fuel tank removal NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1513 of 3051

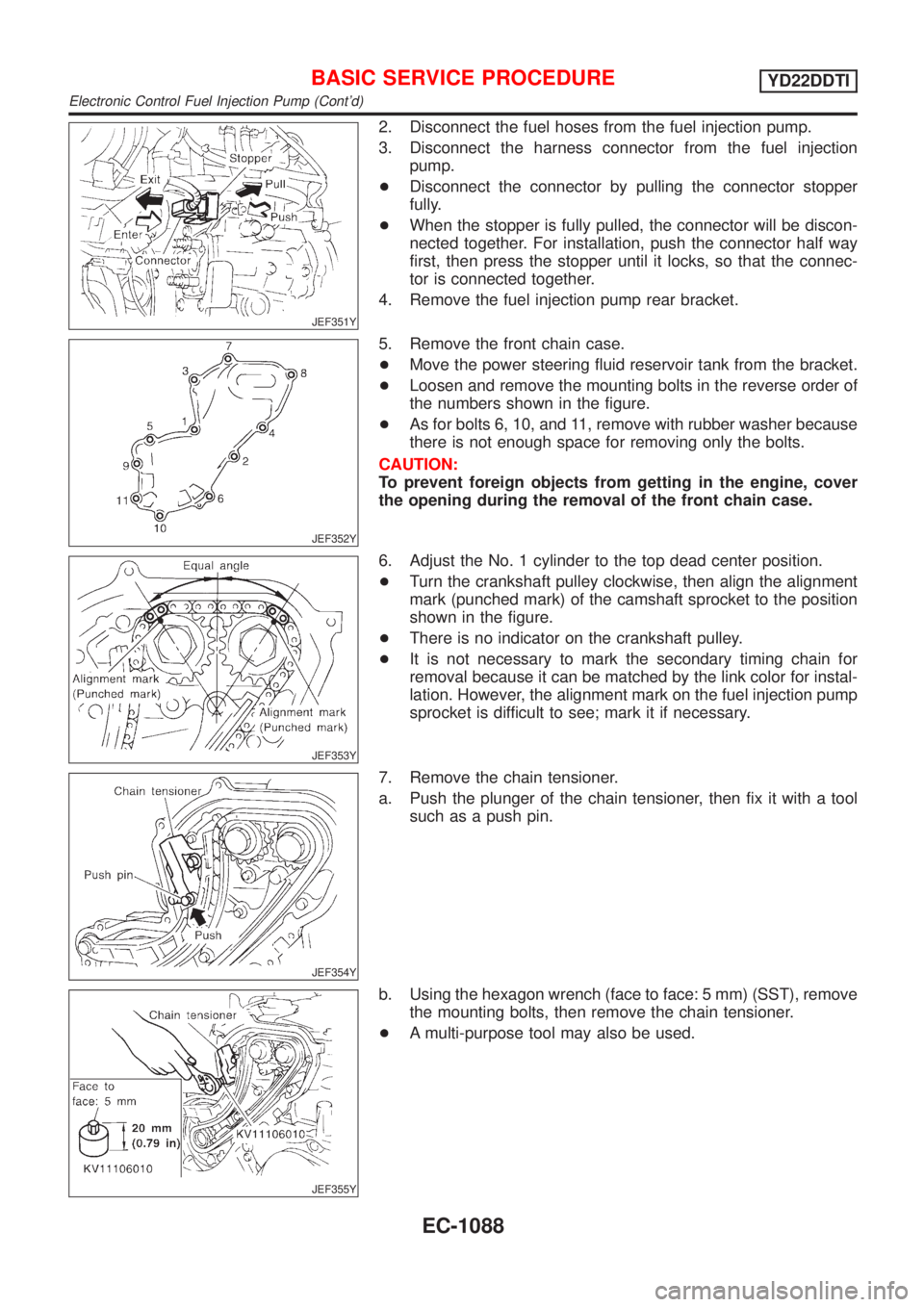

JEF351Y

2. Disconnect the fuel hoses from the fuel injection pump.

3. Disconnect the harness connector from the fuel injection

pump.

+Disconnect the connector by pulling the connector stopper

fully.

+When the stopper is fully pulled, the connector will be discon-

nected together. For installation, push the connector half way

first, then press the stopper until it locks, so that the connec-

tor is connected together.

