width NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 60 of 3051

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

11 P UStep motor A Within 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

+CONSULT-II cable connected to data link connector.

+This inspection cannot be measured by circuit tester.30.0 msec

12 L/W Step motor B10.0 msec

13 OR/BSPORT indicator

lamp

When SPORT indicator lamp illumi-

nates0V

When SPORT indicator lamp does

not illuminateBattery voltage

15 *1 PU (EURO-OBD-II) Ð Ð

16 Y/PUClosed throttle

position switch

(in throttle posi-

tion switch)When releasing accelerator pedal

after warming up engine.

Refer to step 1 to 6 of

ªPreparationº, ªTCM Self-diagnostic

Procedure (No Tools)º, AT-28 Ð

EURO-OBD/AT-35 Ð Except for

EURO-OBD.Battery voltage

When depressing accelerator pedal

after warming up engine.

Refer to step 1 to 6 of

ªPreparationº, ªTCM Self-diagnostic

Procedure (No Tools)º, AT-28 Ð

EURO-OBD/AT-35 Ð Except for

EURO-OBD.0V

17 LGWide open

throttle position

switch

(in throttle posi-

tion switch)When depressing accelerator pedal

more than half-way after warming

up engine.Battery voltage

When releasing accelerator pedal

after warming up engine.0V

18 BR ABS control unit

When driving slowly.Change 0V to

battery voltage

19 G/W Power source

Same as No. 10

20 L/Y Step motor CWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

+CONSULT-II cable connected to data link connector.

+This inspection cannot be measured by circuit tester.30.0 msec

21 P/L Step motor D10.0 msec

22 PSport mode

switch

When SPORT mode switch in ªONº

position.0V

When SPORT mode switch in

ªOFFº position.10V

23 SB ABS control unit

When ABS operates. 0V

When ABS does not operate. 5.6 - 10.0V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

TCM Terminals and Reference Value (Cont'd)

AT-59

Page 113 of 3051

DescriptionNLAT0224+The step motor is ON/OFF of 4 aspects changes according to

the signal from TCM.

As a result, the flow of line pressure to primary pulley is

changed and pulley ratio is controlled.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0224S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Step motorThe vehicle runs a safe condition and

press/depress accelerator pedal.ON/OFF

TCM TERMINALS AND REFERENCE VALUENLAT0224S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

11 P U

Step motorWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

+CONSULT-II cable connect to data link connector.

+This inspection cannot be measured by circuit tester.30.0 msec

12 L/W10.0 msec

20 L/Y30.0 msec

21 P/L10.0 msec

ON BOARD DIAGNOSIS LOGICNLAT0224S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: STEP MOTOR/CIRC

When in operating step motor ON and

OFF, there is no proper change in the

voltage of the terminal TCM which corre-

sponds to it.+Harness or connectors

(The step motor circuit is open or

shorted.)

+Step motor

: P1777

: MI Code No. 1777

DTC P1777 STEP MOTOR Ð CIRCUITEURO-OBD

Description

AT-112

Page 147 of 3051

DescriptionNLAT0261The step motor is turned ON/OFF 4 times according to the signal

from TCM. As a result, the flow of line pressure to primary pulley

is changed and pulley ratio is controlled.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NLAT0261S05Remarks: Specification data are reference values.

Monitor item Condition Specification

Step motorThe vehicle runs a safe condition and

press/depress accelerator pedal.ON/OFF

TCM TERMINALS AND REFERENCE VALUENLAT0261S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard (Approx.)

11 P U

Step motorWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

+CONSULT-II cable connect to data link connector.

