maintenance NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1 of 3051

Release:April 2001 01)GENERALINFORMATIONGIMAINTENANCEMAENGINEMECHANICALEMENGINELUBRICATION&

COOLINGSYSTEMSLCENGINECONTROLSYSTEMECACCELERATORCONTROL,

FUEL&EXHAUSTSYSTEMSFECLUTCHCLMANUALTRANSAXLEMTAUTOMATICTRANSAXLEATFRONT&REARAXLEAXFRONT&REARSUSPENSIONSUBRAKESYSTEMBRSTEERINGSYSTEMSTRESTRAINTSYSTEMRSBODY&TRIMBTHEATER&AIRCONDITIONERHASTARTING&CHARGINGSYSTEMSSCELECTRICALSYSTEMELALPHABETICALINDEXIDXALMERATINOMODELV10SERIESQUICKREFERENCEINDEX

Page 7 of 3051

Precautions for Supplemental Restraint System

(SRS) ªAIR BAGº and ªSEAT BELT

PRE-TENSIONERº

NLAT0002The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified with yellow harness connector (and with

yellow harness protector or yellow insulation tape before the harness connectors).

Precautions for On Board Diagnostic (EURO-

OBD) System of CVT and Engine

NLAT0198The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MI) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MI to light up due to a short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to a malfunction of the EGR system or fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

SEF289H

PrecautionsNLAT0003+Before connecting or disconnecting the TCM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if

ignition switch is turned off.