4. Remove the fuel injection pump rear bracket.

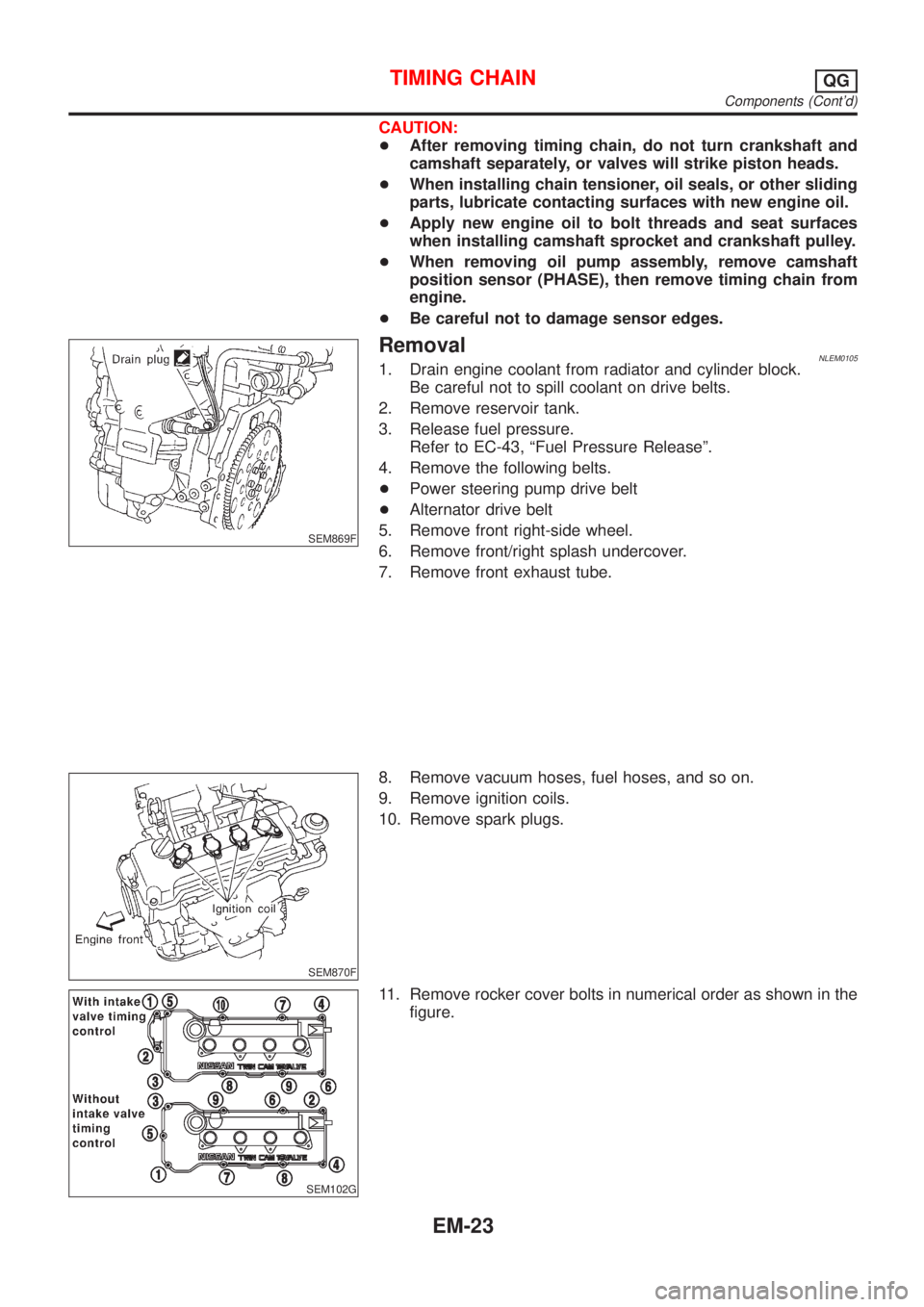

JEF352Y

5. Remove the front chain case.

+Move the power steering fluid reservoir tank from the bracket.

+Loosen and remove the mounting bolts in the reverse order of

the numbers shown in the figure.

+As for bolts 6, 10, and 11, remove with rubber washer because

there is not enough space for removing only the bolts.

CAUTION:

To prevent foreign objects from getting in the engine, cover

the opening during the removal of the front chain case.

