low oil pressure NISSAN ALMERA TINO 2001 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2280 of 3051

CAUTION:

+After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

+When installing chain tensioner, oil seals, or other sliding

parts, lubricate contacting surfaces with new engine oil.

+Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

+When removing oil pump assembly, remove camshaft

position sensor (PHASE), then remove timing chain from

engine.

+Be careful not to damage sensor edges.

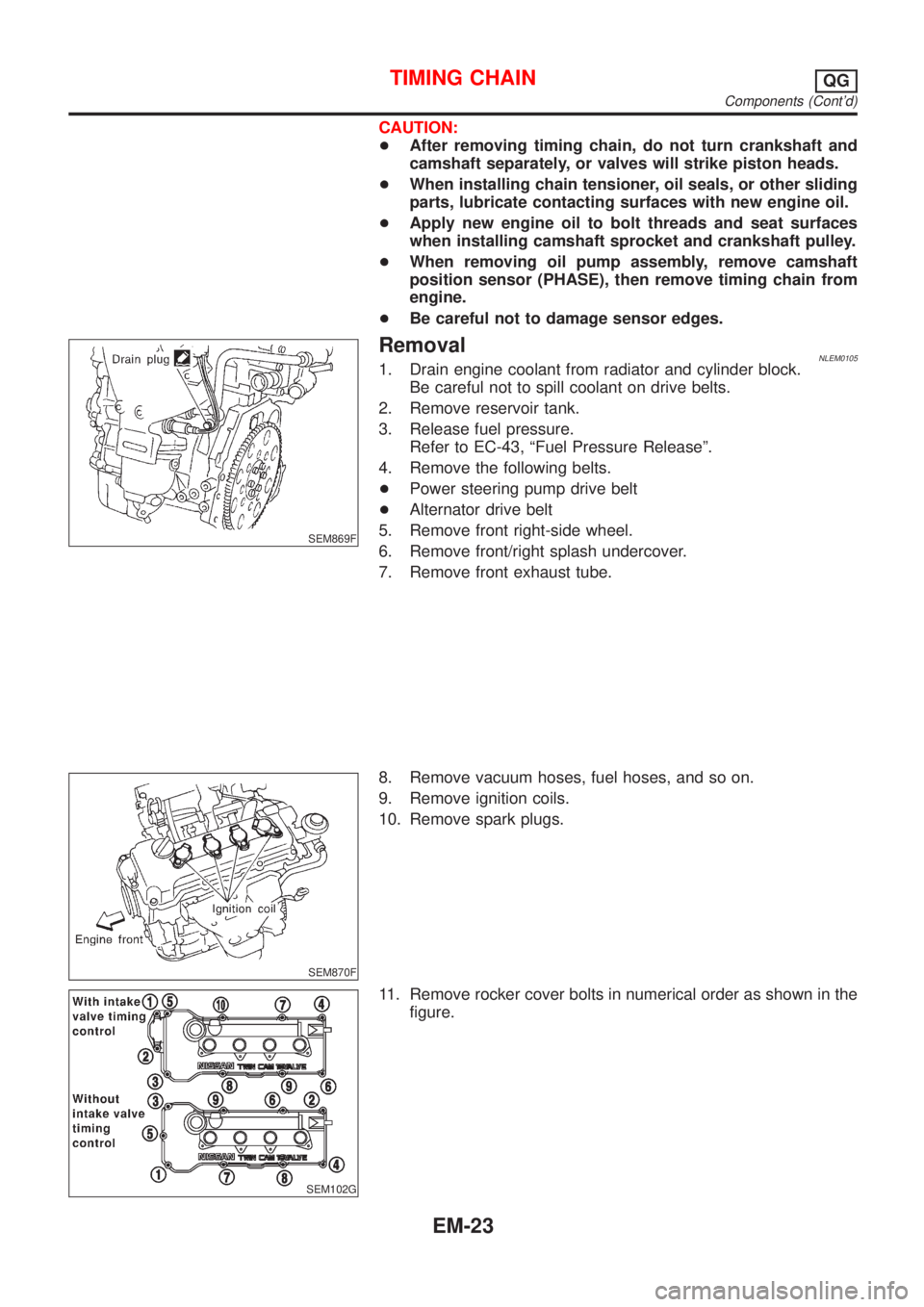

SEM869F

RemovalNLEM01051. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Remove reservoir tank.

3. Release fuel pressure.

Refer to EC-43, ªFuel Pressure Releaseº.

4. Remove the following belts.

+Power steering pump drive belt

+Alternator drive belt

5. Remove front right-side wheel.

6. Remove front/right splash undercover.

7. Remove front exhaust tube.

SEM870F

8. Remove vacuum hoses, fuel hoses, and so on.

9. Remove ignition coils.

10. Remove spark plugs.

SEM102G

11. Remove rocker cover bolts in numerical order as shown in the

figure.

TIMING CHAINQG

Components (Cont'd)

EM-23

Page 2342 of 3051

NLEM0118

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC-578, ªFuel Pressure Releaseº.

