NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2601 of 3051

HFC-134a (R-134a) Service Tools and

Equipment

=NLHA0120Never mix HFC-134a refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/or its lubri-

cant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size fitting to another must never be used: refrigerant/lubricant contamination will

occur and compressor failure will result.

Tool number

Tool nameDescription

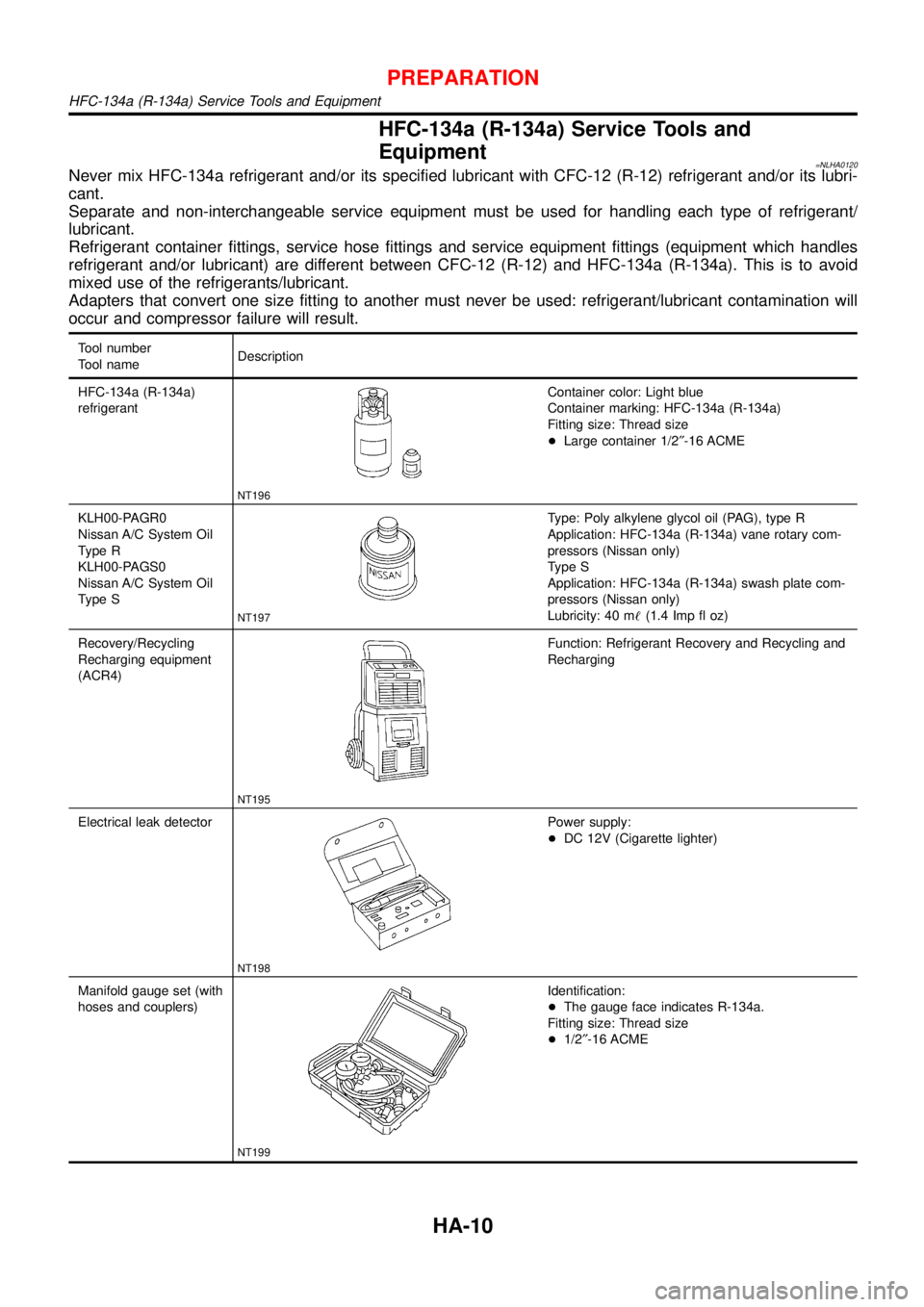

HFC-134a (R-134a)

refrigerant

NT196

Container color: Light blue

Container marking: HFC-134a (R-134a)

Fitting size: Thread size

+Large container 1/2″-16 ACME

KLH00-PAGR0

Nissan A/C System Oil

Type R

KLH00-PAGS0

Nissan A/C System Oil

Type S

NT197

Type: Poly alkylene glycol oil (PAG), type R

Application: HFC-134a (R-134a) vane rotary com-

pressors (Nissan only)

Type S

Application: HFC-134a (R-134a) swash plate com-

pressors (Nissan only)

Lubricity: 40 m!(1.4 Imp fl oz)

Recovery/Recycling

Recharging equipment

(ACR4)

NT195

Function: Refrigerant Recovery and Recycling and

Recharging

Electrical leak detector

NT198

Power supply:

+DC 12V (Cigarette lighter)

Manifold gauge set (with

hoses and couplers)

NT199

Identification:

+The gauge face indicates R-134a.

