fuel filter NISSAN ALMERA TINO 2001 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1519 of 3051

Fuel Filter

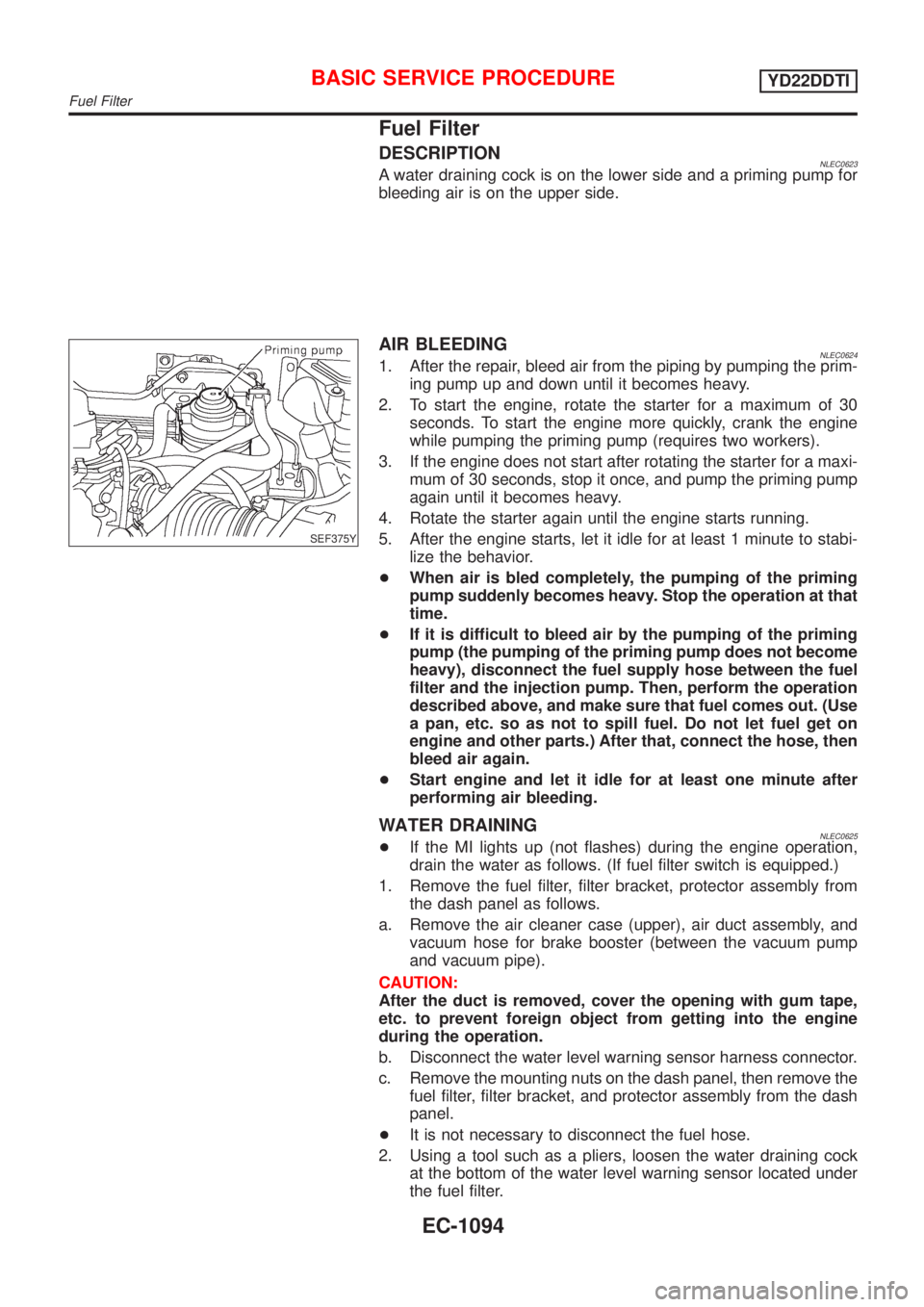

DESCRIPTIONNLEC0623A water draining cock is on the lower side and a priming pump for

bleeding air is on the upper side.

SEF375Y

AIR BLEEDINGNLEC06241. After the repair, bleed air from the piping by pumping the prim-

ing pump up and down until it becomes heavy.

2. To start the engine, rotate the starter for a maximum of 30

seconds. To start the engine more quickly, crank the engine

while pumping the priming pump (requires two workers).

3. If the engine does not start after rotating the starter for a maxi-

mum of 30 seconds, stop it once, and pump the priming pump

again until it becomes heavy.

4. Rotate the starter again until the engine starts running.

5. After the engine starts, let it idle for at least 1 minute to stabi-

lize the behavior.

+When air is bled completely, the pumping of the priming

pump suddenly becomes heavy. Stop the operation at that

time.

+If it is difficult to bleed air by the pumping of the priming

pump (the pumping of the priming pump does not become

heavy), disconnect the fuel supply hose between the fuel

filter and the injection pump. Then, perform the operation

described above, and make sure that fuel comes out. (Use

a pan, etc. so as not to spill fuel. Do not let fuel get on

engine and other parts.) After that, connect the hose, then

bleed air again.