+This inspection cannot be measured by circuit tester.30.0 msec

12 L/W10.0 msec

20 L/Y30.0 msec

21 P/L10.0 msec

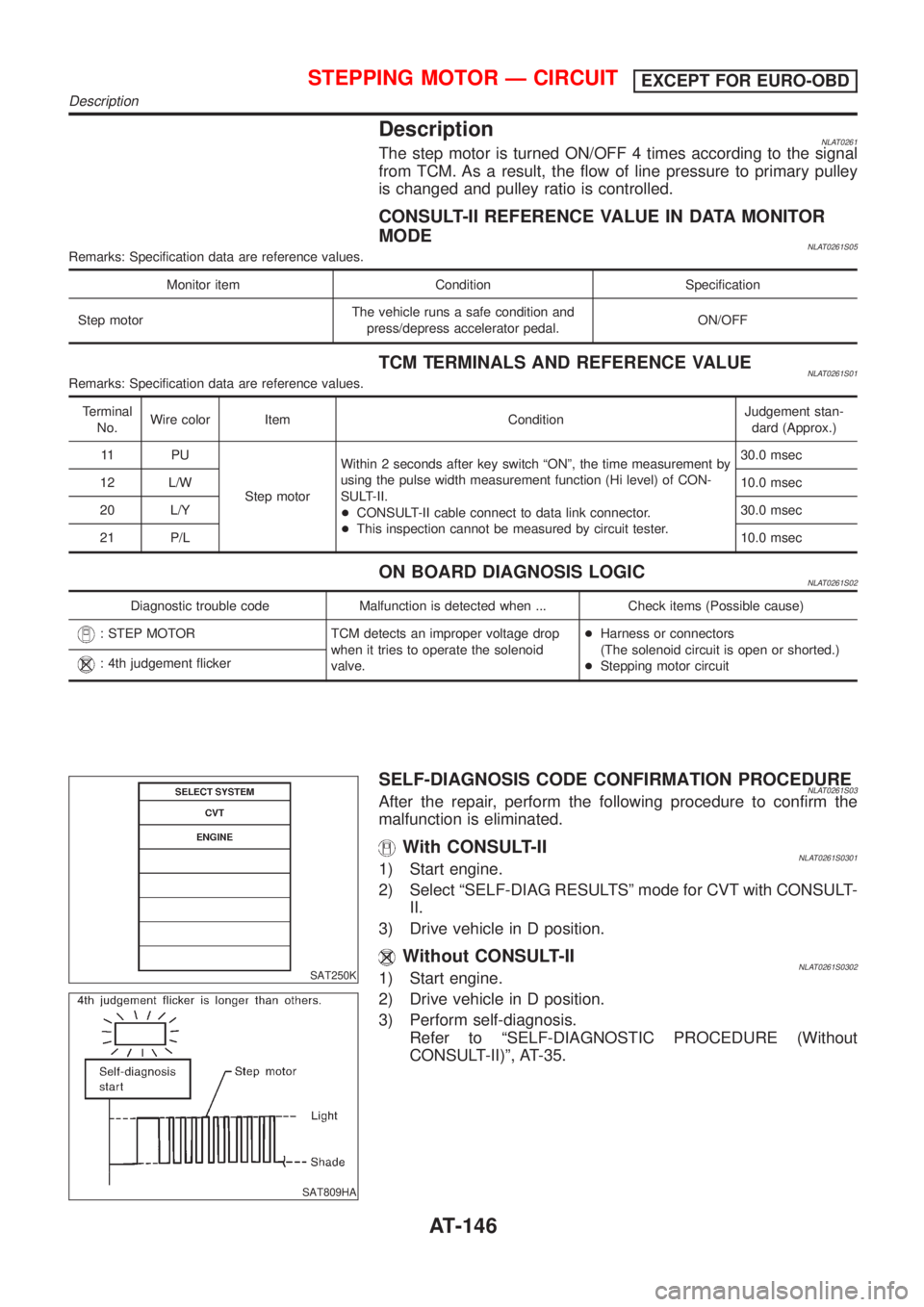

ON BOARD DIAGNOSIS LOGICNLAT0261S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: STEP MOTOR TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or shorted.)

+Stepping motor circuit

: 4th judgement flicker

SAT250K

SAT809HA

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENLAT0261S03After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINLAT0261S03011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for CVT with CONSULT-

II.

3) Drive vehicle in D position.

Without CONSULT-IINLAT0261S03021) Start engine.

2) Drive vehicle in D position.

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-35.

