turn signal NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2645 of 3051

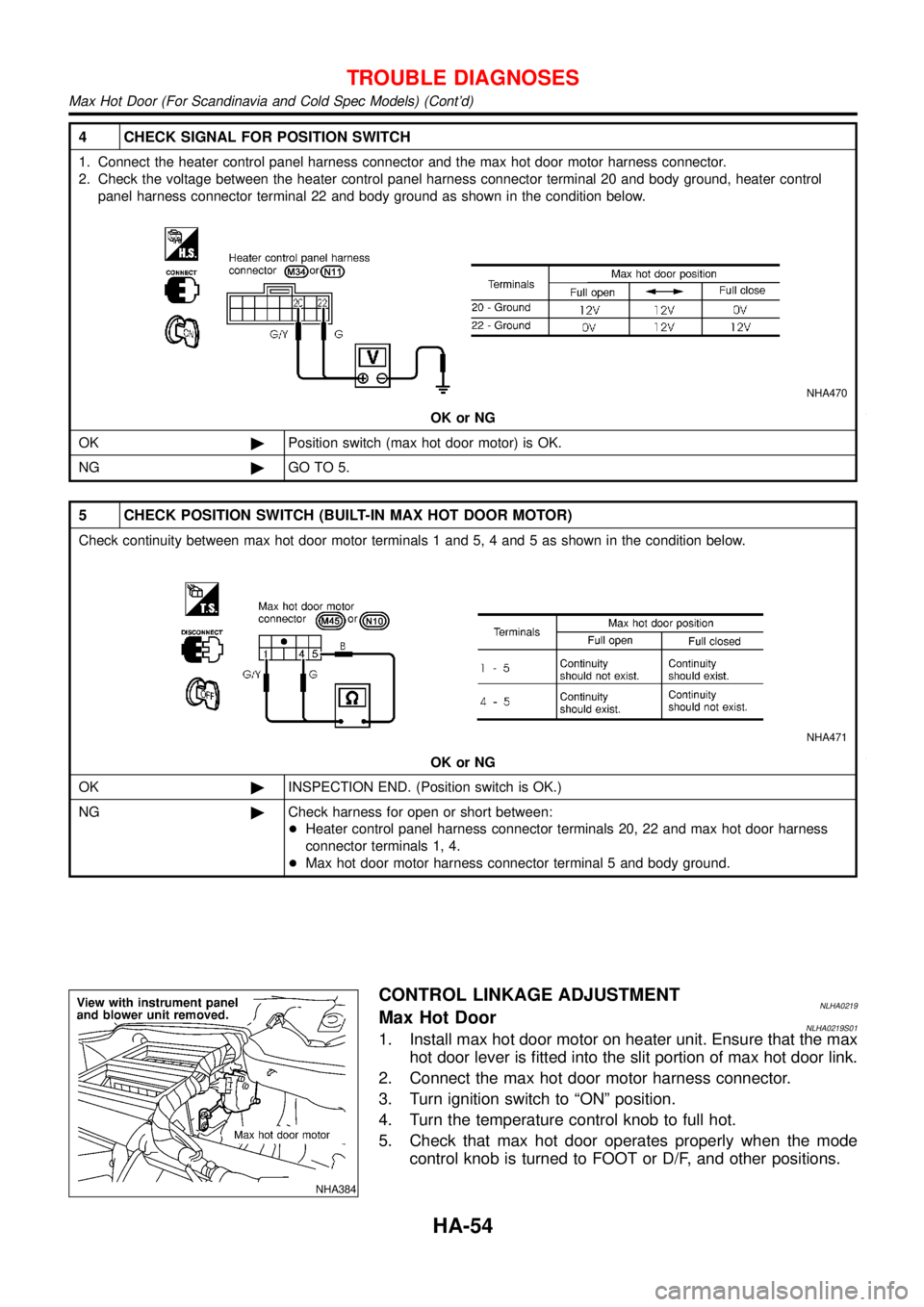

4 CHECK SIGNAL FOR POSITION SWITCH

1. Connect the heater control panel harness connector and the max hot door motor harness connector.

2. Check the voltage between the heater control panel harness connector terminal 20 and body ground, heater control

panel harness connector terminal 22 and body ground as shown in the condition below.

NHA470

OK or NG

OK©Position switch (max hot door motor) is OK.

NG©GO TO 5.

5 CHECK POSITION SWITCH (BUILT-IN MAX HOT DOOR MOTOR)

Check continuity between max hot door motor terminals 1 and 5, 4 and 5 as shown in the condition below.

NHA471

OK or NG

OK©INSPECTION END. (Position switch is OK.)

NG©Check harness for open or short between:

+Heater control panel harness connector terminals 20, 22 and max hot door harness

connector terminals 1, 4.

+Max hot door motor harness connector terminal 5 and body ground.

NHA384

CONTROL LINKAGE ADJUSTMENTNLHA0219Max Hot DoorNLHA0219S011. Install max hot door motor on heater unit. Ensure that the max

hot door lever is fitted into the slit portion of max hot door link.

2. Connect the max hot door motor harness connector.

3. Turn ignition switch to“ON”position.

4. Turn the temperature control knob to full hot.

5. Check that max hot door operates properly when the mode

control knob is turned to FOOT or D/F, and other positions.