4. Remove all spark plugs.

5. Disconnect distributor coil connector.

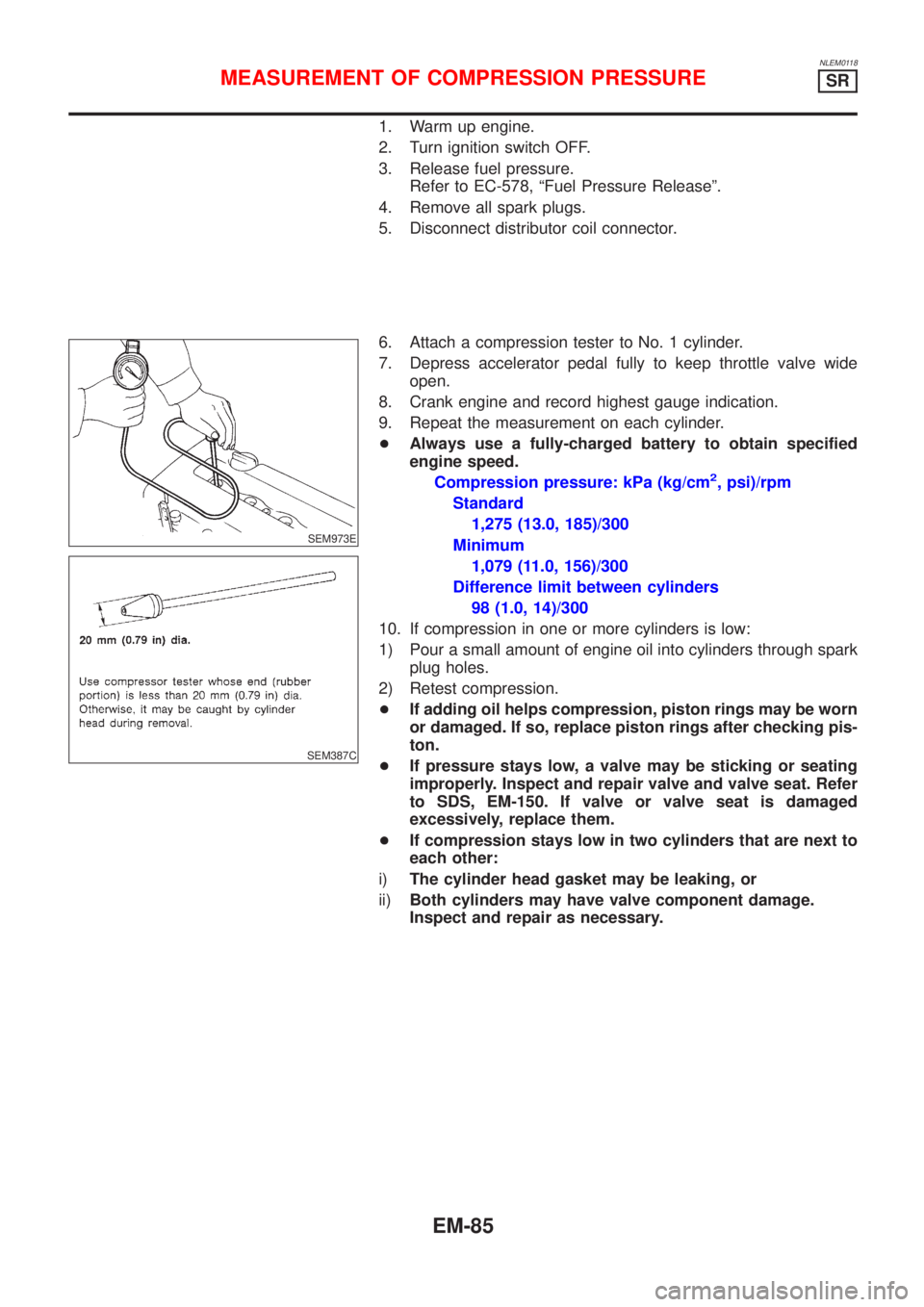

SEM973E

SEM387C

6. Attach a compression tester to No. 1 cylinder.

7. Depress accelerator pedal fully to keep throttle valve wide

open.

8. Crank engine and record highest gauge indication.

9. Repeat the measurement on each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Compression pressure: kPa (kg/cm

2, psi)/rpm

Standard

1,275 (13.0, 185)/300

Minimum

1,079 (11.0, 156)/300

Difference limit between cylinders

98 (1.0, 14)/300

10. If compression in one or more cylinders is low:

1) Pour a small amount of engine oil into cylinders through spark

plug holes.

2) Retest compression.

+If adding oil helps compression, piston rings may be worn

or damaged. If so, replace piston rings after checking pis-

ton.

+If pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat. Refer

to SDS, EM-150. If valve or valve seat is damaged

excessively, replace them.

+If compression stays low in two cylinders that are next to

each other:

i)The cylinder head gasket may be leaking, or

ii)Both cylinders may have valve component damage.

Inspect and repair as necessary.

MEASUREMENT OF COMPRESSION PRESSURESR

EM-85

Page 2362 of 3051

SEM077D

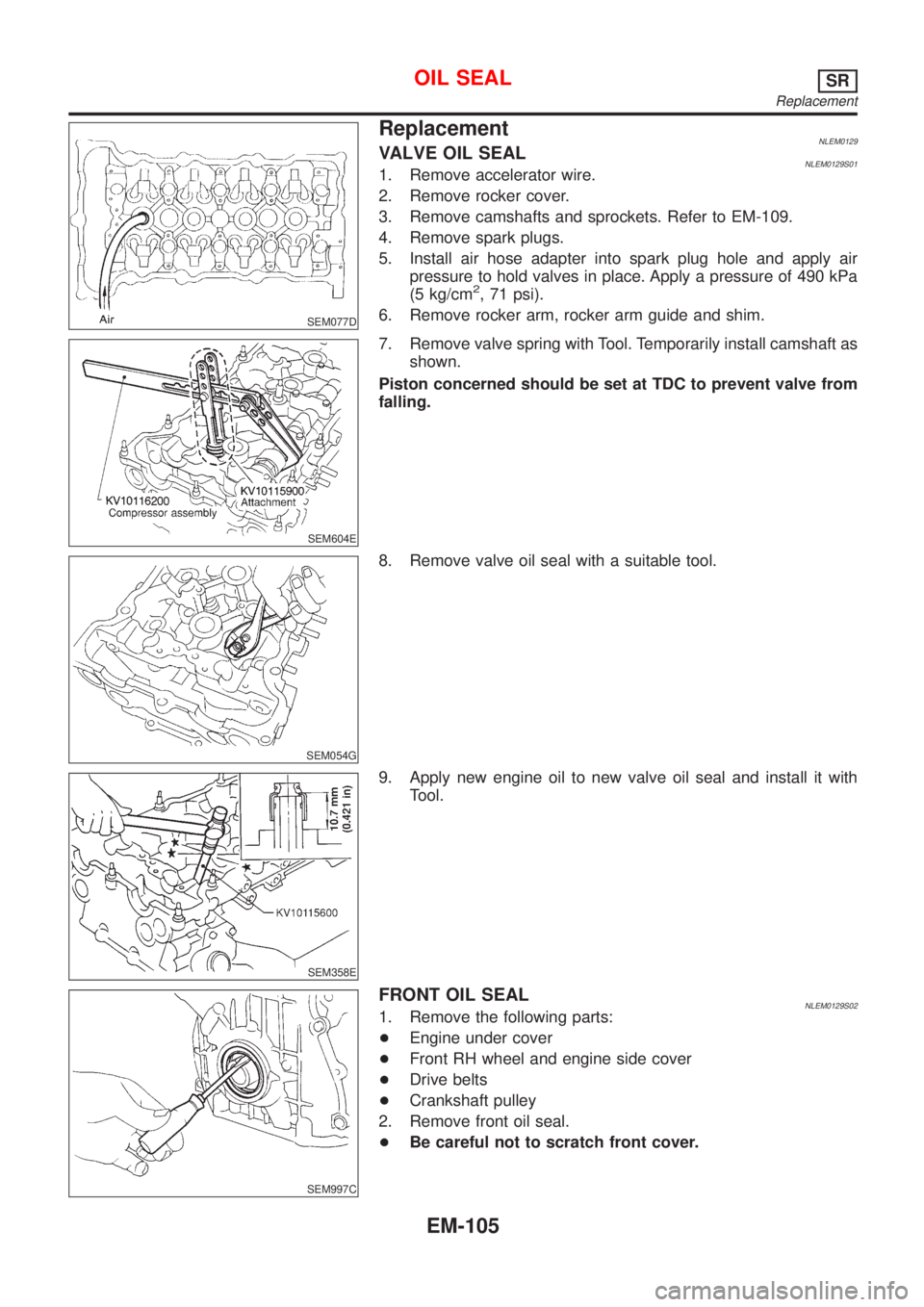

ReplacementNLEM0129VALVE OIL SEALNLEM0129S011. Remove accelerator wire.

