check engine NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2 of 3051

AUTOMATIC TRANSAXLE

SECTION

AT

CONTENTS

EURO-OBD

TROUBLE DIAGNOSIS - INDEX....................................4

Alphabetical & P No. Index for DTC ...........................4

PRECAUTIONS...............................................................6

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²......................................................6

Precautions for On Board Diagnostic (EURO-

OBD) System of CVT and Engine...............................6

Precautions ..................................................................6

Service Notice or Precautions .....................................7

Wiring Diagrams and Trouble Diagnoses....................8

PREPARATION...............................................................9

Special Service Tools ..................................................9

CVT FLUID.....................................................................10

Checking CVT Fluid...................................................10

Changing CVT Fluid .................................................. 11

OVERALL SYSTEM......................................................12

CVT Electrical Parts Location....................................12

Circuit Diagram ..........................................................13

Cross-sectional View - RE0F06A ..............................14

Control System ..........................................................15

EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................18

Introduction ................................................................18

EURO-OBD Function for CVT System......................18

EURO-OBD Diagnostic Trouble Code (DTC)............18

Malfunction Indicator (MI) ..........................................21

CONSULT-II ...............................................................21

EXCEPT FOR EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................31CONSULT-II ...............................................................31

Diagnostic Procedure Without CONSULT-II ..............35

EURO-OBD

TROUBLE DIAGNOSIS - INTRODUCTION..................41

Introduction ................................................................41

Work Flow ..................................................................44

EXCEPT FOR EURO-OBD

TROUBLE DIAGNOSIS - INTRODUCTION..................46

Introduction ................................................................46

Work Flow ..................................................................49

TROUBLE DIAGNOSIS - BASIC INSPECTION...........51

CVT Fluid Check .......................................................51

Stall Test ....................................................................51

Line Pressure Test .....................................................52

Road Test...................................................................53

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................58

TCM Terminals and Reference Value........................58

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........62

Wiring Diagram - AT - MAIN ......................................62

TCM Terminals and Reference Value........................64

Diagnostic Procedure ................................................65

EURO-OBD

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH.........................................................................66

Description .................................................................66

Wiring Diagram - AT - PNP/SW.................................68

Diagnostic Procedure ................................................70

Component Inspection ...............................................72

DTC P0710 CVT FLUID TEMPERATURE SENSOR

CIRCUIT.........................................................................73

Description .................................................................73

Page 11 of 3051

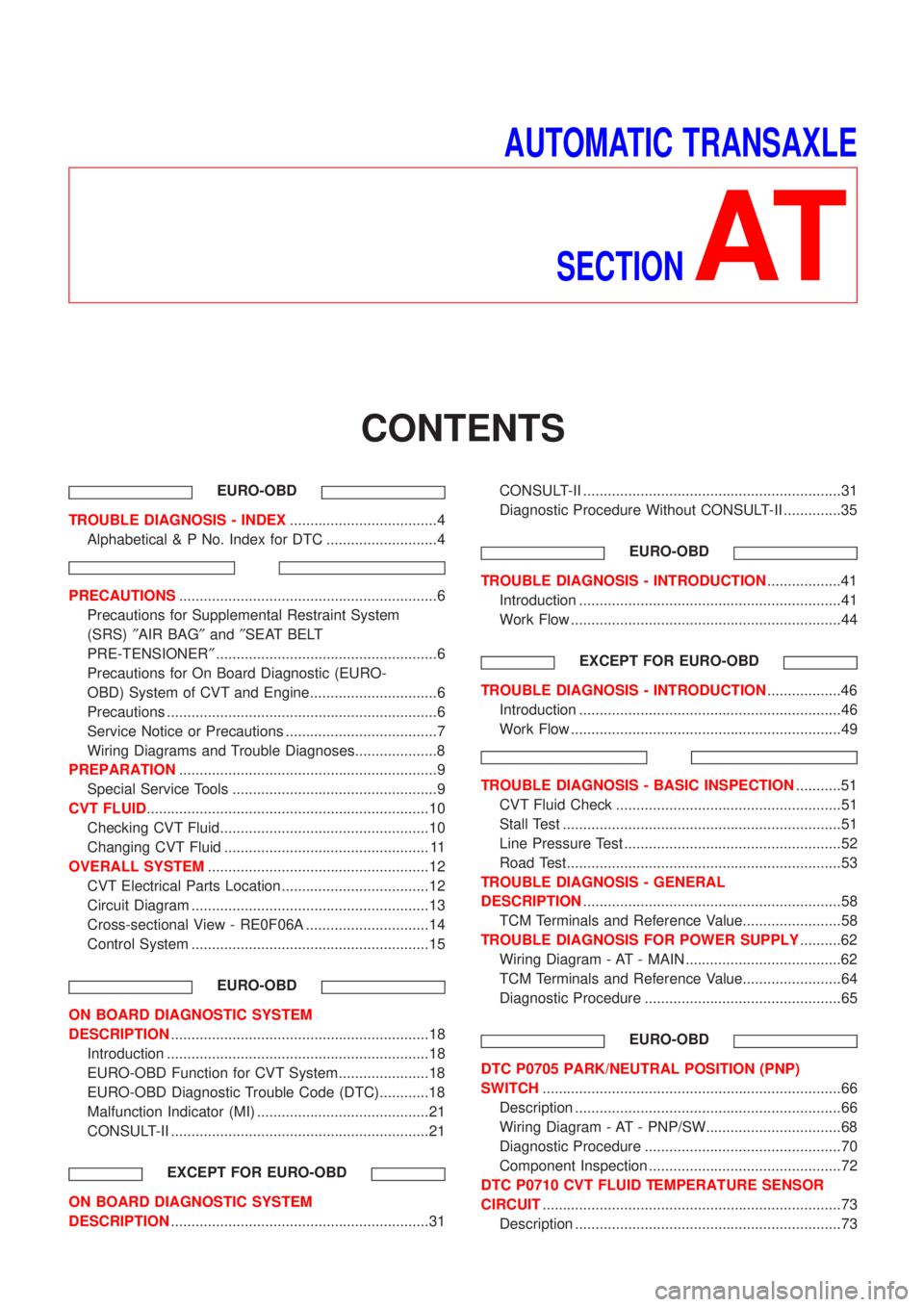

SMA146B

Checking CVT FluidNLAT02431. Check for fluid leakage.

