oil temperature NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 4 of 3051

CONTROL UNIT (EEPROM).......................................182

Description ...............................................................182

Diagnostic Procedure ..............................................183

TROUBLE DIAGNOSES FOR NON-DETECTABLE

ITEMS...........................................................................184

PNP Switch, Stop Lamp Switch and Throttle

Position Switch ........................................................184

Diagnostic Procedure ..............................................184

Wiring Diagram - AT - NONDTC .............................188

TROUBLE DIAGNOSES FOR SYMPTOMS...............192

SPORT Indicator Lamp Does Not Come On ..........192

A/T SHIFT LOCK SYSTEM.........................................195

Description ...............................................................195

Shift Lock System Electrical Parts Location............195

Wiring Diagram - SHIFT -........................................196

Diagnostic Procedure ..............................................198

KEY INTERLOCK CABLE..........................................202

Components.............................................................202

Removal ...................................................................202

Installation ................................................................203ON-VEHICLE SERVICE..............................................204

Control Cable Adjustment ........................................204

Park/Neutral Position (PNP) Switch Adjustment .....204

Differential Side Oil Seal Replacement ...................204

REMOVAL AND INSTALLATION...............................206

Removal ...................................................................206

Inspection.................................................................206

Installation ................................................................207

Air Breather Hose ....................................................208

CVT Fluid Cooler .....................................................208

Components.............................................................209

SERVICE DATA AND SPECIFICATIONS (SDS).......210

General Specifications .............................................210

Stall Revolution ........................................................210

Line Pressure...........................................................210

Removal and Installation .........................................210

A/T Fluid Temperature Sensor.................................210

Solenoid Valves .......................................................210

Dropping Resistor ....................................................210

CONTENTS(Cont'd)

AT-3

Page 52 of 3051

SAT767B

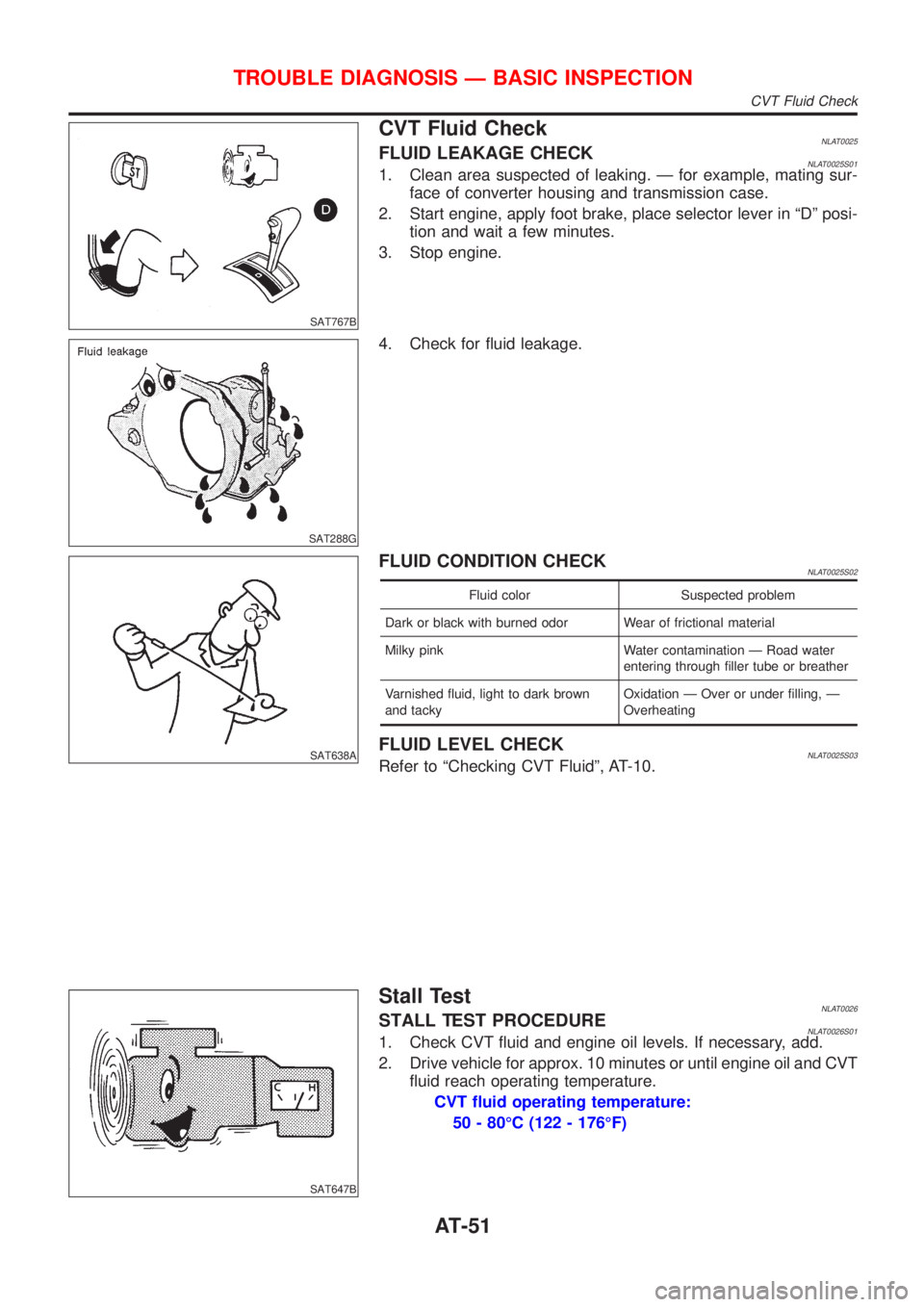

CVT Fluid CheckNLAT0025FLUID LEAKAGE CHECKNLAT0025S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

SAT288G

4. Check for fluid leakage.

SAT638A

FLUID CONDITION CHECKNLAT0025S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNLAT0025S03Refer to ªChecking CVT Fluidº, AT-10.