2. Remove rocker cover.

3. Remove camshafts and sprockets. Refer to EM-109.

4. Remove spark plugs.

5. Install air hose adapter into spark plug hole and apply air

pressure to hold valves in place. Apply a pressure of 490 kPa

(5 kg/cm

2, 71 psi).

6. Remove rocker arm, rocker arm guide and shim.

SEM604E

7. Remove valve spring with Tool. Temporarily install camshaft as

shown.

Piston concerned should be set at TDC to prevent valve from

falling.

SEM054G

8. Remove valve oil seal with a suitable tool.

SEM358E

9. Apply new engine oil to new valve oil seal and install it with

Tool.

SEM997C

FRONT OIL SEALNLEM0129S021. Remove the following parts:

+Engine under cover

+Front RH wheel and engine side cover

+Drive belts

+Crankshaft pulley

2. Remove front oil seal.

+Be careful not to scratch front cover.

OIL SEALSR

Replacement

EM-105

Page 2378 of 3051

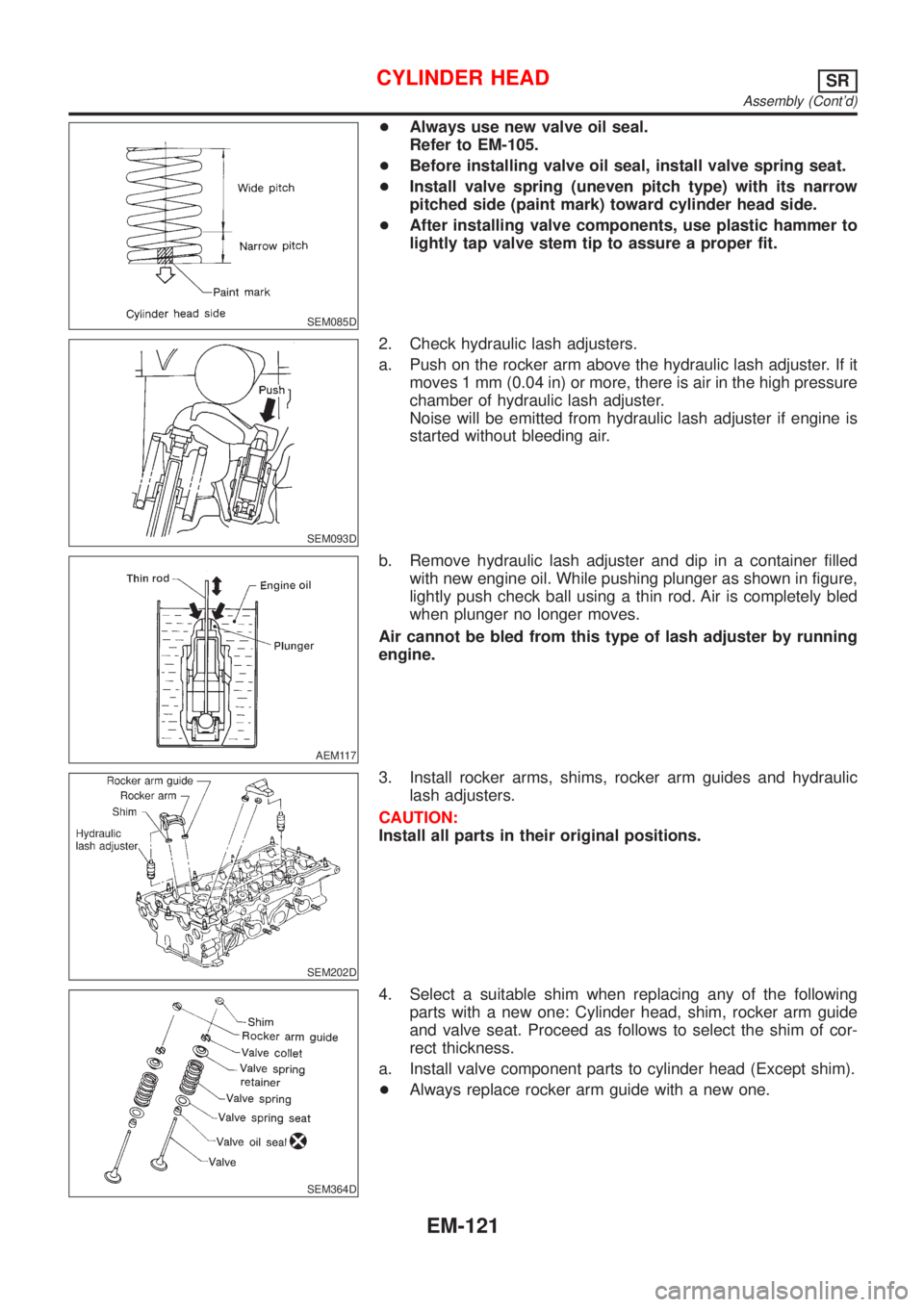

SEM085D

+Always use new valve oil seal.

Refer to EM-105.

+Before installing valve oil seal, install valve spring seat.

+Install valve spring (uneven pitch type) with its narrow

pitched side (paint mark) toward cylinder head side.

+After installing valve components, use plastic hammer to

lightly tap valve stem tip to assure a proper fit.

SEM093D

2. Check hydraulic lash adjusters.

a. Push on the rocker arm above the hydraulic lash adjuster. If it

moves 1 mm (0.04 in) or more, there is air in the high pressure

chamber of hydraulic lash adjuster.

Noise will be emitted from hydraulic lash adjuster if engine is

started without bleeding air.

AEM117

b. Remove hydraulic lash adjuster and dip in a container filled

with new engine oil. While pushing plunger as shown in figure,

lightly push check ball using a thin rod. Air is completely bled

when plunger no longer moves.

Air cannot be bled from this type of lash adjuster by running

engine.

SEM202D

3. Install rocker arms, shims, rocker arm guides and hydraulic

lash adjusters.

CAUTION:

Install all parts in their original positions.