SAT282K

2. Check fluid level.

Fluid level should be check using ªHOTº range on A/T fluid

level gauge at fluid temperatures of 50 to 80ÉC (122 to 176ÉF)

after vehicle has been driven approximately 10 minutes in

urban areas after engine is warmed up. But it can be checked

at fluid temperatures of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº

range on A/T fluid level gauge for reference after engine is

warmed up and before driving. However, fluid level must be

rechecked using ªHOTº range.

a. Park vehicle on level surface and set parking brake.

b. Start engine and then move selector lever through reach gear

range, ending in ªPº.

c. Check fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe it clean with lint-free

paper.

e. Re-insert A/T fluid level gauge into charging pipe as far as it

will go.

f. Remove A/T fluid level gauge and note reading. If level is at

low side of either range, add fluid through the speedometer

cable hole.

Use genuine NISSAN CVT fluid (NS-1) or exact equivalent.

CAUTION:

Do not overfill.

CAUTION:

SMA051D

Firmly fix the A/T fluid level gauge using a lip attached to the

fluid charging pipe.

CVT FLUID

Checking CVT Fluid

AT-10

Page 12 of 3051

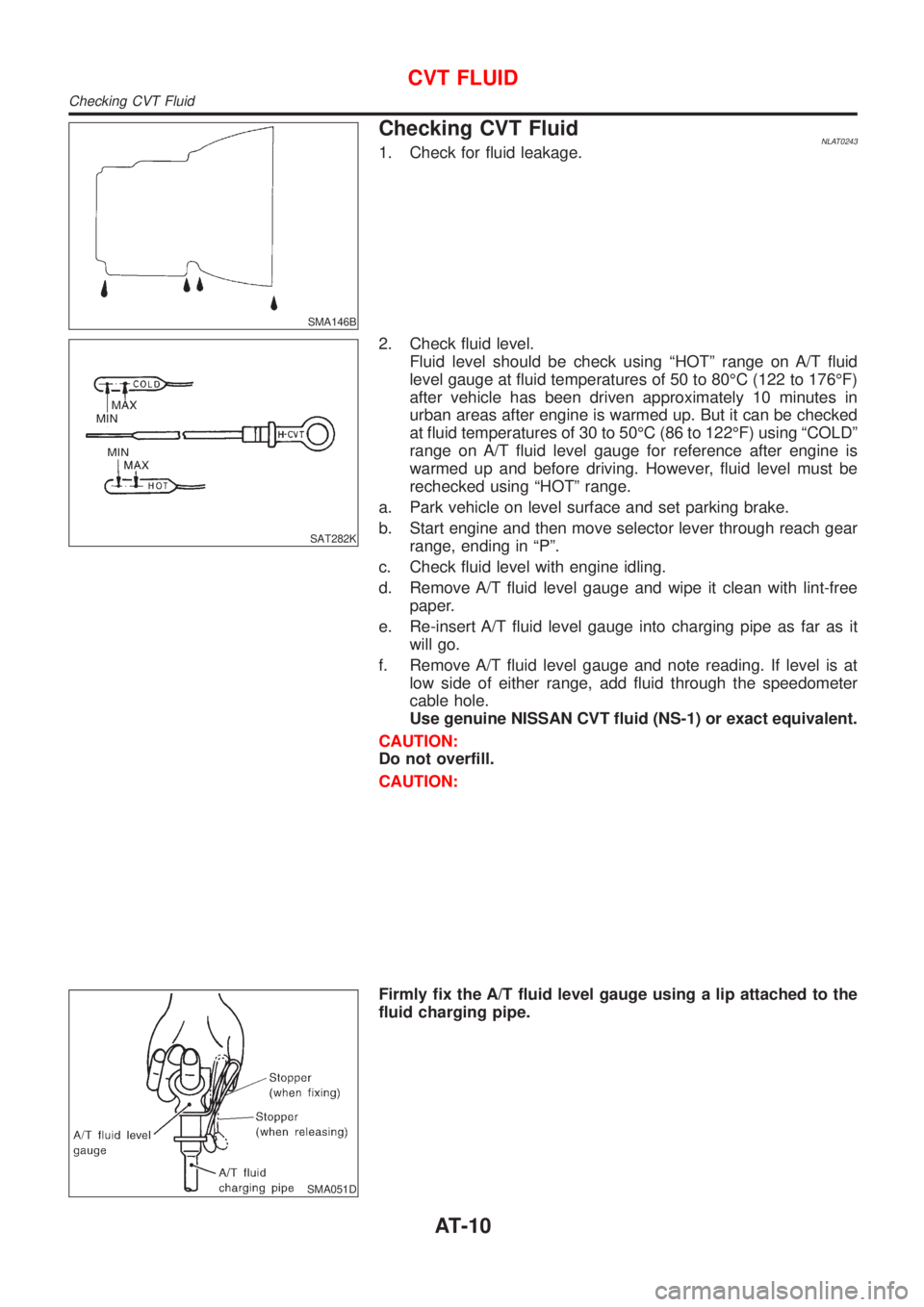

SMA853B

3. Check fluid condition.

Check fluid for contamination. If fluid is very dark, smells

burned or contains frictional material check operation of CVT.

