NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2641 of 3051

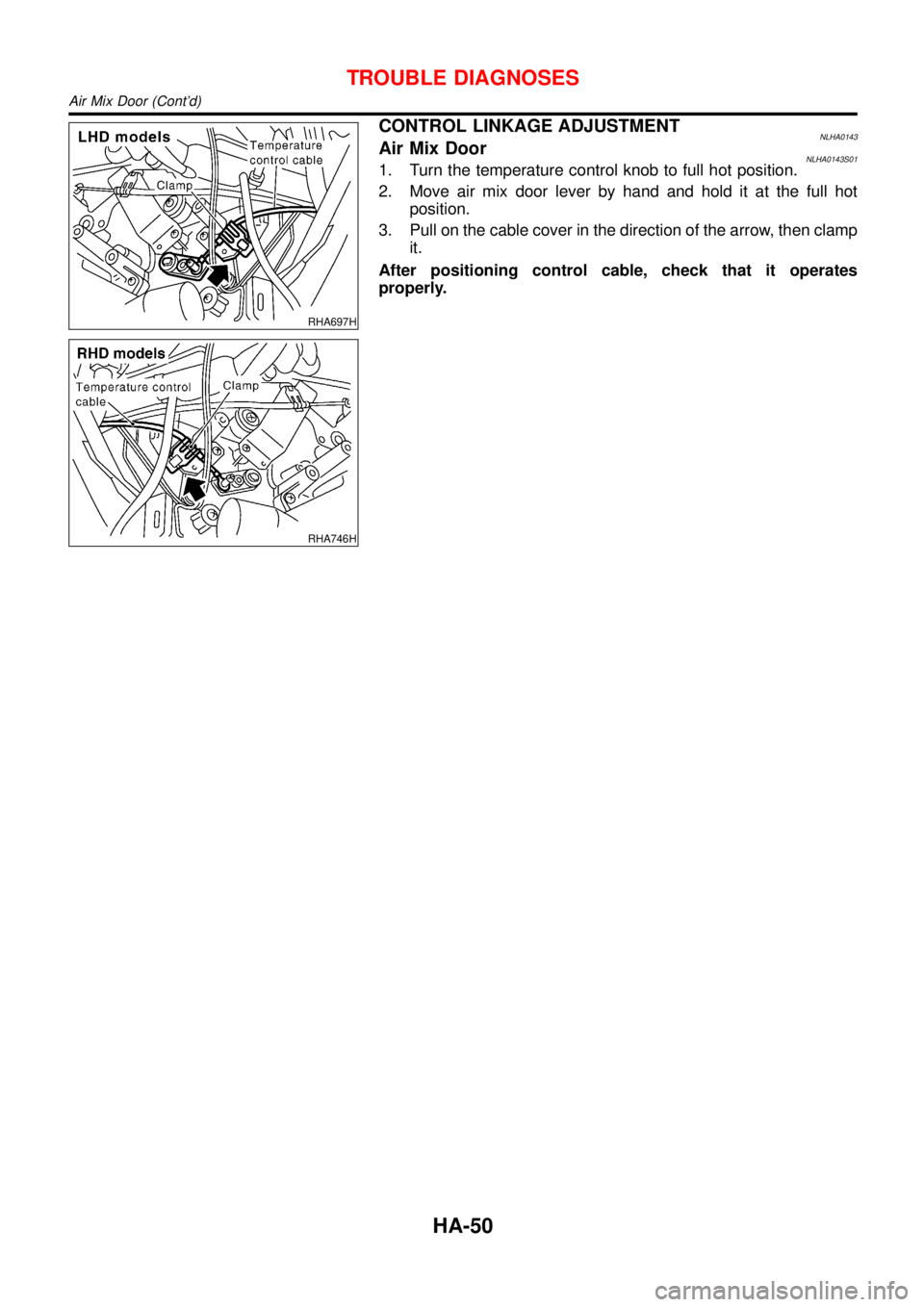

RHA697H

RHA746H

CONTROL LINKAGE ADJUSTMENTNLHA0143Air Mix DoorNLHA0143S011. Turn the temperature control knob to full hot position.

2. Move air mix door lever by hand and hold it at the full hot

position.

3. Pull on the cable cover in the direction of the arrow, then clamp

it.

After positioning control cable, check that it operates

properly.

TROUBLE DIAGNOSES

Air Mix Door (Cont’d)

HA-50

Page 2642 of 3051

Max Hot Door (For Scandinavia and Cold Spec

Models)