Fitting size: Thread size

+1/2″-16 ACME

PREPARATION

HFC-134a (R-134a) Service Tools and Equipment

HA-10

Page 2602 of 3051

Tool number

Tool nameDescription

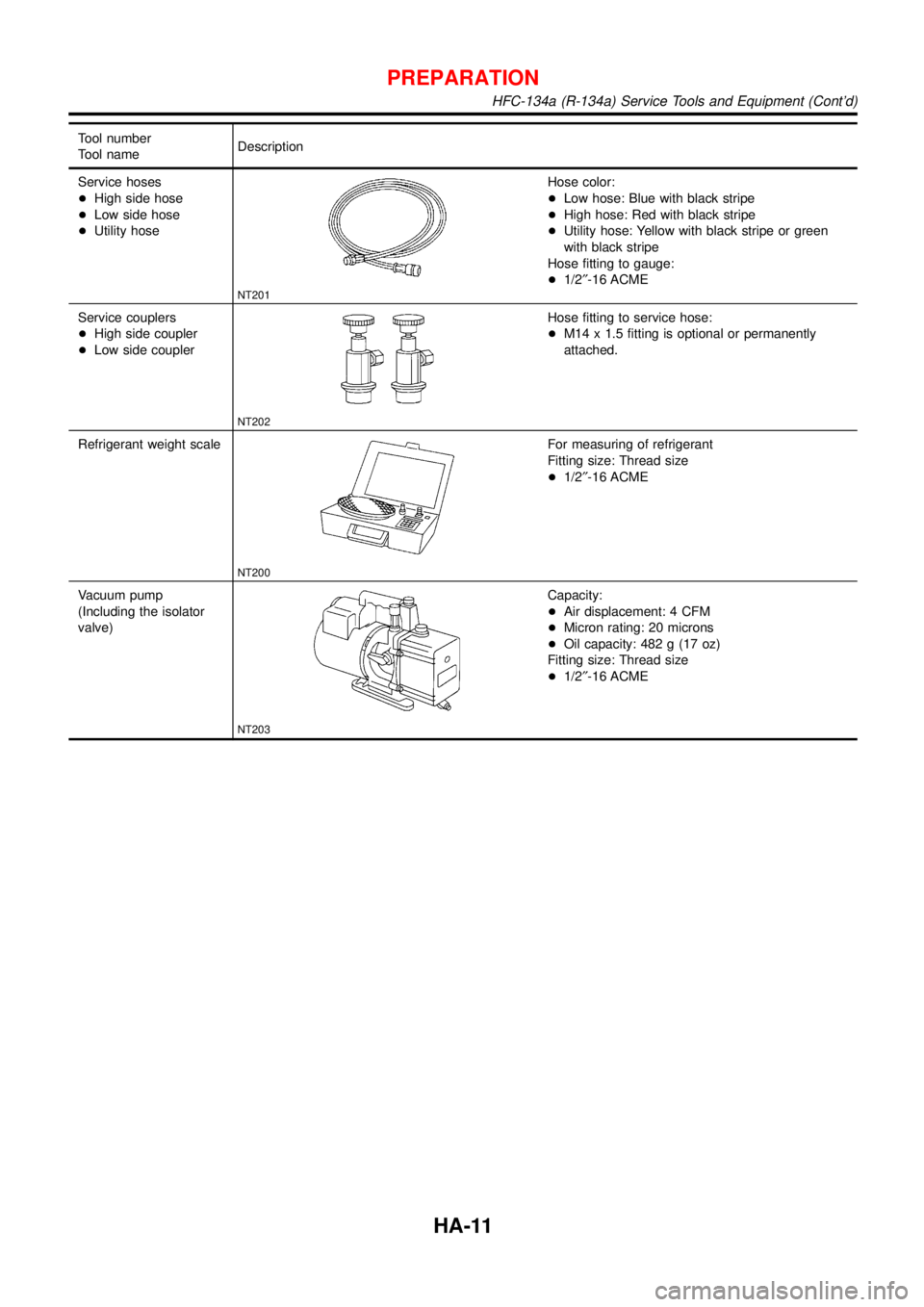

Service hoses

+High side hose

+Low side hose

+Utility hose

NT201

Hose color:

+Low hose: Blue with black stripe

+High hose: Red with black stripe

+Utility hose: Yellow with black stripe or green

with black stripe

Hose fitting to gauge:

+1/2″-16 ACME

Service couplers

+High side coupler

+Low side coupler

NT202

Hose fitting to service hose:

+M14 x 1.5 fitting is optional or permanently

attached.

Refrigerant weight scale

NT200

For measuring of refrigerant

Fitting size: Thread size

+1/2″-16 ACME

Vacuum pump

(Including the isolator

valve)

NT203

Capacity:

+Air displacement: 4 CFM

+Micron rating: 20 microns

+Oil capacity: 482 g (17 oz)

Fitting size: Thread size

+1/2″-16 ACME

PREPARATION

HFC-134a (R-134a) Service Tools and Equipment (Cont’d)