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

AT-6

Page 234 of 3051

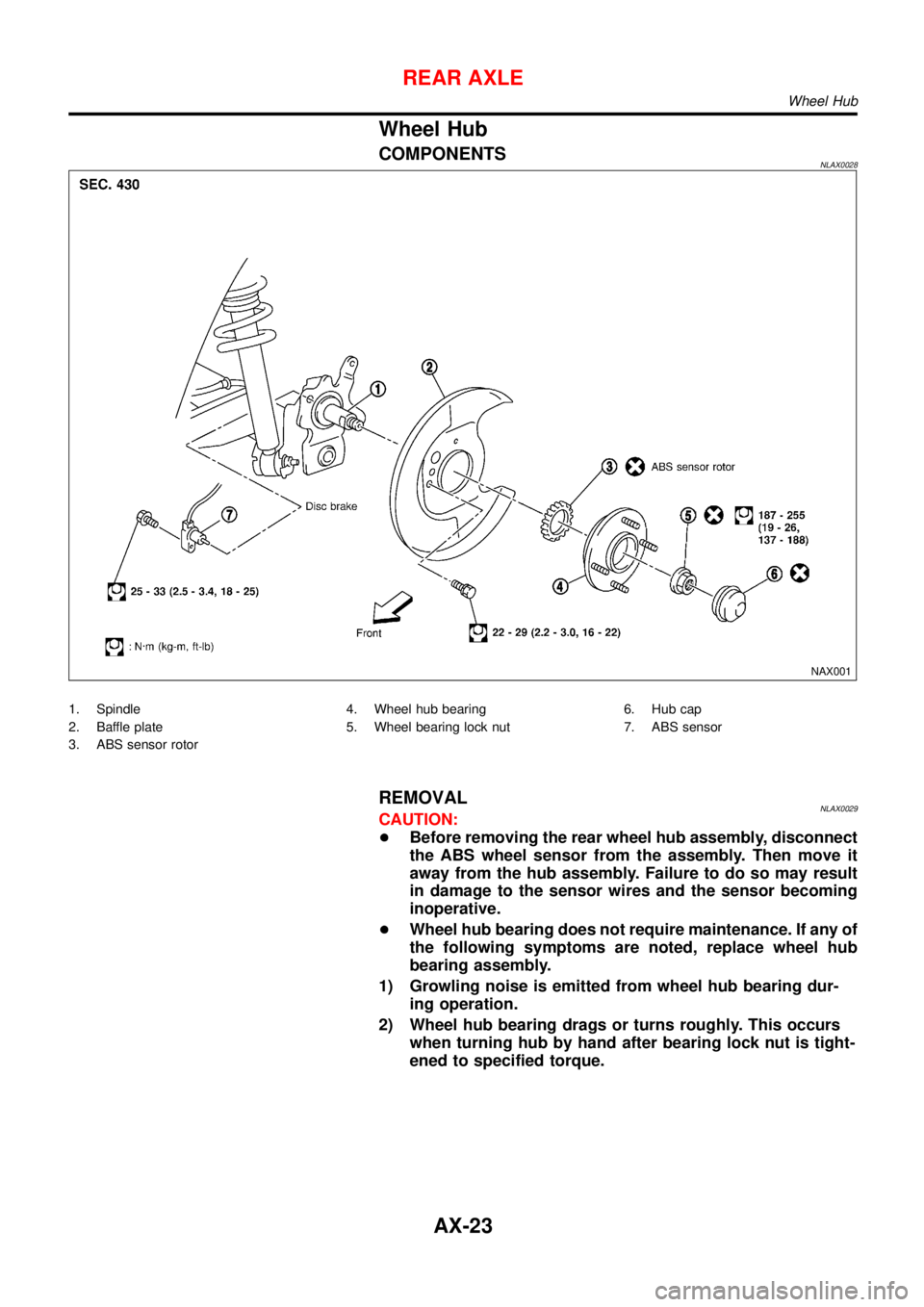

Wheel Hub

COMPONENTSNLAX0028

NAX001

1. Spindle

2. Baffle plate

3. ABS sensor rotor4. Wheel hub bearing

5. Wheel bearing lock nut6. Hub cap

7. ABS sensor

REMOVALNLAX0029CAUTION:

+Before removing the rear wheel hub assembly, disconnect

the ABS wheel sensor from the assembly. Then move it

away from the hub assembly. Failure to do so may result

in damage to the sensor wires and the sensor becoming

inoperative.

+Wheel hub bearing does not require maintenance. If any of

the following symptoms are noted, replace wheel hub

bearing assembly.

1) Growling noise is emitted from wheel hub bearing dur-

ing operation.

2) Wheel hub bearing drags or turns roughly. This occurs

when turning hub by hand after bearing lock nut is tight-

ened to specified torque.

REAR AXLE

Wheel Hub

AX-23

Page 240 of 3051

Supplemental Restraint System (SRS)“AIR

BAG”and“SEAT BELT PRE-TENSIONER”

NLBR0081The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL V10 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

SBR686C

Precautions for Brake SystemNLBR0002+Recommended fluid is brake fluid“DOT 4”.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+To clean or wash all parts of master cylinder, disc brake

caliper and wheel cylinder, use clean brake fluid.

+Never use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of the hydraulic system.

+Use flare nut wrench when removing and installing brake

tube.

+Always torque brake lines when installing.

+Burnish the brake contact surfaces after refinishing or

replacing rotors, after replacing pads, or if a soft pedal

occurs at very low mileage.

Refer to“Brake Burnishing Procedure”,“ON-VEHICLE

SERVICE”, BR-7.

WARNING:

+Clean brake pads with a waste cloth, then wipe with a dust

collector.

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

BR-3

Page 332 of 3051

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS...............................................................3

Service Notice..............................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............3

CLIP AND FASTENER....................................................4

Description ...................................................................4

CHASSIS AND BODY MAINTENANCE.........................6

Checking Body Corrosion ............................................6

BODY FRONT END.........................................................7

Removal and Installation .............................................7

FRONT BUMPER ASSEMBLY....................................7

BODY REAR END AND OPENER................................10

Removal and Installation ...........................................10

REAR BUMPER ASSEMBLY....................................10

DOOR.............................................................................13

Adjustment .................................................................13

STRIKER ADJUSTMENT..........................................13

Front Door Glass .......................................................14

FRONT DOOR GLASS AND REGULATOR................14

Front Door Limit Switch Reset (Driver side only)......15

RESET CONDITIONS..............................................15

RESET PROCEDURES............................................15

Rear Door Glass ........................................................16

REAR DOOR GLASS AND REGULATOR..................16

Front Door Lock .........................................................18

OUTSIDE HANDLE ROD ADJUSTMENT...................18

REMOVAL...............................................................18

Rear Door Lock .........................................................20

OUTSIDE HANDLE ROD ADJUSTMENT...................20

REMOVAL...............................................................21

INSTRUMENT PANEL ASSEMBLY.............................22

Removal and Installation ...........................................22

SIDE AND FLOOR TRIM...............................................28

Removal and Installation ...........................................28

LUGGAGE ROOM TRIM...............................................31

Removal and Installation ...........................................31

DOOR TRIM...................................................................32

Removal and Installation ...........................................32ROOF TRIM...................................................................35