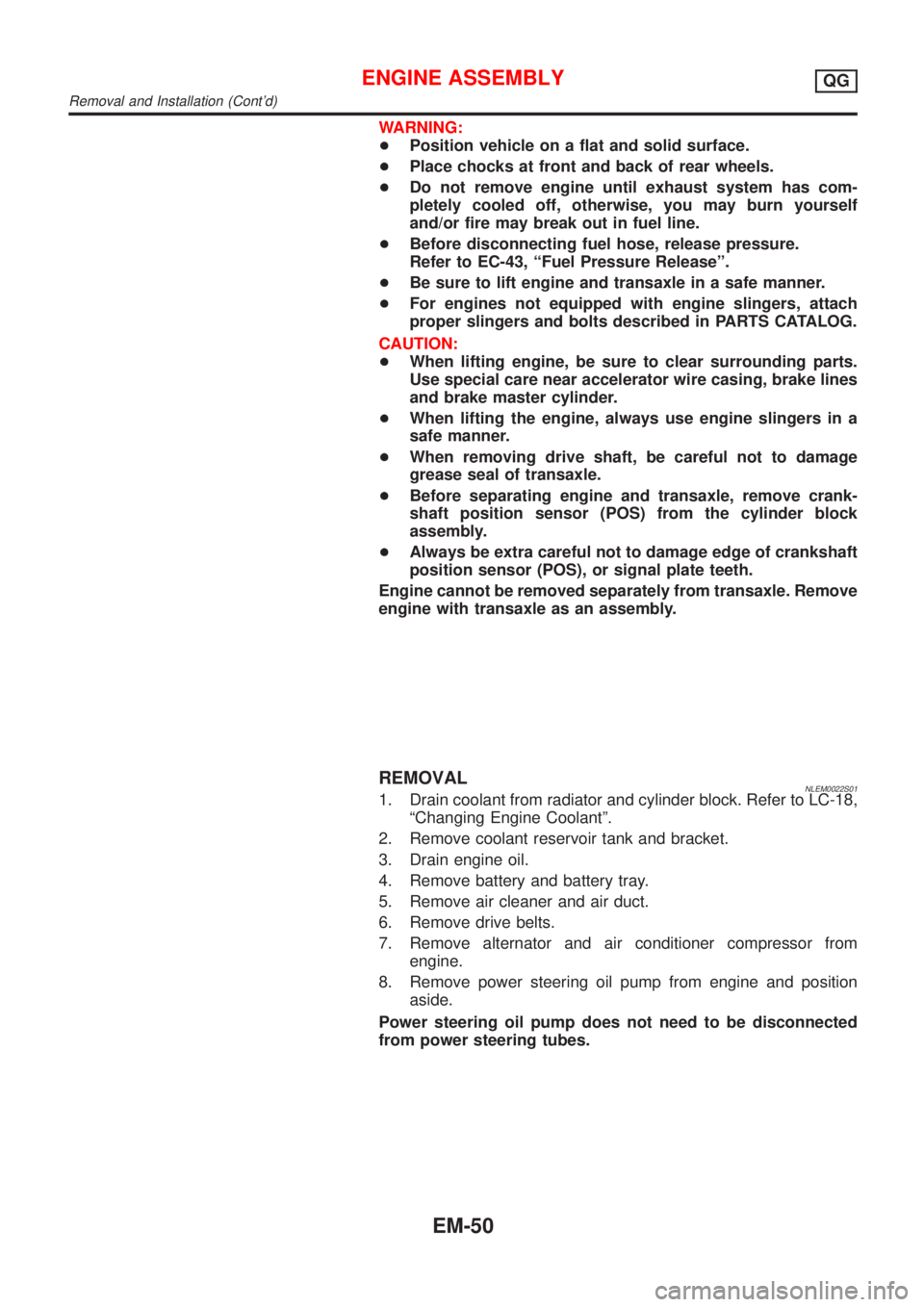

JEF353Y

6. Adjust the No. 1 cylinder to the top dead center position.

+Turn the crankshaft pulley clockwise, then align the alignment

mark (punched mark) of the camshaft sprocket to the position

shown in the figure.

+There is no indicator on the crankshaft pulley.

+It is not necessary to mark the secondary timing chain for

removal because it can be matched by the link color for instal-

lation. However, the alignment mark on the fuel injection pump

sprocket is difficult to see; mark it if necessary.

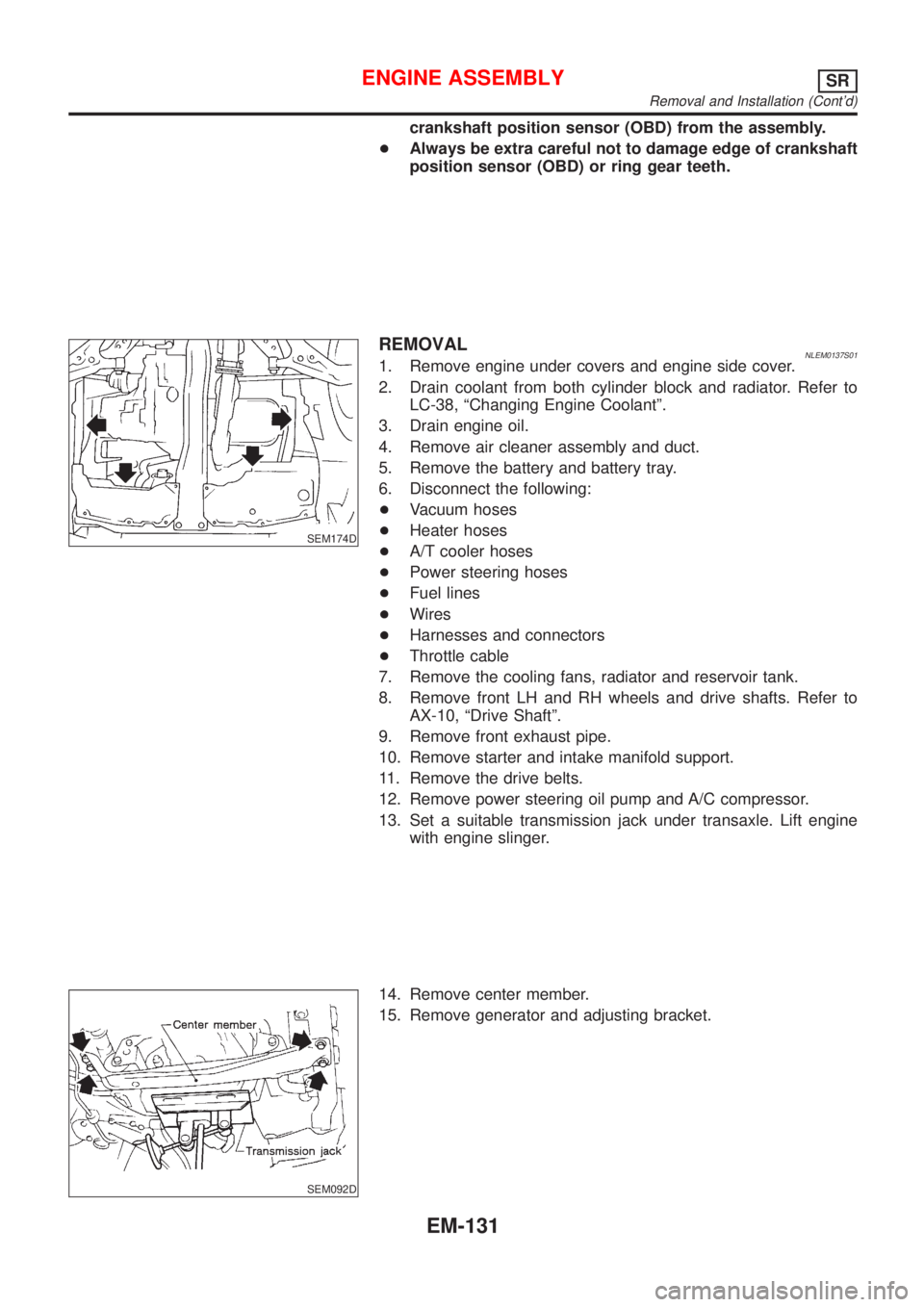

JEF354Y

7. Remove the chain tensioner.

a. Push the plunger of the chain tensioner, then fix it with a tool

such as a push pin.

JEF355Y

b. Using the hexagon wrench (face to face: 5 mm) (SST), remove

the mounting bolts, then remove the chain tensioner.

+A multi-purpose tool may also be used.

