fuel NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1 of 3051

Release:April 2001 01)GENERALINFORMATIONGIMAINTENANCEMAENGINEMECHANICALEMENGINELUBRICATION&

COOLINGSYSTEMSLCENGINECONTROLSYSTEMECACCELERATORCONTROL,

FUEL&EXHAUSTSYSTEMSFECLUTCHCLMANUALTRANSAXLEMTAUTOMATICTRANSAXLEATFRONT&REARAXLEAXFRONT&REARSUSPENSIONSUBRAKESYSTEMBRSTEERINGSYSTEMSTRESTRAINTSYSTEMRSBODY&TRIMBTHEATER&AIRCONDITIONERHASTARTING&CHARGINGSYSTEMSSCELECTRICALSYSTEMELALPHABETICALINDEXIDXALMERATINOMODELV10SERIESQUICKREFERENCEINDEX

Page 7 of 3051

Precautions for Supplemental Restraint System

(SRS) ªAIR BAGº and ªSEAT BELT

PRE-TENSIONERº

NLAT0002The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified with yellow harness connector (and with

yellow harness protector or yellow insulation tape before the harness connectors).

Precautions for On Board Diagnostic (EURO-

OBD) System of CVT and Engine

NLAT0198The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MI) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MI to light up due to a short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to a malfunction of the EGR system or fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

SEF289H

PrecautionsNLAT0003+Before connecting or disconnecting the TCM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if

ignition switch is turned off.