Removal and Installation ...........................................35

BACK DOOR TRIM.......................................................37

Removal and Installation ...........................................37

EXTERIOR.....................................................................38

Removal and Installation ...........................................38

FRONT SEAT................................................................46

Removal and Installation ...........................................46

MANUAL SEAT........................................................47

Heated Seat ...............................................................48

Active Head Restraint ................................................48

OPERATION OUTLINE............................................48

REAR SEAT...................................................................49

Removal and Installation ...........................................49

REAR OUTSIDE SEAT.............................................49

REAR CENTER SEAT..............................................50

SUNROOF......................................................................51

Adjustment .................................................................51

Removal .....................................................................51

Trouble Diagnoses.....................................................55

DIAGNOSTIC TABLE................................................55

WIND DEFLECTOR (WHERE FITTED)......................55

ADJUSTMENT.........................................................56

DRAIN HOSES........................................................57

WEATHERSTRIP.....................................................57

LINK AND WIRE ASSEMBLY....................................58

WINDSHIELD AND WINDOWS....................................59

Removal and Installation ...........................................59

REMOVAL...............................................................59

INSTALLATION........................................................59

WINDSHIELD..........................................................60

SIDE WINDOW........................................................61

BACK DOOR WINDOW............................................62

DOOR MIRROR.............................................................63

Removal and Installation ...........................................63

REAR VIEW MIRROR...................................................64

Removal and Installation ...........................................64

REMOVAL...............................................................64

Page 334 of 3051

Service NoticeNLBT0001+When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

+Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil

or damage them.

+Apply sealing compound where necessary when installing parts.

+When applying sealing compound, be careful that the sealing compound does not protrude from parts.

+When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NLBT0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL V10 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

Service Notice

BT-3

Page 337 of 3051

Checking Body CorrosionNLBT0033Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch flange, fuel filler lid flange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

Checking Body Corrosion

BT-6

Page 446 of 3051

Precautions for Supplemental Restraint System

(SRS) ªAIR BAGº and ªSEAT BELT

PRE-TENSIONERº

NLEC1262The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified with yellow harness connector (and with

yellow harness protector or yellow insulation tape before the harness connectors).

Precautions for On Board Diagnostic (OBD)

System of Engine

NLEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

+Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM before

returning the vehicle to the customer.