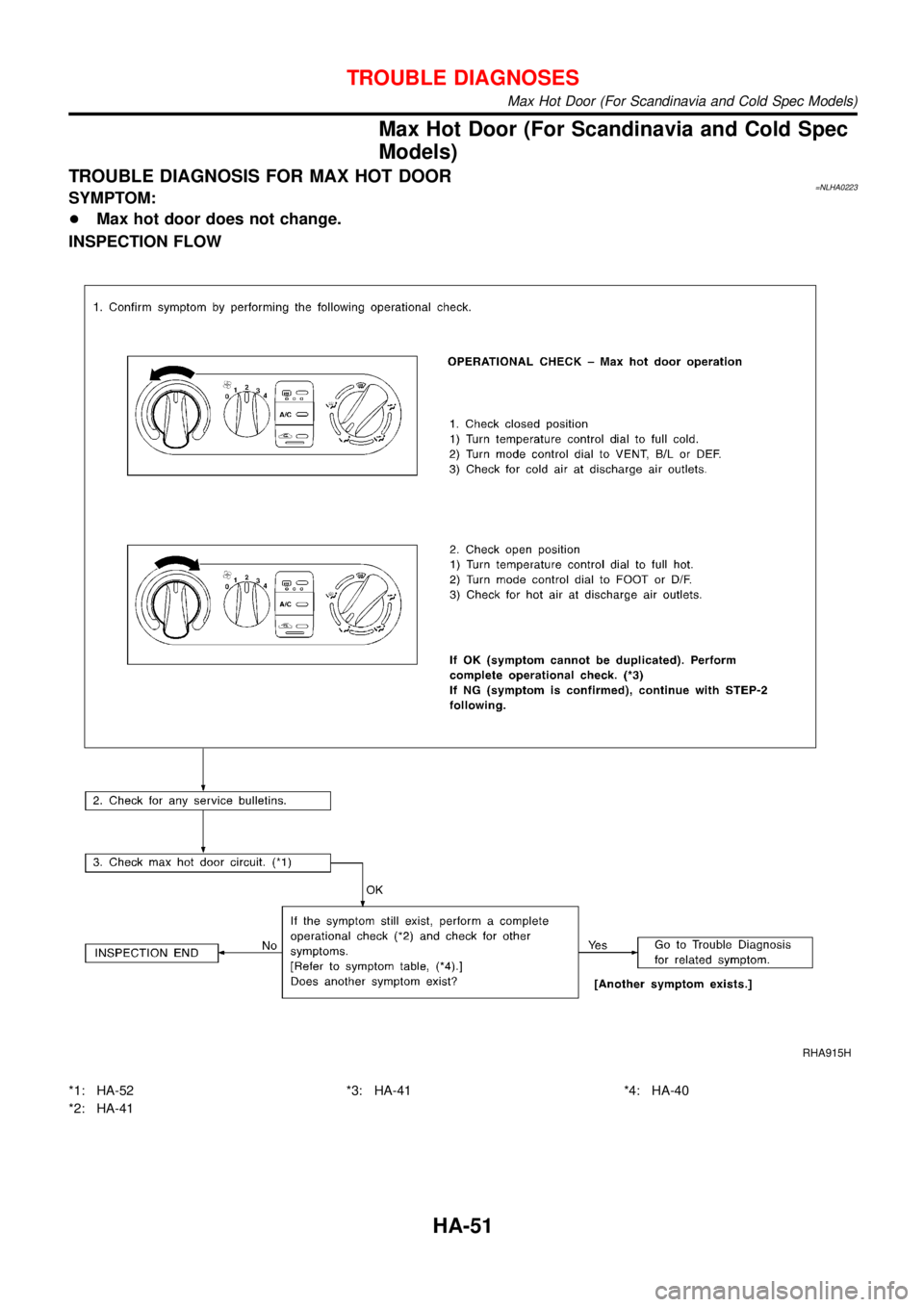

TROUBLE DIAGNOSIS FOR MAX HOT DOOR=NLHA0223SYMPTOM:

+Max hot door does not change.

INSPECTION FLOW

RHA915H

*1: HA-52

*2: HA-41*3: HA-41 *4: HA-40

TROUBLE DIAGNOSES

Max Hot Door (For Scandinavia and Cold Spec Models)

HA-51

Page 2643 of 3051

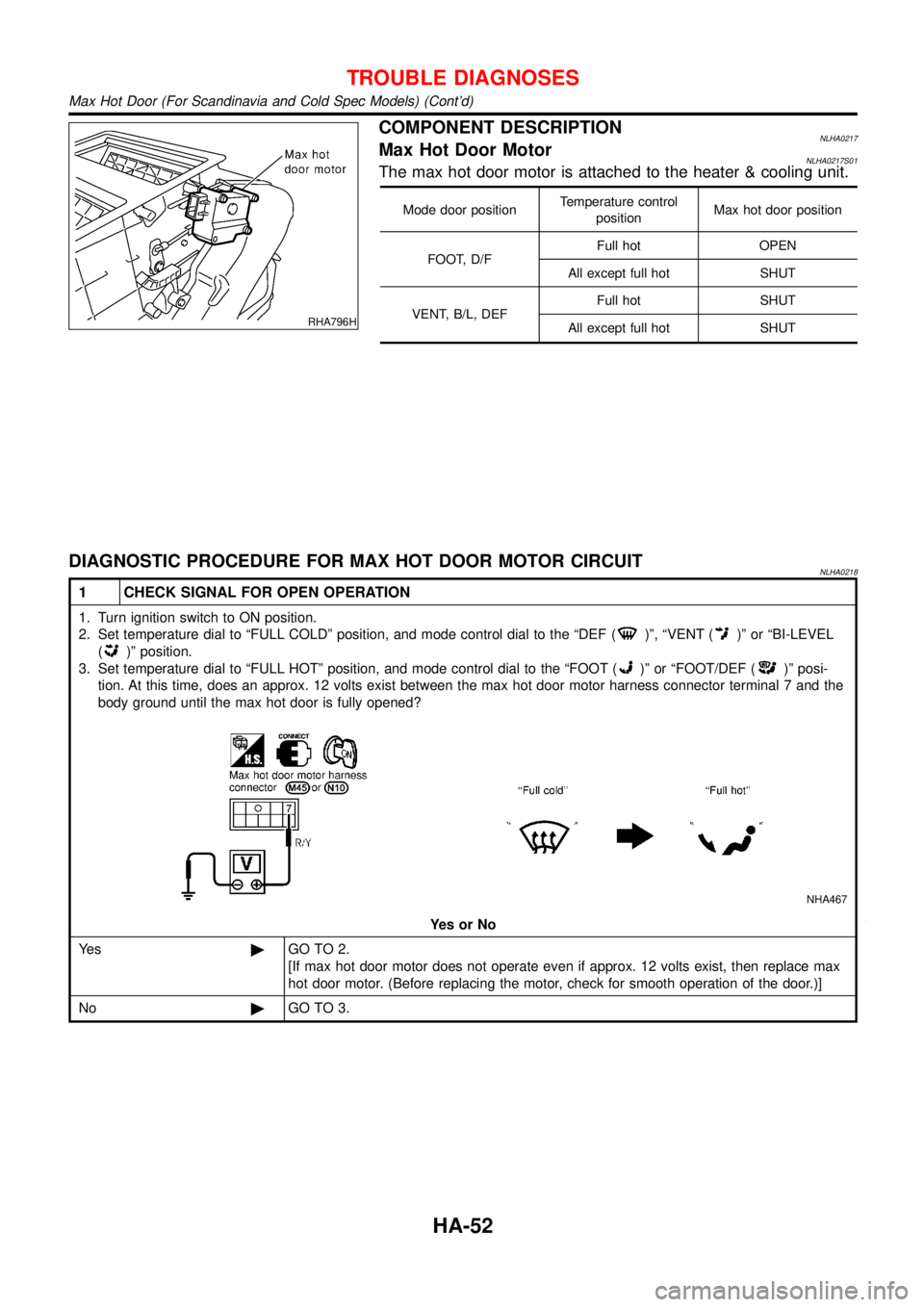

RHA796H

COMPONENT DESCRIPTIONNLHA0217Max Hot Door MotorNLHA0217S01The max hot door motor is attached to the heater & cooling unit.