HA-11

Page 2603 of 3051

Refrigeration System

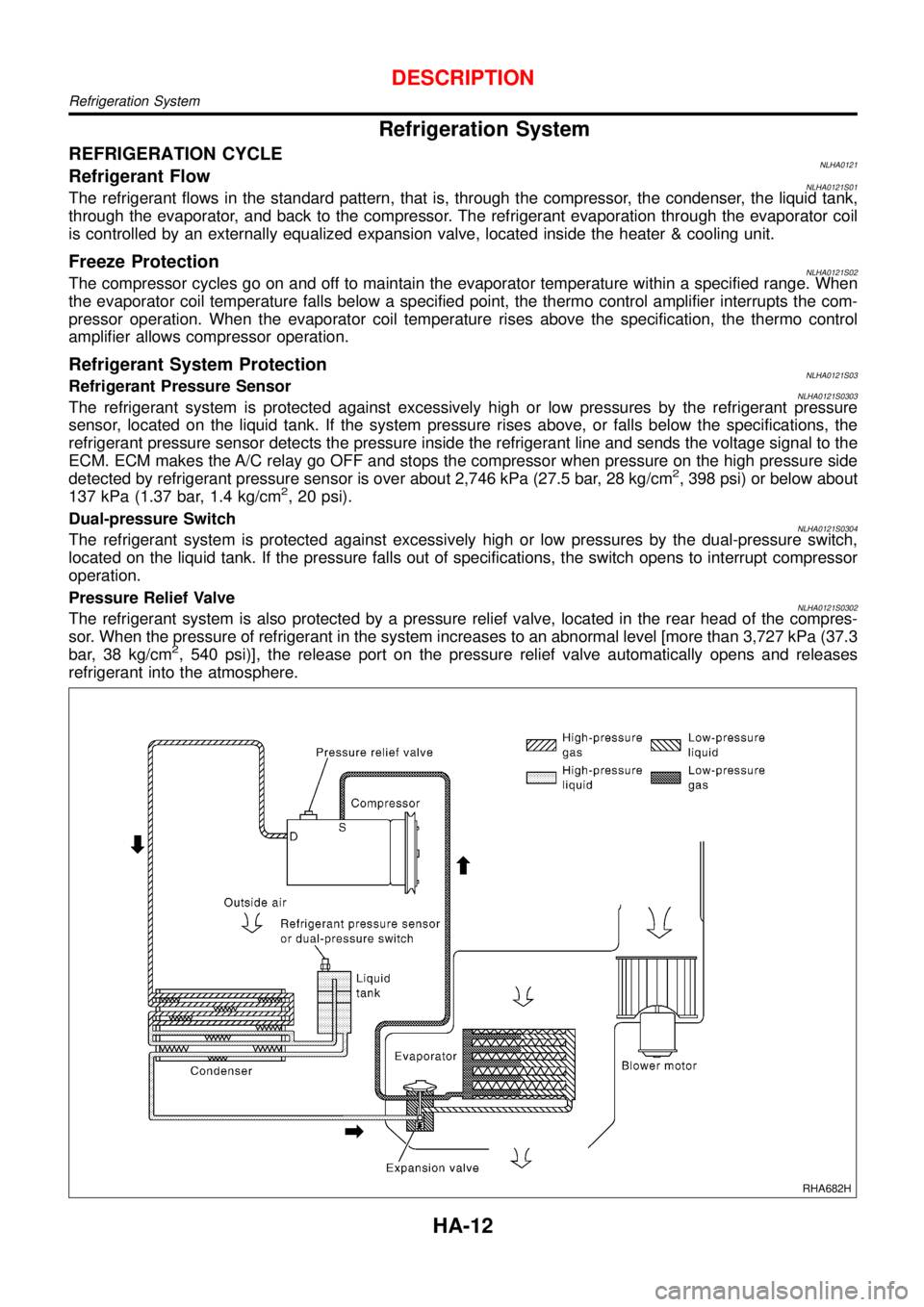

REFRIGERATION CYCLENLHA0121Refrigerant FlowNLHA0121S01The refrigerant flows in the standard pattern, that is, through the compressor, the condenser, the liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator coil

is controlled by an externally equalized expansion valve, located inside the heater & cooling unit.

Freeze ProtectionNLHA0121S02The compressor cycles go on and off to maintain the evaporator temperature within a specified range. When

the evaporator coil temperature falls below a specified point, the thermo control amplifier interrupts the com-

pressor operation. When the evaporator coil temperature rises above the specification, the thermo control

amplifier allows compressor operation.

Refrigerant System ProtectionNLHA0121S03Refrigerant Pressure SensorNLHA0121S0303The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure

sensor, located on the liquid tank. If the system pressure rises above, or falls below the specifications, the

refrigerant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the

ECM. ECM makes the A/C relay go OFF and stops the compressor when pressure on the high pressure side

detected by refrigerant pressure sensor is over about 2,746 kPa (27.5 bar, 28 kg/cm

2, 398 psi) or below about

137 kPa (1.37 bar, 1.4 kg/cm2, 20 psi).

Dual-pressure Switch

NLHA0121S0304The refrigerant system is protected against excessively high or low pressures by the dual-pressure switch,

located on the liquid tank. If the pressure falls out of specifications, the switch opens to interrupt compressor

operation.

Pressure Relief Valve

NLHA0121S0302The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compres-

sor. When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (37.3

bar, 38 kg/cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases

refrigerant into the atmosphere.

RHA682H

DESCRIPTION

Refrigeration System

HA-12

Page 2604 of 3051

CSV613 Variable Displacement Compressor

GENERAL INFORMATIONNLHA02061. The CSV613 compressor differs from previous units. The vent temperatures of the CSV613 compressor

do not drop too far below 5°C (41°F) when:

+evaporator intake air temperature is less than 20°C (68°F)

+engine is running at speeds less than 1,500 rpm.

This is because the CSV613 compressor provides a means of“capacity”control.

2. The CSV613 compressor provides refrigerant control under varying conditions. During cold winters, it may

not produce high refrigerant pressure discharge (compared to previous units) when used with air condi-

tioning systems.