Refer to section AT for checking operation of CVT.

SMA294C

Changing CVT FluidNLAT02441. Warm up CVT fluid by driving the vehicle for 10 minutes.

2. Drain CVT fluid from radiator cooler hose (return side) and refill

with new CVT fluid at charging pipe with the engine running at

idle speed.

3. Refill until new CVT fluid comes out from radiator cooler hose

(return side).

About 30 to 50% extra fluid will be required for this procedure.

Fluid capacity

Hyper CVT: Approx. 8.1!(7-1/8 lmp qt)

Drain plug:

: 23 - 27 N´m (2.4 - 2.8 kg-m, 18 - 20 ft-lb)

CAUTION:

Use genuine NISSAN CVT fluid (NS-1) or exact equivalent.

4. Check fluid level and condition.

CVT FLUID

Checking CVT Fluid (Cont'd)

AT-11

Page 22 of 3051

HOW TO ERASE DTC (WITH GST)=NLAT0020S041. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Perform ªEURO-OBD SELF-DIAGNOSTIC PROCEDURE (No Tools)º. Refer to AT-28. (The engine

warm-up step can be skipped when performing the diagnosis only to erase the DTC.)

3. Select Mode 4 with Generic Scan Tool (GST). For details, refer to EC section ªGeneric Scan Tool (GST)º.

HOW TO ERASE DTC (NO TOOLS)NLAT0020S051. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Perform ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º. Refer to AT-28. (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Change the diagnostic test mode from Mode II to Mode I by turning the mode selector on the ECM.

Refer to EC section ªHOW TO SWITCH DIAGNOSTIC TEST MODESº.

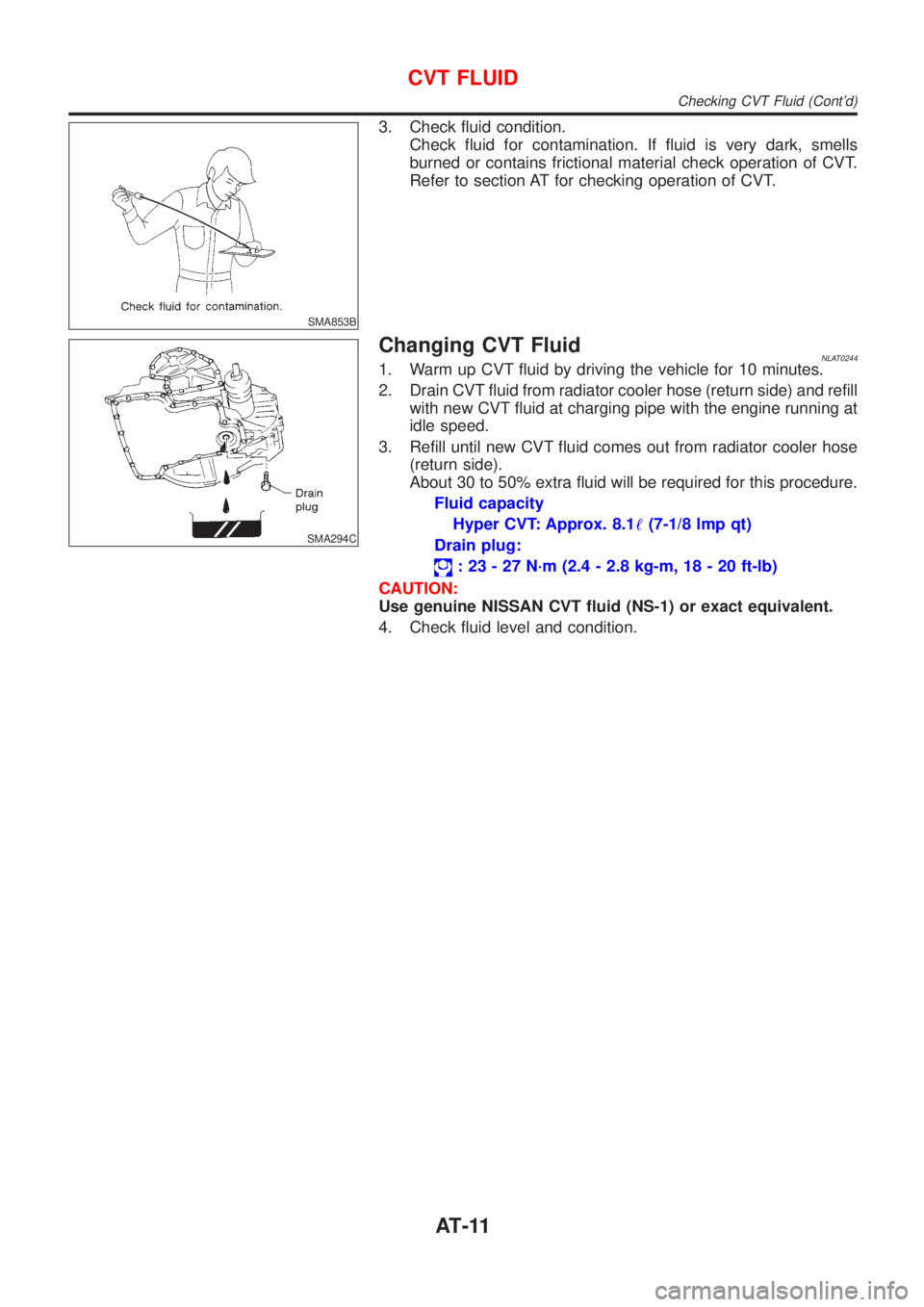

SAT652J

Malfunction Indicator (MI)NLAT00211. The malfunction indicator will light up when the ignition switch

is turned ON without the engine running. This is for checking

the lamp.