+Start engine and let it idle for at least one minute after

performing air bleeding.

WATER DRAININGNLEC0625+If the MI lights up (not flashes) during the engine operation,

drain the water as follows. (If fuel filter switch is equipped.)

1. Remove the fuel filter, filter bracket, protector assembly from

the dash panel as follows.

a. Remove the air cleaner case (upper), air duct assembly, and

vacuum hose for brake booster (between the vacuum pump

and vacuum pipe).

CAUTION:

After the duct is removed, cover the opening with gum tape,

etc. to prevent foreign object from getting into the engine

during the operation.

b. Disconnect the water level warning sensor harness connector.

c. Remove the mounting nuts on the dash panel, then remove the

fuel filter, filter bracket, and protector assembly from the dash

panel.

+It is not necessary to disconnect the fuel hose.

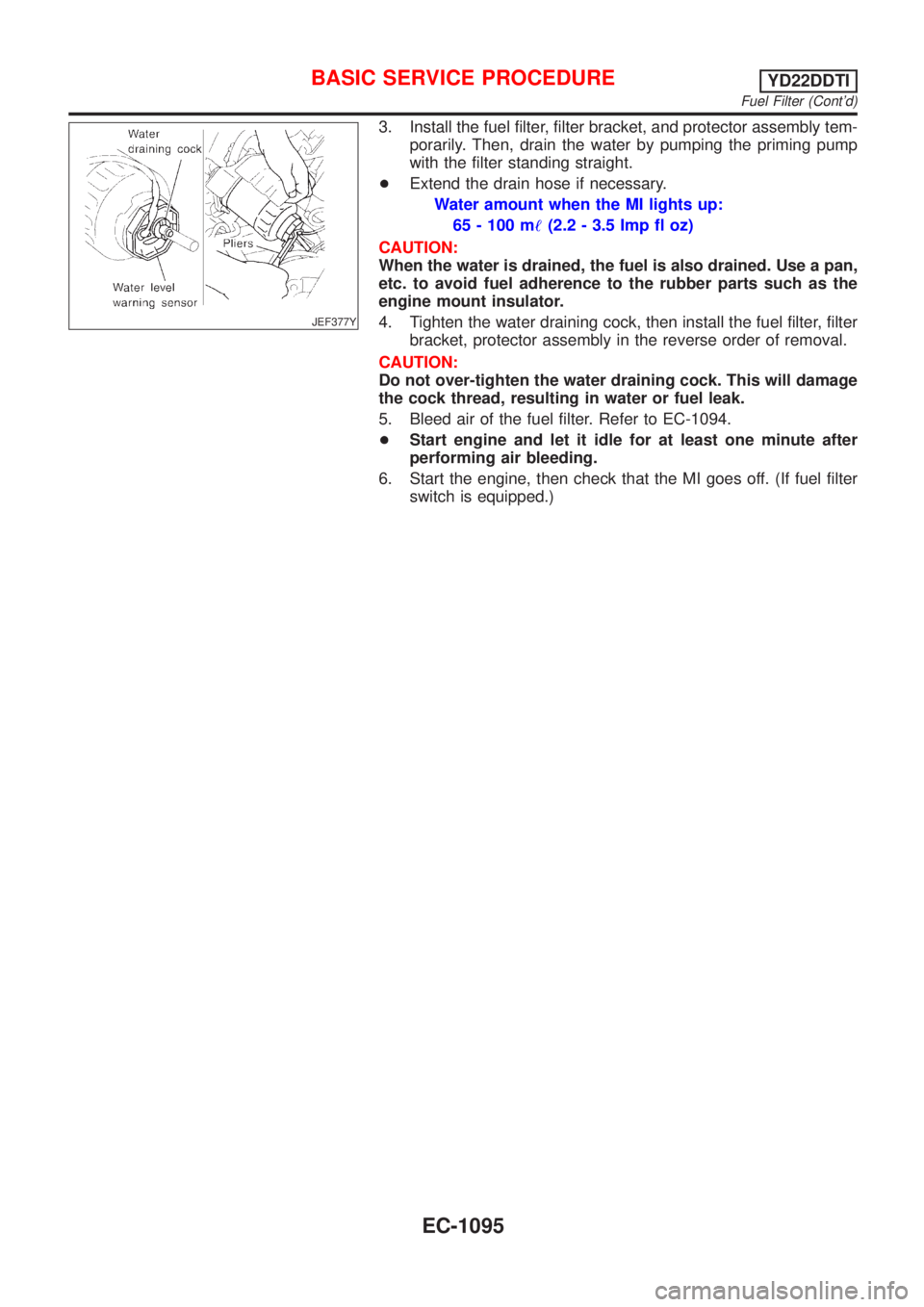

2. Using a tool such as a pliers, loosen the water draining cock

at the bottom of the water level warning sensor located under

the fuel filter.

BASIC SERVICE PROCEDUREYD22DDTI

Fuel Filter

EC-1094

Page 1520 of 3051

JEF377Y

3. Install the fuel filter, filter bracket, and protector assembly tem-

porarily. Then, drain the water by pumping the priming pump

with the filter standing straight.