3. A“clanking”sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the CSV613 compressor, the clutch remains engaged unless: the sys-

tem main switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are

low or when the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.47 to 1.77 bar, 1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying con-

ditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

DESCRIPTION

CSV613 Variable Displacement Compressor

HA-13

Page 2605 of 3051

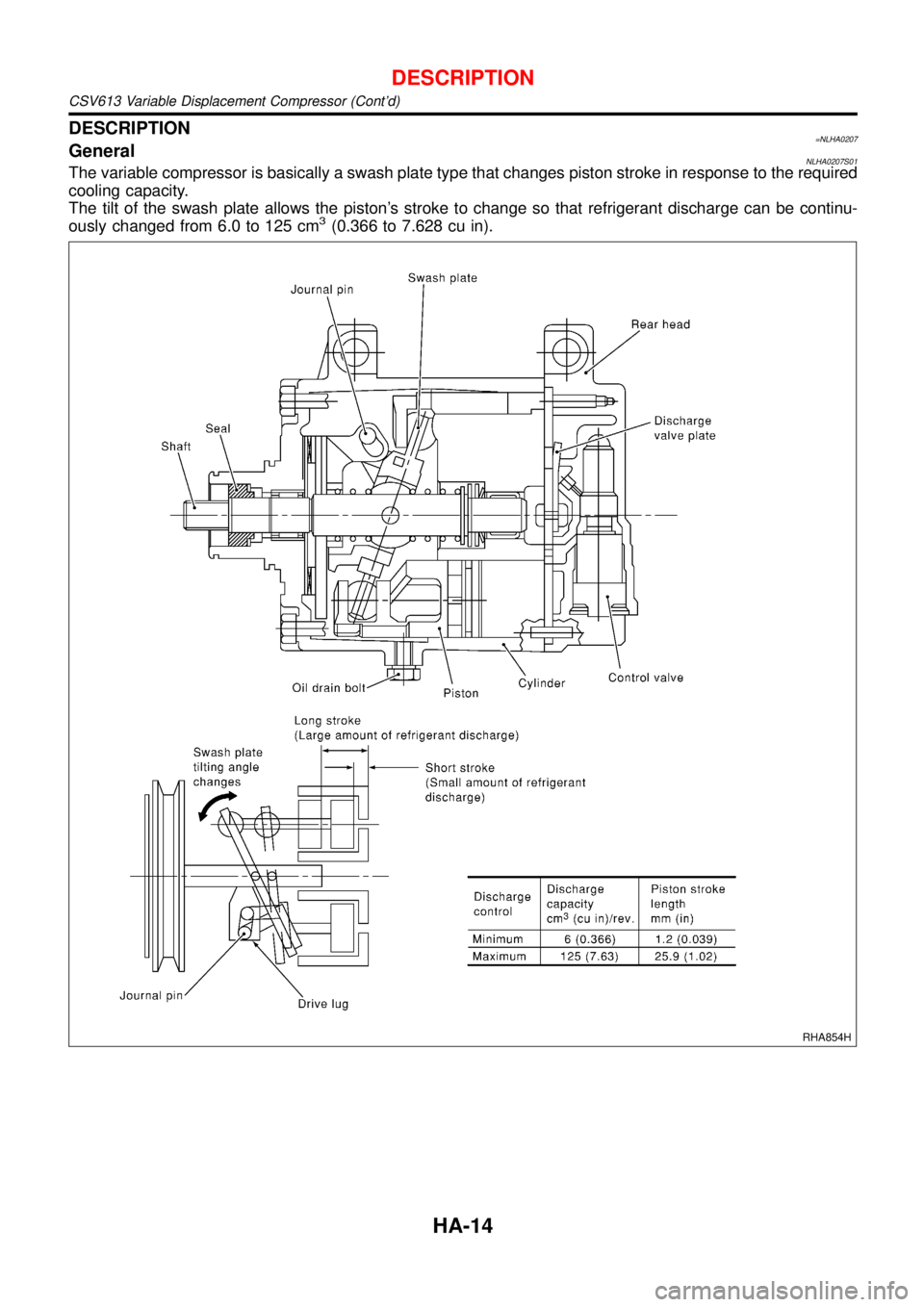

DESCRIPTION=NLHA0207GeneralNLHA0207S01The variable compressor is basically a swash plate type that changes piston stroke in response to the required

cooling capacity.

The tilt of the swash plate allows the piston’s stroke to change so that refrigerant discharge can be continu-

ously changed from 6.0 to 125 cm

3(0.366 to 7.628 cu in).

RHA854H

DESCRIPTION

CSV613 Variable Displacement Compressor (Cont’d)