SAT647B

Stall TestNLAT0026STALL TEST PROCEDURENLAT0026S011. Check CVT fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and CVT

fluid reach operating temperature.

CVT fluid operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

CVT Fluid Check

AT-51

Page 53 of 3051

SAT513G

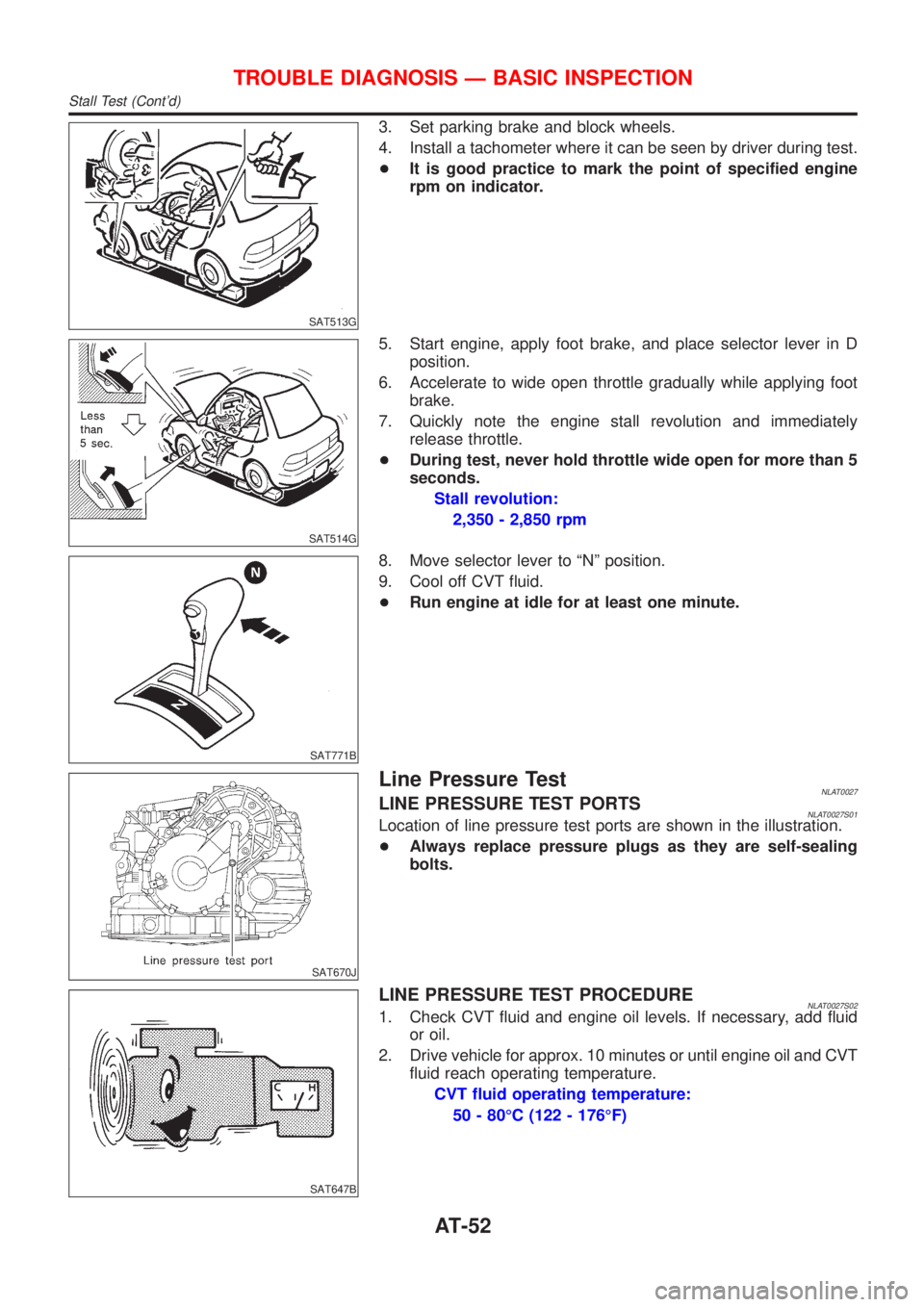

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

+It is good practice to mark the point of specified engine

rpm on indicator.

SAT514G

5. Start engine, apply foot brake, and place selector lever in D

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

+During test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

2,350 - 2,850 rpm

SAT771B

8. Move selector lever to ªNº position.

9. Cool off CVT fluid.

+Run engine at idle for at least one minute.

SAT670J

Line Pressure TestNLAT0027LINE PRESSURE TEST PORTSNLAT0027S01Location of line pressure test ports are shown in the illustration.

+Always replace pressure plugs as they are self-sealing

bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENLAT0027S021. Check CVT fluid and engine oil levels. If necessary, add fluid

or oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and CVT

fluid reach operating temperature.