+Extend the drain hose if necessary.

Water amount when the MI lights up:

65 - 100 m!(2.2 - 3.5 Imp fl oz)

CAUTION:

When the water is drained, the fuel is also drained. Use a pan,

etc. to avoid fuel adherence to the rubber parts such as the

engine mount insulator.

4. Tighten the water draining cock, then install the fuel filter, filter

bracket, protector assembly in the reverse order of removal.

CAUTION:

Do not over-tighten the water draining cock. This will damage

the cock thread, resulting in water or fuel leak.

5. Bleed air of the fuel filter. Refer to EC-1094.

+Start engine and let it idle for at least one minute after

performing air bleeding.

6. Start the engine, then check that the MI goes off. (If fuel filter

switch is equipped.)

BASIC SERVICE PROCEDUREYD22DDTI

Fuel Filter (Cont'd)

EC-1095

Page 1538 of 3051

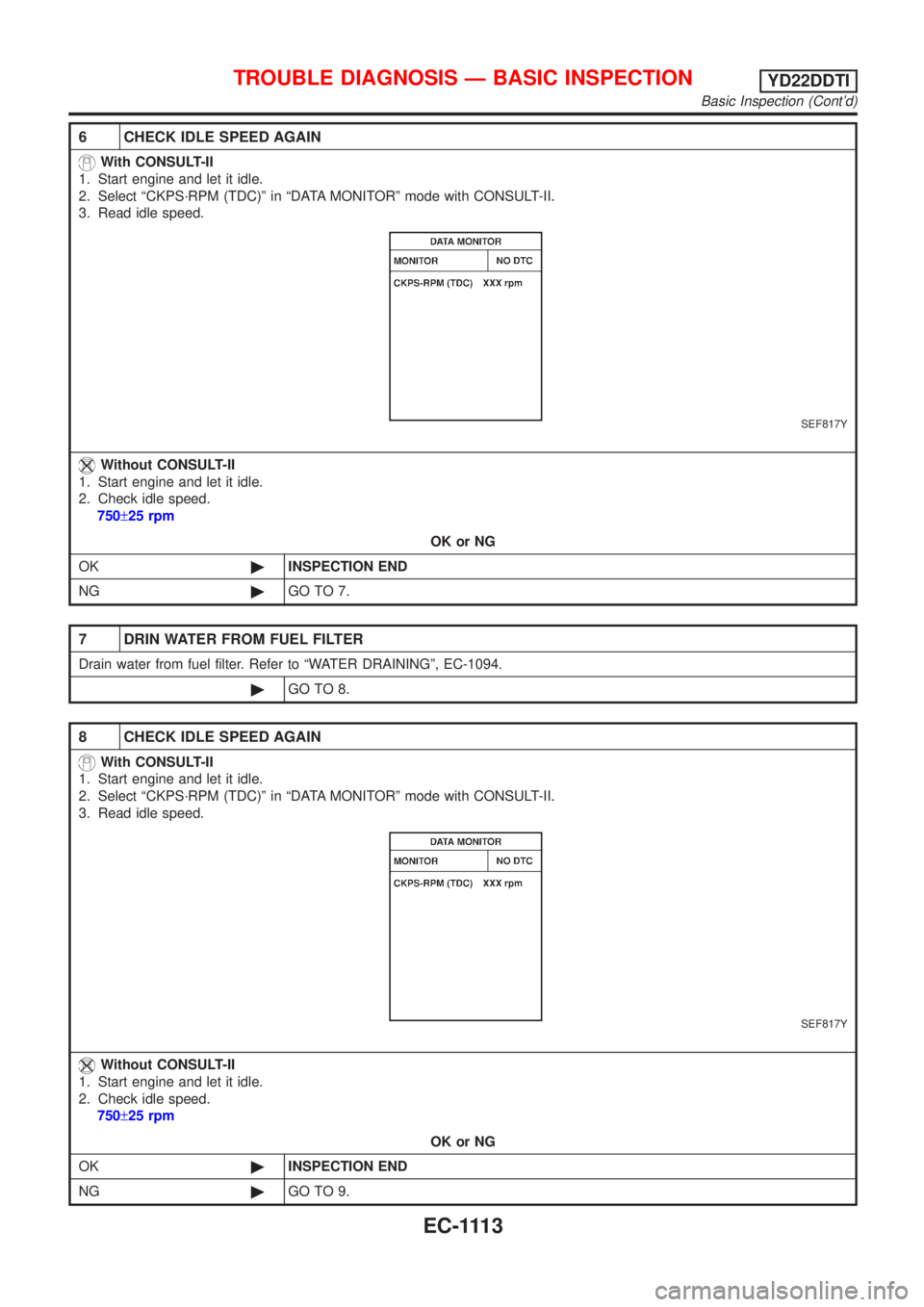

6 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select ªCKPS´RPM (TDC)º in ªDATA MONITORº mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

750±25 rpm

OK or NG

OK©INSPECTION END

NG©GO TO 7.

7 DRIN WATER FROM FUEL FILTER

Drain water from fuel filter. Refer to ªWATER DRAININGº, EC-1094.

©GO TO 8.