HA-14

Page 2606 of 3051

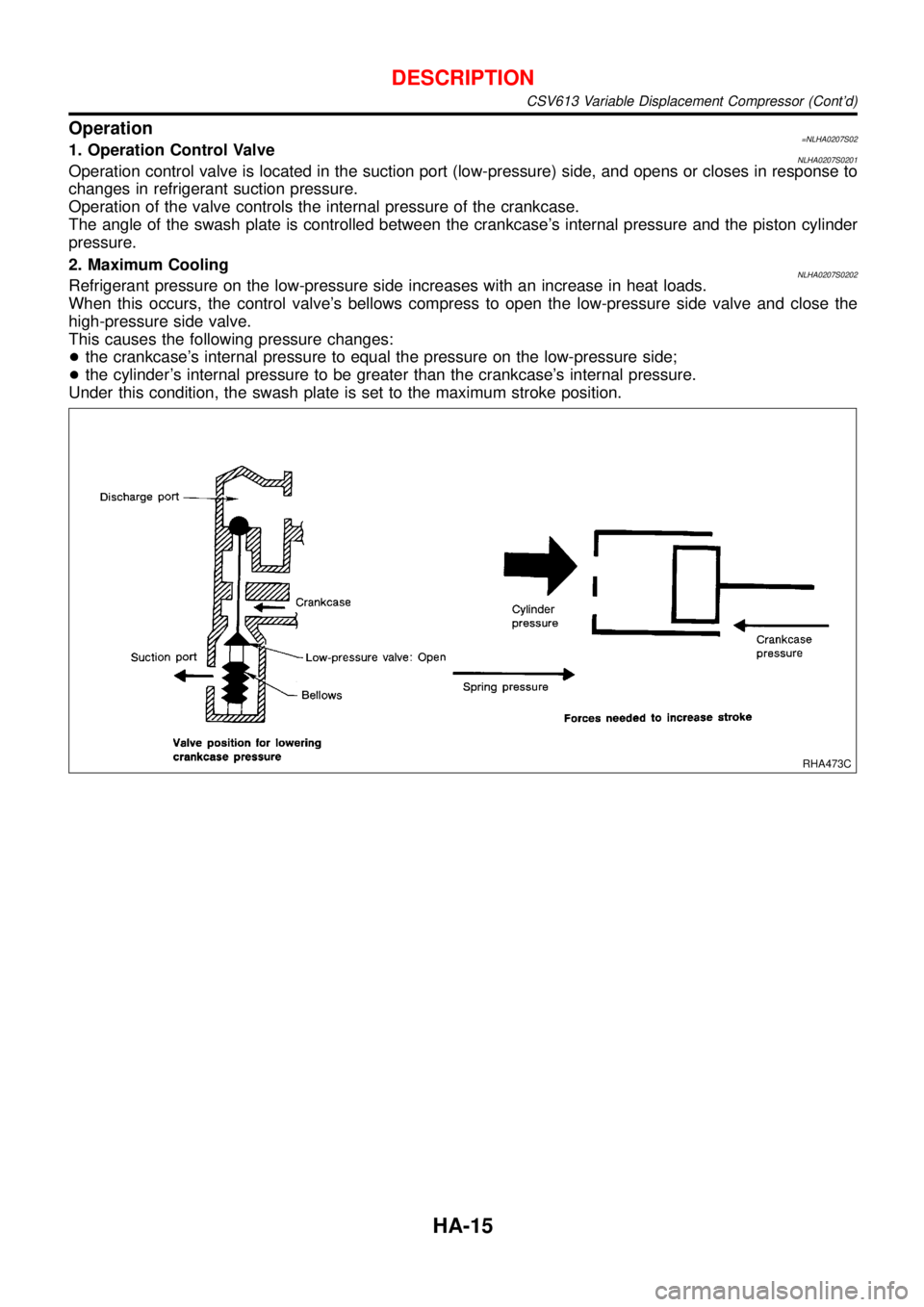

Operation=NLHA0207S021. Operation Control ValveNLHA0207S0201Operation control valve is located in the suction port (low-pressure) side, and opens or closes in response to

changes in refrigerant suction pressure.

Operation of the valve controls the internal pressure of the crankcase.

The angle of the swash plate is controlled between the crankcase’s internal pressure and the piston cylinder

pressure.

2. Maximum Cooling

NLHA0207S0202Refrigerant pressure on the low-pressure side increases with an increase in heat loads.

When this occurs, the control valve’s bellows compress to open the low-pressure side valve and close the

high-pressure side valve.

This causes the following pressure changes:

+the crankcase’s internal pressure to equal the pressure on the low-pressure side;

+the cylinder’s internal pressure to be greater than the crankcase’s internal pressure.

Under this condition, the swash plate is set to the maximum stroke position.

RHA473C

DESCRIPTION

CSV613 Variable Displacement Compressor (Cont’d)