SEM364D

4. Select a suitable shim when replacing any of the following

parts with a new one: Cylinder head, shim, rocker arm guide

and valve seat. Proceed as follows to select the shim of cor-

rect thickness.

a. Install valve component parts to cylinder head (Except shim).

+Always replace rocker arm guide with a new one.

CYLINDER HEADSR

Assembly (Cont'd)

EM-121

Page 2453 of 3051

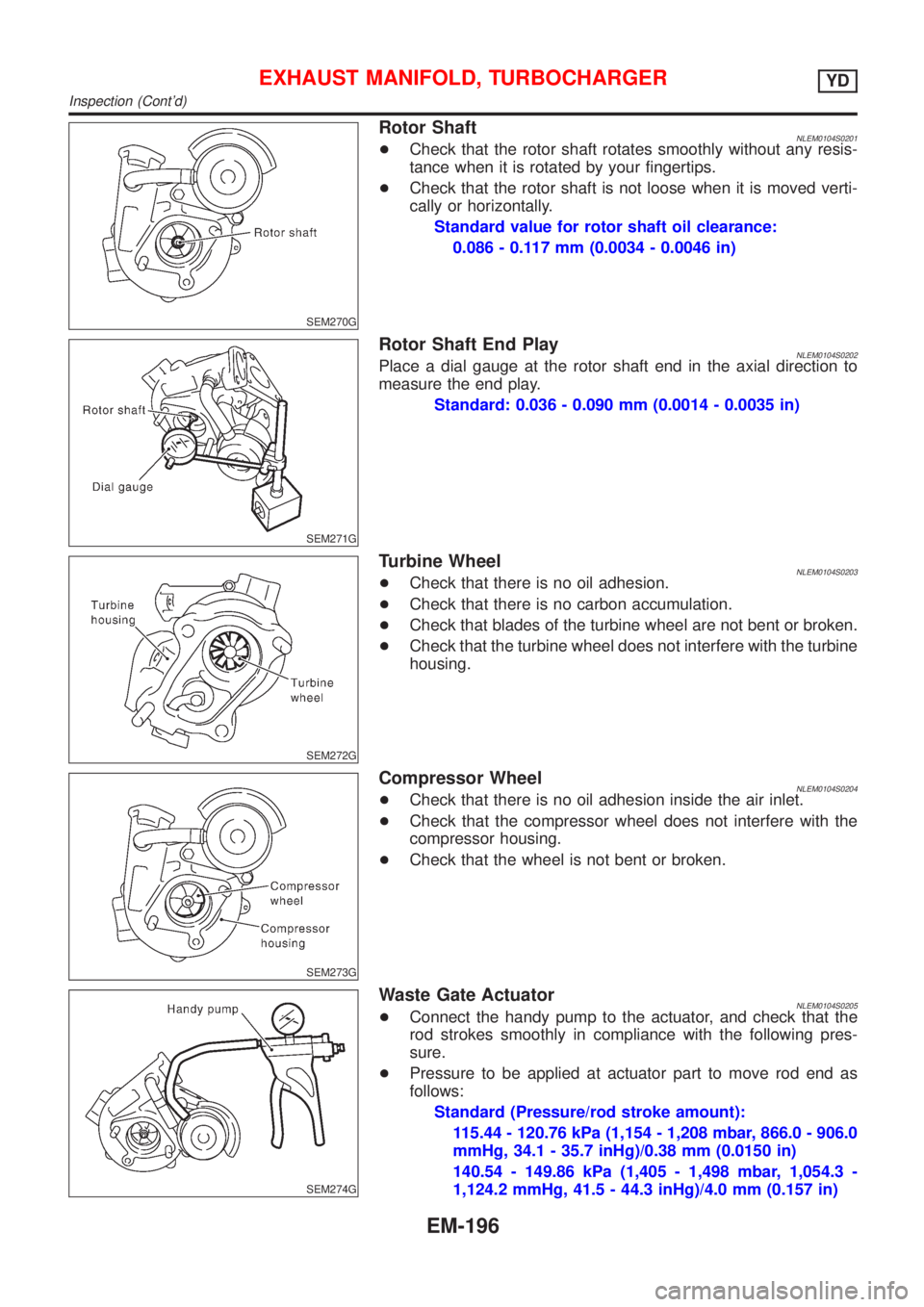

SEM270G

Rotor ShaftNLEM0104S0201+Check that the rotor shaft rotates smoothly without any resis-

tance when it is rotated by your fingertips.

+Check that the rotor shaft is not loose when it is moved verti-

cally or horizontally.

Standard value for rotor shaft oil clearance:

0.086 - 0.117 mm (0.0034 - 0.0046 in)

SEM271G

Rotor Shaft End PlayNLEM0104S0202Place a dial gauge at the rotor shaft end in the axial direction to

measure the end play.

Standard: 0.036 - 0.090 mm (0.0014 - 0.0035 in)

SEM272G

Turbine WheelNLEM0104S0203+Check that there is no oil adhesion.

+Check that there is no carbon accumulation.

+Check that blades of the turbine wheel are not bent or broken.

+Check that the turbine wheel does not interfere with the turbine

housing.

SEM273G

Compressor WheelNLEM0104S0204+Check that there is no oil adhesion inside the air inlet.

+Check that the compressor wheel does not interfere with the

compressor housing.

+Check that the wheel is not bent or broken.

SEM274G

Waste Gate ActuatorNLEM0104S0205+Connect the handy pump to the actuator, and check that the

rod strokes smoothly in compliance with the following pres-

sure.

+Pressure to be applied at actuator part to move rod end as

follows:

Standard (Pressure/rod stroke amount):

115.44 - 120.76 kPa (1,154 - 1,208 mbar, 866.0 - 906.0

mmHg, 34.1 - 35.7 inHg)/0.38 mm (0.0150 in)

140.54 - 149.86 kPa (1,405 - 1,498 mbar, 1,054.3 -

1,124.2 mmHg, 41.5 - 44.3 inHg)/4.0 mm (0.157 in)

EXHAUST MANIFOLD, TURBOCHARGERYD

Inspection (Cont'd)