CVT fluid operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Stall Test (Cont'd)

AT-52

Page 431 of 3051

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................467

ECM Terminals and Reference Value .....................467

Wiring Diagram ........................................................468

Diagnostic Procedure ..............................................470

Component Inspection .............................................474

INTAKE VALVE TIMING CONTROL SOLENOID

VALVE..........................................................................475

Component Description ...........................................475

Operation .................................................................475

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................475

ECM Terminals and Reference Value .....................475

Wiring Diagram ........................................................476

Diagnostic Procedure ..............................................478

Component Inspection .............................................480

SWIRL CONTROL VALVE CONTROL SYSTEM

(WHERE FITTED)........................................................481

Description ...............................................................481

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................481

ECM Terminals and Reference Value .....................482

Component Description ...........................................482

Wiring Diagram ........................................................483

Diagnostic Procedure ..............................................484

Component Inspection .............................................488

PARK/NEUTRAL POSITION (PNP) SWITCH............490

Component Description ...........................................490

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................490

ECM Terminals and Reference Value .....................490

Wiring Diagram ........................................................491

Diagnostic Procedure ..............................................492

INJECTOR...................................................................494

Component Description ...........................................494

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................494

ECM Terminals and Reference Value .....................494

Wiring Diagram ........................................................495

Diagnostic Procedure ..............................................497

Component Inspection .............................................499

IGNITION SIGNAL.......................................................500

Component Description ...........................................500

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................500

ECM Terminals and Reference Value .....................500

Wiring Diagram ........................................................501

Diagnostic Procedure ..............................................505

Component Inspection .............................................509

START SIGNAL........................................................... 511

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 511ECM Terminals and Reference Value ..................... 511

Wiring Diagram ........................................................512

Diagnostic Procedure ..............................................514

FUEL PUMP.................................................................516

System Description ..................................................516

Component Description ...........................................516

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................516

ECM Terminals and Reference Value .....................517

Wiring Diagram ........................................................518

Diagnostic Procedure ..............................................520

Component Inspection .............................................522

POWER STEERING OIL PRESSURE SWITCH.........523

Component Description ...........................................523

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................523

ECM Terminals and Reference Value .....................523

Wiring Diagram ........................................................524

Diagnostic Procedure ..............................................526

Component Inspection .............................................527

REFRIGERANT PRESSURE SENSOR......................529

Description ...............................................................529

ECM Terminals and Reference Value .....................529

Wiring Diagram ........................................................530

Diagnostic Procedure ..............................................532

ELECTRICAL LOAD SIGNAL.....................................535

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................535

ECM Terminals and Reference Value .....................535

Wiring Diagram ........................................................536

Diagnostic Procedure - Load Signal - .....................540

Diagnostic Procedure - Heater Control Panel

(Fan Switch) - ..........................................................544

MI & DATA LINK CONNECTORS..............................545

Wiring Diagram ........................................................545

SERVICE DATA AND SPECIFICATIONS (SDS).......547

Fuel Pressure Regulator..........................................547

Idle Speed and Ignition Timing ................................547

Mass Air Flow Sensor..............................................547

Intake Air Temperature Sensor ................................547

Engine Coolant Temperature Sensor ......................547

Throttle Position Sensor ..........................................547

Heated Oxygen Sensor 1 Heater (Front) ................547

Heated Oxygen Sensor 2 Heater (Rear).................547

EGR Volume Control Valve (where fitted) ...............548

EGR Temperature Sensor (where fitted) .................548

EVAP Canister Purge Volume Control Valve ..........548

IACV-AAC Valve ......................................................548

Injector .....................................................................548

Ignition Coil with Power Transistor ..........................548

Condenser ...............................................................548

Fuel Pump ...............................................................548

CONTENTS(Cont'd)