Mode door positionTemperature control

positionMax hot door position

FOOT, D/FFull hot OPEN

All except full hot SHUT

VENT, B/L, DEFFull hot SHUT

All except full hot SHUT

DIAGNOSTIC PROCEDURE FOR MAX HOT DOOR MOTOR CIRCUITNLHA0218

1 CHECK SIGNAL FOR OPEN OPERATION

1. Turn ignition switch to ON position.

2. Set temperature dial to“FULL COLD”position, and mode control dial to the“DEF (

)”,“VENT ()”or“BI-LEVEL

(

)”position.

3. Set temperature dial to“FULL HOT”position, and mode control dial to the“FOOT (

)”or“FOOT/DEF ()”posi-

tion. At this time, does an approx. 12 volts exist between the max hot door motor harness connector terminal 7 and the

body ground until the max hot door is fully opened?

NHA467

YesorNo

Ye s©GO TO 2.

[If max hot door motor does not operate even if approx. 12 volts exist, then replace max

hot door motor. (Before replacing the motor, check for smooth operation of the door.)]

No©GO TO 3.

TROUBLE DIAGNOSES

Max Hot Door (For Scandinavia and Cold Spec Models) (Cont’d)

HA-52

Page 2644 of 3051

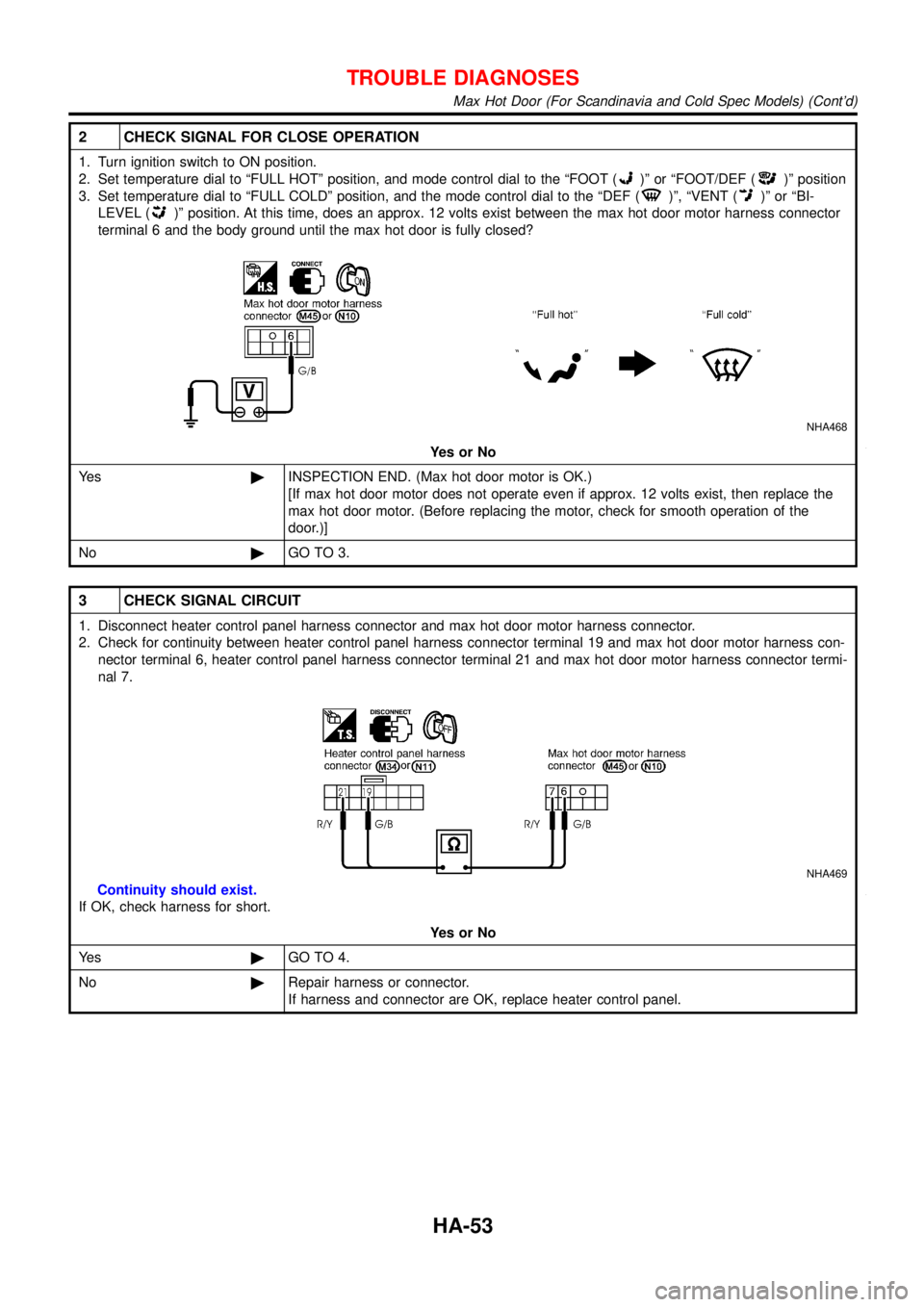

2 CHECK SIGNAL FOR CLOSE OPERATION

1. Turn ignition switch to ON position.

2. Set temperature dial to“FULL HOT”position, and mode control dial to the“FOOT (

)”or“FOOT/DEF ()”position

3. Set temperature dial to“FULL COLD”position, and the mode control dial to the“DEF (

)”,“VENT ()”or“BI-

LEVEL (

)”position. At this time, does an approx. 12 volts exist between the max hot door motor harness connector

terminal 6 and the body ground until the max hot door is fully closed?