EM-196

Page 2454 of 3051

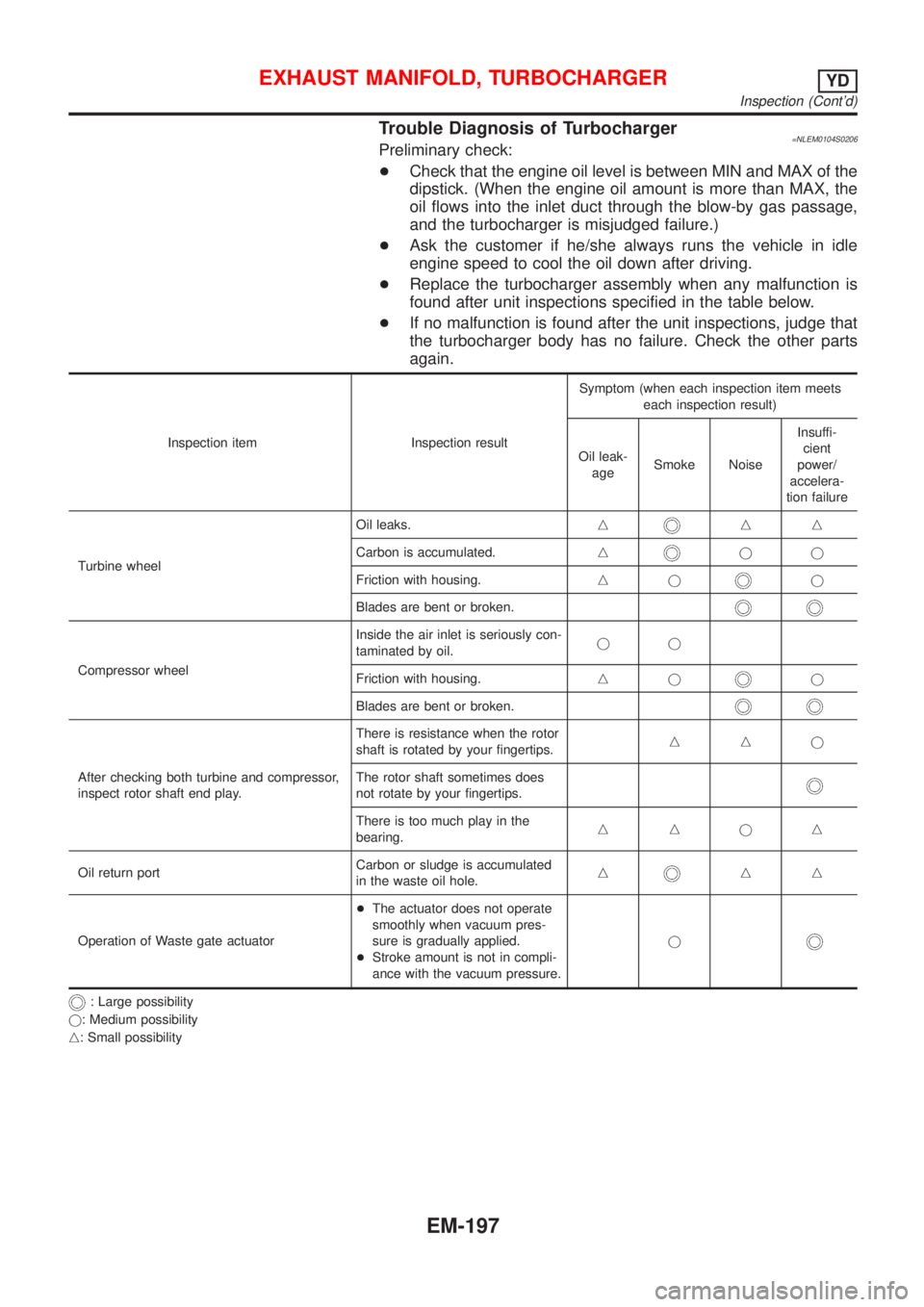

Trouble Diagnosis of Turbocharger=NLEM0104S0206Preliminary check:

+Check that the engine oil level is between MIN and MAX of the

dipstick. (When the engine oil amount is more than MAX, the

oil flows into the inlet duct through the blow-by gas passage,

and the turbocharger is misjudged failure.)

+Ask the customer if he/she always runs the vehicle in idle

engine speed to cool the oil down after driving.

+Replace the turbocharger assembly when any malfunction is

found after unit inspections specified in the table below.

+If no malfunction is found after the unit inspections, judge that

the turbocharger body has no failure. Check the other parts

again.

Inspection item Inspection resultSymptom (when each inspection item meets

each inspection result)

Oil leak-

ageSmoke NoiseInsuffi-

cient

power/

accelera-

tion failure

Turbine wheelOil leaks.n

nn

Carbon is accumulated.n

jj

Friction with housing.nj

j

Blades are bent or broken.

Compressor wheelInside the air inlet is seriously con-

taminated by oil.jj

Friction with housing.njj

Blades are bent or broken.

After checking both turbine and compressor,

inspect rotor shaft end play.There is resistance when the rotor

shaft is rotated by your fingertips.nnj

The rotor shaft sometimes does

not rotate by your fingertips.

There is too much play in the

bearing.nnjn

Oil return portCarbon or sludge is accumulated

in the waste oil hole.n

nn

Operation of Waste gate actuator+The actuator does not operate

smoothly when vacuum pres-

sure is gradually applied.

+Stroke amount is not in compli-

ance with the vacuum pressure.j

: Large possibility

j: Medium possibility

n: Small possibility

EXHAUST MANIFOLD, TURBOCHARGERYD

Inspection (Cont'd)