HA-15

Page 2607 of 3051

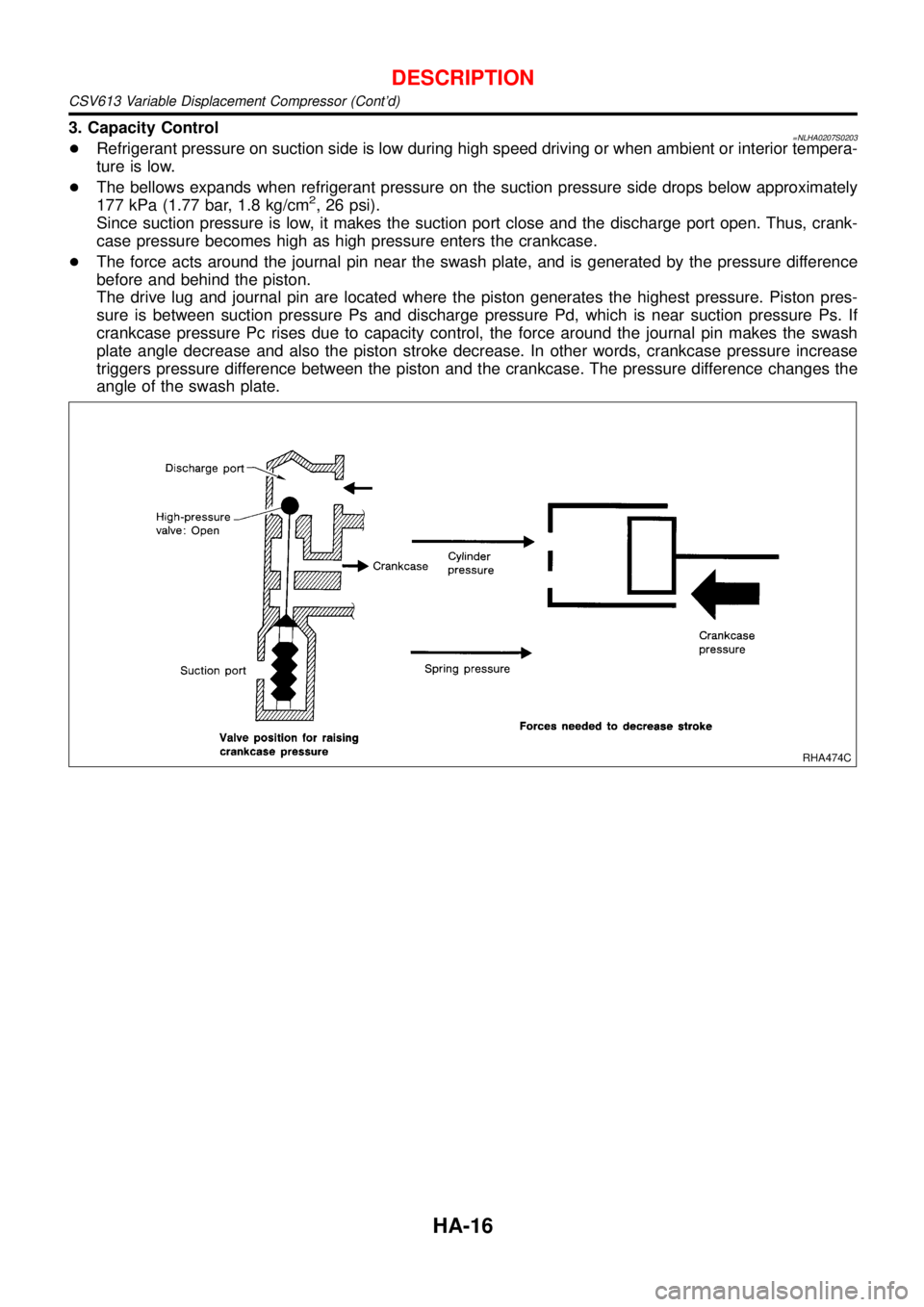

3. Capacity Control=NLHA0207S0203+Refrigerant pressure on suction side is low during high speed driving or when ambient or interior tempera-

ture is low.

+The bellows expands when refrigerant pressure on the suction pressure side drops below approximately

177 kPa (1.77 bar, 1.8 kg/cm

2, 26 psi).

Since suction pressure is low, it makes the suction port close and the discharge port open. Thus, crank-

case pressure becomes high as high pressure enters the crankcase.

+The force acts around the journal pin near the swash plate, and is generated by the pressure difference

before and behind the piston.

The drive lug and journal pin are located where the piston generates the highest pressure. Piston pres-

sure is between suction pressure Ps and discharge pressure Pd, which is near suction pressure Ps. If

crankcase pressure Pc rises due to capacity control, the force around the journal pin makes the swash

plate angle decrease and also the piston stroke decrease. In other words, crankcase pressure increase

triggers pressure difference between the piston and the crankcase. The pressure difference changes the

angle of the swash plate.

RHA474C

DESCRIPTION

CSV613 Variable Displacement Compressor (Cont’d)