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

AT-6

Page 20 of 3051

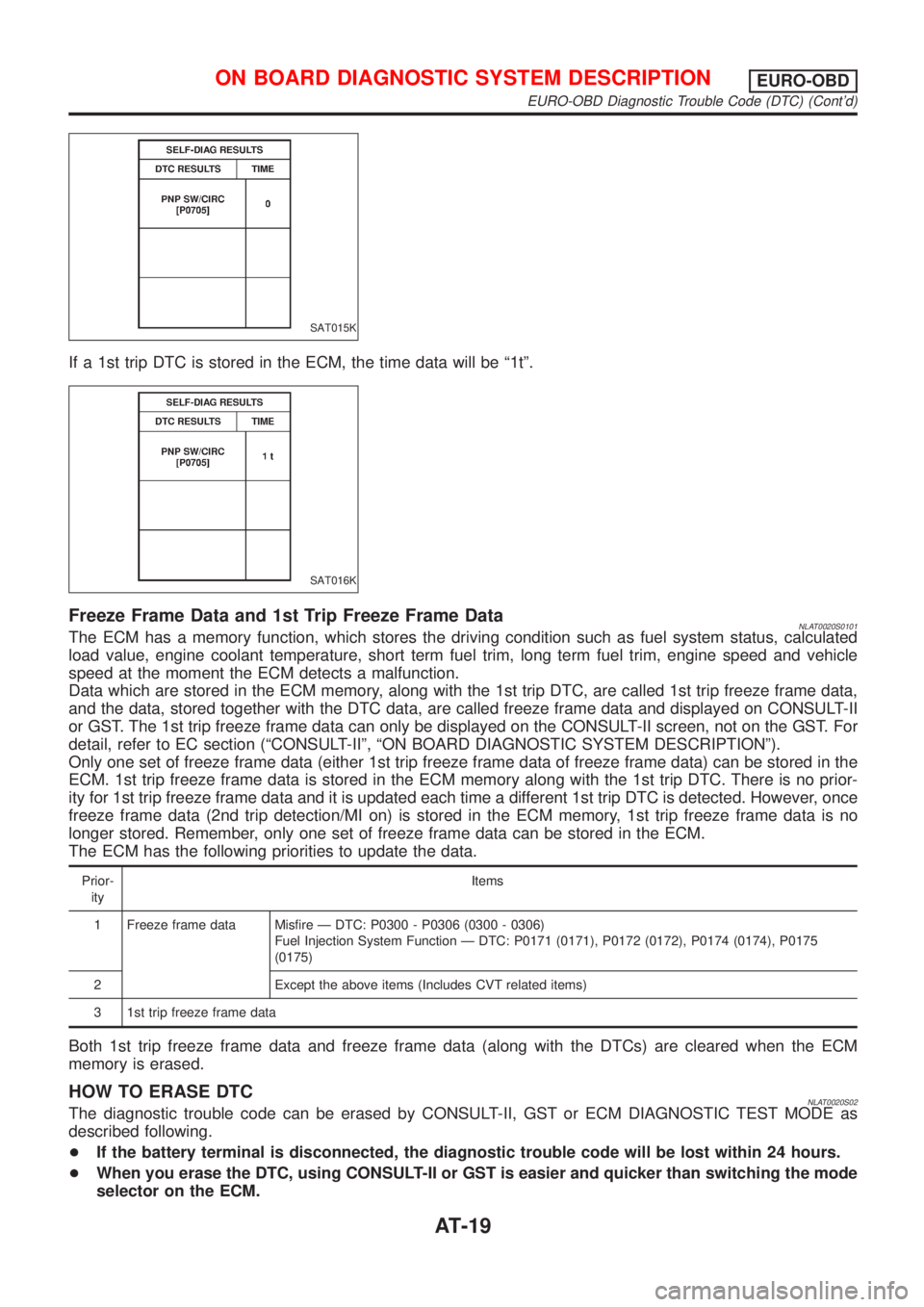

SAT015K

If a 1st trip DTC is stored in the ECM, the time data will be ª1tº.

SAT016K

Freeze Frame Data and 1st Trip Freeze Frame DataNLAT0020S0101The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II

or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

detail, refer to EC section (ªCONSULT-IIº, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº).

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no prior-

ity for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MI on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM.

The ECM has the following priorities to update the data.

Prior-

ityItems

1 Freeze frame data Misfire Ð DTC: P0300 - P0306 (0300 - 0306)

Fuel Injection System Function Ð DTC: P0171 (0171), P0172 (0172), P0174 (0174), P0175

(0175)

2 Except the above items (Includes CVT related items)

3 1st trip freeze frame data

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM

memory is erased.

HOW TO ERASE DTCNLAT0020S02The diagnostic trouble code can be erased by CONSULT-II, GST or ECM DIAGNOSTIC TEST MODE as

described following.

+If the battery terminal is disconnected, the diagnostic trouble code will be lost within 24 hours.

+When you erase the DTC, using CONSULT-II or GST is easier and quicker than switching the mode

selector on the ECM.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONEURO-OBD

EURO-OBD Diagnostic Trouble Code (DTC) (Cont'd)

AT-19

Page 213 of 3051

SBR686C

Precautions

PRECAUTIONSNLAX0001+When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Use flare nut wrench when removing or installing brake

tubes.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNLAX0002

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT146

Removing tie-rod outer end and lower ball joint

KV38106800

Differential side oil seal

protector

NT147

Installing drive shaft

KV38106800

COMMERCIAL SERVICE TOOLSNLAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

FRONT AXLE

Precautions

AX-2

Page 232 of 3051

SBR686C

Precautions

PRECAUTIONSNLAX0022+When installing each rubber part, final tightening must be

carried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+Use flare nut wrench when removing or installing brake

tubes.

+After installing removed suspension parts, check wheel

alignment.

+Do not jack up at the trailing arm and lateral link.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNLAX0032

Tool number

Tool nameDescription

KV40104710

Drift

NT474

Install ABS sensor rotor

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ST3072000

Drift

NT115

Install ABS sensor rotor

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

COMMERCIAL SERVICE TOOLSNLAX0024

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing brake piping

a: 10 mm (0.39 in)

REAR AXLE

Precautions

AX-21

Page 337 of 3051

Checking Body CorrosionNLBT0033Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

Checking Body Corrosion

BT-6

Page 341 of 3051

Removal and InstallationNLBT0034+When removing or installing back door, place a cloth or other padding on back door. This prevents vehicle

body from being scratched.

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Back door adjustment: Adjust at hinge-back door portion for proper back door fit.

+Back door lock system adjustment: Adjust striker so that it is in the center of the lock. After adjustment,

check back door lock operation.

+After installation, make sure that back door and fuel filler lid open smoothly.