STEPPING MOTOR Ð CIRCUITEXCEPT FOR EURO-OBD

Description

AT-146

Page 330 of 3051

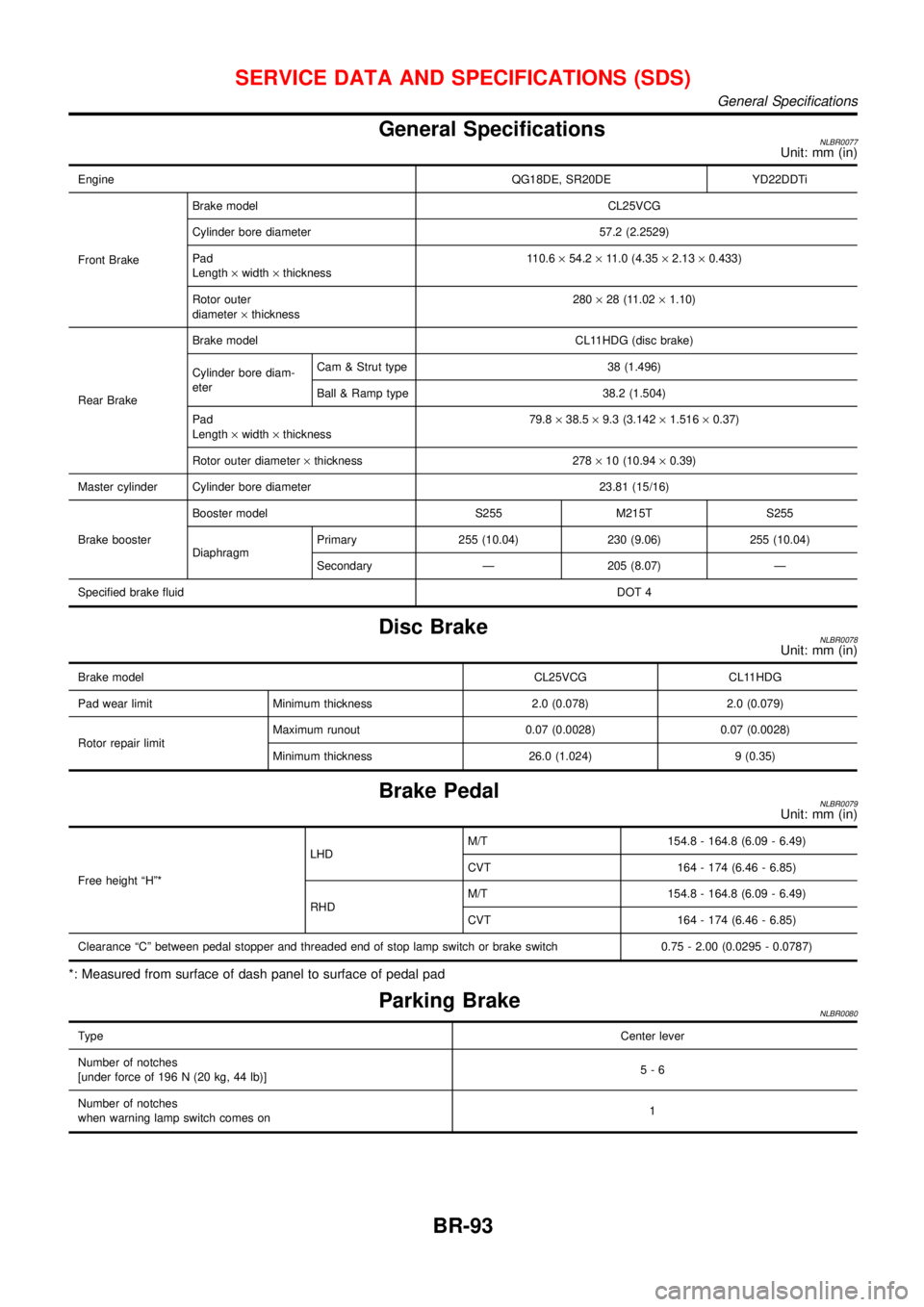

General SpecificationsNLBR0077Unit: mm (in)

EngineQG18DE, SR20DE YD22DDTi

Front BrakeBrake model CL25VCG

Cylinder bore diameter 57.2 (2.2529)

Pad

Length×width×thickness110.6×54.2×11.0 (4.35×2.13×0.433)

Rotor outer

diameter×thickness280×28 (11.02×1.10)

Rear BrakeBrake model CL11HDG (disc brake)

Cylinder bore diam-

eterCam & Strut type 38 (1.496)

Ball & Ramp type 38.2 (1.504)

Pad

Length×width×thickness79.8×38.5×9.3 (3.142×1.516×0.37)

Rotor outer diameter×thickness 278×10 (10.94×0.39)

Master cylinder Cylinder bore diameter 23.81 (15/16)

Brake boosterBooster model S255 M215T S255

DiaphragmPrimary 255 (10.04) 230 (9.06) 255 (10.04)

Secondary—205 (8.07)—

Specified brake fluidDOT 4

Disc BrakeNLBR0078Unit: mm (in)

Brake modelCL25VCG CL11HDG

Pad wear limit Minimum thickness 2.0 (0.078) 2.0 (0.079)

Rotor repair limitMaximum runout 0.07 (0.0028) 0.07 (0.0028)

Minimum thickness 26.0 (1.024) 9 (0.35)

Brake PedalNLBR0079Unit: mm (in)

Free height“H”*LHDM/T 154.8 - 164.8 (6.09 - 6.49)