BASIC SERVICE PROCEDUREYD22DDTI

Electronic Control Fuel Injection Pump (Cont'd)

EC-1088

Page 2280 of 3051

CAUTION:

+After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

+When installing chain tensioner, oil seals, or other sliding

parts, lubricate contacting surfaces with new engine oil.

+Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

+When removing oil pump assembly, remove camshaft

position sensor (PHASE), then remove timing chain from

engine.

+Be careful not to damage sensor edges.

SEM869F

RemovalNLEM01051. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Remove reservoir tank.

3. Release fuel pressure.

Refer to EC-43, ªFuel Pressure Releaseº.

4. Remove the following belts.

+Power steering pump drive belt

+Alternator drive belt

5. Remove front right-side wheel.

6. Remove front/right splash undercover.

7. Remove front exhaust tube.

SEM870F

8. Remove vacuum hoses, fuel hoses, and so on.

9. Remove ignition coils.

10. Remove spark plugs.

SEM102G

11. Remove rocker cover bolts in numerical order as shown in the

figure.

TIMING CHAINQG

Components (Cont'd)

EM-23

Page 2307 of 3051

WARNING:

+Position vehicle on a flat and solid surface.

+Place chocks at front and back of rear wheels.

+Do not remove engine until exhaust system has com-

pletely cooled off, otherwise, you may burn yourself

and/or fire may break out in fuel line.

+Before disconnecting fuel hose, release pressure.

Refer to EC-43, ªFuel Pressure Releaseº.

+Be sure to lift engine and transaxle in a safe manner.

+For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

+When lifting engine, be sure to clear surrounding parts.

Use special care near accelerator wire casing, brake lines

and brake master cylinder.

+When lifting the engine, always use engine slingers in a

safe manner.

+When removing drive shaft, be careful not to damage

grease seal of transaxle.

+Before separating engine and transaxle, remove crank-

shaft position sensor (POS) from the cylinder block

assembly.

+Always be extra careful not to damage edge of crankshaft

position sensor (POS), or signal plate teeth.

Engine cannot be removed separately from transaxle. Remove

engine with transaxle as an assembly.

REMOVALNLEM0022S011. Drain coolant from radiator and cylinder block. Refer to LC-18,

ªChanging Engine Coolantº.

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from

engine.

8. Remove power steering oil pump from engine and position

aside.

Power steering oil pump does not need to be disconnected

from power steering tubes.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-50

Page 2388 of 3051

crankshaft position sensor (OBD) from the assembly.

+Always be extra careful not to damage edge of crankshaft

position sensor (OBD) or ring gear teeth.

SEM174D

REMOVALNLEM0137S011. Remove engine under covers and engine side cover.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-38, ªChanging Engine Coolantº.

3. Drain engine oil.

4. Remove air cleaner assembly and duct.

5. Remove the battery and battery tray.

6. Disconnect the following:

+Vacuum hoses

+Heater hoses

+A/T cooler hoses

+Power steering hoses

+Fuel lines

+Wires

+Harnesses and connectors

+Throttle cable

7. Remove the cooling fans, radiator and reservoir tank.

8. Remove front LH and RH wheels and drive shafts. Refer to

AX-10, ªDrive Shaftº.

9. Remove front exhaust pipe.

10. Remove starter and intake manifold support.

11. Remove the drive belts.

12. Remove power steering oil pump and A/C compressor.

13. Set a suitable transmission jack under transaxle. Lift engine

with engine slinger.

SEM092D

14. Remove center member.

15. Remove generator and adjusting bracket.

ENGINE ASSEMBLYSR

Removal and Installation (Cont'd)