NHA468

YesorNo

Ye s©INSPECTION END. (Max hot door motor is OK.)

[If max hot door motor does not operate even if approx. 12 volts exist, then replace the

max hot door motor. (Before replacing the motor, check for smooth operation of the

door.)]

No©GO TO 3.

3 CHECK SIGNAL CIRCUIT

1. Disconnect heater control panel harness connector and max hot door motor harness connector.

2. Check for continuity between heater control panel harness connector terminal 19 and max hot door motor harness con-

nector terminal 6, heater control panel harness connector terminal 21 and max hot door motor harness connector termi-

nal 7.

NHA469

Continuity should exist.

If OK, check harness for short.

YesorNo

Ye s©GO TO 4.

No©Repair harness or connector.

If harness and connector are OK, replace heater control panel.

TROUBLE DIAGNOSES

Max Hot Door (For Scandinavia and Cold Spec Models) (Cont’d)

HA-53

Page 2645 of 3051

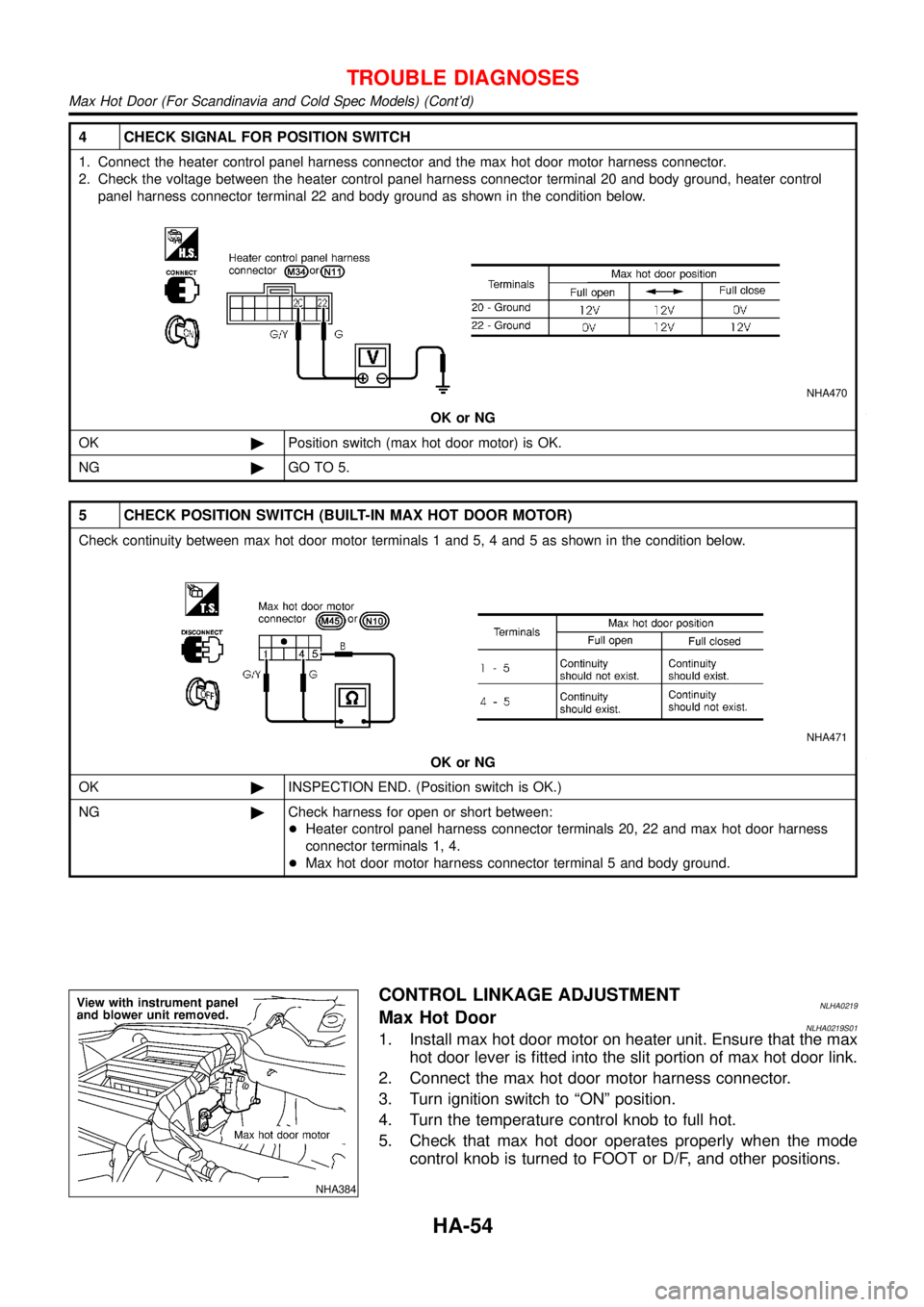

4 CHECK SIGNAL FOR POSITION SWITCH

1. Connect the heater control panel harness connector and the max hot door motor harness connector.

2. Check the voltage between the heater control panel harness connector terminal 20 and body ground, heater control

panel harness connector terminal 22 and body ground as shown in the condition below.

NHA470

OK or NG

OK©Position switch (max hot door motor) is OK.

NG©GO TO 5.

5 CHECK POSITION SWITCH (BUILT-IN MAX HOT DOOR MOTOR)

Check continuity between max hot door motor terminals 1 and 5, 4 and 5 as shown in the condition below.

NHA471

OK or NG

OK©INSPECTION END. (Position switch is OK.)

NG©Check harness for open or short between:

+Heater control panel harness connector terminals 20, 22 and max hot door harness

connector terminals 1, 4.

+Max hot door motor harness connector terminal 5 and body ground.