EM-197

Page 2458 of 3051

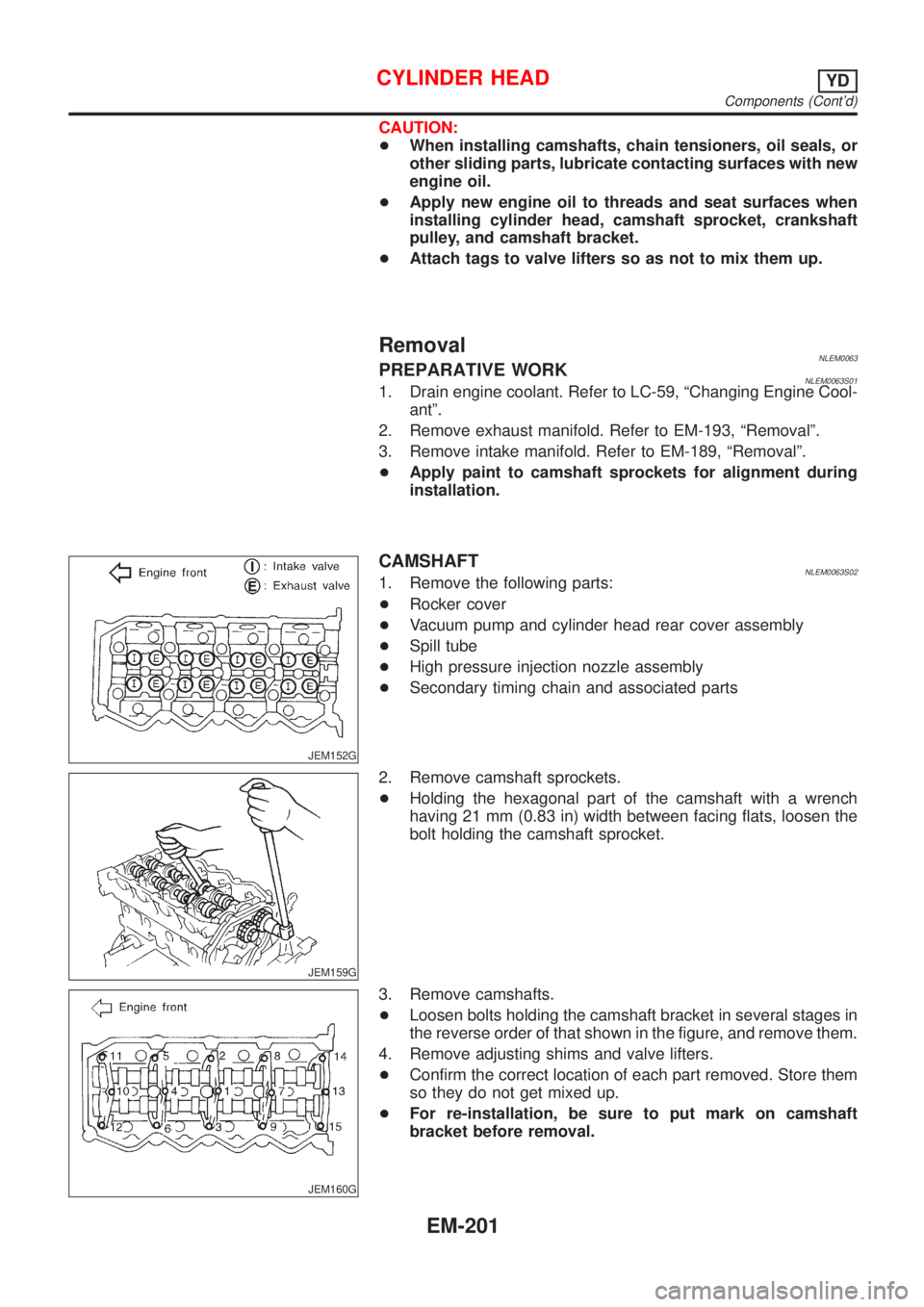

CAUTION:

+When installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

+Apply new engine oil to threads and seat surfaces when

installing cylinder head, camshaft sprocket, crankshaft

pulley, and camshaft bracket.

+Attach tags to valve lifters so as not to mix them up.

RemovalNLEM0063PREPARATIVE WORKNLEM0063S011. Drain engine coolant. Refer to LC-59, ªChanging Engine Cool-

antº.

2. Remove exhaust manifold. Refer to EM-193, ªRemovalº.

3. Remove intake manifold. Refer to EM-189, ªRemovalº.

+Apply paint to camshaft sprockets for alignment during

installation.

JEM152G

CAMSHAFTNLEM0063S021. Remove the following parts:

+Rocker cover

+Vacuum pump and cylinder head rear cover assembly

+Spill tube

+High pressure injection nozzle assembly

+Secondary timing chain and associated parts

JEM159G

2. Remove camshaft sprockets.

+Holding the hexagonal part of the camshaft with a wrench

having 21 mm (0.83 in) width between facing flats, loosen the

bolt holding the camshaft sprocket.

JEM160G

3. Remove camshafts.

+Loosen bolts holding the camshaft bracket in several stages in

the reverse order of that shown in the figure, and remove them.

4. Remove adjusting shims and valve lifters.

+Confirm the correct location of each part removed. Store them

so they do not get mixed up.

+For re-installation, be sure to put mark on camshaft

bracket before removal.

CYLINDER HEADYD

Components (Cont'd)