EM-131

Page 2433 of 3051

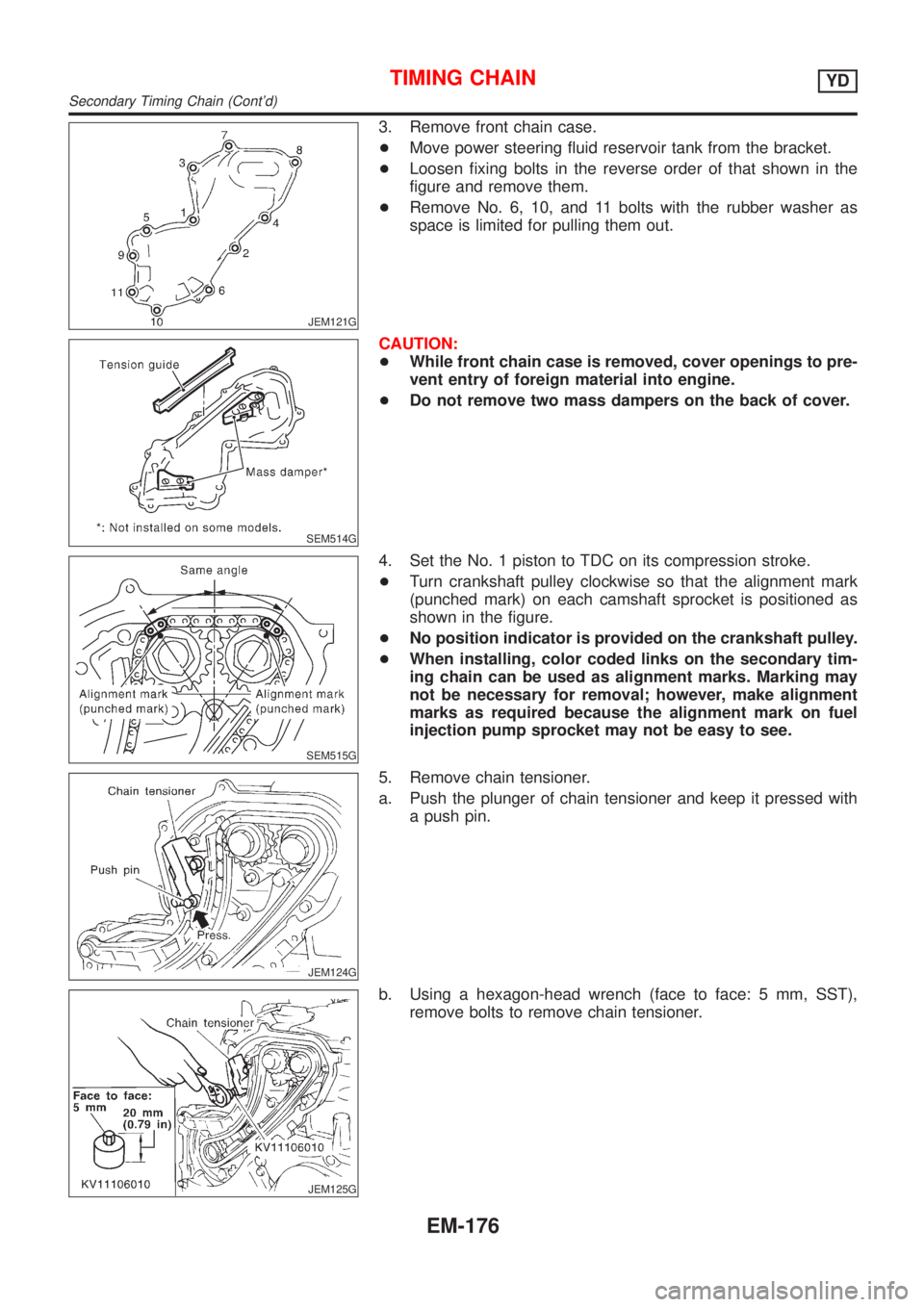

JEM121G

3. Remove front chain case.

+Move power steering fluid reservoir tank from the bracket.

+Loosen fixing bolts in the reverse order of that shown in the

figure and remove them.

+Remove No. 6, 10, and 11 bolts with the rubber washer as

space is limited for pulling them out.

SEM514G

CAUTION:

+While front chain case is removed, cover openings to pre-

vent entry of foreign material into engine.

+Do not remove two mass dampers on the back of cover.

SEM515G

4. Set the No. 1 piston to TDC on its compression stroke.

+Turn crankshaft pulley clockwise so that the alignment mark

(punched mark) on each camshaft sprocket is positioned as

shown in the figure.

+No position indicator is provided on the crankshaft pulley.

+When installing, color coded links on the secondary tim-

ing chain can be used as alignment marks. Marking may

not be necessary for removal; however, make alignment

marks as required because the alignment mark on fuel

injection pump sprocket may not be easy to see.

JEM124G

5. Remove chain tensioner.

a. Push the plunger of chain tensioner and keep it pressed with

a push pin.

JEM125G

b. Using a hexagon-head wrench (face to face: 5 mm, SST),

remove bolts to remove chain tensioner.

TIMING CHAINYD

Secondary Timing Chain (Cont'd)

EM-176

Page 2510 of 3051

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

CONTENTS

QG/SR

PREPARATION...............................................................2

Special Service Tools ..................................................2

Commercial Service Tools ...........................................2

ACCELERATOR CONTROL SYSTEM...........................3

Removal and Installation .............................................3

Adjusting Accelerator Wire ..........................................3

MODELS WITH THROTTLE OPENER.........................3

MODELS WITHOUT THROTTLE OPENER..................4

FUEL SYSTEM................................................................5

Checking Fuel Lines ....................................................5

Removal and Installation .............................................5

Fuel Tank .....................................................................6

REMOVAL.................................................................6

INSTALLATION..........................................................8

Fuel Pump, Fuel Level Sensor Unit and Fuel

Filter .............................................................................9

REMOVAL.................................................................9

INSTALLATION........................................................10

EXHAUST SYSTEM...................................................... 11

Checking Exhaust System......................................... 11

Removal and Installation ........................................... 11

YD

PREPARATION.............................................................13

Special Service Tool ..................................................13Commercial Service Tool ...........................................13

ACCELERATOR CONTROL SYSTEM.........................14

Removal and Installation ...........................................14

Inspection...................................................................14

FUEL SYSTEM..............................................................15

Checking Fuel Lines ..................................................15

Water Draining from Fuel Filter .................................15

DRAINING WATER..................................................15

FUEL FILTER CHECK..............................................15

Changing Fuel Filter ..................................................15

REMOVAL...............................................................15

INSTALLATION........................................................16

Bleeding Fuel Filter....................................................16

Checking Priming Pump ............................................16

Checking Water in Fuel Filter Sensor (where

fitted) ..........................................................................17