EC-6

Page 437 of 3051

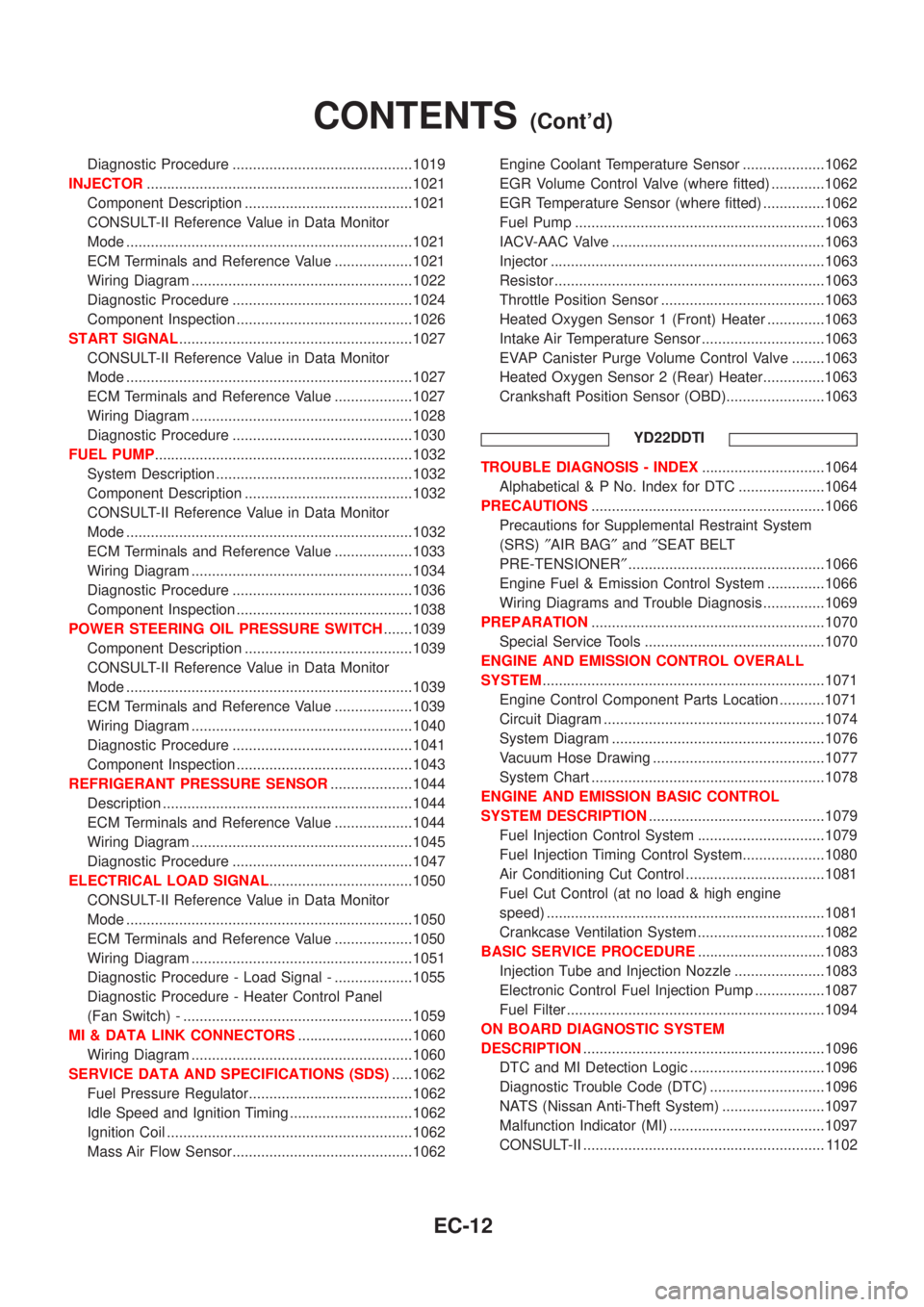

Diagnostic Procedure ............................................1019

INJECTOR.................................................................1021

Component Description .........................................1021

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1021

ECM Terminals and Reference Value ...................1021

Wiring Diagram ......................................................1022

Diagnostic Procedure ............................................1024

Component Inspection ...........................................1026

START SIGNAL.........................................................1027

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1027

ECM Terminals and Reference Value ...................1027

Wiring Diagram ......................................................1028

Diagnostic Procedure ............................................1030

FUEL PUMP...............................................................1032

System Description ................................................1032

Component Description .........................................1032

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1032

ECM Terminals and Reference Value ...................1033

Wiring Diagram ......................................................1034

Diagnostic Procedure ............................................1036

Component Inspection ...........................................1038

POWER STEERING OIL PRESSURE SWITCH.......1039

Component Description .........................................1039

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1039

ECM Terminals and Reference Value ...................1039

Wiring Diagram ......................................................1040

Diagnostic Procedure ............................................1041

Component Inspection ...........................................1043

REFRIGERANT PRESSURE SENSOR....................1044

Description .............................................................1044

ECM Terminals and Reference Value ...................1044

Wiring Diagram ......................................................1045

Diagnostic Procedure ............................................1047

ELECTRICAL LOAD SIGNAL...................................1050

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1050

ECM Terminals and Reference Value ...................1050

Wiring Diagram ......................................................1051

Diagnostic Procedure - Load Signal - ...................1055

Diagnostic Procedure - Heater Control Panel

(Fan Switch) - ........................................................1059

MI & DATA LINK CONNECTORS............................1060

Wiring Diagram ......................................................1060

SERVICE DATA AND SPECIFICATIONS (SDS).....1062

Fuel Pressure Regulator........................................1062

Idle Speed and Ignition Timing ..............................1062

Ignition Coil ............................................................1062

Mass Air Flow Sensor............................................1062Engine Coolant Temperature Sensor ....................1062

EGR Volume Control Valve (where fitted) .............1062

EGR Temperature Sensor (where fitted) ...............1062

Fuel Pump .............................................................1063

IACV-AAC Valve ....................................................1063

Injector ...................................................................1063

Resistor ..................................................................1063

Throttle Position Sensor ........................................1063

Heated Oxygen Sensor 1 (Front) Heater ..............1063

Intake Air Temperature Sensor ..............................1063

EVAP Canister Purge Volume Control Valve ........1063

Heated Oxygen Sensor 2 (Rear) Heater...............1063

Crankshaft Position Sensor (OBD)........................1063

YD22DDTI

TROUBLE DIAGNOSIS - INDEX..............................1064

Alphabetical & P No. Index for DTC .....................1064

PRECAUTIONS.........................................................1066

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²................................................1066

Engine Fuel & Emission Control System ..............1066

Wiring Diagrams and Trouble Diagnosis ...............1069

PREPARATION.........................................................1070

Special Service Tools ............................................1070

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.....................................................................1071

Engine Control Component Parts Location ...........1071

Circuit Diagram ......................................................1074

System Diagram ....................................................1076

Vacuum Hose Drawing ..........................................1077

System Chart .........................................................1078

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...........................................1079