+If the malfunction indicator lamp does not light up, refer to EL

section (ªWarning Lamps/System Descriptionº, ªWARNING

LAMPS AND CHIMEº).

(Or see MI & Data Link Connectors in EC section.)

2. When the engine is started, the malfunction indicator lamp

should go off.

If the lamp remains on, the on board diagnostic system has

detected an emission-related (EURO-OBD) malfunction. For

detail, refer to EC section (ªON BOARD DIAGNOSTIC SYS-

TEM DESCRIPTIONº).

CONSULT-IINLAT0022After performing ªSELF-DIAGNOSTIC PROCEDURE (WITH CON-

SULT-II)º (AT-22), place check marks for results on the ªDIAGNOS-

TIC WORKSHEETº, AT-43. Reference pages are provided follow-

ing the items.

NOTICE:

+Additional CONSULT-II information can be found in the Opera-

tion Manual supplied with the CONSULT-II unit.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONEURO-OBD

EURO-OBD Diagnostic Trouble Code (DTC) (Cont'd)

AT-21

Page 23 of 3051

SAT250K

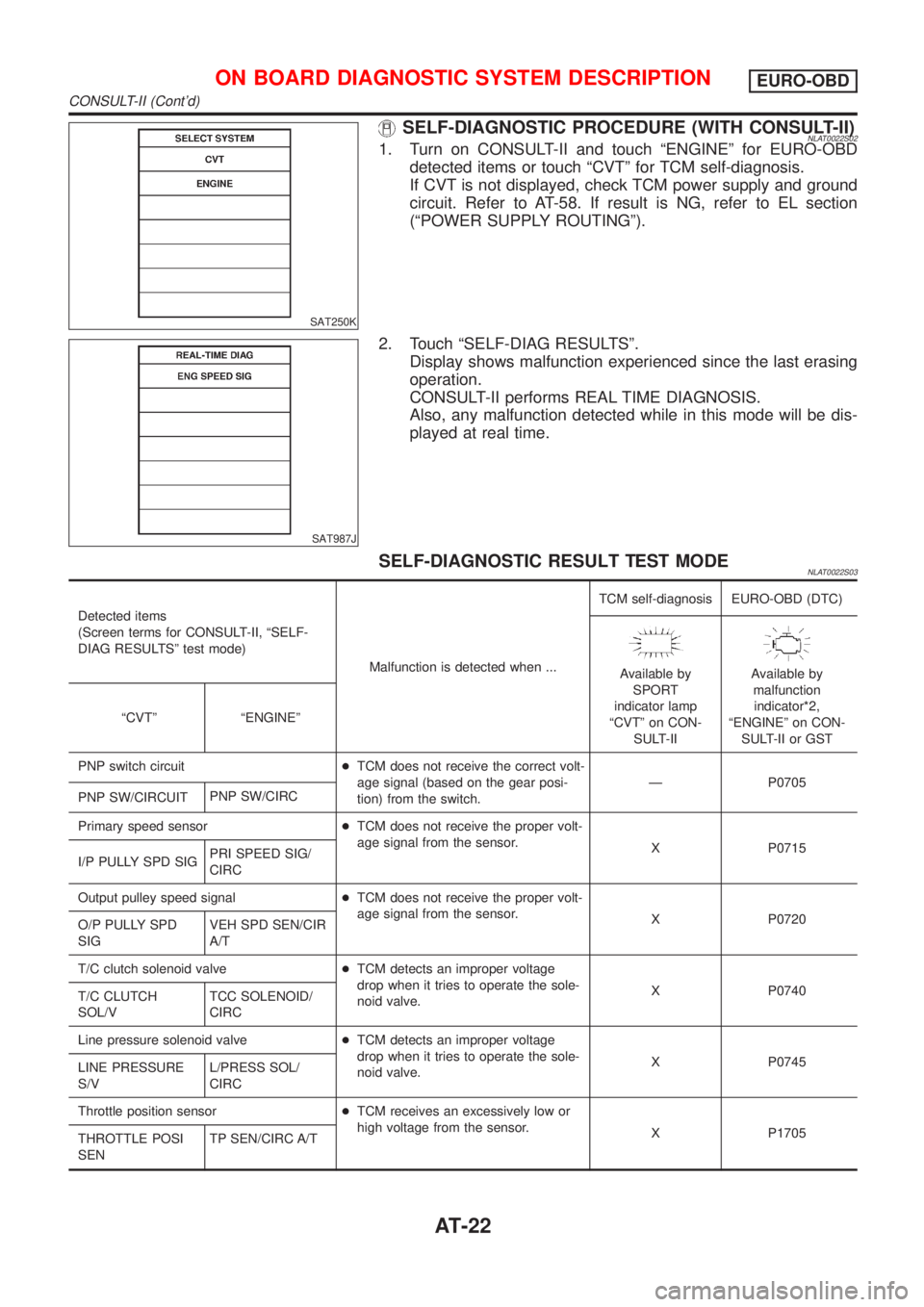

SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)NLAT0022S021. Turn on CONSULT-II and touch ªENGINEº for EURO-OBD

detected items or touch ªCVTº for TCM self-diagnosis.

If CVT is not displayed, check TCM power supply and ground

circuit. Refer to AT-58. If result is NG, refer to EL section

(ªPOWER SUPPLY ROUTINGº).