CVT 164 - 174 (6.46 - 6.85)

RHDM/T 154.8 - 164.8 (6.09 - 6.49)

CVT 164 - 174 (6.46 - 6.85)

Clearance“C”between pedal stopper and threaded end of stop lamp switch or brake switch 0.75 - 2.00 (0.0295 - 0.0787)

*: Measured from surface of dash panel to surface of pedal pad

Parking BrakeNLBR0080

TypeCenter lever

Number of notches

[under force of 196 N (20 kg, 44 lb)]5-6

Number of notches

when warning lamp switch comes on1

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

BR-93

Page 461 of 3051

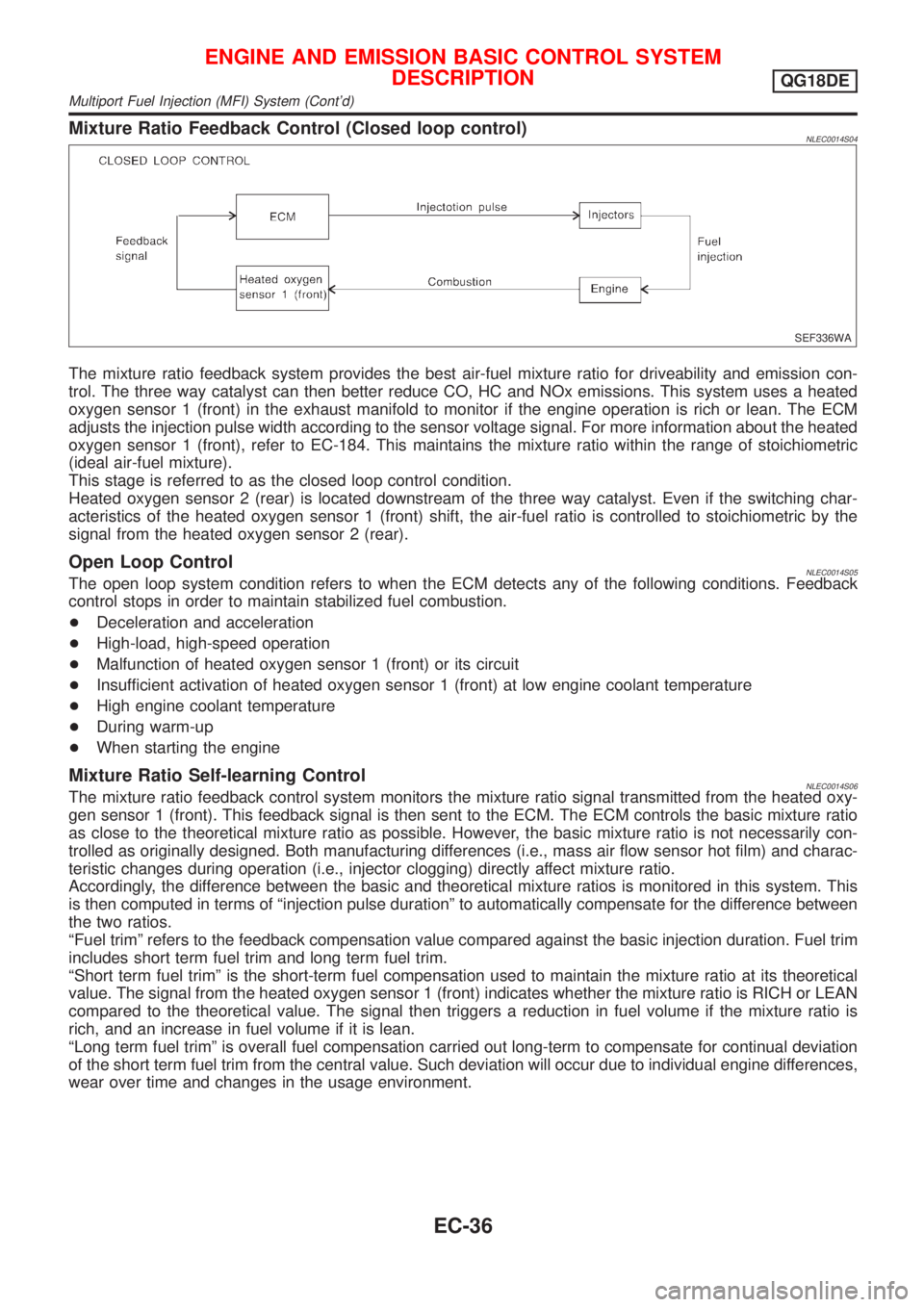

Mixture Ratio Feedback Control (Closed loop control)NLEC0014S04

SEF336WA

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission con-

trol. The three way catalyst can then better reduce CO, HC and NOx emissions. This system uses a heated

oxygen sensor 1 (front) in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about the heated

oxygen sensor 1 (front), refer to EC-184. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 (rear) is located downstream of the three way catalyst. Even if the switching char-

acteristics of the heated oxygen sensor 1 (front) shift, the air-fuel ratio is controlled to stoichiometric by the

signal from the heated oxygen sensor 2 (rear).