Removal and Installation ...........................................17

Fuel Tank ...................................................................18

REMOVAL...............................................................19

INSTALLATION........................................................20

Fuel Level Sensor Unit ..............................................21

REMOVAL...............................................................21

INSTALLATION........................................................22

EXHAUST SYSTEM......................................................23

Checking Exhaust System.........................................23

Removal and Installation ...........................................23

Page 2515 of 3051

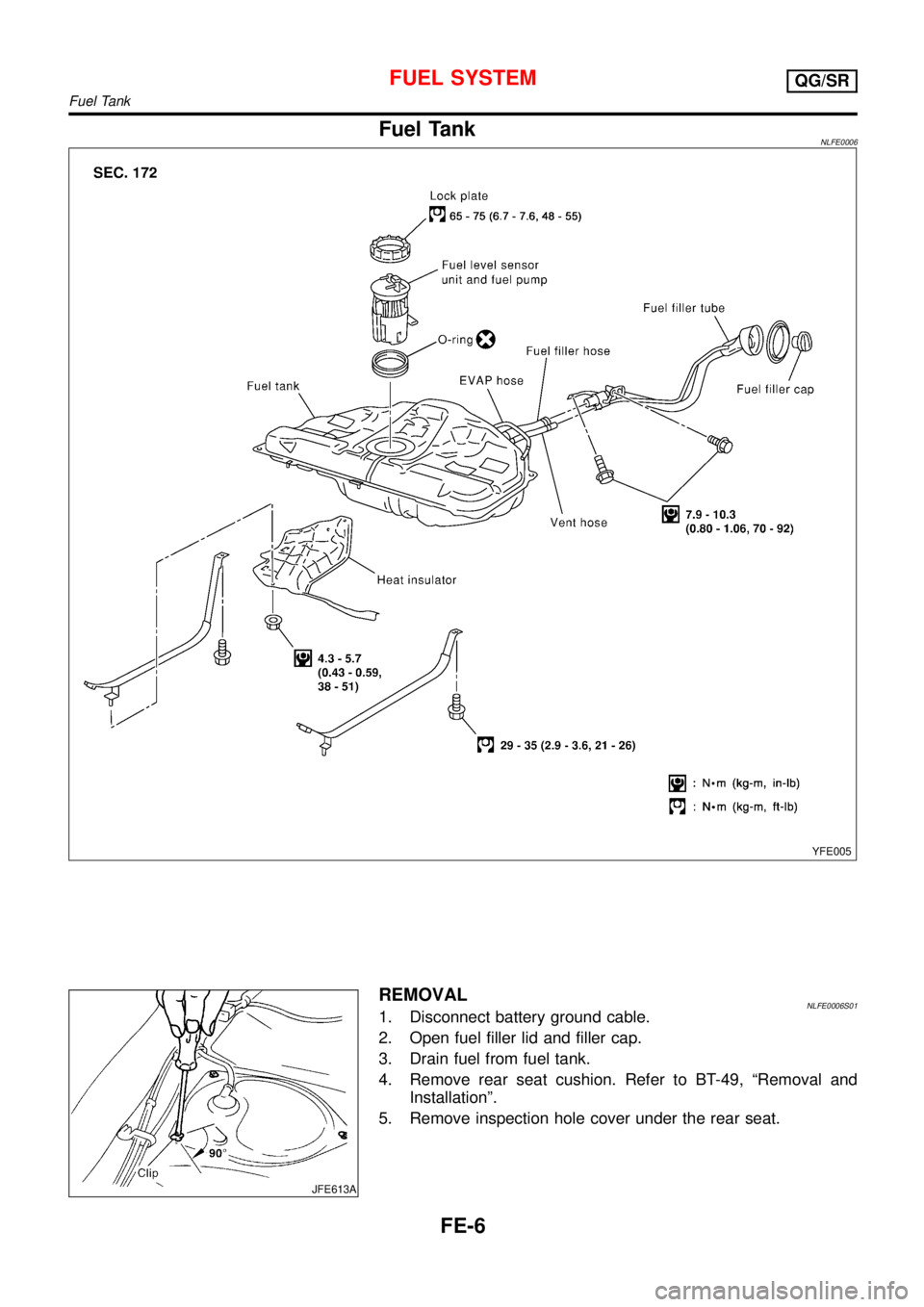

Fuel TankNLFE0006

YFE005

JFE613A

REMOVALNLFE0006S011. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Drain fuel from fuel tank.

4. Remove rear seat cushion. Refer to BT-49,“Removal and

Installation”.