SAT987J

2. Touch ªSELF-DIAG RESULTSº.

Display shows malfunction experienced since the last erasing

operation.

CONSULT-II performs REAL TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be dis-

played at real time.

SELF-DIAGNOSTIC RESULT TEST MODENLAT0022S03

Detected items

(Screen terms for CONSULT-II, ªSELF-

DIAG RESULTSº test mode)

Malfunction is detected when ...TCM self-diagnosis EURO-OBD (DTC)

Available by

SPORT

indicator lamp

ªCVTº on CON-

SULT-IIAvailable by

malfunction

indicator*2,

ªENGINEº on CON-

SULT-II or GST ªCVTº ªENGINEº

PNP switch circuit+TCM does not receive the correct volt-

age signal (based on the gear posi-

tion) from the switch.Ð P0705

PNP SW/CIRCUITPNP SW/CIRC

Primary speed sensor+TCM does not receive the proper volt-

age signal from the sensor.

X P0715

I/P PULLY SPD SIGPRI SPEED SIG/

CIRC

Output pulley speed signal+TCM does not receive the proper volt-

age signal from the sensor.

X P0720

O/P PULLY SPD

SIGVEH SPD SEN/CIR

A/T

T/C clutch solenoid valve+TCM detects an improper voltage

drop when it tries to operate the sole-

noid valve.X P0740

T/C CLUTCH

SOL/VTCC SOLENOID/

CIRC

Line pressure solenoid valve+TCM detects an improper voltage

drop when it tries to operate the sole-

noid valve.X P0745

LINE PRESSURE

S/VL/PRESS SOL/

CIRC

Throttle position sensor+TCM receives an excessively low or

high voltage from the sensor.

X P1705

THROTTLE POSI

SENTP SEN/CIRC A/T

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONEURO-OBD

CONSULT-II (Cont'd)

AT-22

Page 29 of 3051

SAT491J

SAT234K

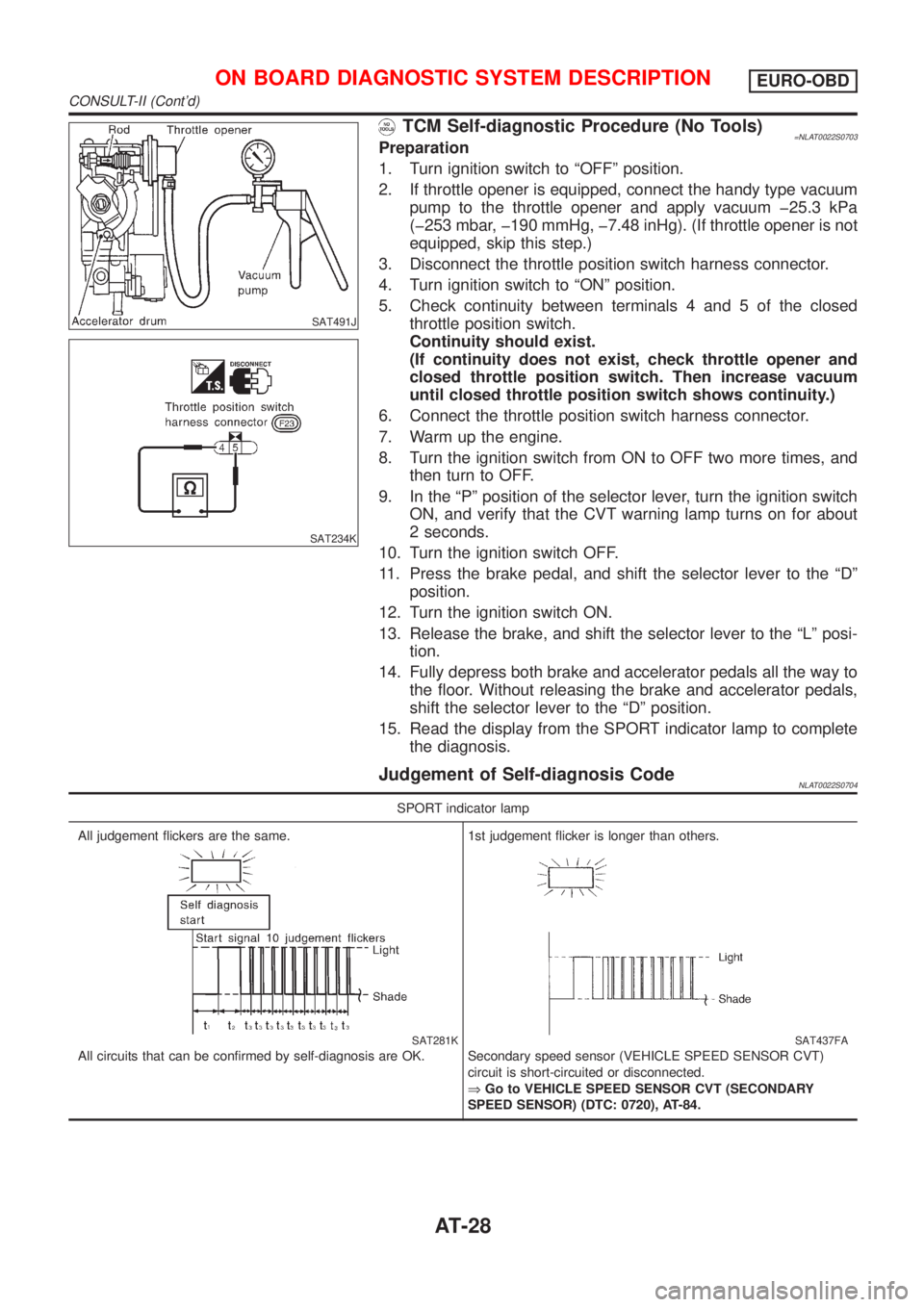

TCM Self-diagnostic Procedure (No Tools)=NLAT0022S0703Preparation

1. Turn ignition switch to ªOFFº position.

2. If throttle opener is equipped, connect the handy type vacuum

pump to the throttle opener and apply vacuum þ25.3 kPa

(þ253 mbar, þ190 mmHg, þ7.48 inHg). (If throttle opener is not

equipped, skip this step.)