8 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select ªCKPS´RPM (TDC)º in ªDATA MONITORº mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

750±25 rpm

OK or NG

OK©INSPECTION END

NG©GO TO 9.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONYD22DDTI

Basic Inspection (Cont'd)

EC-1113

Page 1539 of 3051

9 CHECK AIR CLEANER FILTER

Check air cleaner filter for clogging or braks.

OK or NG

OK©GO TO 10.

NG©Replace air cleaner filter.

10 CHECK FUEL INJECTION NOZZLE

Check fuel injection nozzle opening pressure. Refer to ªInjection Pressure Testº, EC-1086.

OK or NG

OK©GO TO 11.

NG©Replace fuel injection nozzle assembly.

11 CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select ªCKPS´RPM (TDC)º in ªDATA MONITORº mode with CONSULT-II.

3. Read idle speed.

SEF817Y

Without CONSULT-II

1. Start engine and let it idle.

2. Check idle speed.

750±25 rpm

OK or NG

OK©INSPECTION END

NG©GO TO 12.

12 CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-164, ªMEASUREMENT OF COMPRESSION PRESSUREº.

OK or NG

OK©GO TO 13.

NG©Follow the instruction of ªMEASUREMENT OF COMPRESSION PRESSUREº.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONYD22DDTI

Basic Inspection (Cont'd)

EC-1114

Page 2260 of 3051

PISTON RING END GAP........................................135

CONNECTING ROD BEND AND TORSION.............136

CYLINDER BLOCK DISTORTION AND WEAR.........136

PISTON-TO-BORE CLEARANCE............................137

CRANKSHAFT.......................................................138

BEARING CLEARANCE.........................................138

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

........................................................141

REPLACEMENT OF CONNECTING ROD

BUSHING (SMALL END)

........................................141

REPLACEMENT OF PILOT CONVERTER (CVT).....141

DRIVE PLATE RUNOUT........................................142

Assembly .................................................................142

PISTON................................................................142

CRANKSHAFT.......................................................143

SERVICE DATA AND SPECIFICATIONS (SDS).......146

General Specifications .............................................146

Compression Pressure ............................................146

Cylinder Head ..........................................................146

Valve ........................................................................147

VALVE..................................................................147

VALVE SPRING.....................................................147

HYDRAULIC LASH ADJUSTER (HLA).....................147

VALVE GUIDE.......................................................148

VALVE SHIM CLEARANCE ADJUSTMENT..............148

AVAILABLE SHIM..................................................149

VALVE SEAT.........................................................150

Camshaft and Camshaft Bearing ............................151

Cylinder Block ..........................................................152

Piston, Piston Ring and Piston Pin .........................153

PISTON................................................................153

PISTON RING.......................................................153

PISTON PIN..........................................................153

Connecting Rod .......................................................154

Crankshaft................................................................155

Main Bearing............................................................156

STANDARD...........................................................156

UNDERSIZE..........................................................156

Connecting Rod Bearing .........................................156

STANDARD SIZE..................................................156

UNDERSIZE..........................................................156

Bearing Clearance ...................................................157

Miscellaneous Components.....................................157

YD

PRECAUTIONS...........................................................158

Parts Requiring Angular Tightening .........................158

Liquid Gasket Application Procedure ......................158

PREPARATION...........................................................159

Special Service Tools ..............................................159

Commercial Service Tools .......................................161

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.................................................163

NVH Troubleshooting - Engine Noise .....................163MEASUREMENT OF COMPRESSION PRESSURE..164

DRIVE BELTS..............................................................166

Inspection.................................................................166

Adjustment ...............................................................166

AIR CONDITIONER COMPRESSOR BELT..............167

ALTERNATOR & WATER PUMP BELT...................167

Removal ...................................................................167

Installation ................................................................168

AIR CLEANER.............................................................169

Changing Air Cleaner Filter .....................................169

VISCOUS PAPER TYPE.........................................169

OIL PAN.......................................................................170

Components.............................................................170

Removal ...................................................................170

Installation ................................................................172

TIMING CHAIN............................................................175

Secondary Timing Chain .........................................175

REMOVAL.............................................................175

INSPECTION.........................................................177

INSTALLATION......................................................177

Primary Timing Chain ..............................................180

REMOVAL.............................................................181

INSPECTION.........................................................183

INSTALLATION......................................................183

INTAKE MANIFOLD....................................................188

Removal and Installation .........................................188

PREPARATIVE WORK...........................................188

FUEL PIPING........................................................189

INTAKE MANIFOLD...............................................189

EGR VOLUME CONTROL VALVE...........................189

WATER HOSE.......................................................189

Inspection.................................................................190

INTAKE MANIFOLD...............................................190

SWIRL CONTROL VALVE......................................190

CATALYST..................................................................191

Removal and Installation .........................................191

PREPARATIVE WORK...........................................191

THREE WAY CATALYST.......................................191

GUSSET...............................................................192

EXHAUST MANIFOLD, TURBOCHARGER...............193

Removal and Installation .........................................193

PREPARATIVE WORK...........................................193

EXHAUST MANIFOLD AND TURBOCHARGER.......193

EXHAUST MANIFOLD GASKET.............................194

Disassembly and Assembly .....................................194

TURBOCHARGER.................................................194

Inspection.................................................................195

EXHAUST MANIFOLD...........................................195

TURBOCHARGER.................................................195

ROCKER COVER........................................................198

Removal and Installation .........................................198

PREPARATIVE WORK...........................................198

ROCKER COVER..................................................198

CYLINDER HEAD........................................................200

CONTENTS(Cont'd)