HA-16

Page 2608 of 3051

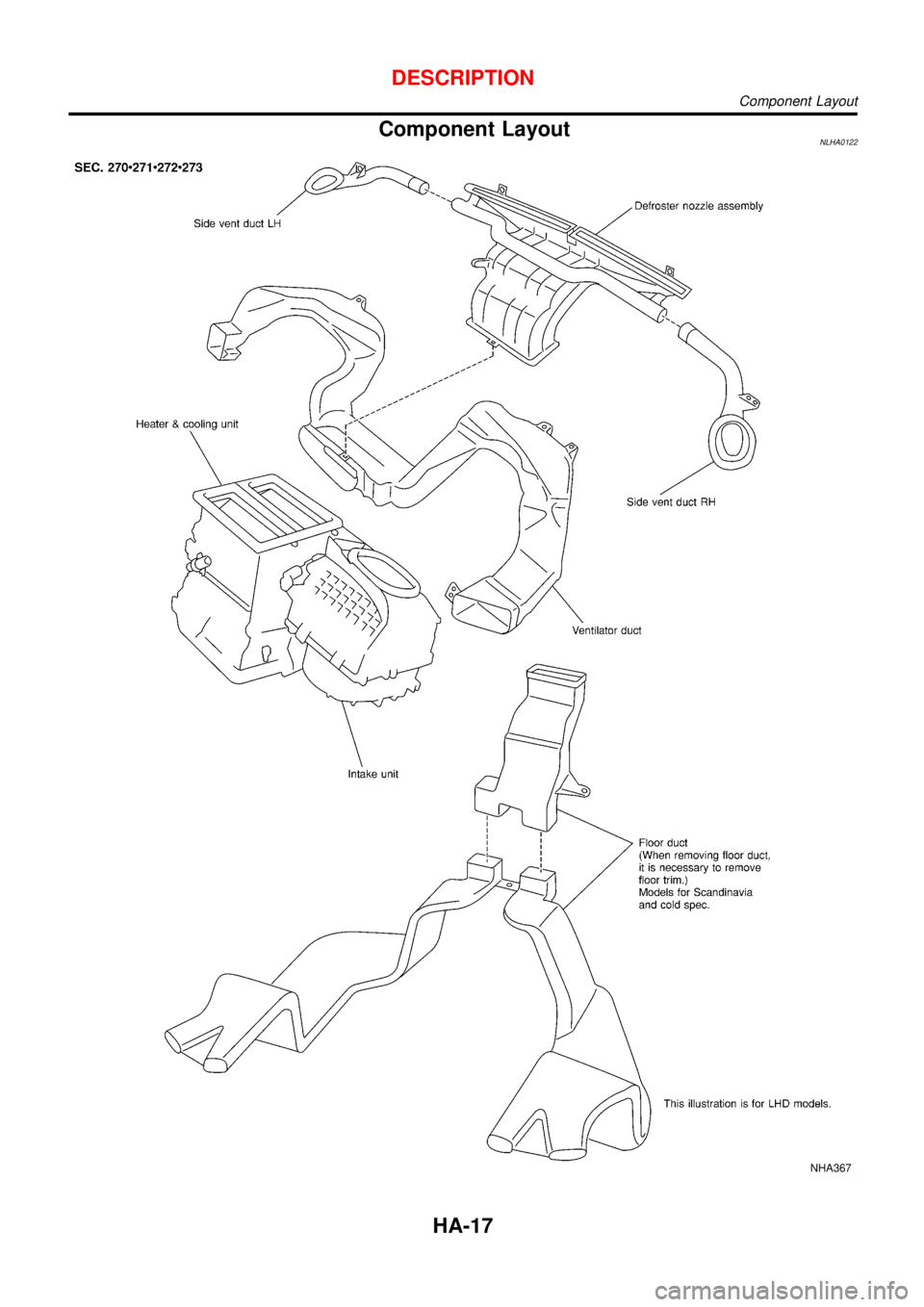

Component LayoutNLHA0122

NHA367

DESCRIPTION

Component Layout

HA-17

Page 2609 of 3051

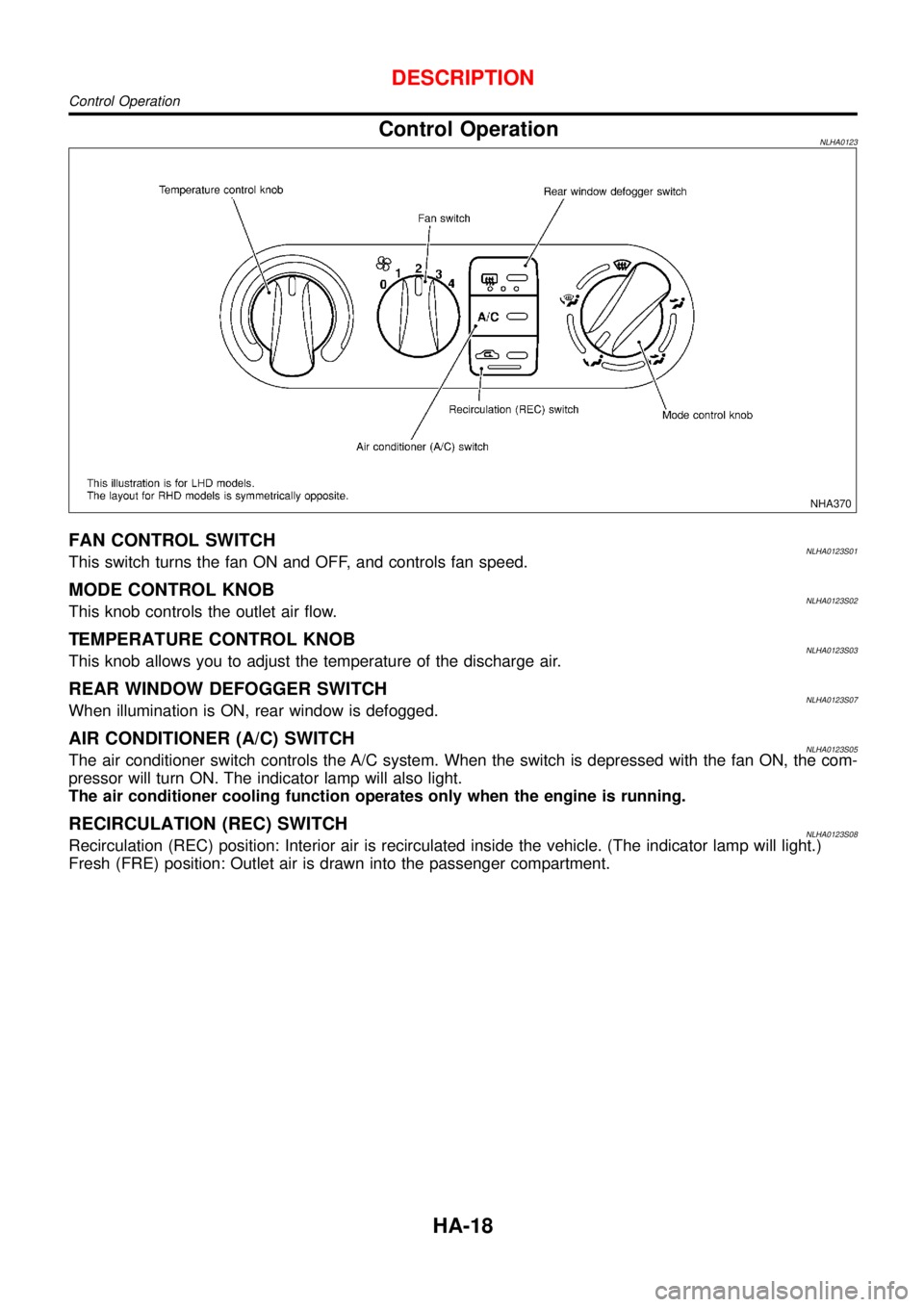

Control OperationNLHA0123

NHA370

FAN CONTROL SWITCHNLHA0123S01This switch turns the fan ON and OFF, and controls fan speed.