3. Disconnect the throttle position switch harness connector.

4. Turn ignition switch to ªONº position.

5. Check continuity between terminals 4 and 5 of the closed

throttle position switch.

Continuity should exist.

(If continuity does not exist, check throttle opener and

closed throttle position switch. Then increase vacuum

until closed throttle position switch shows continuity.)

6. Connect the throttle position switch harness connector.

7. Warm up the engine.

8. Turn the ignition switch from ON to OFF two more times, and

then turn to OFF.

9. In the ªPº position of the selector lever, turn the ignition switch

ON, and verify that the CVT warning lamp turns on for about

2 seconds.

10. Turn the ignition switch OFF.

11. Press the brake pedal, and shift the selector lever to the ªDº

position.

12. Turn the ignition switch ON.

13. Release the brake, and shift the selector lever to the ªLº posi-

tion.

14. Fully depress both brake and accelerator pedals all the way to

the floor. Without releasing the brake and accelerator pedals,

shift the selector lever to the ªDº position.

15. Read the display from the SPORT indicator lamp to complete

the diagnosis.

Judgement of Self-diagnosis CodeNLAT0022S0704

SPORT indicator lamp

All judgement flickers are the same.

SAT281K

All circuits that can be confirmed by self-diagnosis are OK.1st judgement flicker is longer than others.

SAT437FA

Secondary speed sensor (VEHICLE SPEED SENSOR CVT)

circuit is short-circuited or disconnected.

ÞGo to VEHICLE SPEED SENSOR CVT (SECONDARY

SPEED SENSOR) (DTC: 0720), AT-84.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONEURO-OBD

CONSULT-II (Cont'd)

AT-28

Page 37 of 3051

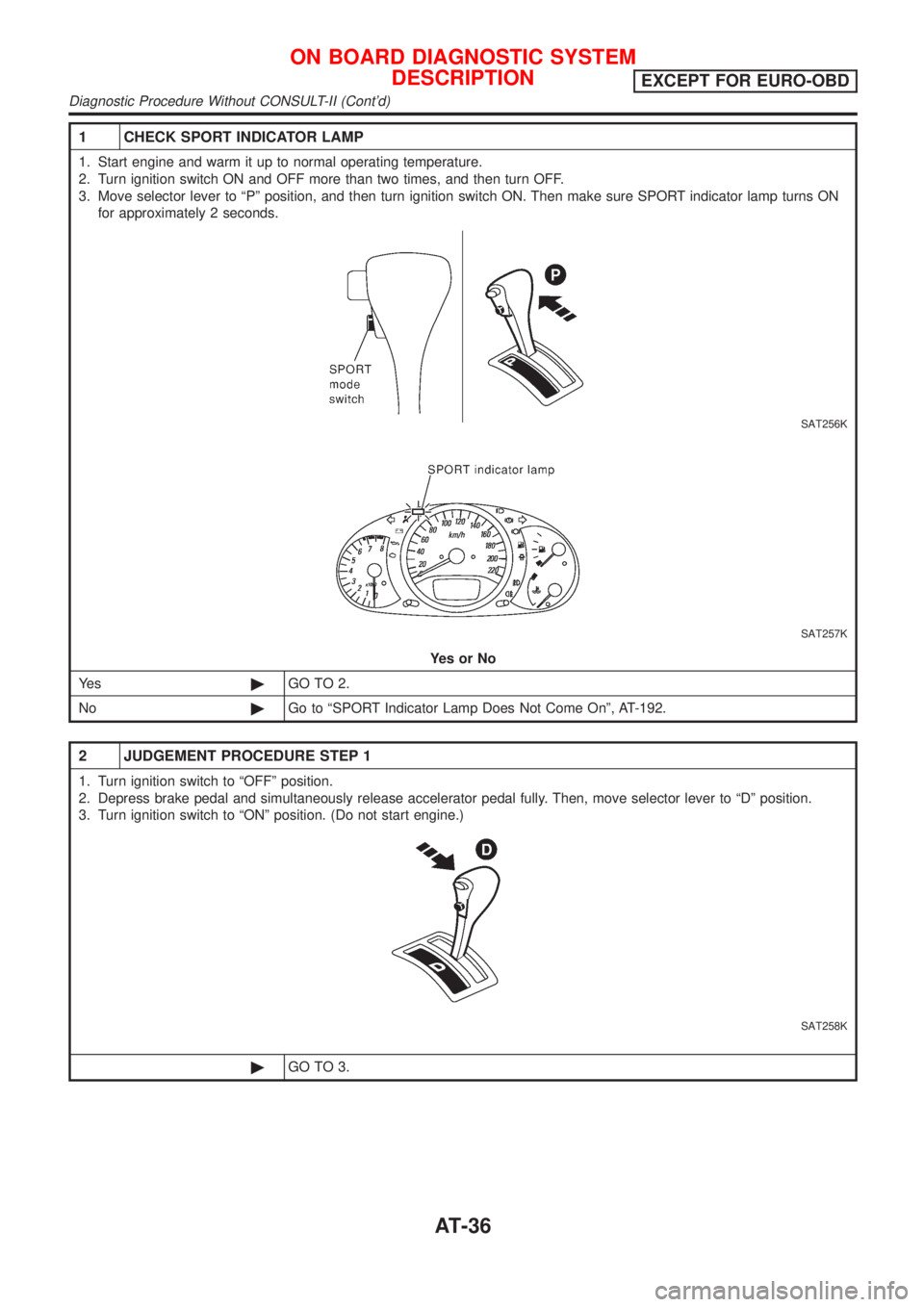

1 CHECK SPORT INDICATOR LAMP

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ON and OFF more than two times, and then turn OFF.

