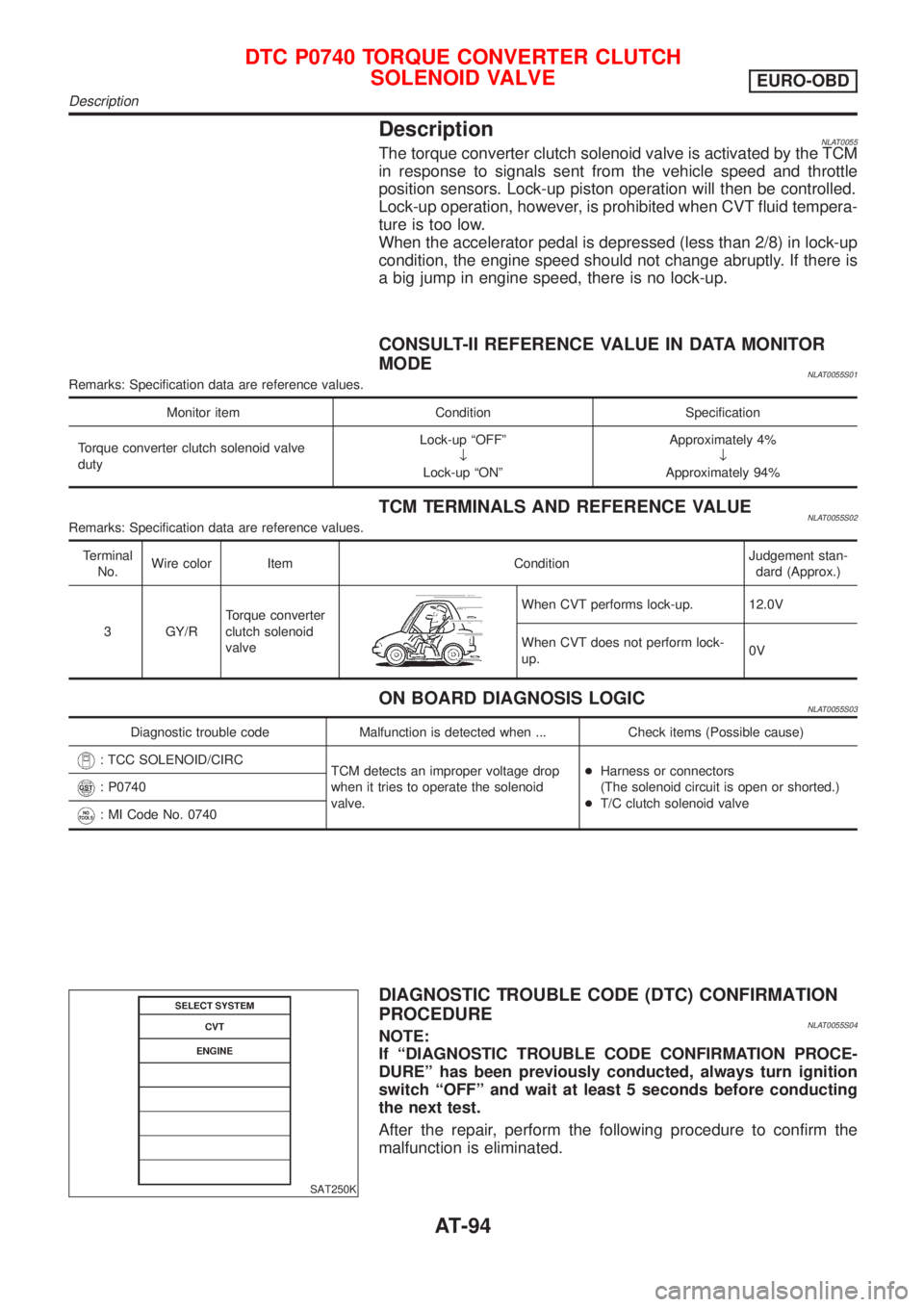

DescriptionNLAT0055The torque converter clutch solenoid valve is activated by the TCM

in response to signals sent from the vehicle speed and throttle

position sensors. Lock-up piston operation will then be controlled.