Fuel Injection Control System ...............................1079

Fuel Injection Timing Control System....................1080

Air Conditioning Cut Control ..................................1081

Fuel Cut Control (at no load & high engine

speed) ....................................................................1081

Crankcase Ventilation System ...............................1082

BASIC SERVICE PROCEDURE...............................1083

Injection Tube and Injection Nozzle ......................1083

Electronic Control Fuel Injection Pump .................1087

Fuel Filter ...............................................................1094

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...........................................................1096

DTC and MI Detection Logic .................................1096

Diagnostic Trouble Code (DTC) ............................1096

NATS (Nissan Anti-Theft System) .........................1097

Malfunction Indicator (MI) ......................................1097

CONSULT-II ........................................................... 1102

CONTENTS(Cont'd)

EC-12

Page 459 of 3051

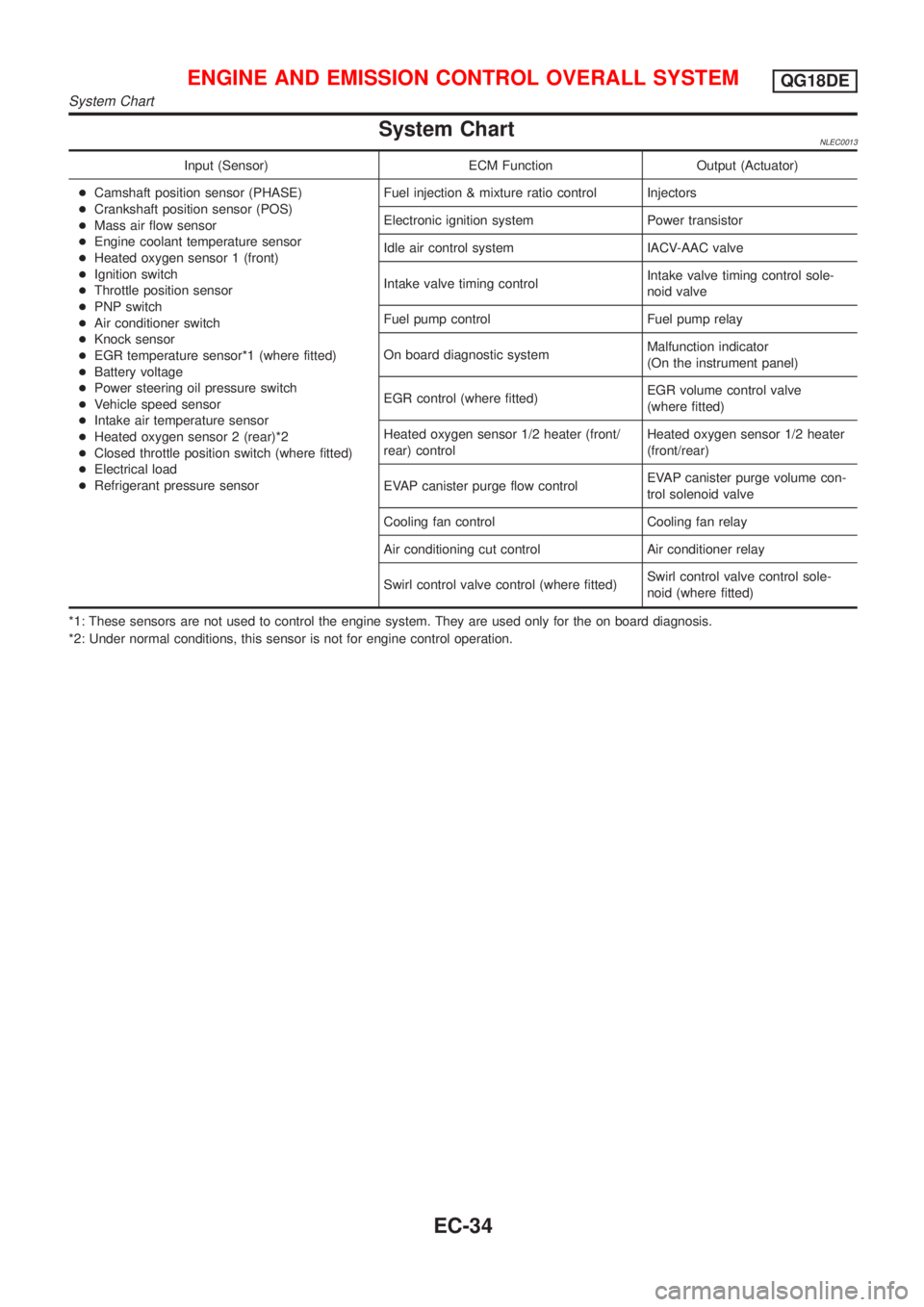

System ChartNLEC0013

Input (Sensor) ECM Function Output (Actuator)

+Camshaft position sensor (PHASE)

+Crankshaft position sensor (POS)

+Mass air flow sensor

+Engine coolant temperature sensor

+Heated oxygen sensor 1 (front)

+Ignition switch

+Throttle position sensor

+PNP switch

+Air conditioner switch

+Knock sensor

+EGR temperature sensor*1 (where fitted)

+Battery voltage

+Power steering oil pressure switch

+Vehicle speed sensor

+Intake air temperature sensor

+Heated oxygen sensor 2 (rear)*2

+Closed throttle position switch (where fitted)

+Electrical load

+Refrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Intake valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

On board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control (where fitted)EGR volume control valve

(where fitted)

Heated oxygen sensor 1/2 heater (front/

rear) controlHeated oxygen sensor 1/2 heater

(front/rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Swirl control valve control (where fitted)Swirl control valve control sole-

noid (where fitted)