REAR BUMPER ASSEMBLYNLBT0034S011. Remove clips securing left and right chipping protectors.

2. Remove screws securing left and right rear fenders to bumper fascia.

3. Remove clips securing bumper fascia assembly.

4. Remove bolts securing left and right rear body to bumper fascia.

5. Open the bumper fascia side outward to disengage from side clips.

6. Extract bumper fascia assembly.

7. Remove nuts securing bumper reinforcement to left and right bumper stays.

8. Remove bolts securing bumper stays, then remove the bumper stays.

NBT168

BODY REAR END AND OPENER

Removal and Installation

BT-10

Page 417 of 3051

SCL729

RemovalNLCL00421. Remove fuel filter mounting bracket.

2. Remove air cleaner and air duct.

3. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

4. Remove flare nut using a flare nut wrench.

5. Remove clutch hose and clutch tube.

SCL730

InstallationNLCL00431. When installing clutch hose to bracket, face lock plate in the

correct direction as shown to secure clutch hose.

CAUTION:

Install clutch hose without twisting or bending it.

2. Tighten flare nut to the specified torque, using a flare nut

wrench.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

CAUTION:

Be careful not to damage flare nut and clutch tube.

3. Install clutch hose to operating cylinder, and tighten mounting

bolts to the specified torque.

: 17 - 19 N´m (1.7 - 2.0 kg-m, 13 - 14 ft-lb)

4. After finishing the operation, bleed air from the clutch piping.

Refer to ªBleeding Procedureº, CL-10.

PIPING

Removal

CL-16

Page 426 of 3051

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG18DE

TROUBLE DIAGNOSIS - INDEX..................................16

Alphabetical & P No. Index for DTC .........................16

PRECAUTIONS.............................................................21

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²....................................................21

Precautions for On Board Diagnostic (OBD)

System of Engine ......................................................21

Engine Fuel & Emission Control System ..................22

Wiring Diagrams and Trouble Diagnosis ...................24

PREPARATION.............................................................25

Special Service Tools ................................................25

Commercial Service Tools .........................................25

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................26

Engine Control Component Parts Location ...............26

Circuit Diagram ..........................................................30

System Diagram ........................................................32

Vacuum Hose Drawing ..............................................33

System Chart .............................................................34

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................35

Multiport Fuel Injection (MFI) System .......................35

Electronic Ignition (EI) System ..................................37

Air Conditioning Cut Control ......................................38

Fuel Cut Control (at no load & high engine

speed) ........................................................................39

Evaporative Emission System ...................................39

Positive Crankcase Ventilation ..................................42

BASIC SERVICE PROCEDURE...................................43

Fuel Pressure Release ..............................................43

Fuel Pressure Check .................................................43

Fuel Pressure Regulator Check ................................44

Injector .......................................................................44

How to Check Idle Speed and Ignition Timing ..........46

Preparation ................................................................47

Inspection Procedure .................................................49Idle Air Volume Learning ...........................................57