Lock-up operation, however, is prohibited when CVT fluid tempera-

ture is too low.

When the accelerator pedal is depressed (less than 2/8) in lock-up

condition, the engine speed should not change abruptly. If there is

a big jump in engine speed, there is no lock-up.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0055S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Torque converter clutch solenoid valve

dutyLock-up ªOFFº

¯

Lock-up ªONºApproximately 4%

¯

Approximately 94%

TCM TERMINALS AND REFERENCE VALUENLAT0055S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

3 GY/RTorque converter

clutch solenoid

valve

When CVT performs lock-up. 12.0V

When CVT does not perform lock-

up.0V

ON BOARD DIAGNOSIS LOGICNLAT0055S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: TCC SOLENOID/CIRC

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+T/C clutch solenoid valve

: P0740

: MI Code No. 0740

SAT250K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NLAT0055S04NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EURO-OBD

Description

AT-94

Page 100 of 3051

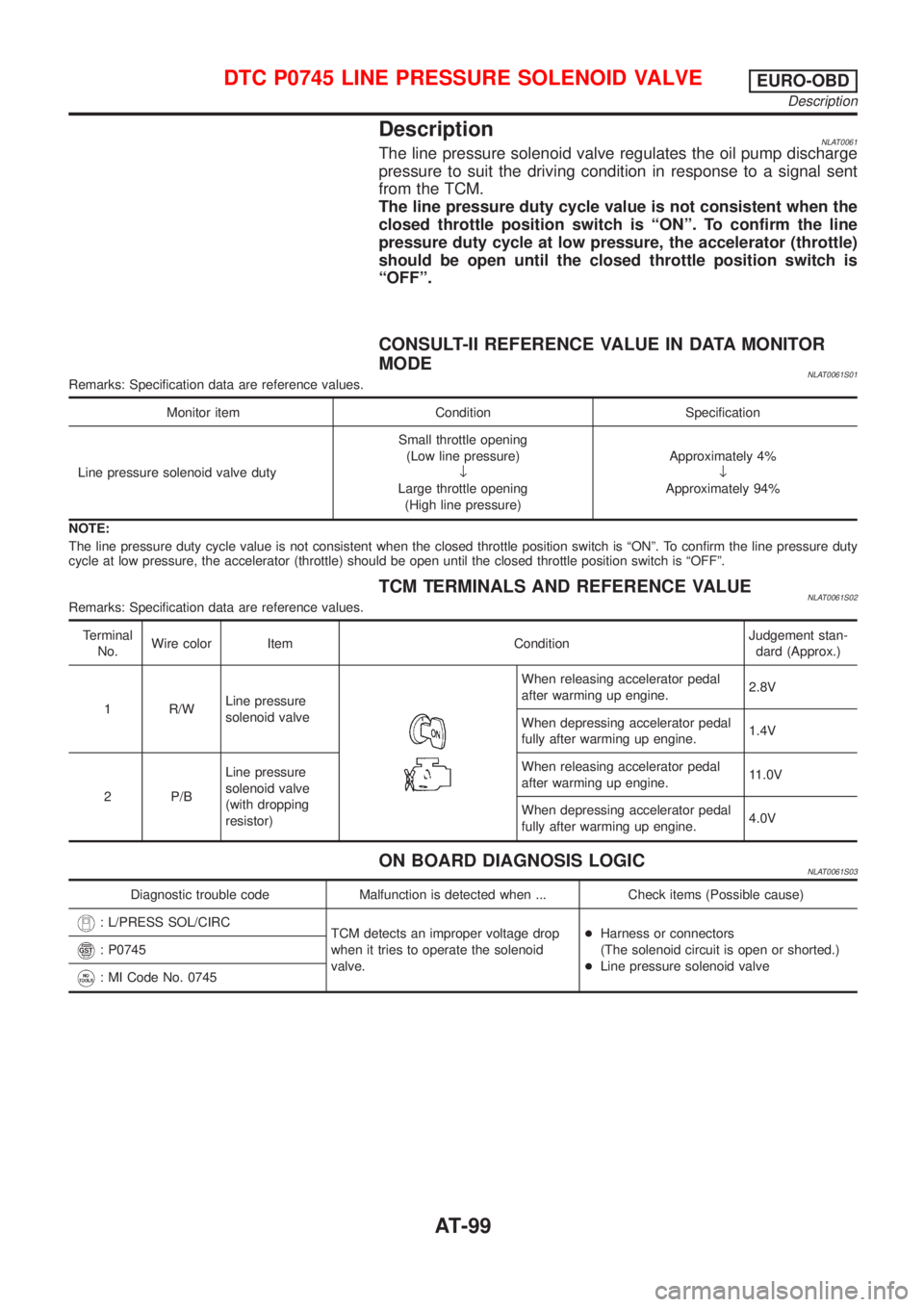

DescriptionNLAT0061The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

The line pressure duty cycle value is not consistent when the

closed throttle position switch is ªONº. To confirm the line

pressure duty cycle at low pressure, the accelerator (throttle)

should be open until the closed throttle position switch is

ªOFFº.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0061S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve dutySmall throttle opening

(Low line pressure)

¯

Large throttle opening

(High line pressure)Approximately 4%

¯

Approximately 94%

NOTE:

The line pressure duty cycle value is not consistent when the closed throttle position switch is ªONº. To confirm the line pressure duty

cycle at low pressure, the accelerator (throttle) should be open until the closed throttle position switch is ªOFFº.

TCM TERMINALS AND REFERENCE VALUENLAT0061S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

1 R/WLine pressure

solenoid valve

When releasing accelerator pedal

after warming up engine.2.8V

When depressing accelerator pedal

fully after warming up engine.1.4V

2 P/BLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal

after warming up engine.11.0V

When depressing accelerator pedal

fully after warming up engine.4.0V

ON BOARD DIAGNOSIS LOGICNLAT0061S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: L/PRESS SOL/CIRC

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Line pressure solenoid valve