EM-201

Page 2480 of 3051

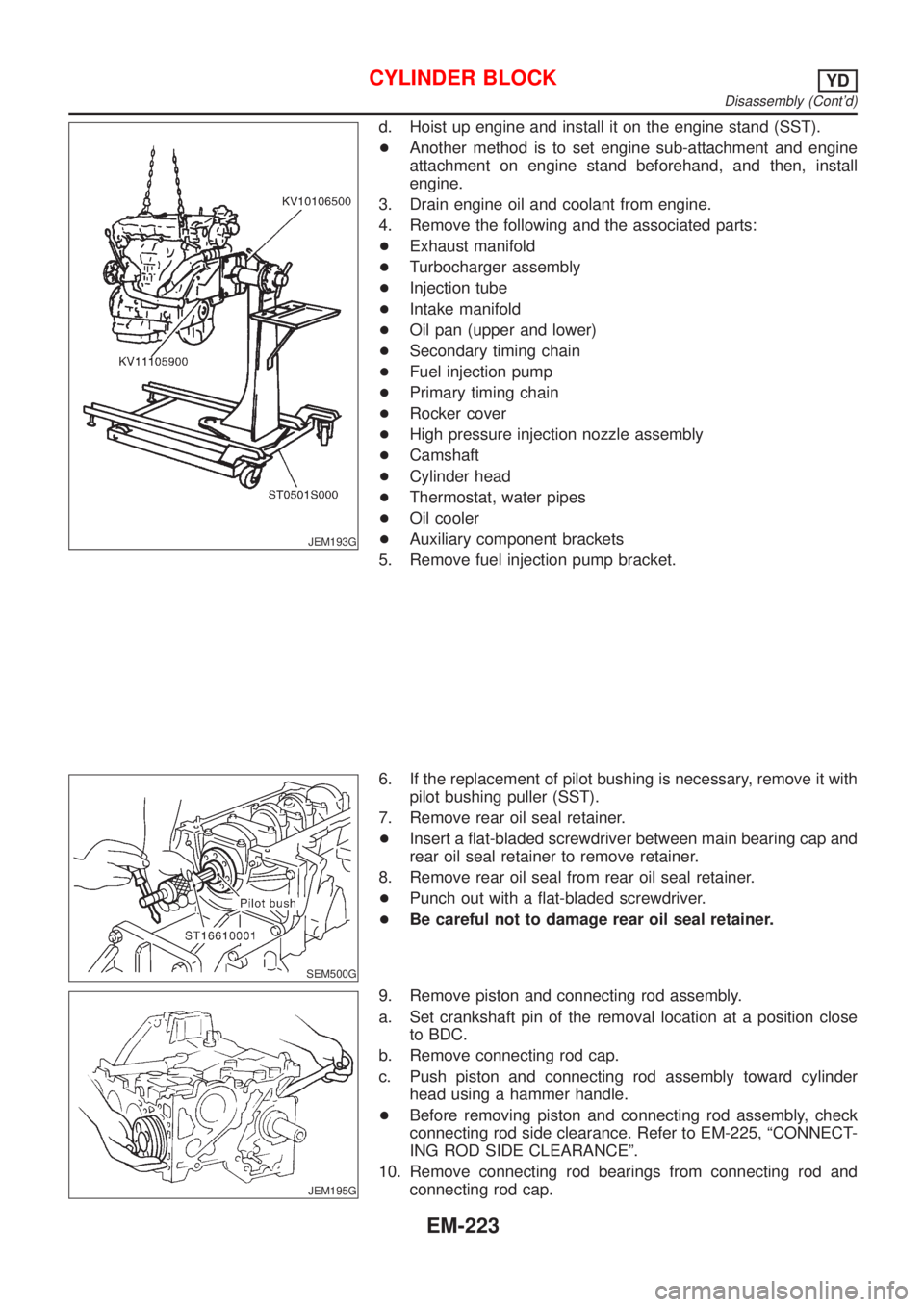

JEM193G

d. Hoist up engine and install it on the engine stand (SST).

+Another method is to set engine sub-attachment and engine

attachment on engine stand beforehand, and then, install

engine.

3. Drain engine oil and coolant from engine.

4. Remove the following and the associated parts:

+Exhaust manifold

+Turbocharger assembly

+Injection tube

+Intake manifold

+Oil pan (upper and lower)

+Secondary timing chain

+Fuel injection pump

+Primary timing chain

+Rocker cover

+High pressure injection nozzle assembly

+Camshaft

+Cylinder head

+Thermostat, water pipes

+Oil cooler

+Auxiliary component brackets

5. Remove fuel injection pump bracket.

SEM500G

6. If the replacement of pilot bushing is necessary, remove it with

pilot bushing puller (SST).

7. Remove rear oil seal retainer.

+Insert a flat-bladed screwdriver between main bearing cap and

rear oil seal retainer to remove retainer.

8. Remove rear oil seal from rear oil seal retainer.

+Punch out with a flat-bladed screwdriver.

+Be careful not to damage rear oil seal retainer.

JEM195G

9. Remove piston and connecting rod assembly.

a. Set crankshaft pin of the removal location at a position close

to BDC.

b. Remove connecting rod cap.

c. Push piston and connecting rod assembly toward cylinder

head using a hammer handle.

+Before removing piston and connecting rod assembly, check

connecting rod side clearance. Refer to EM-225, ªCONNECT-

ING ROD SIDE CLEARANCEº.

10. Remove connecting rod bearings from connecting rod and

connecting rod cap.

CYLINDER BLOCKYD

Disassembly (Cont'd)

EM-223

Page 2498 of 3051

General SpecificationsNLEM0075

Cylinder arrangementIn-line 4

Displacement cm

3(cu in)2,184 (133.27)

Bore and stroke mm (in)86 x 94 (3.39 x 3.70)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil 1

Number of main bearings5

Compression ratio18.0

Compression PressureNLEM0076Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressureStandard 3,138 (31.4, 32.0, 455)

Minimum 2,452 (24.5, 25.0, 356)

Differential limit between cylinders 490 (4.9, 5.0, 71)

Belt DeflectionNLEM0111

Applied belt Belt specificationBelt deflection with 98 N (10 kg, 22 lb) force applied*

mm (in)

New AdjustedLimit for re-tighten-

ing

Air conditioner compressor belt HA type low edge belt4-5

(0.16 - 0.20)6-7

(0.24 - 0.28)8.5 (0.335)

Alternator & water pump beltHA type low-edge wide angle

belt9.0 - 10.5

(0.354 - 0.413)11.0 - 12.5

(0.433 - 0.492)16.5 (0.650)

*: When engine is cold.

