remove seats NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 359 of 3051

Removal and InstallationNLBT0013CAUTION:

+Wrap the tip of flat-bladed screwdriver with a cloth when removing metal clips from garnishes.

1. Remove front and rear seats. Refer to ªFRONT SEATº and ªREAR SEATº for details, BT-46 and BT-49.

2. Remove front and rear seat belts. Refer to RS-5 and RS-7, ªFront Seat Beltº and ªRear Seat Beltº for

details.

3. Remove carpet rear finish, front seat mounting cover and rear seat mounting cover. Refer to ªLUGGAGE

ROOM TRIMº for details, BT-31.

4. Remove front and rear outer kicking plates.

5. Remove front and rear inner kicking plates.

6. Remove dash side finishers.

7. Remove front and rear body side welts.

8. Remove front pillar garnishes.

9. Remove center pillar lower garnishes.

10. Remove center pillar upper garnishes.

11. Remove front and rear room carpet.

12. Remove rear pillar garnish.

13. Remove rear parcel shelf side finish.

14. Remove luggage room carpet.

15. Remove luggage room rear plate.

16. Remove luggage room rear side plate.

17. Remove luggage room rear side lower finish.

SIDE AND FLOOR TRIM

Removal and Installation

BT-28

Page 713 of 3051

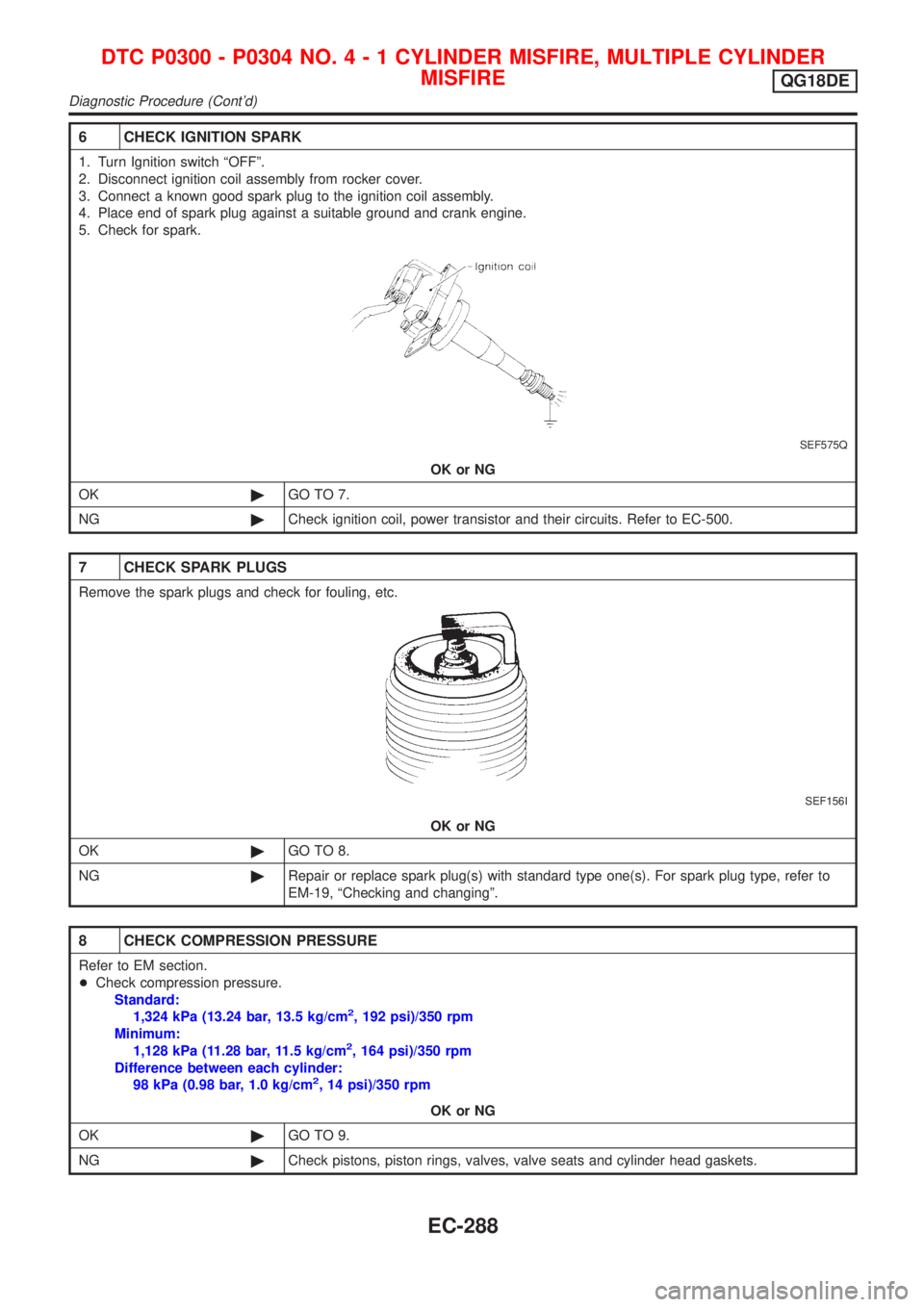

6 CHECK IGNITION SPARK

1. Turn Ignition switch ªOFFº.

2. Disconnect ignition coil assembly from rocker cover.

3. Connect a known good spark plug to the ignition coil assembly.

4. Place end of spark plug against a suitable ground and crank engine.

5. Check for spark.

SEF575Q

OK or NG

OK©GO TO 7.

NG©Check ignition coil, power transistor and their circuits. Refer to EC-500.

7 CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

SEF156I

OK or NG

OK©GO TO 8.

NG©Repair or replace spark plug(s) with standard type one(s). For spark plug type, refer to

EM-19, ªChecking and changingº.

8 CHECK COMPRESSION PRESSURE

Refer to EM section.

+Check compression pressure.

Standard:

1,324 kPa (13.24 bar, 13.5 kg/cm

2, 192 psi)/350 rpm

Minimum:

1,128 kPa (11.28 bar, 11.5 kg/cm

2, 164 psi)/350 rpm

Difference between each cylinder:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)/350 rpm

OK or NG

OK©GO TO 9.

NG©Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

QG18DE

Diagnostic Procedure (Cont'd)