: P0745

: MI Code No. 0745

DTC P0745 LINE PRESSURE SOLENOID VALVEEURO-OBD

Description

AT-99

Page 105 of 3051

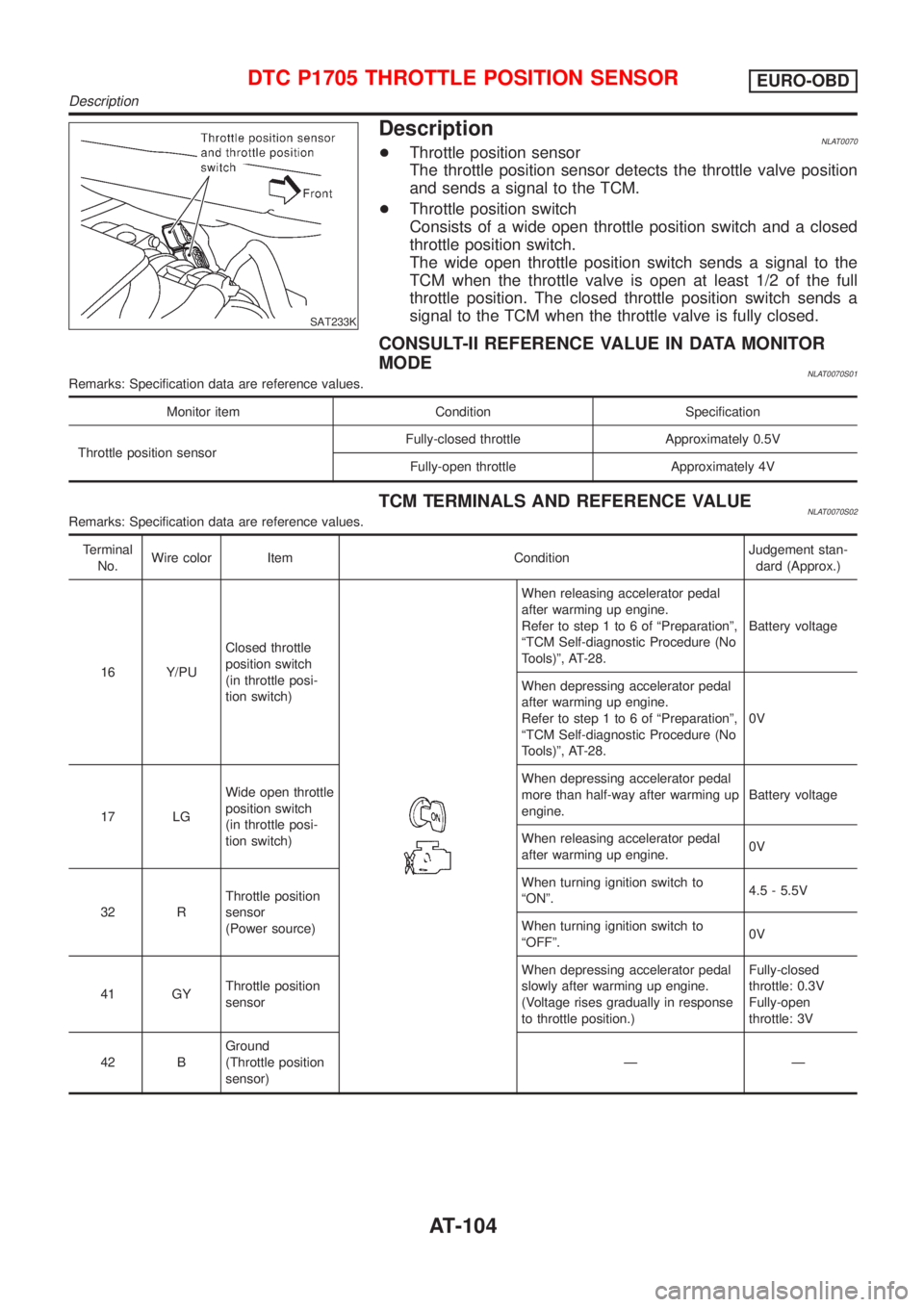

SAT233K

DescriptionNLAT0070+Throttle position sensor

The throttle position sensor detects the throttle valve position

and sends a signal to the TCM.

+Throttle position switch

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0070S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Throttle position sensorFully-closed throttle Approximately 0.5V

Fully-open throttle Approximately 4V

TCM TERMINALS AND REFERENCE VALUENLAT0070S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

16 Y/PUClosed throttle

position switch

(in throttle posi-

tion switch)

When releasing accelerator pedal

after warming up engine.

Refer to step 1 to 6 of ªPreparationº,

ªTCM Self-diagnostic Procedure (No

Tools)º, AT-28.Battery voltage

When depressing accelerator pedal

after warming up engine.

Refer to step 1 to 6 of ªPreparationº,

ªTCM Self-diagnostic Procedure (No

Tools)º, AT-28.0V

17 LGWide open throttle

position switch

(in throttle posi-

tion switch)When depressing accelerator pedal

more than half-way after warming up

engine.Battery voltage

When releasing accelerator pedal

after warming up engine.0V

32 RThrottle position

sensor

(Power source)When turning ignition switch to

ªONº.4.5 - 5.5V

When turning ignition switch to

ªOFFº.0V

41 GYThrottle position

sensorWhen depressing accelerator pedal

slowly after warming up engine.

(Voltage rises gradually in response

to throttle position.)Fully-closed

throttle: 0.3V

Fully-open

throttle: 3V

42 BGround

(Throttle position

sensor)ÐÐ

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Description

AT-104