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................59

Introduction ................................................................59

Two Trip Detection Logic ...........................................59

Emission-related Diagnostic Information ...................60

NATS (Nissan Anti-theft System) ..............................72

Malfunction Indicator (MI) ..........................................73

OBD System Operation Chart (With Euro-OBD

Models Only)..............................................................77

CONSULT-II ...............................................................82

Generic Scan Tool (GST) ..........................................93

TROUBLE DIAGNOSIS - INTRODUCTION..................95

Introduction ................................................................95

Work Flow ..................................................................97

TROUBLE DIAGNOSIS - BASIC INSPECTION...........99

Basic Inspection.........................................................99

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................122

DTC Inspection Priority Chart..................................122

Fail-safe Chart .........................................................123

Symptom Matrix Chart .............................................124

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................128

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................130

ECM Terminals and Reference Value .....................133

TROUBLE DIAGNOSIS - SPECIFICATION VALUE..141

Description ...............................................................141

Testing Condition .....................................................141

Inspection Procedure ...............................................141

Diagnostic Procedure ..............................................142

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................145

Description ...............................................................145

Diagnostic Procedure ..............................................145

TROUBLE DIAGNOSIS FOR POWER SUPPLY........146

Main Power Supply and Ground Circuit ..................146

Page 428 of 3051

On Board Diagnosis Logic.......................................221

DTC Confirmation Procedure ..................................222

Wiring Diagram ........................................................223

Diagnostic Procedure ..............................................225

Component Inspection .............................................226

DTC P0137 HEATED OXYGEN SENSOR 2

(REAR) (MIN. VOLTAGE MONITORING)...................227

Component Description ...........................................227

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................227

ECM Terminals and Reference Value .....................227

On Board Diagnosis Logic.......................................227

DTC Confirmation Procedure ..................................228

Overall Function Check ...........................................229

Wiring Diagram ........................................................230

Diagnostic Procedure ..............................................232

Component Inspection .............................................235

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING).................237

Component Description ...........................................237

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................237

ECM Terminals and Reference Value .....................237

On Board Diagnosis Logic.......................................237

DTC Confirmation Procedure ..................................238

Overall Function Check ...........................................239

Wiring Diagram ........................................................240

Diagnostic Procedure ..............................................242

Component Inspection .............................................244

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING).........................246

Component Description ...........................................246

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................246

ECM Terminals and Reference Value .....................246

On Board Diagnosis Logic.......................................246

DTC Confirmation Procedure ..................................247

Overall Function Check ...........................................248

Wiring Diagram ........................................................249

Diagnostic Procedure ..............................................251

Component Inspection .............................................254

DTC P0140 HEATED OXYGEN SENSOR 2

(REAR) (HIGH VOLTAGE)..........................................256

Component Description ...........................................256

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................256

ECM Terminals and Reference Value .....................256

On Board Diagnosis Logic.......................................256

DTC Confirmation Procedure ..................................257

Overall Function Check ...........................................257

Wiring Diagram ........................................................258

Diagnostic Procedure ..............................................260Component Inspection .............................................261

DTC P0141 HEATED OXYGEN SENSOR 2

HEATER (REAR).........................................................263

Description ...............................................................263

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................263

ECM Terminals and Reference Value .....................263

On Board Diagnosis Logic.......................................264

DTC Confirmation Procedure ..................................264

Wiring Diagram ........................................................265

Diagnostic Procedure ..............................................267

Component Inspection .............................................268

DTC P0171 FUEL INJECTION SYSTEM

FUNCTION (LEAN SIDE)............................................269

On Board Diagnosis Logic.......................................269

DTC Confirmation Procedure ..................................269

Wiring Diagram ........................................................271

Diagnostic Procedure ..............................................273

DTC P0172 FUEL INJECTION SYSTEM

FUNCTION (RICH SIDE).............................................277

On Board Diagnosis Logic.......................................277

DTC Confirmation Procedure ..................................277

Wiring Diagram ........................................................279

Diagnostic Procedure ..............................................281

DTC P0300 - P0304 NO.4-1CYLINDER

MISFIRE, MULTIPLE CYLINDER MISFIRE...............285

On Board Diagnosis Logic.......................................285

DTC Confirmation Procedure ..................................285

Diagnostic Procedure ..............................................286

DTC P0325 KNOCK SENSOR (KS)...........................291

Component Description ...........................................291

ECM Terminals and Reference Value .....................291

On Board Diagnosis Logic.......................................291

DTC Confirmation Procedure ..................................291

Wiring Diagram ........................................................292

Diagnostic Procedure ..............................................293

Component Inspection .............................................294

DTC P0335 CRANKSHAFT POSITION SENSOR

(POS)............................................................................295

Component Description ...........................................295

ECM Terminals and Reference Value .....................295

On Board Diagnosis Logic.......................................296

DTC Confirmation Procedure ..................................296

Wiring Diagram ........................................................297

Diagnostic Procedure ..............................................299

Component Inspection .............................................301

DTC P0340 CAMSHAFT POSITION SENSOR

(CMPS) (PHASE).........................................................302

Component Description ...........................................302

ECM Terminals and Reference Value .....................302

On Board Diagnosis Logic.......................................303

DTC Confirmation Procedure ..................................303

CONTENTS(Cont'd)

EC-3