EM-3

Page 2510 of 3051

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

CONTENTS

QG/SR

PREPARATION...............................................................2

Special Service Tools ..................................................2

Commercial Service Tools ...........................................2

ACCELERATOR CONTROL SYSTEM...........................3

Removal and Installation .............................................3

Adjusting Accelerator Wire ..........................................3

MODELS WITH THROTTLE OPENER.........................3

MODELS WITHOUT THROTTLE OPENER..................4

FUEL SYSTEM................................................................5

Checking Fuel Lines ....................................................5

Removal and Installation .............................................5

Fuel Tank .....................................................................6

REMOVAL.................................................................6

INSTALLATION..........................................................8

Fuel Pump, Fuel Level Sensor Unit and Fuel

Filter .............................................................................9

REMOVAL.................................................................9

INSTALLATION........................................................10

EXHAUST SYSTEM...................................................... 11

Checking Exhaust System......................................... 11

Removal and Installation ........................................... 11

YD

PREPARATION.............................................................13

Special Service Tool ..................................................13Commercial Service Tool ...........................................13

ACCELERATOR CONTROL SYSTEM.........................14

Removal and Installation ...........................................14

Inspection...................................................................14

FUEL SYSTEM..............................................................15

Checking Fuel Lines ..................................................15

Water Draining from Fuel Filter .................................15

DRAINING WATER..................................................15

FUEL FILTER CHECK..............................................15

Changing Fuel Filter ..................................................15

REMOVAL...............................................................15

INSTALLATION........................................................16

Bleeding Fuel Filter....................................................16

Checking Priming Pump ............................................16

Checking Water in Fuel Filter Sensor (where

fitted) ..........................................................................17