3. Move selector lever to ªPº position, and then turn ignition switch ON. Then make sure SPORT indicator lamp turns ON

for approximately 2 seconds.

SAT256K

SAT257K

YesorNo

Ye s©GO TO 2.

No©Go to ªSPORT Indicator Lamp Does Not Come Onº, AT-192.

2 JUDGEMENT PROCEDURE STEP 1

1. Turn ignition switch to ªOFFº position.

2. Depress brake pedal and simultaneously release accelerator pedal fully. Then, move selector lever to ªDº position.

3. Turn ignition switch to ªONº position. (Do not start engine.)

SAT258K

©GO TO 3.

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION

EXCEPT FOR EURO-OBD

Diagnostic Procedure Without CONSULT-II (Cont'd)

AT-36

Page 42 of 3051

SAT631IA

SAT632I

SEF234G

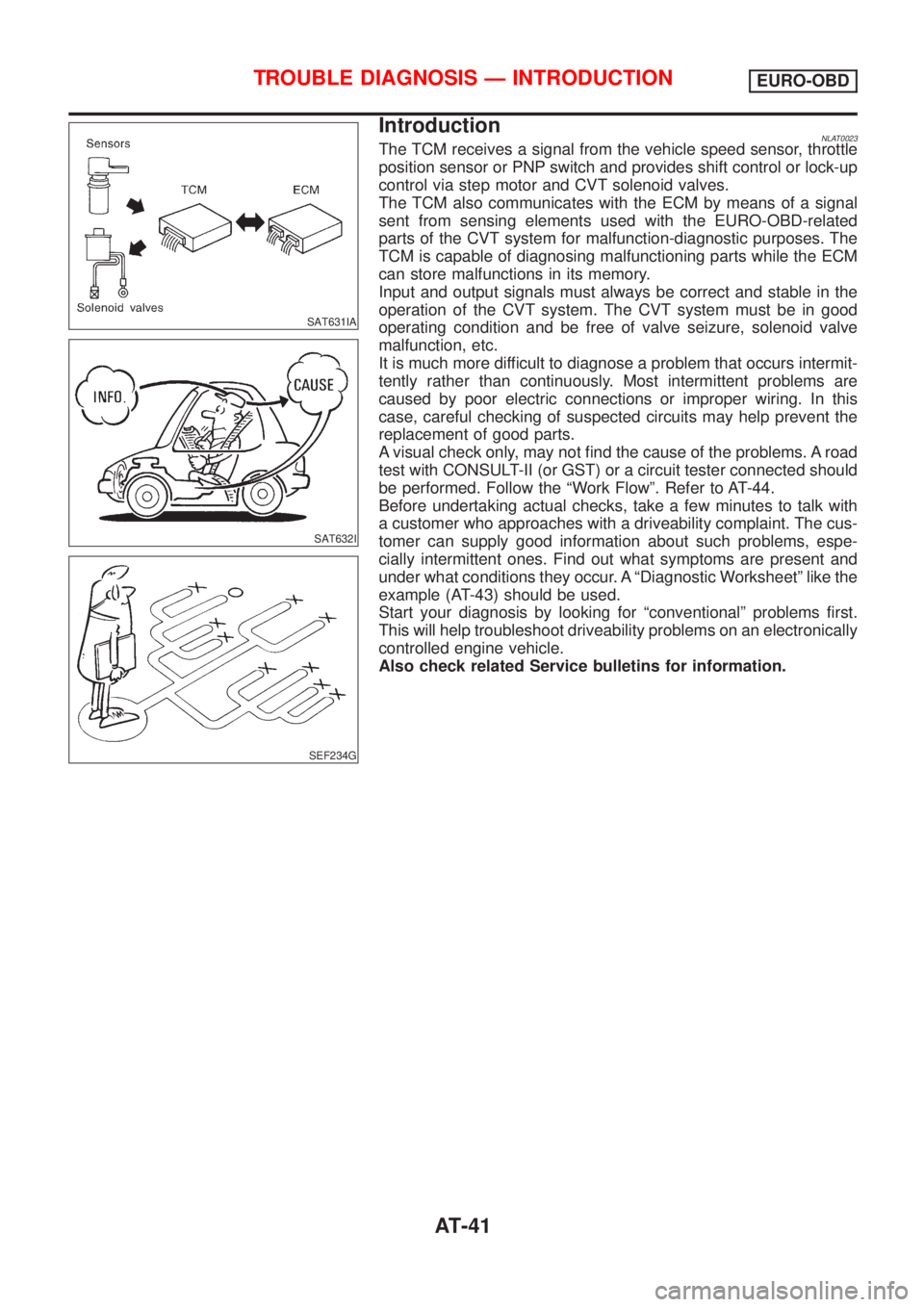

IntroductionNLAT0023The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via step motor and CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the EURO-OBD-related

parts of the CVT system for malfunction-diagnostic purposes. The

TCM is capable of diagnosing malfunctioning parts while the ECM

can store malfunctions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº. Refer to AT-44.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-43) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