NHA384

CONTROL LINKAGE ADJUSTMENTNLHA0219Max Hot DoorNLHA0219S011. Install max hot door motor on heater unit. Ensure that the max

hot door lever is fitted into the slit portion of max hot door link.

2. Connect the max hot door motor harness connector.

3. Turn ignition switch to“ON”position.

4. Turn the temperature control knob to full hot.

5. Check that max hot door operates properly when the mode

control knob is turned to FOOT or D/F, and other positions.

TROUBLE DIAGNOSES

Max Hot Door (For Scandinavia and Cold Spec Models) (Cont’d)

HA-54

Page 2646 of 3051

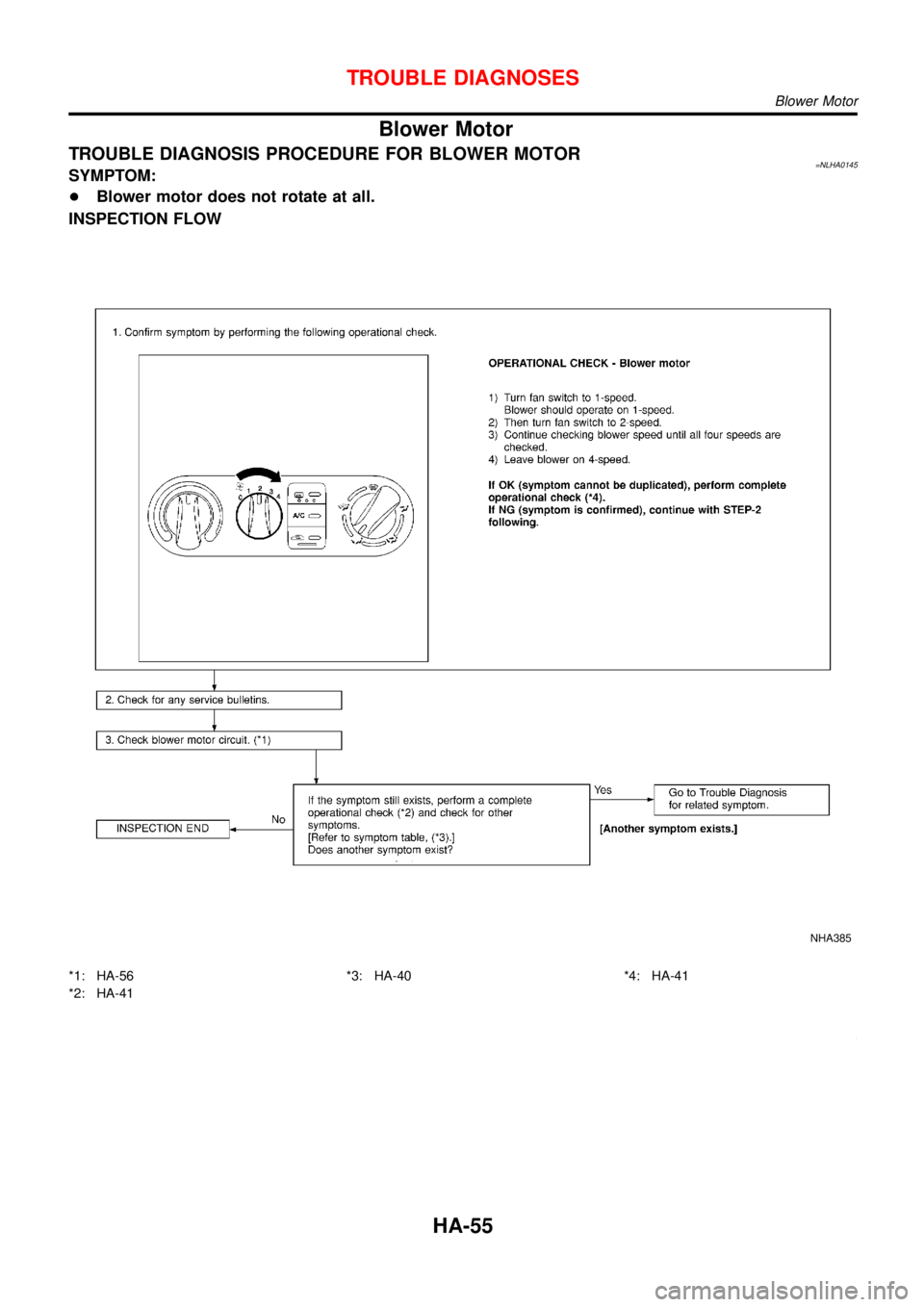

Blower Motor

TROUBLE DIAGNOSIS PROCEDURE FOR BLOWER MOTOR=NLHA0145SYMPTOM:

+Blower motor does not rotate at all.