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG18DE

System Chart

EC-34

Page 460 of 3051

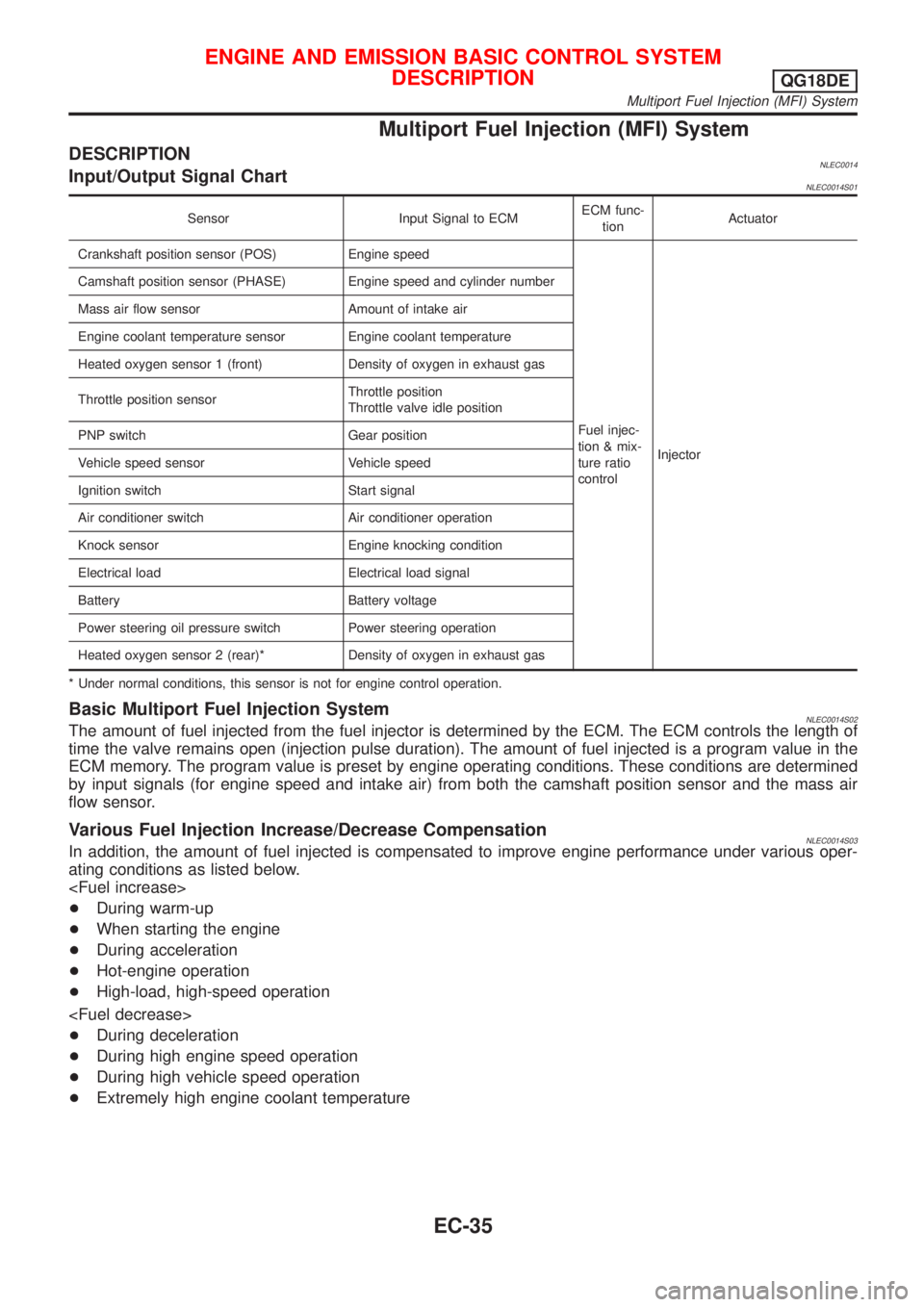

Multiport Fuel Injection (MFI) System

DESCRIPTIONNLEC0014Input/Output Signal ChartNLEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Fuel injec-

tion & mix-

ture ratio

controlInjector Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 (front) Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

PNP switch Gear position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Electrical load Electrical load signal

Battery Battery voltage

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2 (rear)* Density of oxygen in exhaust gas

* Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNLEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the camshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNLEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

+During warm-up

+When starting the engine

+During acceleration

+Hot-engine operation

+High-load, high-speed operation

+During deceleration

+During high engine speed operation

+During high vehicle speed operation

+Extremely high engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Multiport Fuel Injection (MFI) System