MODE CONTROL KNOBNLHA0123S02This knob controls the outlet air flow.

TEMPERATURE CONTROL KNOBNLHA0123S03This knob allows you to adjust the temperature of the discharge air.

REAR WINDOW DEFOGGER SWITCHNLHA0123S07When illumination is ON, rear window is defogged.

AIR CONDITIONER (A/C) SWITCHNLHA0123S05The air conditioner switch controls the A/C system. When the switch is depressed with the fan ON, the com-

pressor will turn ON. The indicator lamp will also light.

The air conditioner cooling function operates only when the engine is running.

RECIRCULATION (REC) SWITCHNLHA0123S08Recirculation (REC) position: Interior air is recirculated inside the vehicle. (The indicator lamp will light.)

Fresh (FRE) position: Outlet air is drawn into the passenger compartment.

DESCRIPTION

Control Operation

HA-18

Page 2610 of 3051

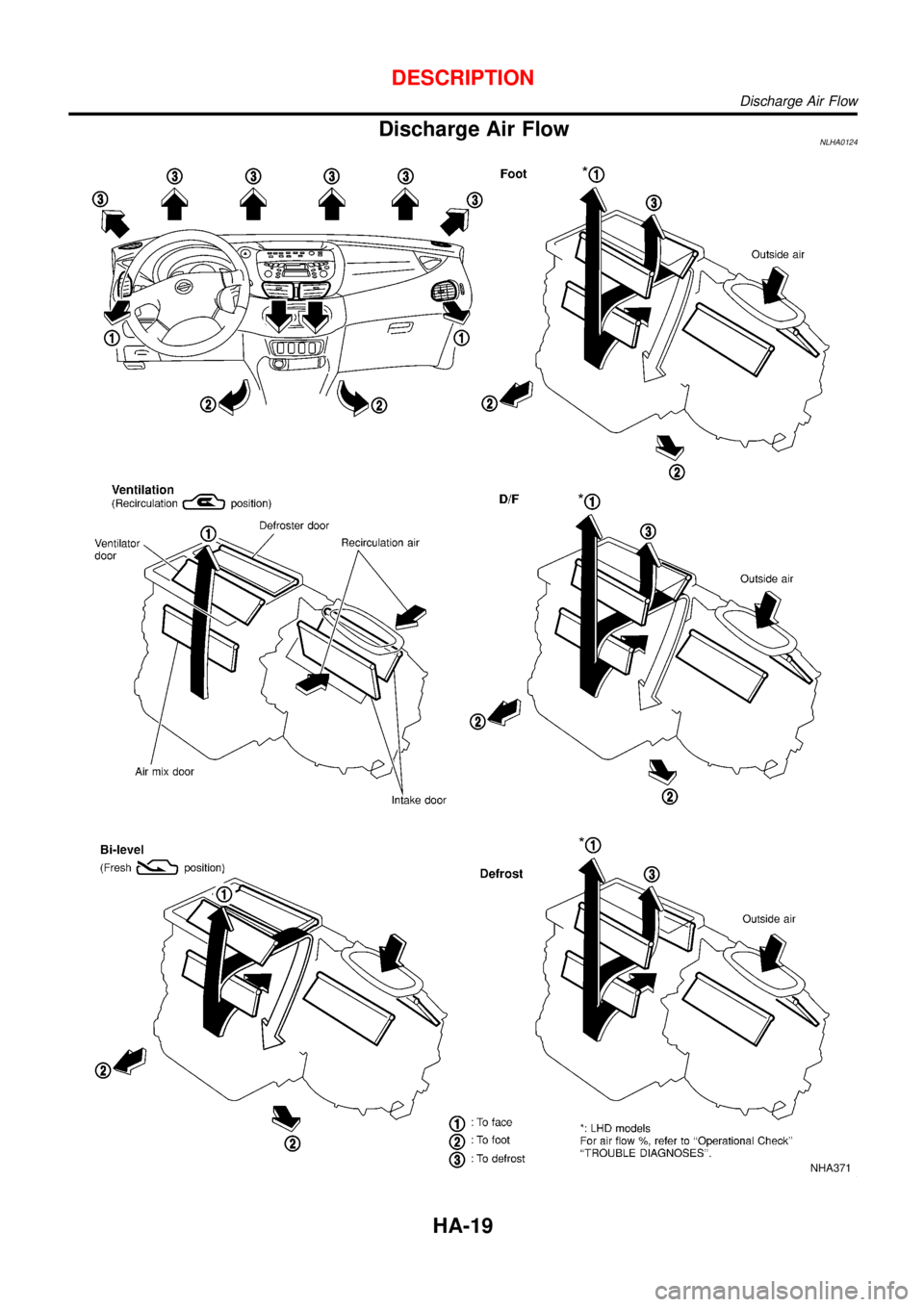

Discharge Air FlowNLHA0124

NHA371

DESCRIPTION

Discharge Air Flow

HA-19