Open Loop ControlNLEC0014S05The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

+Deceleration and acceleration

+High-load, high-speed operation

+Malfunction of heated oxygen sensor 1 (front) or its circuit

+Insufficient activation of heated oxygen sensor 1 (front) at low engine coolant temperature

+High engine coolant temperature

+During warm-up

+When starting the engine

Mixture Ratio Self-learning ControlNLEC0014S06The mixture ratio feedback control system monitors the mixture ratio signal transmitted from the heated oxy-

gen sensor 1 (front). This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio

as close to the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily con-

trolled as originally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and charac-

teristic changes during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This

is then computed in terms of ªinjection pulse durationº to automatically compensate for the difference between

the two ratios.

ªFuel trimº refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

ªShort term fuel trimº is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from the heated oxygen sensor 1 (front) indicates whether the mixture ratio is RICH or LEAN

compared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is

rich, and an increase in fuel volume if it is lean.

ªLong term fuel trimº is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Multiport Fuel Injection (MFI) System (Cont'd)

EC-36

Page 462 of 3051

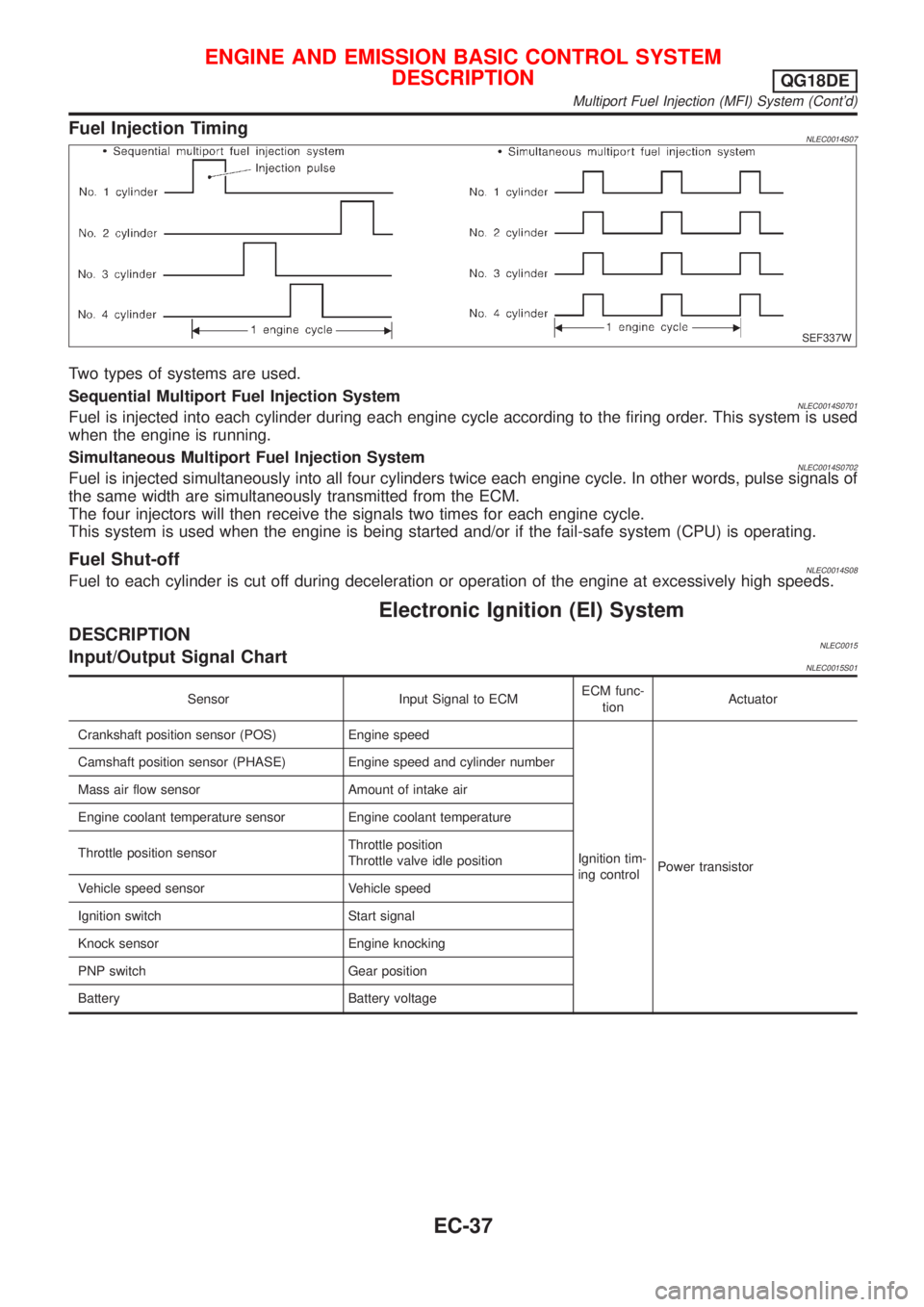

Fuel Injection TimingNLEC0014S07

SEF337W

Two types of systems are used.

Sequential Multiport Fuel Injection System

NLEC0014S0701Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

NLEC0014S0702Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

Fuel Shut-offNLEC0014S08Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Electronic Ignition (EI) System

DESCRIPTIONNLEC0015Input/Output Signal ChartNLEC0015S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Ignition tim-

ing controlPower transistor Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensorThrottle position

Throttle valve idle position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Knock sensor Engine knocking

PNP switch Gear position

Battery Battery voltage

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Multiport Fuel Injection (MFI) System (Cont'd)