EC-288

Page 1237 of 3051

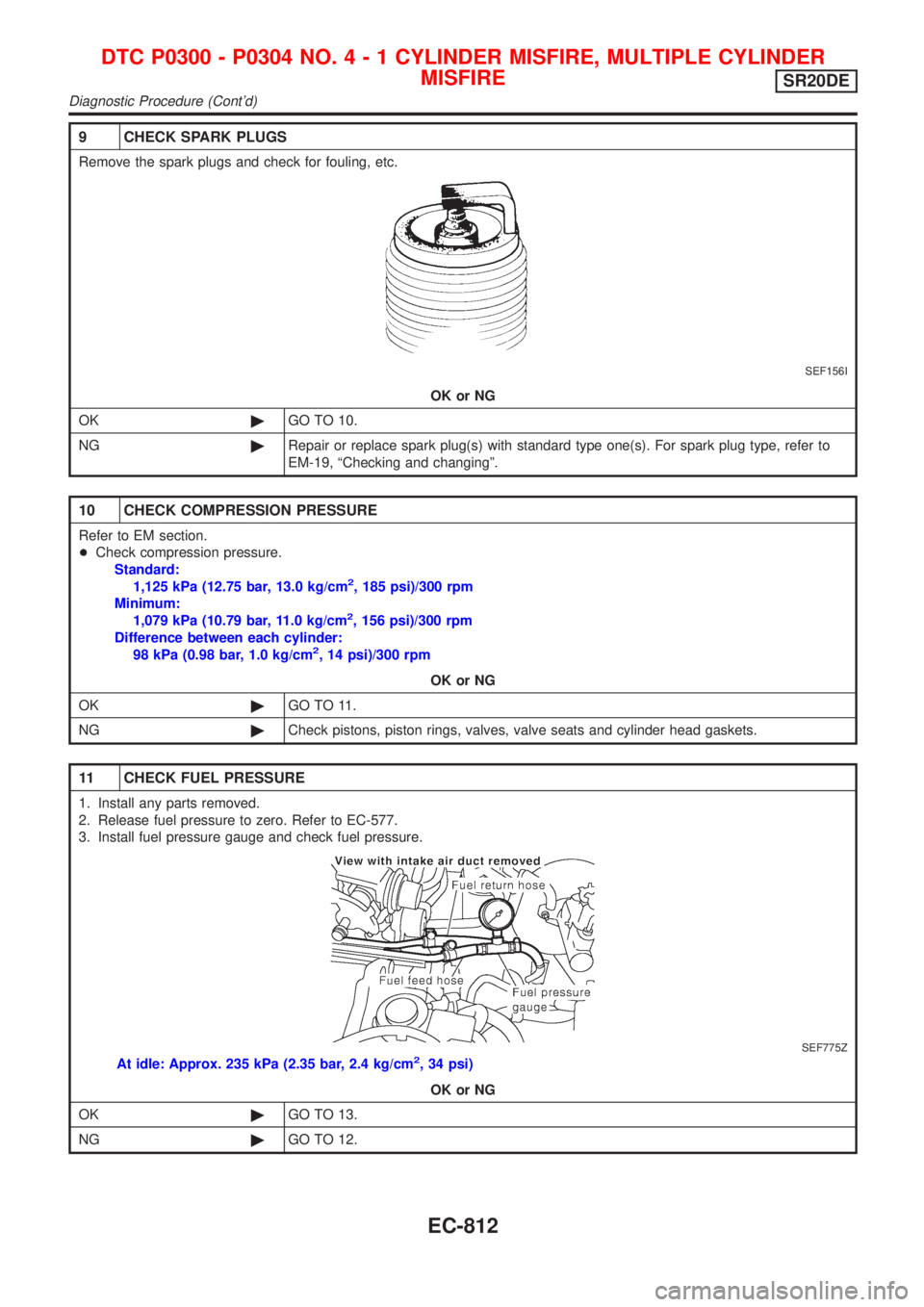

9 CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

SEF156I

OK or NG

OK©GO TO 10.

NG©Repair or replace spark plug(s) with standard type one(s). For spark plug type, refer to

EM-19, ªChecking and changingº.

10 CHECK COMPRESSION PRESSURE

Refer to EM section.

+Check compression pressure.

Standard:

1,125 kPa (12.75 bar, 13.0 kg/cm

2, 185 psi)/300 rpm

Minimum:

1,079 kPa (10.79 bar, 11.0 kg/cm

2, 156 psi)/300 rpm

Difference between each cylinder:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)/300 rpm

OK or NG

OK©GO TO 11.

NG©Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

11 CHECK FUEL PRESSURE

1. Install any parts removed.

2. Release fuel pressure to zero. Refer to EC-577.

3. Install fuel pressure gauge and check fuel pressure.

SEF775Z

At idle: Approx. 235 kPa (2.35 bar, 2.4 kg/cm2, 34 psi)

OK or NG

OK©GO TO 13.

NG©GO TO 12.

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

SR20DE

Diagnostic Procedure (Cont'd)