INSPECTION FLOW

NHA385

*1: HA-56

*2: HA-41*3: HA-40 *4: HA-41

TROUBLE DIAGNOSES

Blower Motor

HA-55

Page 2647 of 3051

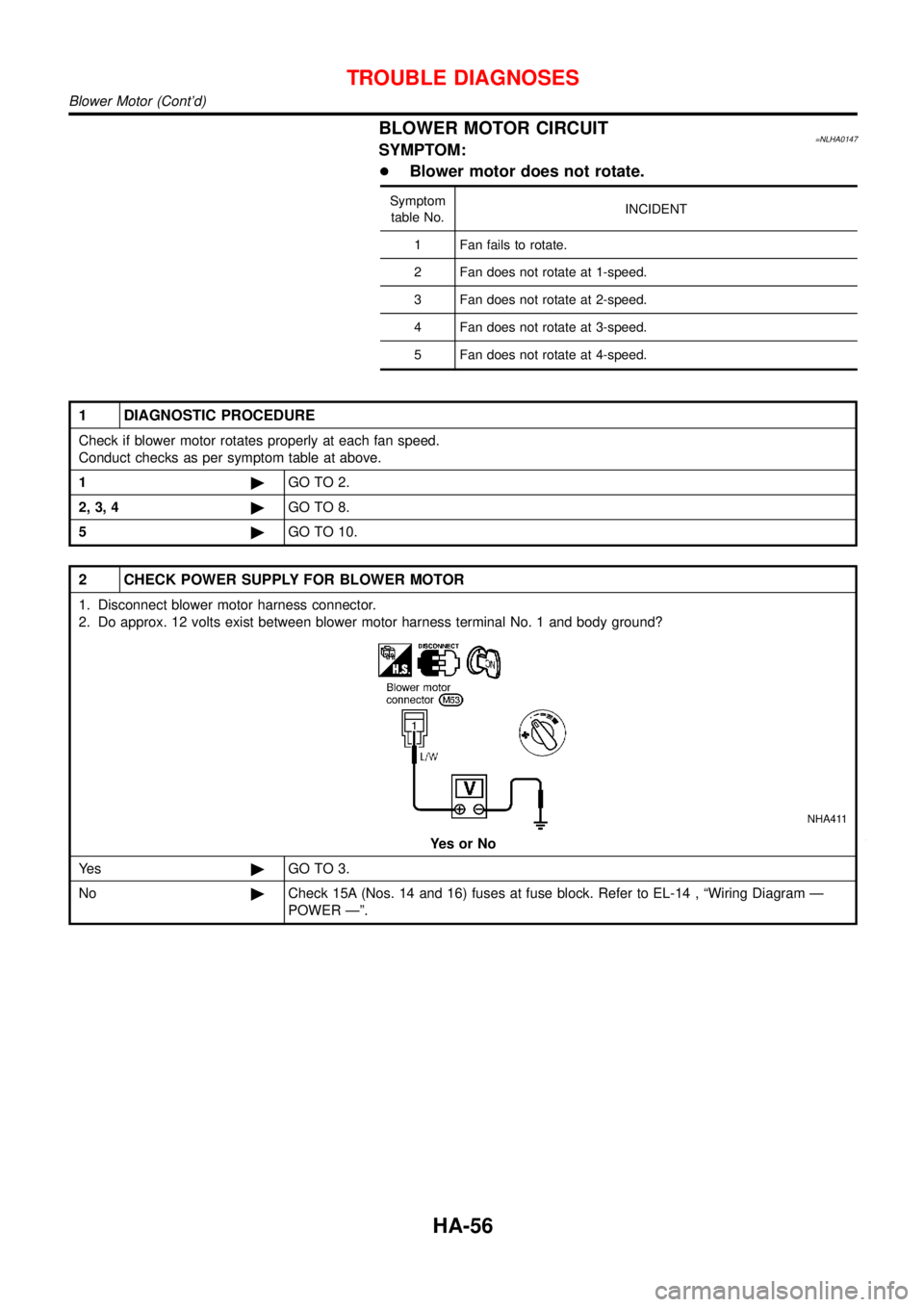

BLOWER MOTOR CIRCUIT=NLHA0147SYMPTOM:

+Blower motor does not rotate.

Symptom

table No.INCIDENT

1 Fan fails to rotate.

2 Fan does not rotate at 1-speed.

3 Fan does not rotate at 2-speed.

4 Fan does not rotate at 3-speed.

5 Fan does not rotate at 4-speed.

1 DIAGNOSTIC PROCEDURE

Check if blower motor rotates properly at each fan speed.

Conduct checks as per symptom table at above.

1©GO TO 2.

2, 3, 4©GO TO 8.

5©GO TO 10.

2 CHECK POWER SUPPLY FOR BLOWER MOTOR

1. Disconnect blower motor harness connector.

2. Do approx. 12 volts exist between blower motor harness terminal No. 1 and body ground?

NHA411

YesorNo

Ye s©GO TO 3.

No©Check 15A (Nos. 14 and 16) fuses at fuse block. Refer to EL-14 ,“Wiring Diagram—

POWER—”.

TROUBLE DIAGNOSES

Blower Motor (Cont’d)