EC-37

Page 463 of 3051

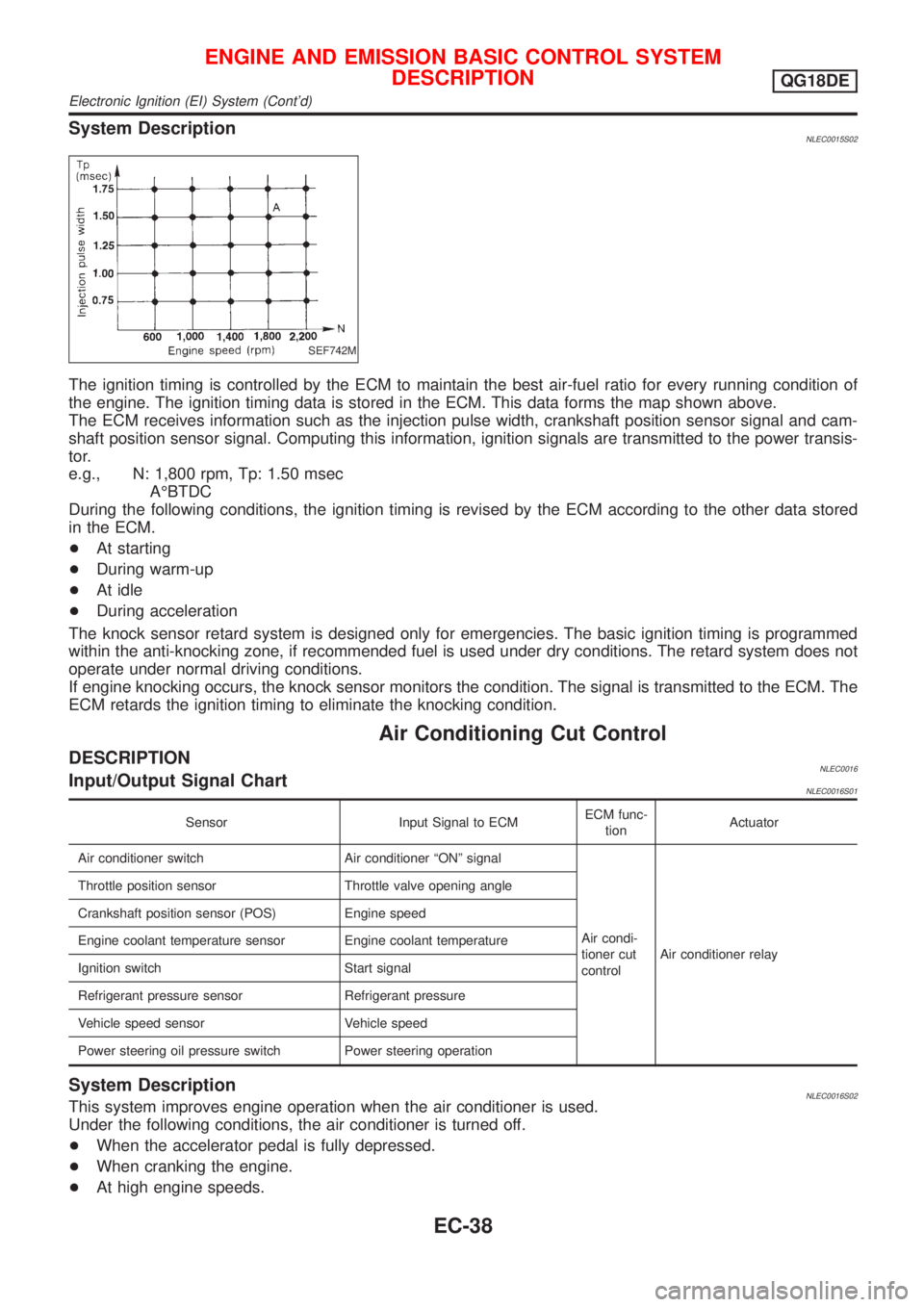

System DescriptionNLEC0015S02

SEF742M

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width, crankshaft position sensor signal and cam-

shaft position sensor signal. Computing this information, ignition signals are transmitted to the power transis-

tor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

+At starting

+During warm-up

+At idle

+During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut Control

DESCRIPTIONNLEC0016Input/Output Signal ChartNLEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Crankshaft position sensor (POS) Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Vehicle speed sensor Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNLEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

+When the accelerator pedal is fully depressed.

+When cranking the engine.

+At high engine speeds.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Electronic Ignition (EI) System (Cont'd)

EC-38

Page 511 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual Freeze frame data

item*Description

S-FUEL TRIM-B1 [%]+ªShort-term fuel trimº at the moment a malfunction is detected is displayed.

+The short-term fuel trim indicates dynamic or instantaneous feedba NISSAN ALMERA TINO 2001 Service Repair Manual Freeze frame data

item*Description

S-FUEL TRIM-B1 [%]+ªShort-term fuel trimº at the moment a malfunction is detected is displayed.

+The short-term fuel trim indicates dynamic or instantaneous feedba](/img/5/57352/w960_57352-510.png)

Freeze frame data

item*Description

S-FUEL TRIM-B1 [%]+ªShort-term fuel trimº at the moment a malfunction is detected is displayed.

+The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel

schedule.

ENGINE SPEED [rpm]+The engine speed at the moment a malfunction is detected is displayed.

VEHICL SPEED [km/h]

or [mph]+The vehicle speed at the moment a malfunction is detected is displayed.