Removal and Installation ...........................................17

Fuel Tank ...................................................................18

REMOVAL...............................................................19

INSTALLATION........................................................20

Fuel Level Sensor Unit ..............................................21

REMOVAL...............................................................21

INSTALLATION........................................................22

EXHAUST SYSTEM......................................................23

Checking Exhaust System.........................................23

Removal and Installation ...........................................23

Page 2518 of 3051

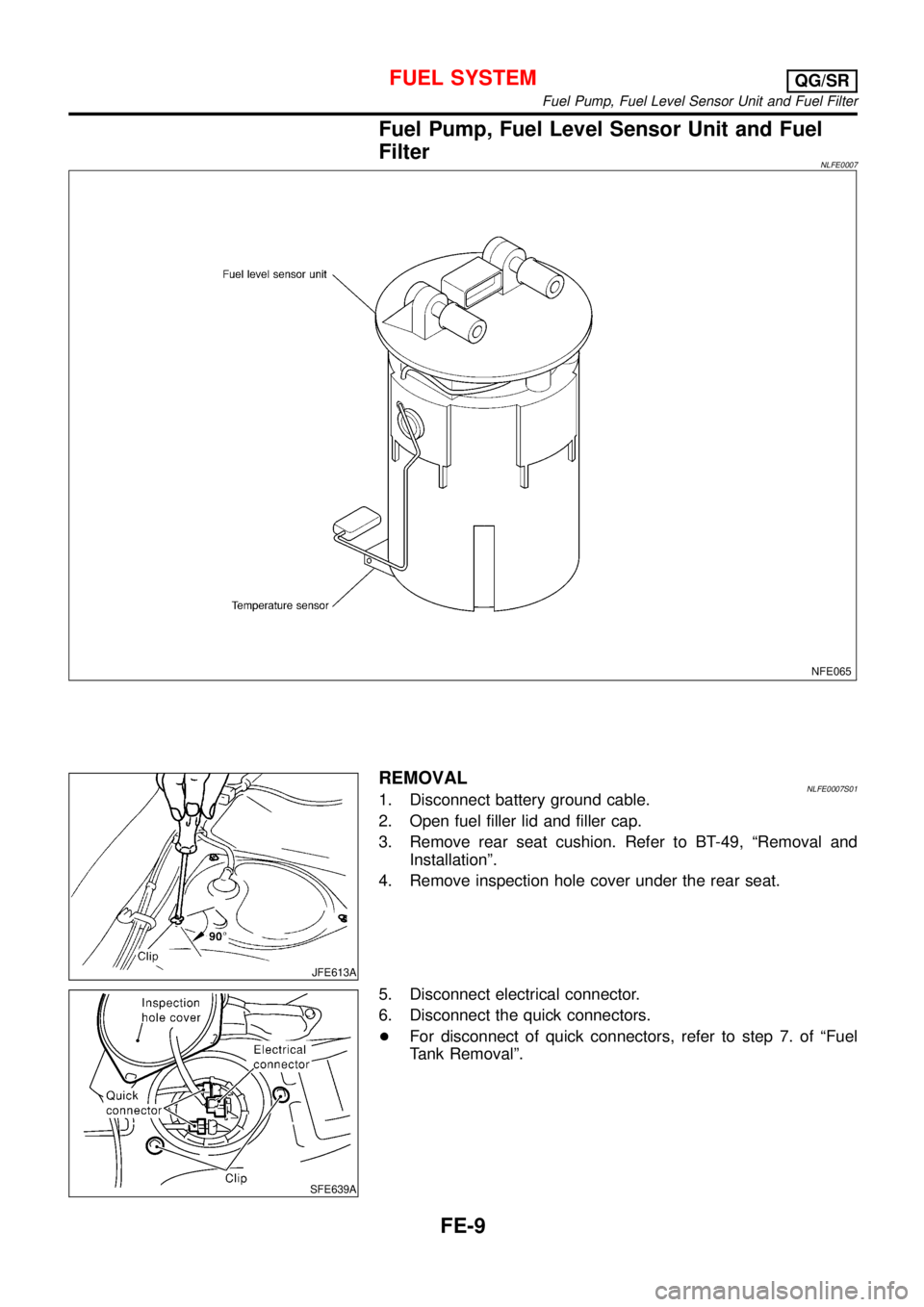

Fuel Pump, Fuel Level Sensor Unit and Fuel

Filter

NLFE0007

NFE065

JFE613A

REMOVALNLFE0007S011. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Remove rear seat cushion. Refer to BT-49,“Removal and

Installation”.

4. Remove inspection hole cover under the rear seat.

SFE639A

5. Disconnect electrical connector.

6. Disconnect the quick connectors.

+For disconnect of quick connectors, refer to step 7. of“Fuel

Tank Removal”.