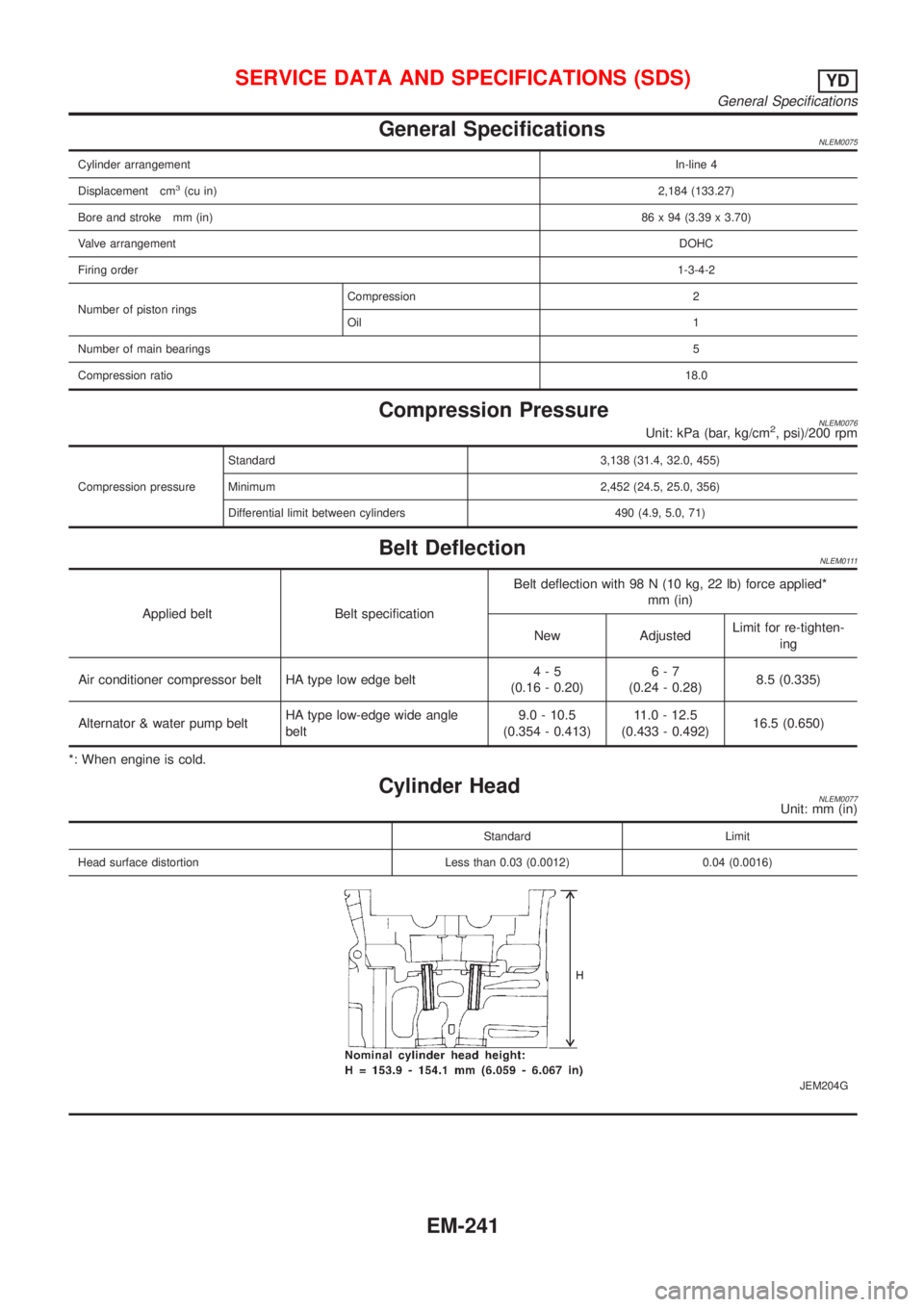

Cylinder HeadNLEM0077Unit: mm (in)

Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.04 (0.0016)

JEM204G

SERVICE DATA AND SPECIFICATIONS (SDS)YD

General Specifications

EM-241

Page 2597 of 3051

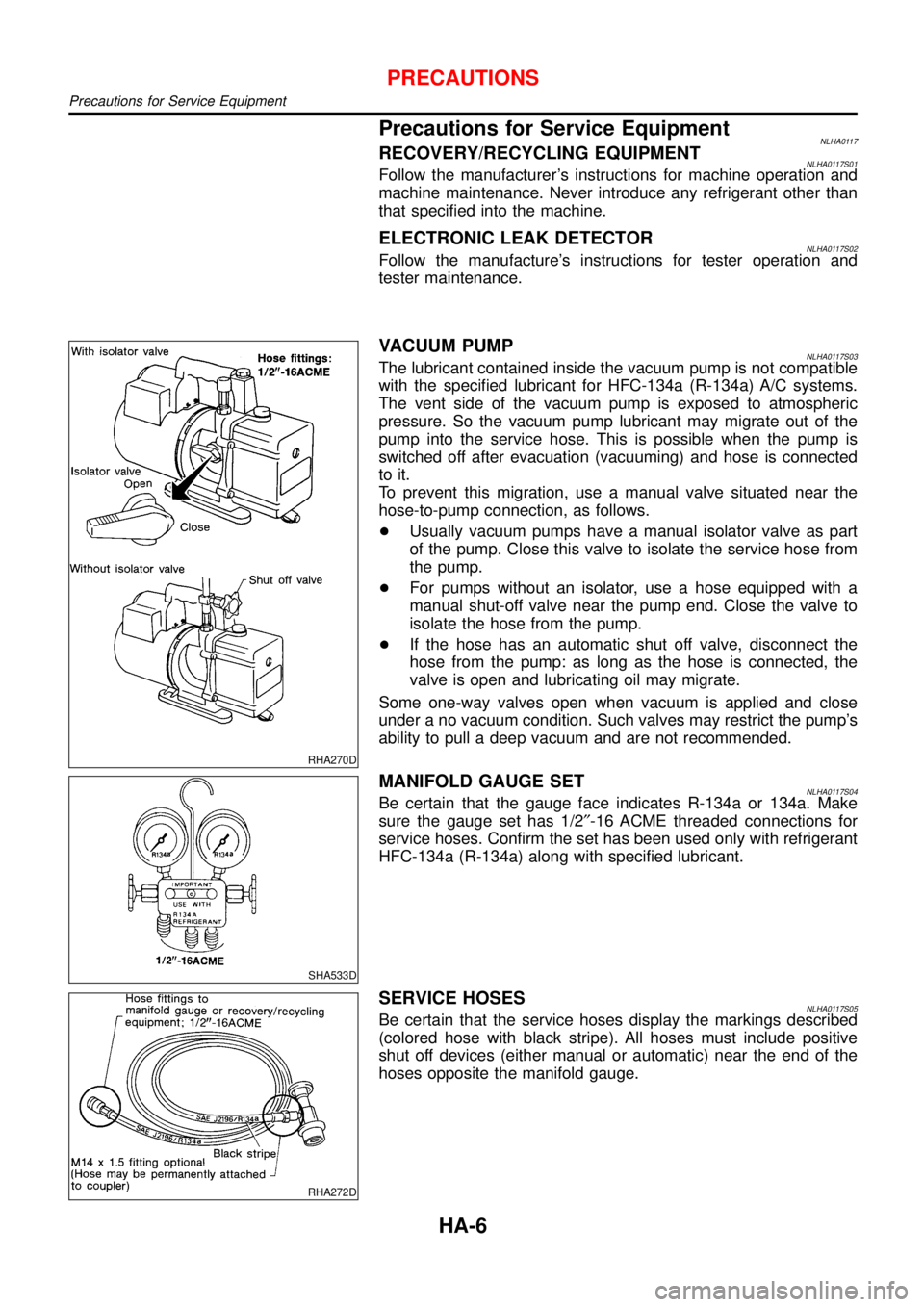

Precautions for Service EquipmentNLHA0117RECOVERY/RECYCLING EQUIPMENTNLHA0117S01Follow the manufacturer’s instructions for machine operation and

machine maintenance. Never introduce any refrigerant other than

that specified into the machine.

ELECTRONIC LEAK DETECTORNLHA0117S02Follow the manufacture’s instructions for tester operation and

tester maintenance.

RHA270D

VACUUM PUMPNLHA0117S03The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

The vent side of the vacuum pump is exposed to atmospheric

pressure. So the vacuum pump lubricant may migrate out of the

pump into the service hose. This is possible when the pump is

switched off after evacuation (vacuuming) and hose is connected

to it.

To prevent this migration, use a manual valve situated near the

hose-to-pump connection, as follows.

+Usually vacuum pumps have a manual isolator valve as part

of the pump. Close this valve to isolate the service hose from

the pump.

+For pumps without an isolator, use a hose equipped with a

manual shut-off valve near the pump end. Close the valve to

isolate the hose from the pump.

+If the hose has an automatic shut off valve, disconnect the

hose from the pump: as long as the hose is connected, the

valve is open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

SHA533D

MANIFOLD GAUGE SETNLHA0117S04Be certain that the gauge face indicates R-134a or 134a. Make

sure the gauge set has 1/2″-16 ACME threaded connections for

service hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) along with specified lubricant.

RHA272D

SERVICE HOSESNLHA0117S05Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive

shut off devices (either manual or automatic) near the end of the

hoses opposite the manifold gauge.

PRECAUTIONS

Precautions for Service Equipment

HA-6