HA-56

Page 2648 of 3051

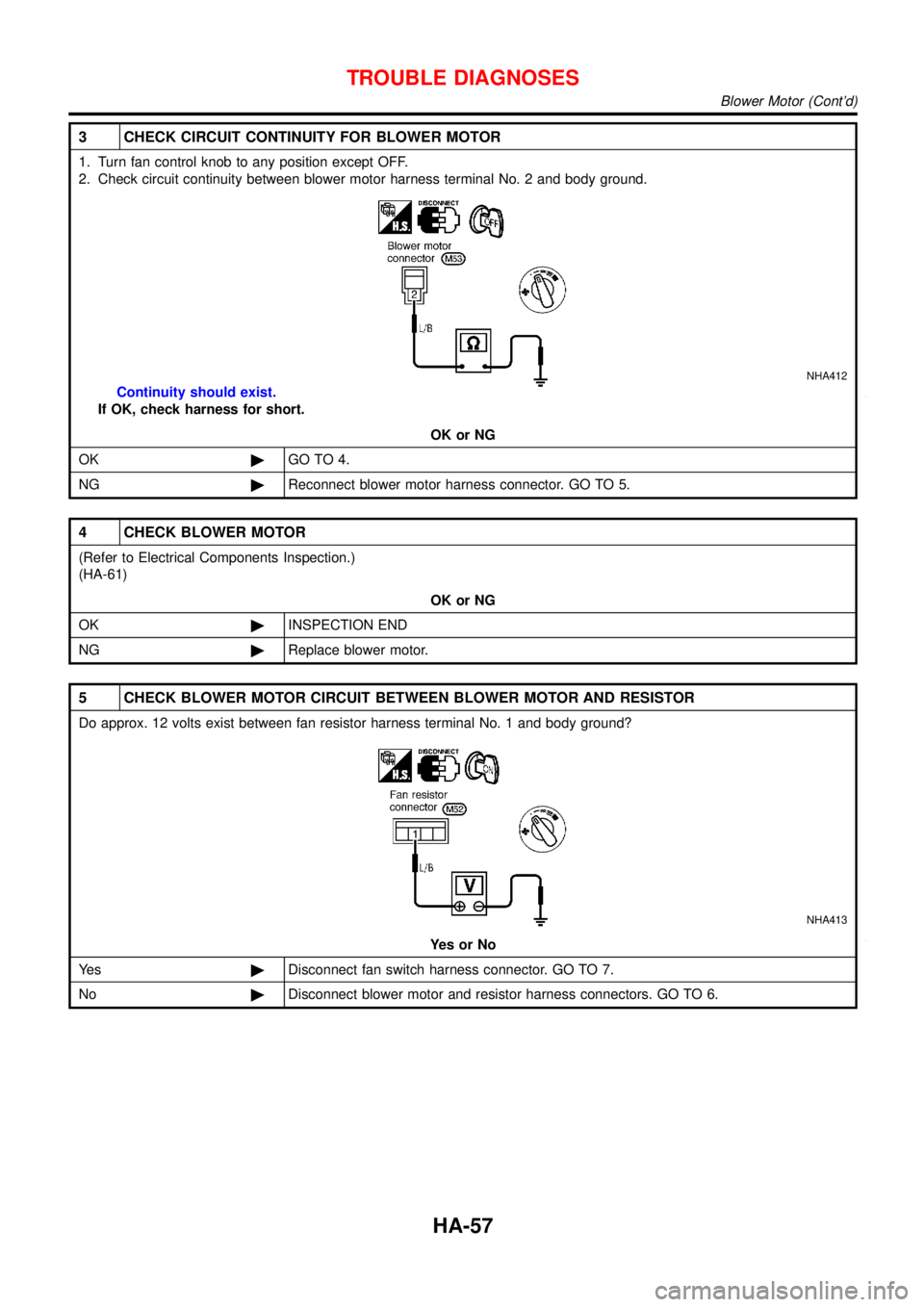

3 CHECK CIRCUIT CONTINUITY FOR BLOWER MOTOR

1. Turn fan control knob to any position except OFF.

2. Check circuit continuity between blower motor harness terminal No. 2 and body ground.

NHA412

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©GO TO 4.

NG©Reconnect blower motor harness connector. GO TO 5.

4 CHECK BLOWER MOTOR

(Refer to Electrical Components Inspection.)

(HA-61)

OK or NG

OK©INSPECTION END

NG©Replace blower motor.

5 CHECK BLOWER MOTOR CIRCUIT BETWEEN BLOWER MOTOR AND RESISTOR

Do approx. 12 volts exist between fan resistor harness terminal No. 1 and body ground?

NHA413

YesorNo

Ye s©Disconnect fan switch harness connector. GO TO 7.

No©Disconnect blower motor and resistor harness connectors. GO TO 6.

TROUBLE DIAGNOSES

Blower Motor (Cont’d)

HA-57

Page 2649 of 3051

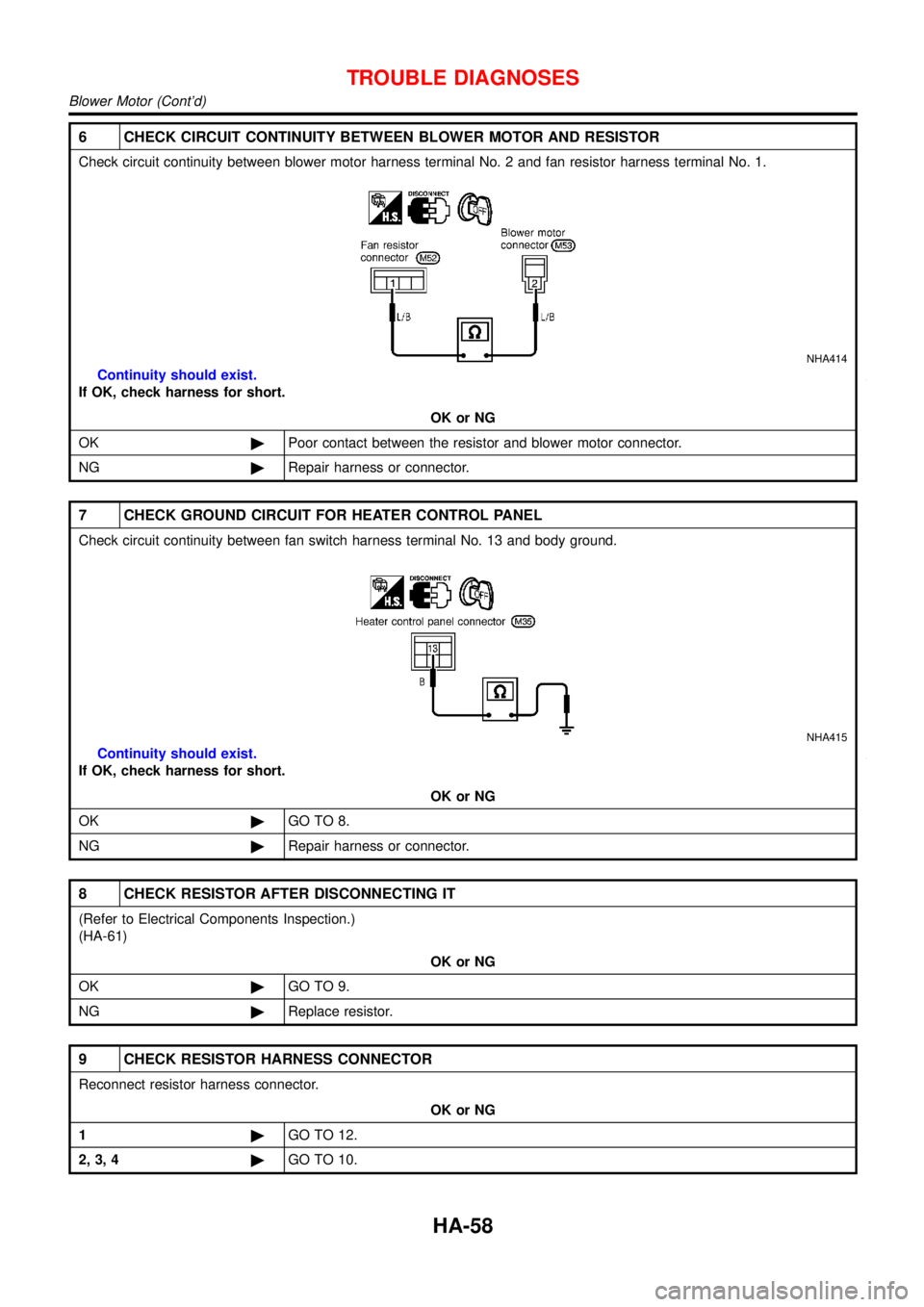

6 CHECK CIRCUIT CONTINUITY BETWEEN BLOWER MOTOR AND RESISTOR

Check circuit continuity between blower motor harness terminal No. 2 and fan resistor harness terminal No. 1.