TROUBLE DIAGNOSES

Max Hot Door (For Scandinavia and Cold Spec Models) (Cont’d)

HA-54

Page 2702 of 3051

S

S/LOCK - Wiring diagram ................ EL-260, 286

S/SIG - Wiring diagram ................. EC-512, 1028

SAE J1930 terminology list ........................ GI-48

SHIFT - Wiring diagram ........................... AT-196

SROOF - Wiring diagram ........................ EL-238

SRS - See Supplemental Restraint

System ................................................... RS-16

START - Wiring diagram ........................... SC-14

STOP/L - Wiring diagram .......................... EL-91

SWL/V - Wiring diagram ................. EC-366, 481

Seal - See Exterior .................................... BT-38

Seat belt pre-tensioner disposal ............... RS-30

Seat belt pre-tensioner ............................... RS-3

Seat belt, front ............................................ RS-5

Seat belt, rear ............................................. RS-7

Seat, front .................................................. BT-46

Seat, rear ................................................... BT-49

Self-diagnostic results ............ EC-73, 598, 1098

Shift control components (M/T) .......... MT-26, 64

Shift fork (M/T) .................................... MT-26, 64

Shift lever .................................................. MT-23

Shift lock system ...................................... AT-195

Shock absorber (front) .............................. SU-11

Shock absorber (rear) ............................... SU-23

Side air bag ............................................... RS-28

Side trim .................................................... BT-28

Speedometer ........................................... EL-130

Spiral cable ............................................... RS-24

Spring (Wheelarch) height .......................... SU-6

Stabilizer bar (front) .................................. SU-12

Stall test (A/T) ............................................ AT-51

Standardized relay ....................................... EL-7

Start signal .......................... EC-511, 1027, 1293

Starter ....................................................... SC-17

Starting system ......................................... SC-13

Steering linkage ......................................... ST-15

Steering switch .......................................... EL-67

Steering wheel and column ....................... ST-10

Steering wheel play ..................................... ST-6

Steering wheel turning force ....................... ST-8

Stop lamp .................................................. EL-91

Striking rod (M/T) ................................ MT-26, 64

Strut (front) ................................................ SU-10

Strut (rear) ................................................. SU-22

Sub-gear (M/T) .......................................... MT-25

Sunroof, electric ....................................... EL-238

Sunroof ...................................................... BT-51

Super lock ................................................ EL-281

Supplemental Restraint System ............... RS-16

Swirl control valve control solenoid

valve .................................. EC-366, 481, 1285

Symbols and abbreviations .......................... GI-9

Symptom matrix chart ........... EC-124, 648, 1116

Synchronizer (M/T) ............................. MT-25, 63

System readiness test (SRT) code ... EC-62, 586

T

TCM circuit diagram ................................... AT-13

TCM inspection table ................................. AT-58

TP/SW - Wiring diagram ................. EC-354, 874

TPS - Wiring diagram ..................... EC-178, 703

TURN - Wiring diagram ........................... EL-102

Tachometer .............................................. EL-130

Tail lamp .................................................... EL-87

Thermostat .................................... LC-15, 35, 57

Three way catalyst precautions ................... GI-6

Three way catalyst .......................... EC-327, 848

Throttle position sensor (TPS) ........ EC-175, 700

Throttle position sensor adjustment .. EC-99, 623

Throttle position switch ................... AT-111, 145,

EC-352, 872

Throwout bearing - See Clutch release

bearing ............................................. CL-17, 20

Tie-rod ball joints ....................................... ST-18

Tie-rod ........................................................ ST-15

Tightening torque of standard bolts ........... GI-47

Timing belt .......................................... EM-22, 96

Timing chain ........................................... EM-175

Tire size ...................................................... GI-41

Torque converter installation .................... AT-207

Tow truck towing ........................................ GI-45

Transmission case (M/T) .................... MT-24, 62

Tread-FR&RR (Dimensions) ...................... GI-41

Trim ............................................................ BT-28

Trouble diagnoses ...................................... GI-31

Trunk lid finisher ........................................ BT-31

Trunk lid opener - See Trunk lid ................ BT-10

Trunk lid trim .............................................. BT-31

Trunk lid ..................................................... BT-10

Trunk room trim ......................................... BT-31

Turn signal lamp ...................................... EL-101

Two trip detection logic ..................... EC-59, 583

Two-pole lift ................................................ GI-44

U

Under body ................................................ BT-68

V

VSS - Wiring diagram ........... EC-340, 860, 1172

Vacuum hose (brake system) ................... BR-18

Vacuum hose drawing (Engine control) ... EC-33,

567, 1077

Vacuum pump ........................................... BR-20

Valve clearance ................................ EM-42, 214

Valve guide ............................... EM-38, 116, 205

Valve lifter ................................................. EM-41

Valve seat ................................. EM-40, 117, 207

Valve spring .............................. EM-41, 119, 209

ALPHABETICAL INDEX

IDX-7

Page 2770 of 3051

NLMA0004

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-13

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-8

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.—

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-3

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold. LC-19, LC-59

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-28

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.BR-7

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

GENERAL MAINTENANCE

MA-3