ABSOL TH´P/S [%]+The throttle valve opening angle at the moment a malfunction is detected is displayed.

B/FUEL SCHDL [msec]+The base fuel schedule at the moment a malfunction is detected is displayed.

INT/A TEMP SE [ÉC]

or [ÉF]+The intake air temperature at the moment a malfunction is detected is displayed.

*: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODENLEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]jj+Indicates the engine speed computed from

the POS signal of the crankshaft position

sensor.+Accuracy becomes poor if engine

speed drops below the idle rpm.

+If the signal is interrupted while the

engine is running, an abnormal

value may be indicated.

MAS A/F SE-B1 [V]jj+The signal voltage of the mass air flow sen-

sor is displayed.+When the engine is stopped, a cer-

tain value is indicated.

B/FUEL SCHDL

[msec]+ªBase fuel scheduleº indicates the fuel injec-

tion pulse width programmed into ECM, prior

to any learned on board correction.

A/F ALPHA-B1 [%]j+Indicates the mean value of the air-fuel ratio

feedback correction factor per cycle.+When the engine is stopped, a cer-

tain value is indicated.

+This data also includes the data for

the air-fuel ratio learning control.

COOLAN TEMP/S

[ÉC] or [ÉF]jj+The engine coolant temperature (determined

by the signal voltage of the engine coolant

temperature sensor) is displayed.+When the engine coolant tempera-

ture sensor is open or short-

circuited, ECM enters fail-safe

mode. The engine coolant tempera-

ture determined by the ECM is dis-

played.

HO2S1 (B1) [V]jj+The signal voltage of the heated oxygen sen-

sor 1 (front) is displayed.

HO2S2 (B1) [V]j+The signal voltage of the heated oxygen sen-

sor 2 (rear) is displayed.

HO2S1 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 1 (front)

signal during air-fuel ratio feedback control:

RICH ... means the mixture became ªrichº,

and control is being affected toward a leaner

mixture.