PRECAUTIONSQG18DE

Precautions for Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-21

Page 485 of 3051

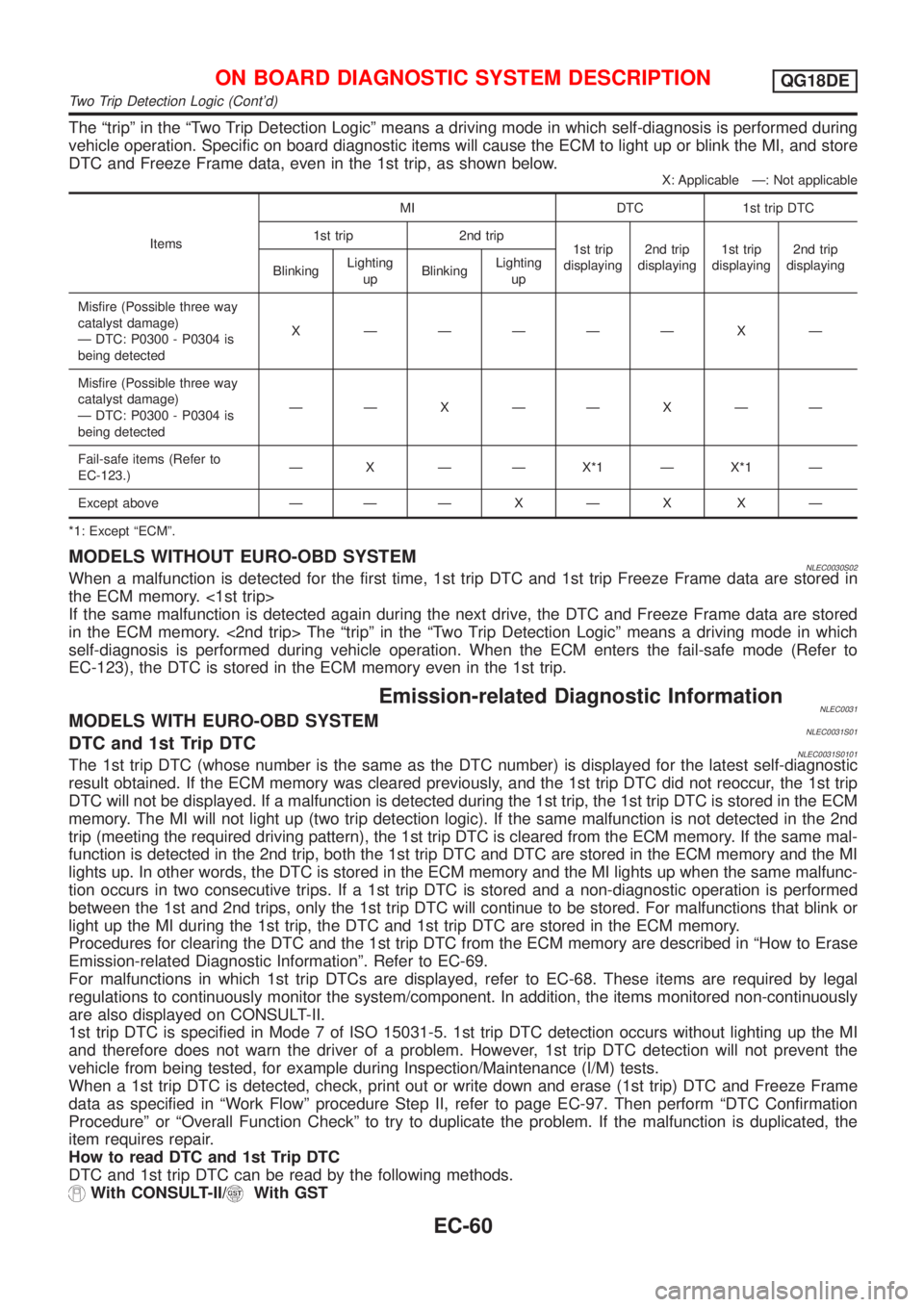

The ªtripº in the ªTwo Trip Detection Logicº means a driving mode in which self-diagnosis is performed during

vehicle operation. Specific on board diagnostic items will cause the ECM to light up or blink the MI, and store

DTC and Freeze Frame data, even in the 1st trip, as shown below.

X: Applicable Ð: Not applicable

ItemsMI DTC 1st trip DTC

1st trip 2nd trip

1st trip

displaying2nd trip

displaying1st trip

displaying2nd trip

displaying

BlinkingLighting

upBlinkingLighting

up

Misfire (Possible three way

catalyst damage)

Ð DTC: P0300 - P0304 is

being detectedX ÐÐÐÐÐ X Ð

Misfire (Possible three way

catalyst damage)

Ð DTC: P0300 - P0304 is

being detectedÐÐXÐÐXÐÐ

Fail-safe items (Refer to

EC-123.)Ð X Ð Ð X*1 Ð X*1 Ð

Except above Ð ÐÐXÐX XÐ

*1: Except ªECMº.

MODELS WITHOUT EURO-OBD SYSTEMNLEC0030S02When a malfunction is detected for the first time, 1st trip DTC and 1st trip Freeze Frame data are stored in

the ECM memory. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored

in the ECM memory. <2nd trip> The ªtripº in the ªTwo Trip Detection Logicº means a driving mode in which

self-diagnosis is performed during vehicle operation. When the ECM enters the fail-safe mode (Refer to

EC-123), the DTC is stored in the ECM memory even in the 1st trip.

Emission-related Diagnostic InformationNLEC0031MODELS WITH EURO-OBD SYSTEMNLEC0031S01DTC and 1st Trip DTCNLEC0031S0101The 1st trip DTC (whose number is the same as the DTC number) is displayed for the latest self-diagnostic

result obtained. If the ECM memory was cleared previously, and the 1st trip DTC did not reoccur, the 1st trip

DTC will not be displayed. If a malfunction is detected during the 1st trip, the 1st trip DTC is stored in the ECM

memory. The MI will not light up (two trip detection logic). If the same malfunction is not detected in the 2nd

trip (meeting the required driving pattern), the 1st trip DTC is cleared from the ECM memory. If the same mal-

function is detected in the 2nd trip, both the 1st trip DTC and DTC are stored in the ECM memory and the MI

lights up. In other words, the DTC is stored in the ECM memory and the MI lights up when the same malfunc-

tion occurs in two consecutive trips. If a 1st trip DTC is stored and a non-diagnostic operation is performed

between the 1st and 2nd trips, only the 1st trip DTC will continue to be stored. For malfunctions that blink or

light up the MI during the 1st trip, the DTC and 1st trip DTC are stored in the ECM memory.