5. Remove inspection hole cover under the rear seat.

FUEL SYSTEMQG/SR

Fuel Tank

FE-6

Page 2516 of 3051

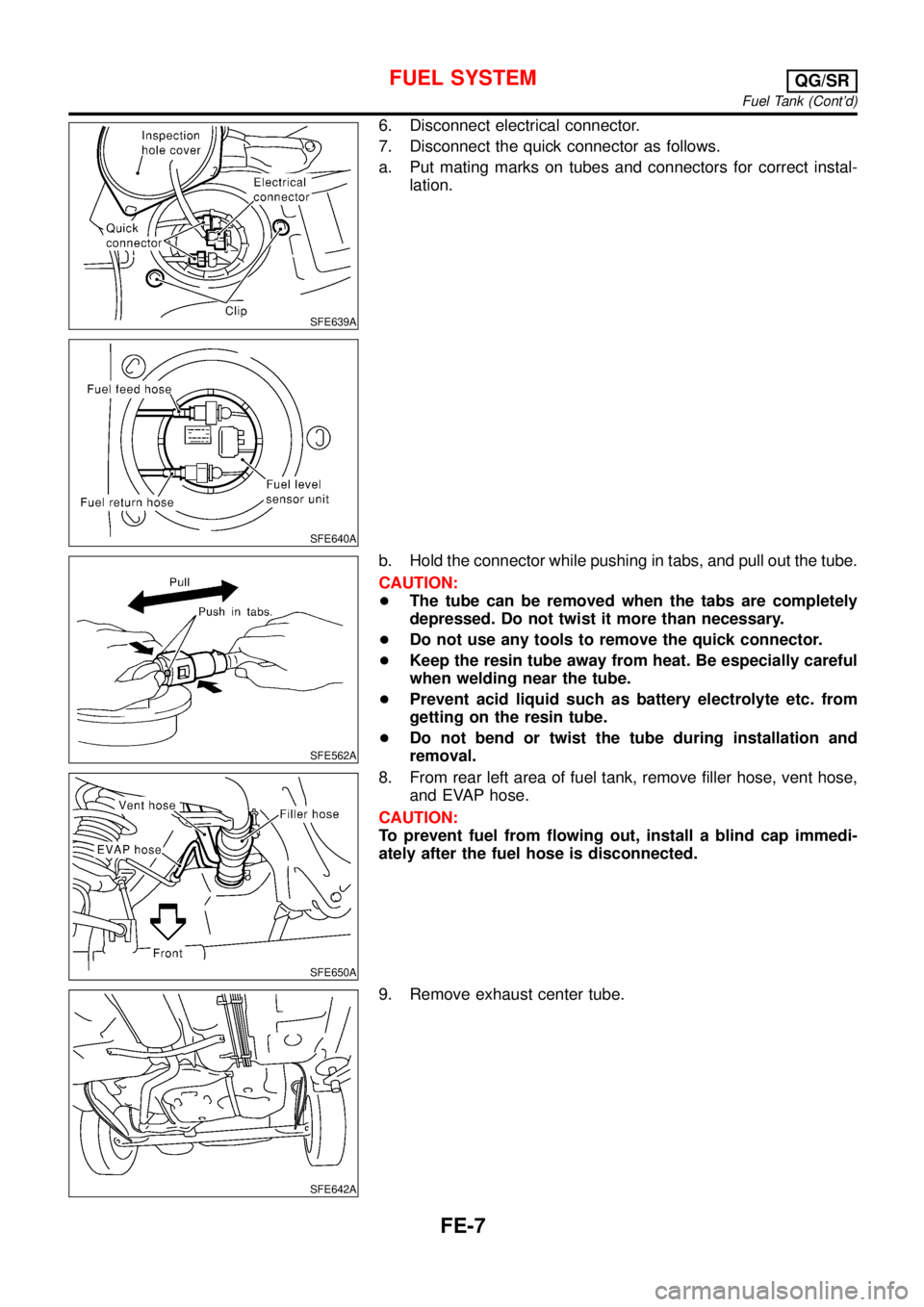

SFE639A

SFE640A

6. Disconnect electrical connector.

7. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct instal-

lation.

SFE562A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

+The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

+Do not use any tools to remove the quick connector.

+Keep the resin tube away from heat. Be especially careful

when welding near the tube.

+Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

+Do not bend or twist the tube during installation and

removal.

SFE650A

8. From rear left area of fuel tank, remove filler hose, vent hose,

and EVAP hose.

CAUTION:

To prevent fuel from flowing out, install a blind cap immedi-

ately after the fuel hose is disconnected.

SFE642A

9. Remove exhaust center tube.

FUEL SYSTEMQG/SR

Fuel Tank (Cont’d)

FE-7

Page 2517 of 3051

SFE643A

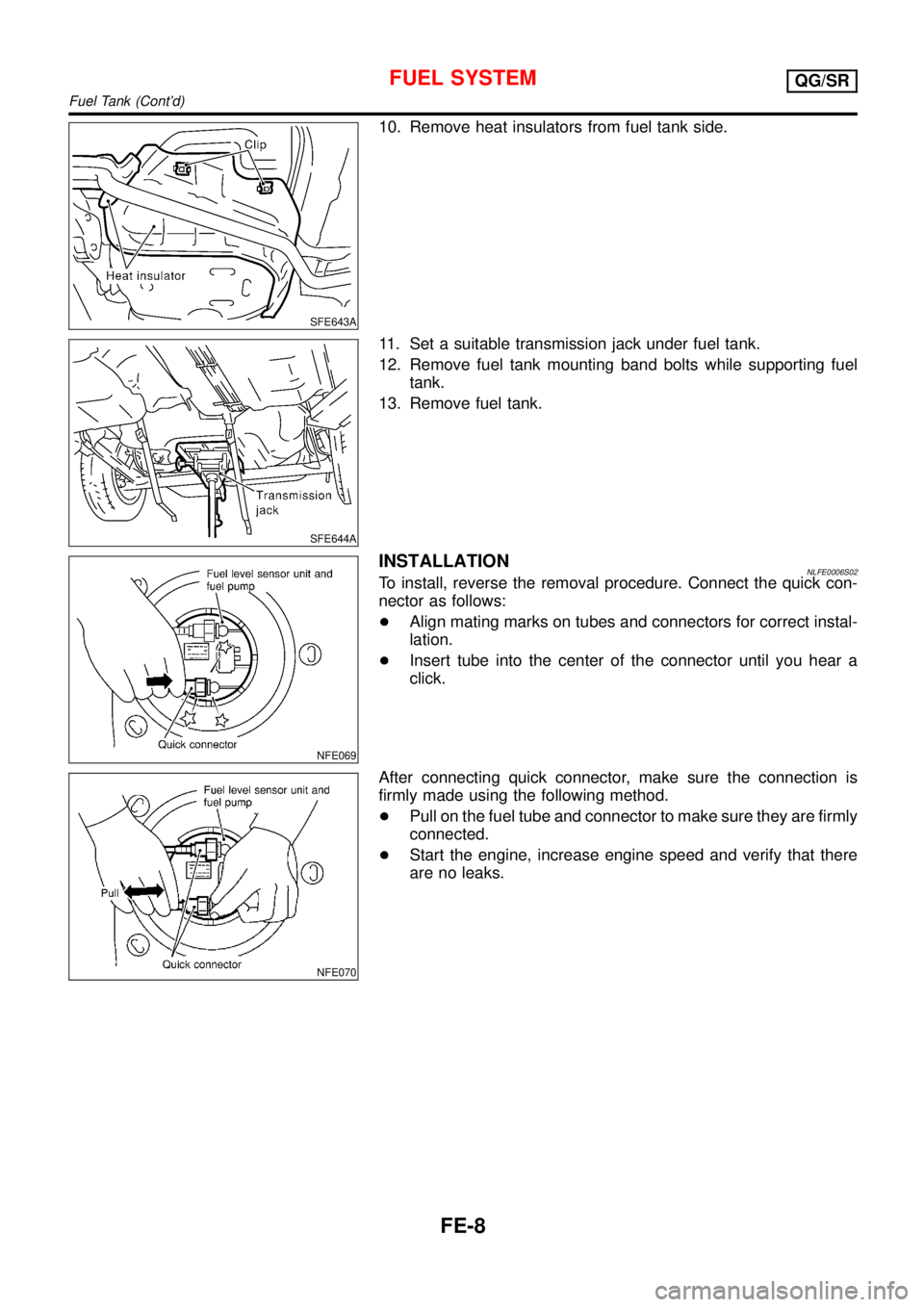

10. Remove heat insulators from fuel tank side.

SFE644A

11. Set a suitable transmission jack under fuel tank.

12. Remove fuel tank mounting band bolts while supporting fuel

tank.