EC-35

Page 463 of 3051

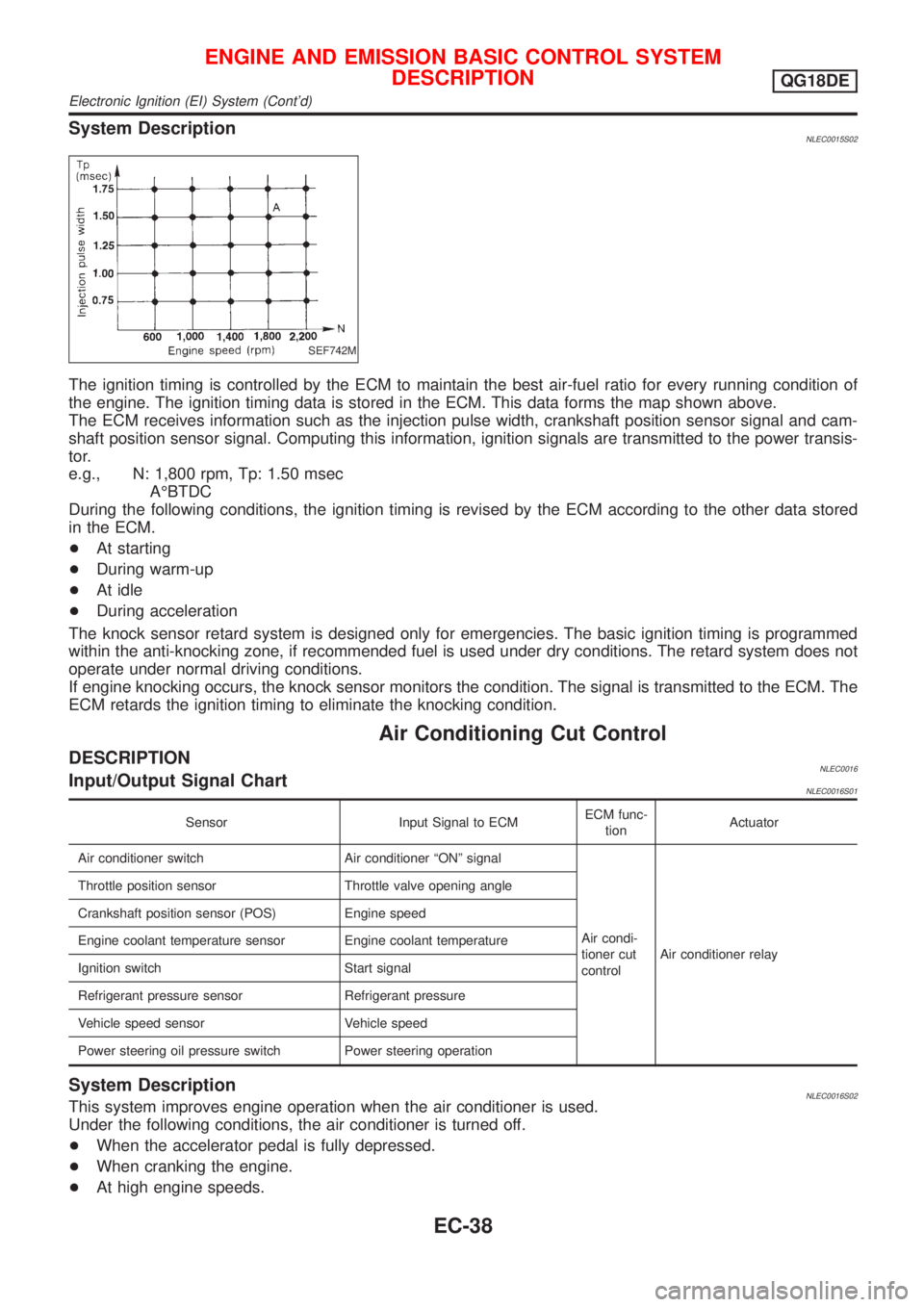

System DescriptionNLEC0015S02

SEF742M

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width, crankshaft position sensor signal and cam-

shaft position sensor signal. Computing this information, ignition signals are transmitted to the power transis-

tor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

+At starting

+During warm-up

+At idle

+During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut Control

DESCRIPTIONNLEC0016Input/Output Signal ChartNLEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Crankshaft position sensor (POS) Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Vehicle speed sensor Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNLEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

+When the accelerator pedal is fully depressed.

+When cranking the engine.

+At high engine speeds.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

QG18DE

Electronic Ignition (EI) System (Cont'd)