Procedures for clearing the DTC and the 1st trip DTC from the ECM memory are described in ªHow to Erase

Emission-related Diagnostic Informationº. Refer to EC-69.

For malfunctions in which 1st trip DTCs are displayed, refer to EC-68. These items are required by legal

regulations to continuously monitor the system/component. In addition, the items monitored non-continuously

are also displayed on CONSULT-II.

1st trip DTC is specified in Mode 7 of ISO 15031-5. 1st trip DTC detection occurs without lighting up the MI

and therefore does not warn the driver of a problem. However, 1st trip DTC detection will not prevent the

vehicle from being tested, for example during Inspection/Maintenance (I/M) tests.

When a 1st trip DTC is detected, check, print out or write down and erase (1st trip) DTC and Freeze Frame

data as specified in ªWork Flowº procedure Step II, refer to page EC-97. Then perform ªDTC Confirmation

Procedureº or ªOverall Function Checkº to try to duplicate the problem. If the malfunction is duplicated, the

item requires repair.

How to read DTC and 1st Trip DTC

DTC and 1st trip DTC can be read by the following methods.

With CONSULT-II/With GST

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

Two Trip Detection Logic (Cont'd)

EC-60

Page 487 of 3051

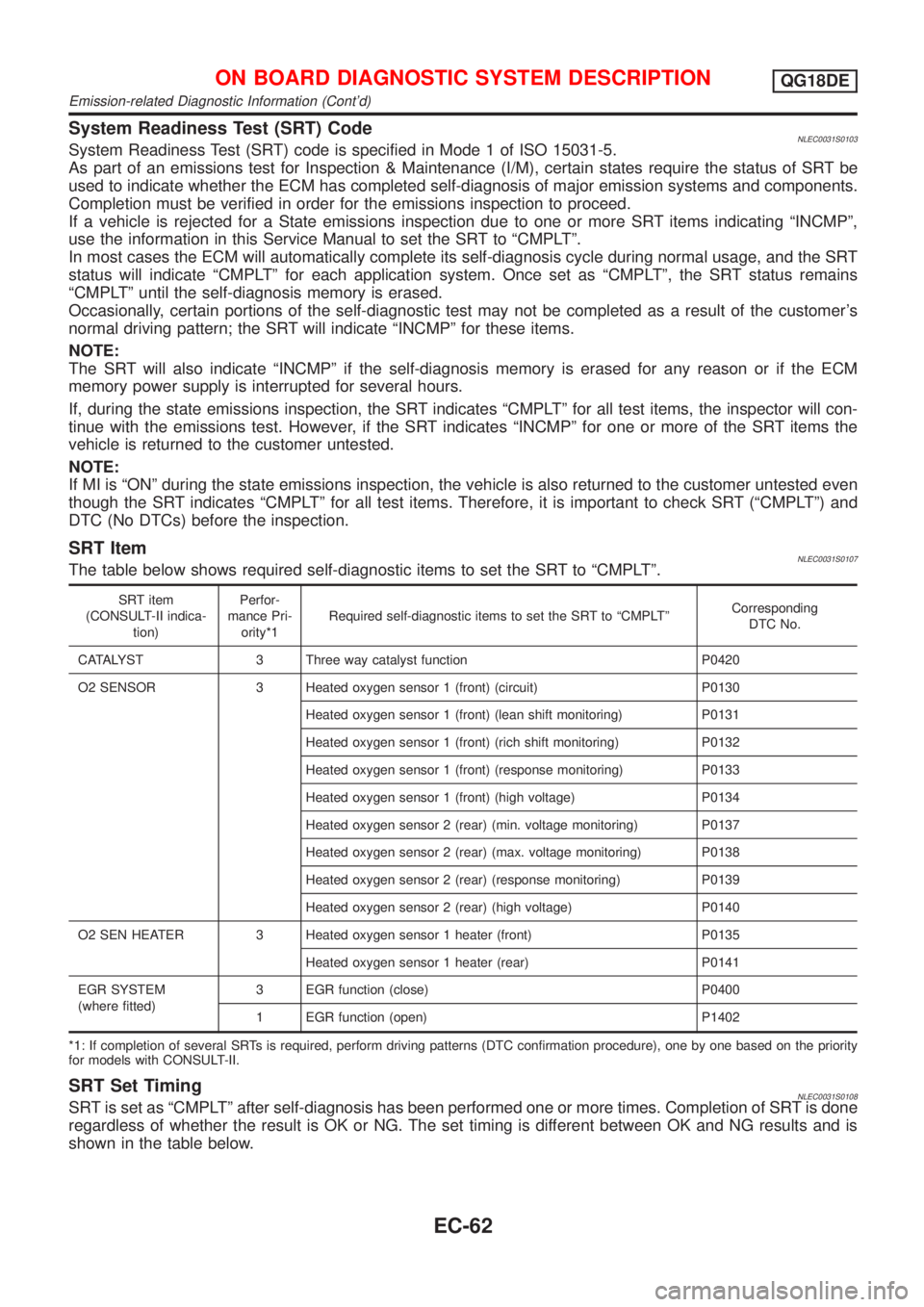

System Readiness Test (SRT) CodeNLEC0031S0103System Readiness Test (SRT) code is specified in Mode 1 of ISO 15031-5.

As part of an emissions test for Inspection & Maintenance (I/M), certain states require the status of SRT be

used to indicate whether the ECM has completed self-diagnosis of major emission systems and components.

Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating ªINCMPº,

use the information in this Service Manual to set the SRT to ªCMPLTº.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate ªCMPLTº for each application system. Once set as ªCMPLTº, the SRT status remains

ªCMPLTº until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate ªINCMPº for these items.

NOTE:

The SRT will also indicate ªINCMPº if the self-diagnosis memory is erased for any reason or if the ECM