FUEL SYSTEMQG/SR

Fuel Pump, Fuel Level Sensor Unit and Fuel Filter

FE-9

Page 2519 of 3051

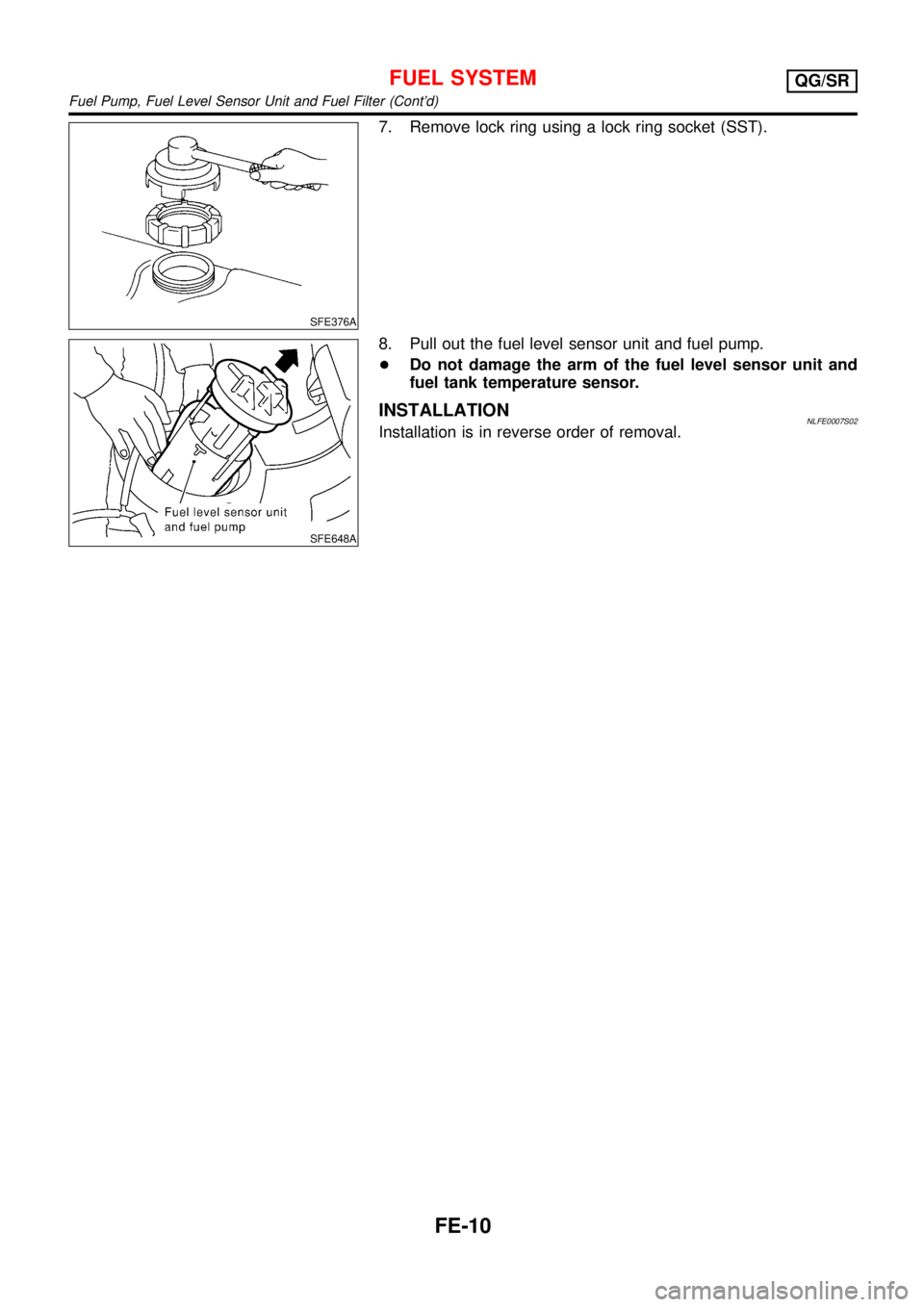

SFE376A

7. Remove lock ring using a lock ring socket (SST).

SFE648A

8. Pull out the fuel level sensor unit and fuel pump.

+Do not damage the arm of the fuel level sensor unit and

fuel tank temperature sensor.

INSTALLATIONNLFE0007S02Installation is in reverse order of removal.

FUEL SYSTEMQG/SR

Fuel Pump, Fuel Level Sensor Unit and Fuel Filter (Cont’d)

FE-10

Page 2522 of 3051

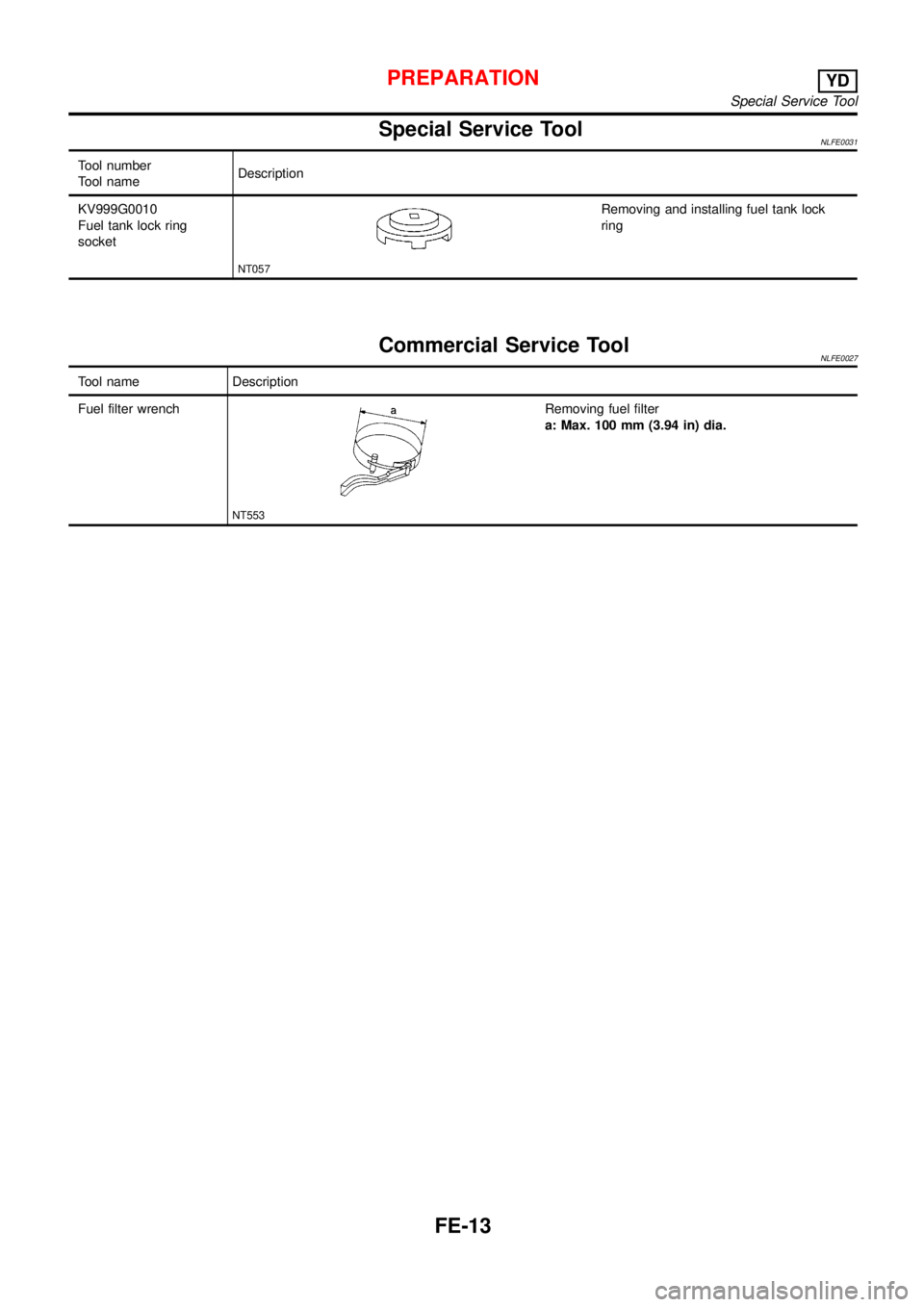

Special Service ToolNLFE0031

Tool number

Tool nameDescription

KV999G0010

Fuel tank lock ring

socket

NT057

Removing and installing fuel tank lock

ring

Commercial Service ToolNLFE0027

Tool name Description

Fuel filter wrench

NT553

Removing fuel filter

a: Max. 100 mm (3.94 in) dia.