EC-38

Page 508 of 3051

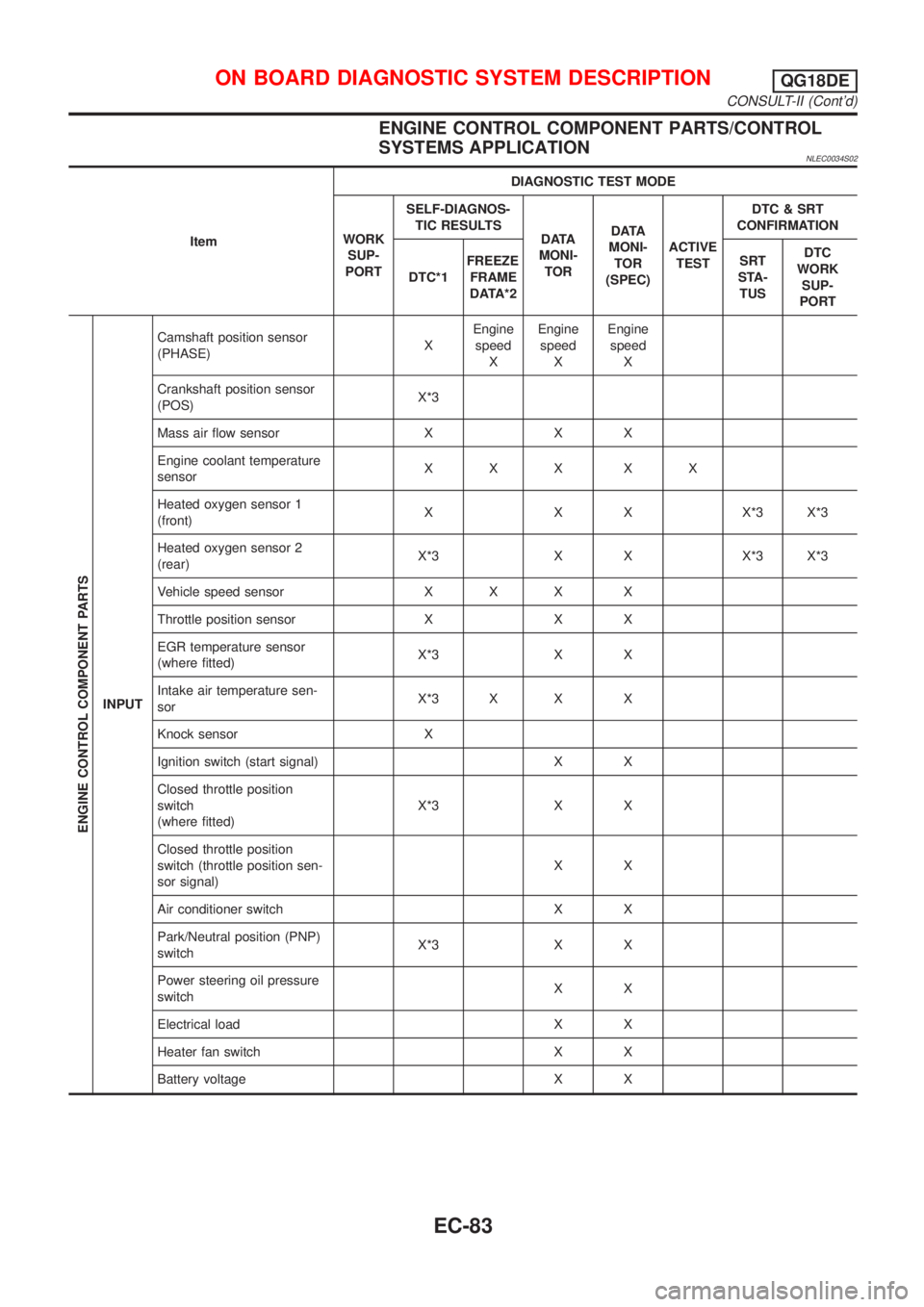

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

NLEC0034S02

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOS-

TIC RESULTS

D ATA

MONI-

TORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STA-

TUSDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

INPUTCamshaft position sensor

(PHASE)XEngine

speed

XEngine

speed

XEngine

speed

X

Crankshaft position sensor

(POS)X*3

Mass air flow sensor X X X

Engine coolant temperature

sensorXXX XX

Heated oxygen sensor 1

(front)X X X X*3 X*3

Heated oxygen sensor 2

(rear)X*3 X X X*3 X*3

Vehicle speed sensor X X X X

Throttle position sensor X X X

EGR temperature sensor

(where fitted)X*3 X X

Intake air temperature sen-

sorX*3 X X X

Knock sensor X

Ignition switch (start signal) X X

Closed throttle position

switch

(where fitted)X*3 X X

Closed throttle position

switch (throttle position sen-

sor signal)XX

Air conditioner switch X X

Park/Neutral position (PNP)

switchX*3 X X

Power steering oil pressure

switchXX

Electrical load X X

Heater fan switch X X

Battery voltage X X

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-83

Page 512 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three wa NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three wa](/img/5/57352/w960_57352-511.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 MNTR (B1)

[RICH/LEAN]j+Display of heated oxygen sensor 2 (rear) sig-

nal:

RICH ... means the amount of oxygen after

three way catalyst is relatively small.

LEAN ... means the amount of oxygen after

three way catalyst is relatively large.+When the engine is stopped, a cer-

tain value is indicated.

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the vehicle

speed sensor signal is displayed.

BATTERY VOLT [V]j+The power supply voltage of ECM is dis-

played.

THRTL POS SEN [V]jj+The throttle position sensor signal voltage is

displayed.

INT/A TEMP SE

[ÉC] or [ÉF]j+The intake air temperature determined by the

signal voltage of the intake air temperature

sensor is indicated.

EGR TEMP SEN [V]

(where fitted)jj+The signal voltage of the EGR temperature

sensor is displayed.

START SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the starter

signal.+After starting the engine, [OFF] is

displayed regardless of the starter

signal.

CLSD THL POS

[ON/OFF]jj+Indicates idle position [ON/OFF] computed by

ECM according to the throttle position sensor

signal.

CLSD THL/P SW

[ON/OFF]

(where fitted)j+Indicates mechanical contact [ON/OFF] con-

dition of the closed throttle position switch.

AIR COND SIG

[ON/OFF]jj+Indicates [ON/OFF] condition of the air condi-

tioner switch as determined by the air condi-

tioning signal.

P/N POSI SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the PNP

switch signal.

PW/ST SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition of the power

steering oil pressure switch determined by

the power steering oil pressure switch signal.

LOAD SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the electri-

cal load signal and/or lighting switch.

ON ... rear defogger is operating and/or light-

ing switch is on.

OFF ... rear defogger is not operating and

lighting switch is not on.

IGNITION SW

[ON/OFF]j+Indicates [ON/OFF] condition from ignition

switch.

HEATER FAN SW

[ON/OFF]j+Indicates [ON/OFF] condition from the heater

fan switch.

INJ PULSE-B1

[msec]j+Indicates the actual fuel injection pulse width

compensated by ECM according to the input

signals.+When the engine is stopped, a cer-

tain computed value is indicated.

IGN TIMING [BTDC]j+Indicates the ignition timing computed by

ECM according to the input signals.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-87