memory power supply is interrupted for several hours.

If, during the state emissions inspection, the SRT indicates ªCMPLTº for all test items, the inspector will con-

tinue with the emissions test. However, if the SRT indicates ªINCMPº for one or more of the SRT items the

vehicle is returned to the customer untested.

NOTE:

If MI is ªONº during the state emissions inspection, the vehicle is also returned to the customer untested even

though the SRT indicates ªCMPLTº for all test items. Therefore, it is important to check SRT (ªCMPLTº) and

DTC (No DTCs) before the inspection.

SRT ItemNLEC0031S0107The table below shows required self-diagnostic items to set the SRT to ªCMPLTº.

SRT item

(CONSULT-II indica-

tion)Perfor-

mance Pri-

ority*1Required self-diagnostic items to set the SRT to ªCMPLTºCorresponding

DTC No.

CATALYST 3 Three way catalyst function P0420

O2 SENSOR 3 Heated oxygen sensor 1 (front) (circuit) P0130

Heated oxygen sensor 1 (front) (lean shift monitoring) P0131

Heated oxygen sensor 1 (front) (rich shift monitoring) P0132

Heated oxygen sensor 1 (front) (response monitoring) P0133

Heated oxygen sensor 1 (front) (high voltage) P0134

Heated oxygen sensor 2 (rear) (min. voltage monitoring) P0137

Heated oxygen sensor 2 (rear) (max. voltage monitoring) P0138

Heated oxygen sensor 2 (rear) (response monitoring) P0139

Heated oxygen sensor 2 (rear) (high voltage) P0140

O2 SEN HEATER 3 Heated oxygen sensor 1 heater (front) P0135

Heated oxygen sensor 1 heater (rear) P0141

EGR SYSTEM

(where fitted)3 EGR function (close) P0400

1 EGR function (open) P1402

*1: If completion of several SRTs is required, perform driving patterns (DTC confirmation procedure), one by one based on the priority

for models with CONSULT-II.

SRT Set TimingNLEC0031S0108SRT is set as ªCMPLTº after self-diagnosis has been performed one or more times. Completion of SRT is done

regardless of whether the result is OK or NG. The set timing is different between OK and NG results and is

shown in the table below.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

Emission-related Diagnostic Information (Cont'd)

EC-62