AT-41

Page 44 of 3051

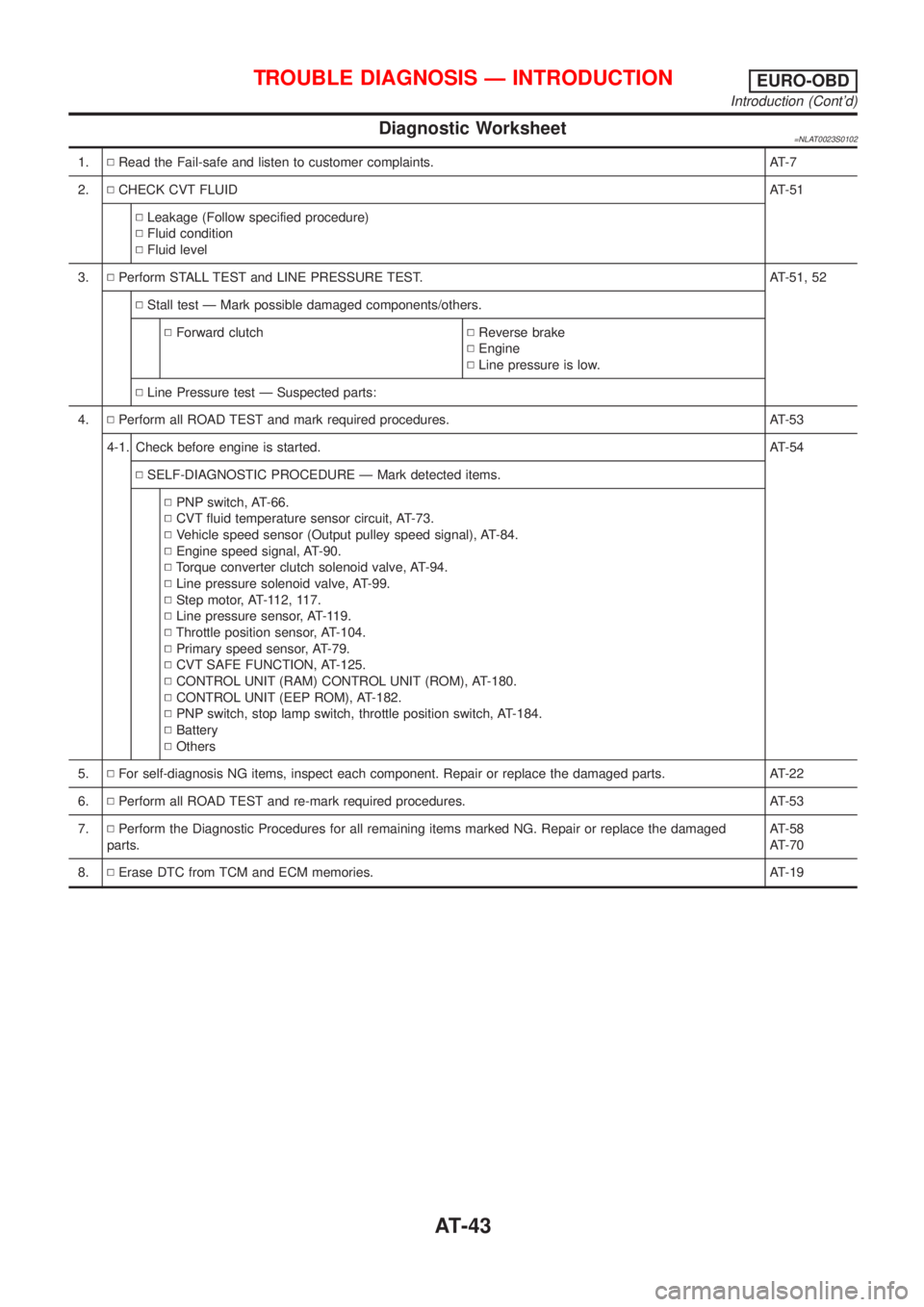

Diagnostic Worksheet=NLAT0023S0102

1.NRead the Fail-safe and listen to customer complaints. AT-7

2.NCHECK CVT FLUIDAT-51

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-51, 52

NStall test Ð Mark possible damaged components/others.

NForward clutchNReverse brake

NEngine

NLine pressure is low.

NLine Pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-53

4-1. Check before engine is started.AT-54

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NPNP switch, AT-66.

NCVT fluid temperature sensor circuit, AT-73.

NVehicle speed sensor (Output pulley speed signal), AT-84.

NEngine speed signal, AT-90.

NTorque converter clutch solenoid valve, AT-94.

NLine pressure solenoid valve, AT-99.

NStep motor, AT-112, 117.

NLine pressure sensor, AT-119.

NThrottle position sensor, AT-104.

NPrimary speed sensor, AT-79.

NCVT SAFE FUNCTION, AT-125.

NCONTROL UNIT (RAM) CONTROL UNIT (ROM), AT-180.

NCONTROL UNIT (EEP ROM), AT-182.

NPNP switch, stop lamp switch, throttle position switch, AT-184.

NBattery

NOthers

5.NFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-22

6.NPerform all ROAD TEST and re-mark required procedures. AT-53

7.NPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.AT-58

AT-70

8.NErase DTC from TCM and ECM memories. AT-19

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Introduction (Cont'd)

AT-43

Page 47 of 3051

SAT631IA

SAT632I

SEF234G

IntroductionNLAT0247The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via CVT solenoid valves.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II or a circuit tester connected should be per-

formed. Follow the ªWork Flowº. Refer to AT-49.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-48) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

AT-46