EC-812

Page 2460 of 3051

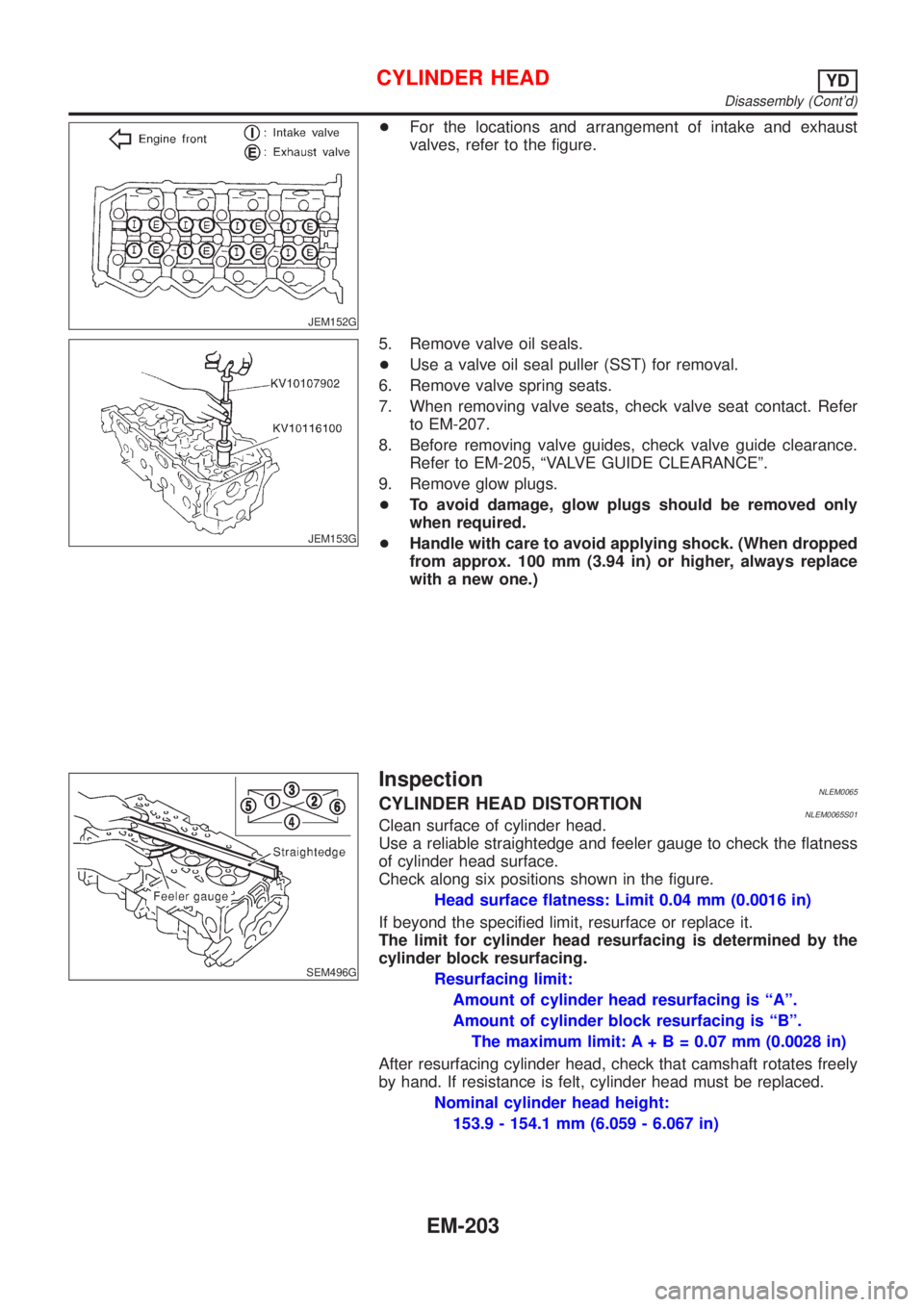

JEM152G

+For the locations and arrangement of intake and exhaust

valves, refer to the figure.

JEM153G

5. Remove valve oil seals.

+Use a valve oil seal puller (SST) for removal.

6. Remove valve spring seats.

7. When removing valve seats, check valve seat contact. Refer

to EM-207.

8. Before removing valve guides, check valve guide clearance.

Refer to EM-205, ªVALVE GUIDE CLEARANCEº.

9. Remove glow plugs.

+To avoid damage, glow plugs should be removed only

when required.

+Handle with care to avoid applying shock. (When dropped

from approx. 100 mm (3.94 in) or higher, always replace

with a new one.)

SEM496G

InspectionNLEM0065CYLINDER HEAD DISTORTIONNLEM0065S01Clean surface of cylinder head.

Use a reliable straightedge and feeler gauge to check the flatness

of cylinder head surface.

Check along six positions shown in the figure.

Head surface flatness: Limit 0.04 mm (0.0016 in)

If beyond the specified limit, resurface or replace it.

The limit for cylinder head resurfacing is determined by the

cylinder block resurfacing.

Resurfacing limit:

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit: A+ B = 0.07 mm (0.0028 in)

After resurfacing cylinder head, check that camshaft rotates freely

by hand. If resistance is felt, cylinder head must be replaced.

Nominal cylinder head height:

153.9 - 154.1 mm (6.059 - 6.067 in)

CYLINDER HEADYD

Disassembly (Cont'd)