LEAN ... means the mixture became ªleanº,

and control is being affected toward a rich

mixture.+After turning ON the ignition switch,

ªRICHº is displayed until air-fuel mix-

ture ratio feedback control begins.

+When the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continuously.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-86

Page 512 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three wa NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three wa](/img/5/57352/w960_57352-511.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three way catalyst is relatively small.

LEAN ... means the amount of oxygen after

three way catalyst is relatively large.+When the engine is stopped, a cer-

tain value is indicated.

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the vehicle

speed sensor signal is displayed.

BATTERY VOLT [V]j+The power supply voltage of ECM is dis-

played.

THRTL POS SEN [V]jj+The throttle position sensor signal voltage is

displayed.

INT/A TEMP SE

[ÉC] or [ÉF]j+The intake air temperature determined by the

signal voltage of the intake air temperature

sensor is indicated.

EGR TEMP SEN [V]

(where fitted)jj+The signal voltage of the EGR temperature

sensor is displayed.

START SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the starter

signal.+After starting the engine, [OFF] is

displayed regardless of the starter

signal.

CLSD THL POS

[ON/OFF]jj+Indicates idle position [ON/OFF] computed by

ECM according to the throttle position sensor

signal.

CLSD THL/P SW

[ON/OFF]

(where fitted)j+Indicates mechanical contact [ON/OFF] con-

dition of the closed throttle position switch.

AIR COND SIG

[ON/OFF]jj+Indicates [ON/OFF] condition of the air condi-

tioner switch as determined by the air condi-

tioning signal.

P/N POSI SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the PNP

switch signal.

PW/ST SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition of the power

steering oil pressure switch determined by

the power steering oil pressure switch signal.

LOAD SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the electri-

cal load signal and/or lighting switch.

ON ... rear defogger is operating and/or light-

ing switch is on.

OFF ... rear defogger is not operating and

lighting switch is not on.

IGNITION SW

[ON/OFF]j+Indicates [ON/OFF] condition from ignition

switch.

HEATER FAN SW

[ON/OFF]j+Indicates [ON/OFF] condition from the heater

fan switch.

INJ PULSE-B1

[msec]j+Indicates the actual fuel injection pulse width

compensated by ECM according to the input

signals.+When the engine is stopped, a cer-

tain computed value is indicated.

IGN TIMING [BTDC]j+Indicates the ignition timing computed by

ECM according to the input signals.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-87

Page 514 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

IDL A/V LEARN+Display the condition of idle air volume learn-

ing

YET ... Idle air volume learning has not been

performed yet.

CMP NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

IDL A/V LEARN+Display the condition of idle air volume learn-

ing

YET ... Idle air volume learning has not been

performed yet.

CMP](/img/5/57352/w960_57352-513.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

IDL A/V LEARN+Display the condition of idle air volume learn-

ing

YET ... Idle air volume learning has not been

performed yet.

CMPLT ... Idle air volume learning has

already been performed successfully.

INCMP ... Idle air volume learning has not

been performed successfully.

TRVL AFTER MIL

[km] or [Mile]+Distance traveled while MI is activated

VOLTAGE [V]+Voltage measured by the voltage probe.

PULSE

[msec] or [Hz] or [%]+Pulse width, frequency or duty cycle mea-

sured by the pulse probe.+Only ª#º is displayed if item is

unable to be measured.

+Figures with ª#ºs are temporary

ones. They are the same figures as

an actual piece of data which was

just previously measured.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

DATA MONITOR (SPEC) MODENLEC0034S11

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

MAS A/F SE-B1 [V]jj+The signal voltage of the mass air flow sen-

sor specification is displayed.+When the engine is running, specifi-

cation range is indicated.

B/FUEL SCHDL

[msec]+ªBase fuel scheduleº indicates the fuel injec-

tion pulse width programmed into ECM, prior

to any learned on board correction.+When the engine is running, specifi-

cation range is indicated.

A/F ALPHA-B1 [%]j+Indicates the mean value of the air-fuel ratio

feedback correction factor per cycle.+When the engine is running, specifi-

cation range is indicated.

+This data also includes the data for

the air-fuel ratio learning control.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODENLEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION+Engine: Return to the original

trouble condition

+Change the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.+Harness and connector

+Fuel injectors

+Heated oxygen sensor 1 (front)

IGNITION TIM-

ING+Engine: Return to the original

trouble condition

+Timing light: Set

+Retard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.+ªIdle Air Volume Leaningº (Refer

to EC-57.)

+Camshaft position sensor

(PHASE)

+Crankshaft position sensor

(POS)

+Engine component parts and

installing conditions

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-89