PREPARATIONYD

Special Service Tool

FE-13

Page 2524 of 3051

SMA803A

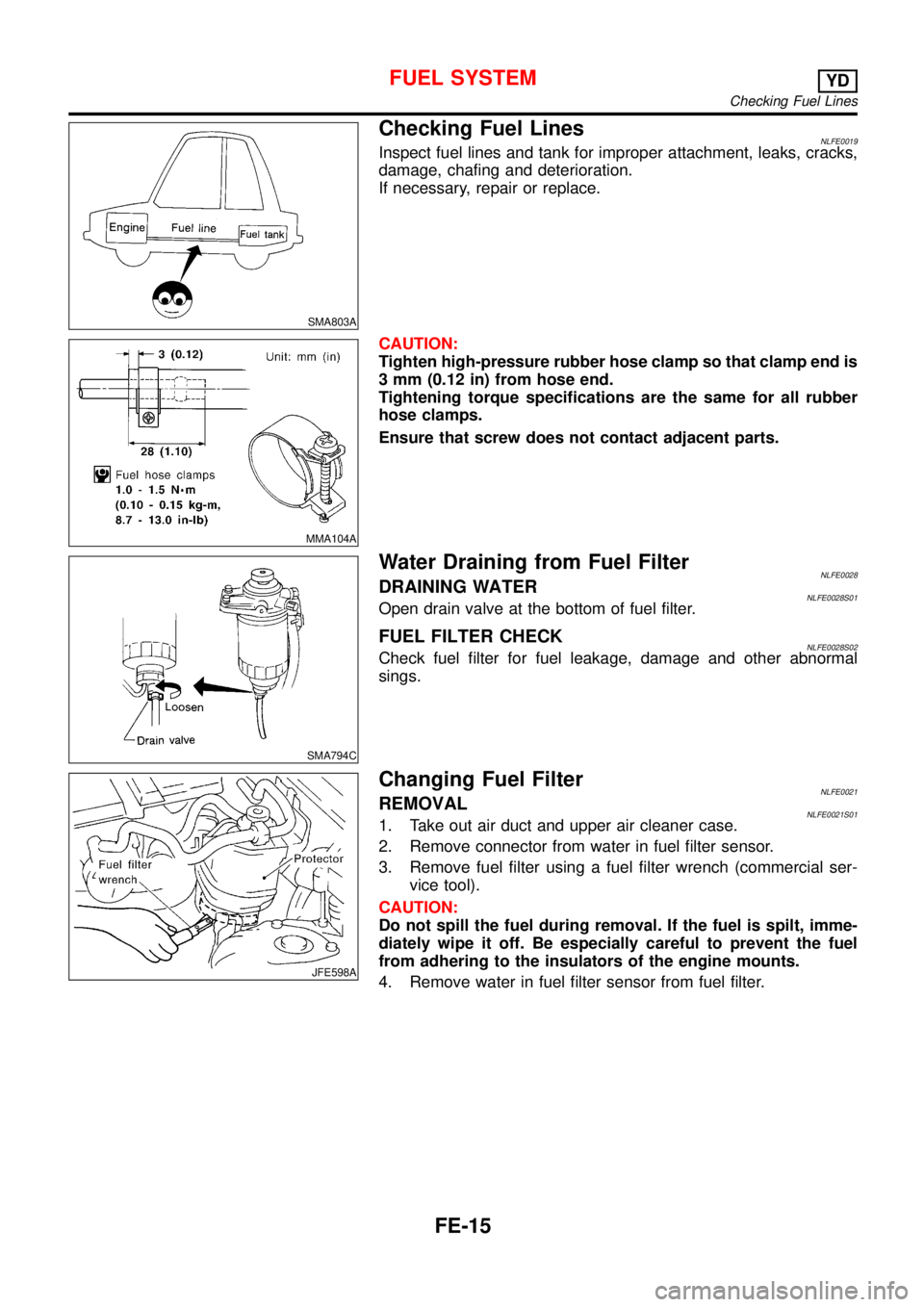

Checking Fuel LinesNLFE0019Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, chafing and deterioration.

If necessary, repair or replace.

MMA104A

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

SMA794C

Water Draining from Fuel FilterNLFE0028DRAINING WATERNLFE0028S01Open drain valve at the bottom of fuel filter.

FUEL FILTER CHECKNLFE0028S02Check fuel filter for fuel leakage, damage and other abnormal

sings.

JFE598A

Changing Fuel FilterNLFE0021REMOVALNLFE0021S011. Take out air duct and upper air cleaner case.

2. Remove connector from water in fuel filter sensor.

3. Remove fuel filter using a fuel filter wrench (commercial ser-

vice tool).

CAUTION:

Do not spill the fuel during removal. If the fuel is spilt, imme-

diately wipe it off. Be especially careful to prevent the fuel

from adhering to the insulators of the engine mounts.

4. Remove water in fuel filter sensor from fuel filter.

FUEL SYSTEMYD

Checking Fuel Lines

FE-15