NHA414

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©Poor contact between the resistor and blower motor connector.

NG©Repair harness or connector.

7 CHECK GROUND CIRCUIT FOR HEATER CONTROL PANEL

Check circuit continuity between fan switch harness terminal No. 13 and body ground.

NHA415

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©GO TO 8.

NG©Repair harness or connector.

8 CHECK RESISTOR AFTER DISCONNECTING IT

(Refer to Electrical Components Inspection.)

(HA-61)

OK or NG

OK©GO TO 9.

NG©Replace resistor.

9 CHECK RESISTOR HARNESS CONNECTOR

Reconnect resistor harness connector.

OK or NG

1©GO TO 12.

2, 3, 4©GO TO 10.

TROUBLE DIAGNOSES

Blower Motor (Cont’d)

HA-58

Page 2650 of 3051

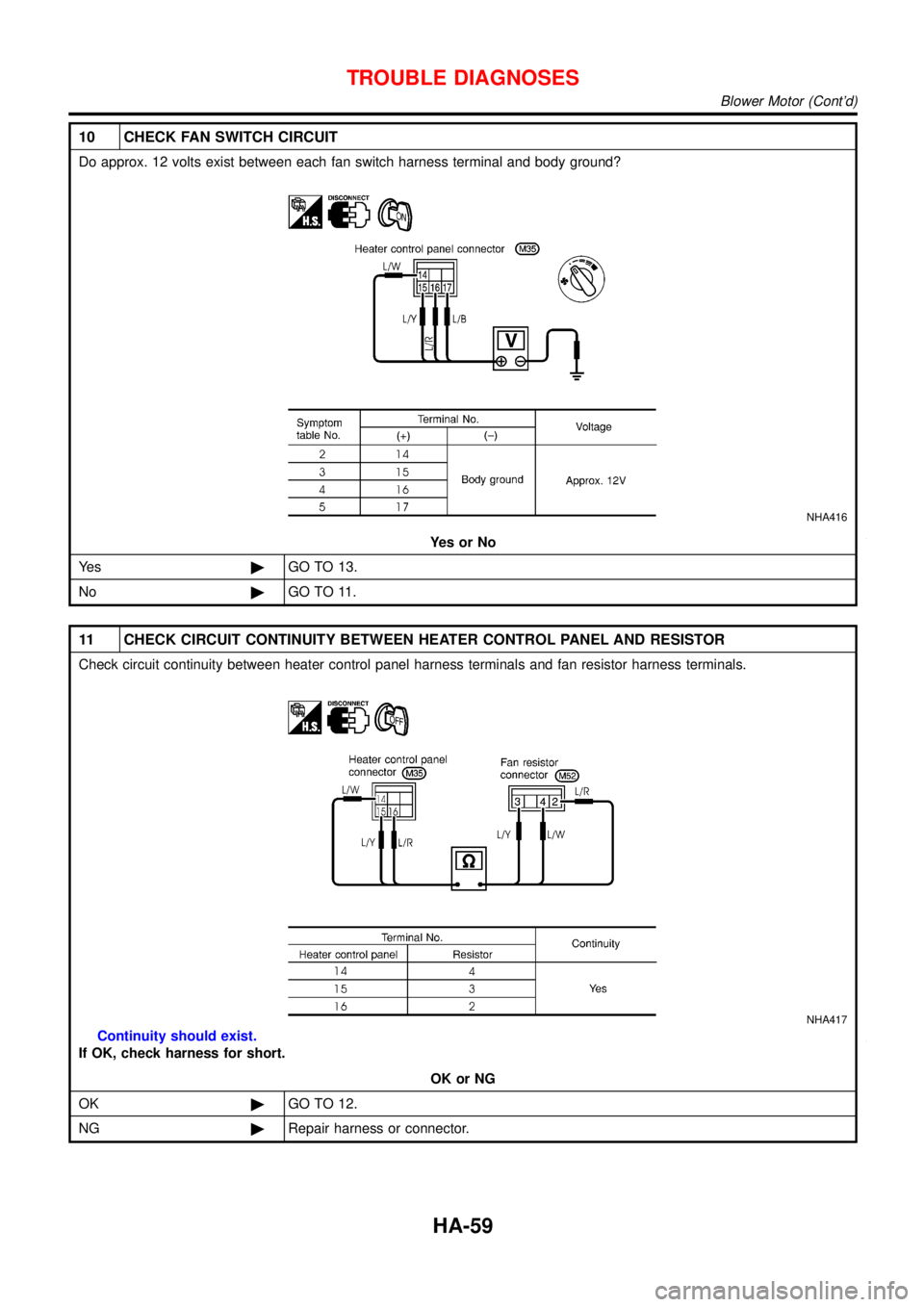

10 CHECK FAN SWITCH CIRCUIT

Do approx. 12 volts exist between each fan switch harness terminal and body ground?

NHA416

YesorNo

Ye s©GO TO 13.

No©GO TO 11.

11 CHECK CIRCUIT CONTINUITY BETWEEN HEATER CONTROL PANEL AND RESISTOR

Check circuit continuity between heater control panel harness terminals and fan resistor harness terminals.

NHA417

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©GO TO 12.

NG©Repair harness or connector.

TROUBLE DIAGNOSES

Blower Motor (Cont’d)

HA-59