EM-203

Page 2769 of 3051

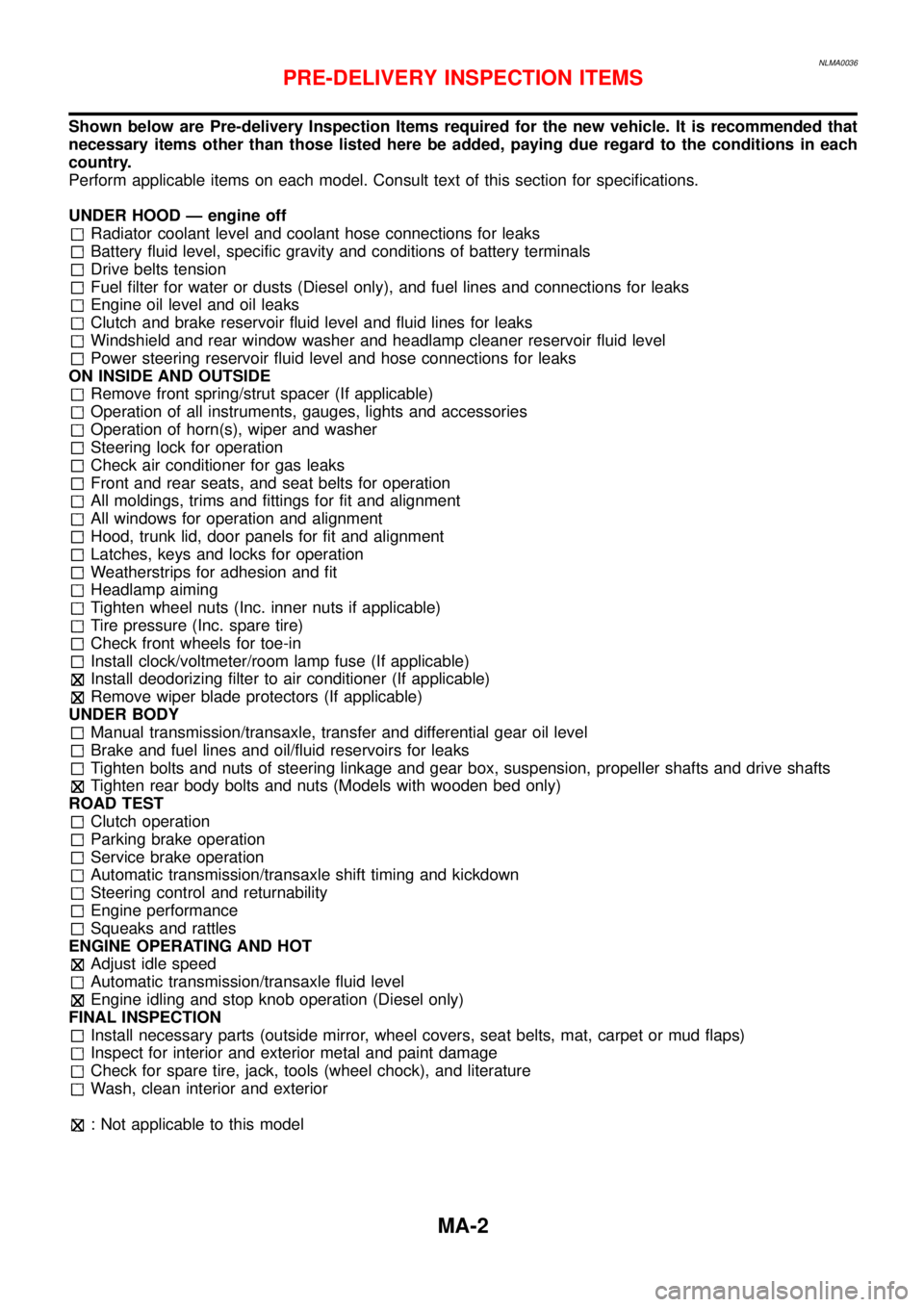

NLMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 2898 of 3051

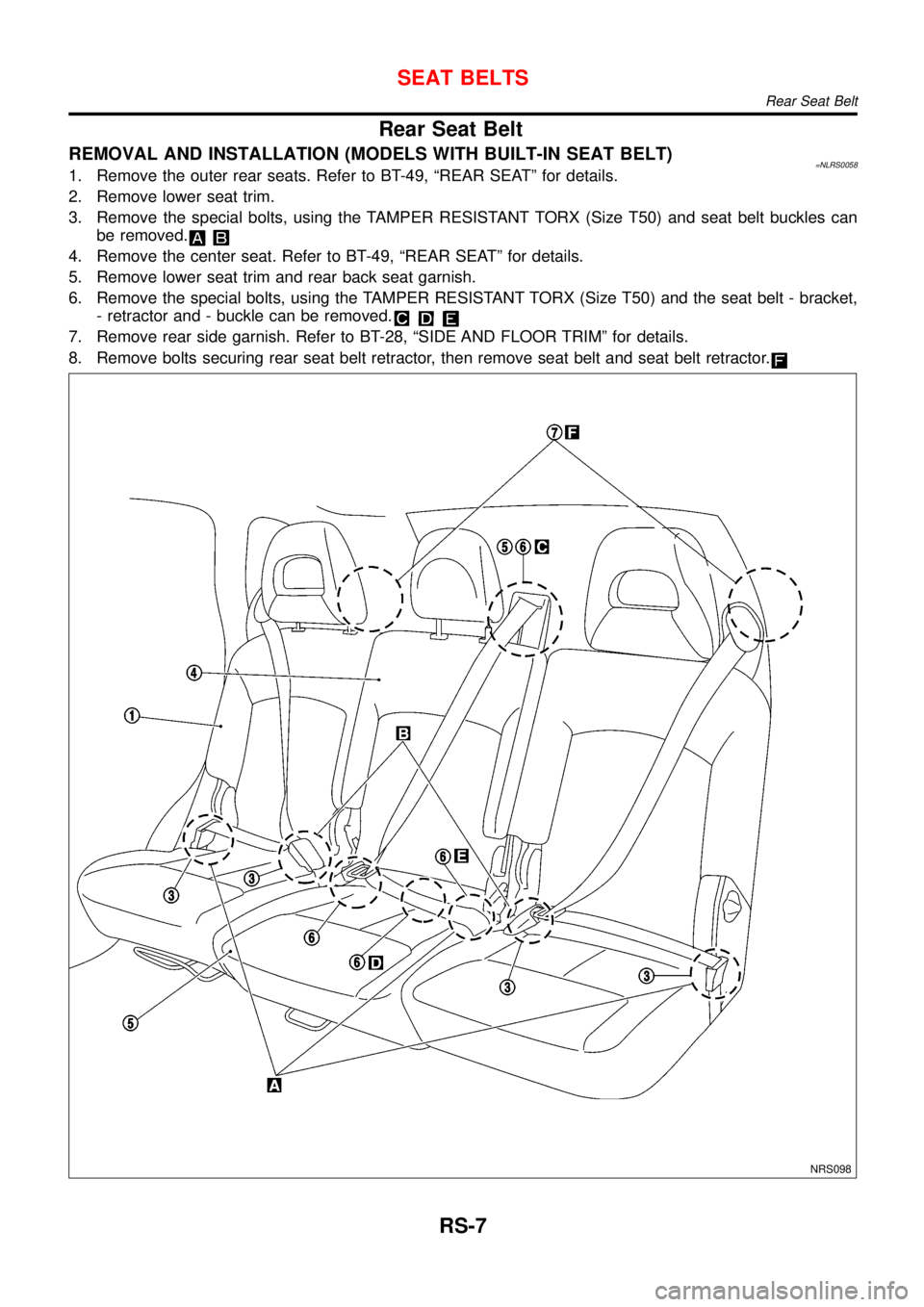

Rear Seat Belt

REMOVAL AND INSTALLATION (MODELS WITH BUILT-IN SEAT BELT)=NLRS00581. Remove the outer rear seats. Refer to BT-49,“REAR SEAT”for details.

2. Remove lower seat trim.

3. Remove the special bolts, using the TAMPER RESISTANT TORX (Size T50) and seat belt buckles can

be removed.

4. Remove the center seat. Refer to BT-49,“REAR SEAT”for details.

5. Remove lower seat trim and rear back seat garnish.

6. Remove the special bolts, using the TAMPER RESISTANT TORX (Size T50) and the seat belt - bracket,

- retractor and - buckle can be removed.