13. Remove fuel tank.

NFE069

INSTALLATIONNLFE0006S02To install, reverse the removal procedure. Connect the quick con-

nector as follows:

+Align mating marks on tubes and connectors for correct instal-

lation.

+Insert tube into the center of the connector until you hear a

click.

NFE070

After connecting quick connector, make sure the connection is

firmly made using the following method.

+Pull on the fuel tube and connector to make sure they are firmly

connected.

+Start the engine, increase engine speed and verify that there

are no leaks.

FUEL SYSTEMQG/SR

Fuel Tank (Cont’d)

FE-8

Page 2518 of 3051

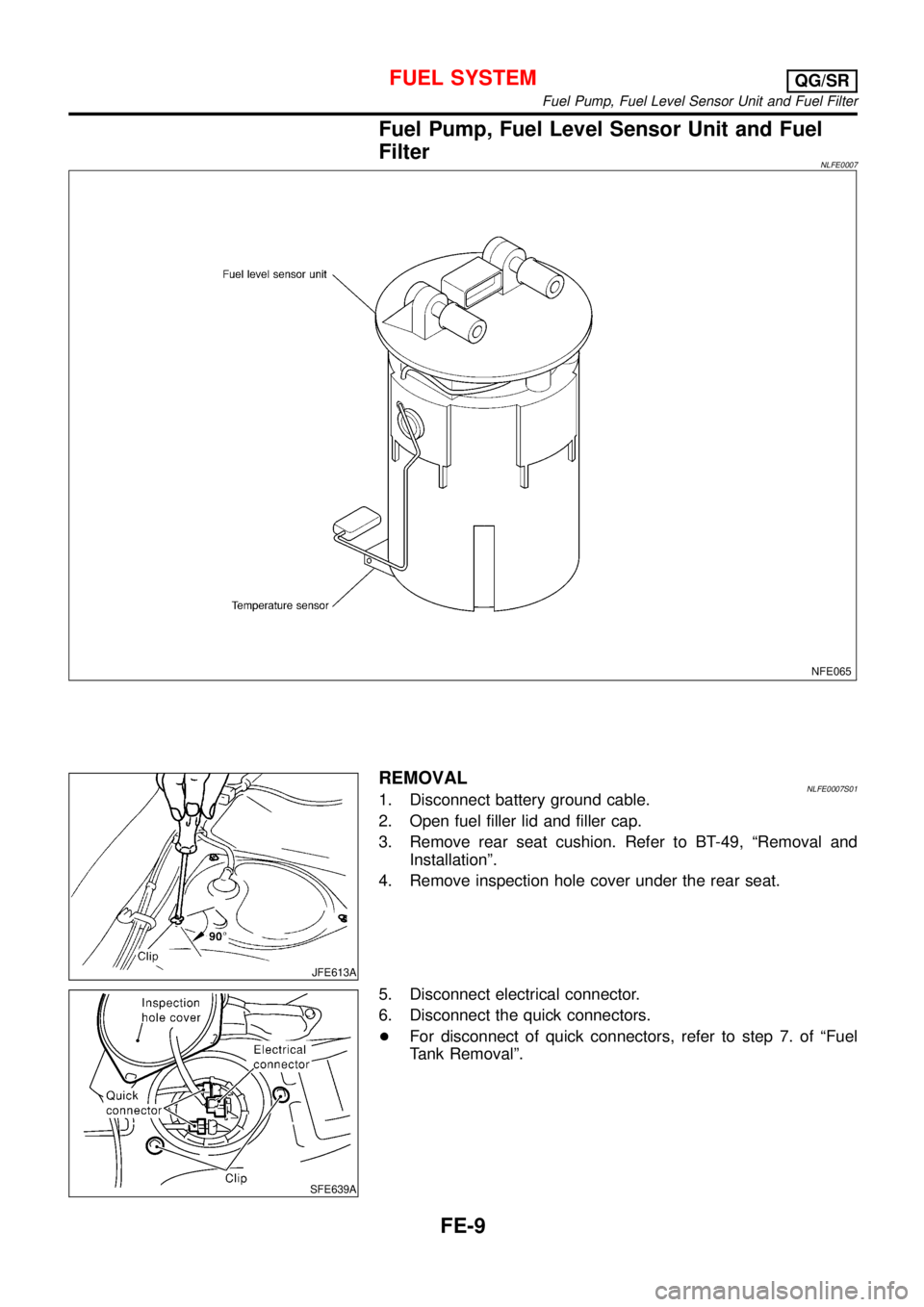

Fuel Pump, Fuel Level Sensor Unit and Fuel

Filter

NLFE0007

NFE065

JFE613A

REMOVALNLFE0007S011. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Remove rear seat cushion. Refer to BT-49,“Removal and

Installation”.

4. Remove inspection hole cover under the rear seat.

SFE639A

5. Disconnect electrical connector.

6. Disconnect the quick connectors.

+For disconnect of quick connectors, refer to step 7. of“Fuel

Tank Removal”.

FUEL SYSTEMQG/SR

Fuel Pump, Fuel Level Sensor Unit and Fuel Filter

FE-9