7. Remove rear side garnish. Refer to BT-28,“SIDE AND FLOOR TRIM”for details.

8. Remove bolts securing rear seat belt retractor, then remove seat belt and seat belt retractor.

NRS098

SEAT BELTS

Rear Seat Belt

RS-7

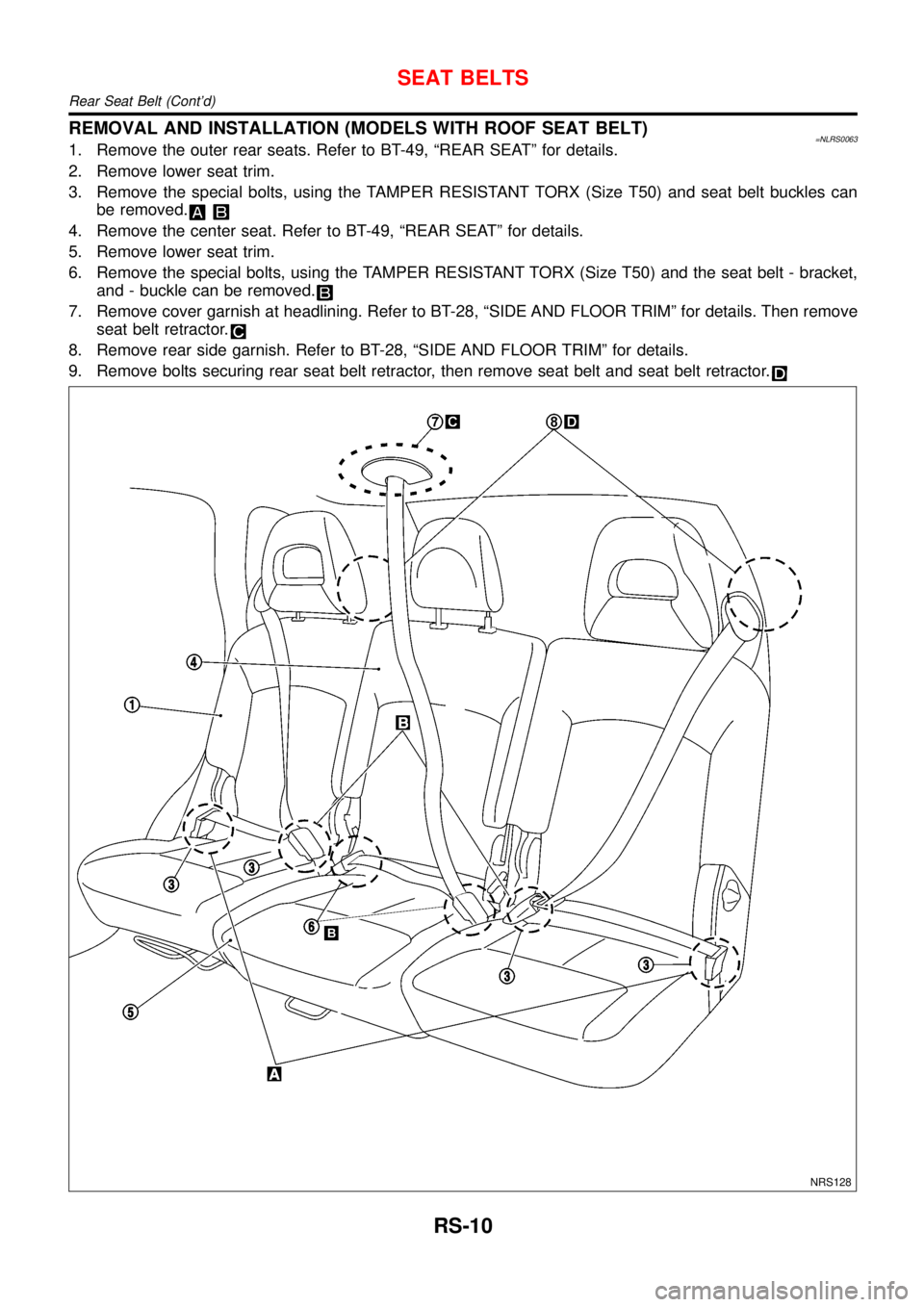

Page 2901 of 3051

REMOVAL AND INSTALLATION (MODELS WITH ROOF SEAT BELT)=NLRS00631. Remove the outer rear seats. Refer to BT-49,“REAR SEAT”for details.

2. Remove lower seat trim.

3. Remove the special bolts, using the TAMPER RESISTANT TORX (Size T50) and seat belt buckles can

be removed.

4. Remove the center seat. Refer to BT-49,“REAR SEAT”for details.

5. Remove lower seat trim.

6. Remove the special bolts, using the TAMPER RESISTANT TORX (Size T50) and the seat belt - bracket,

and - buckle can be removed.

7. Remove cover garnish at headlining. Refer to BT-28,“SIDE AND FLOOR TRIM”for details. Then remove

seat belt retractor.

8. Remove rear side garnish. Refer to BT-28,“SIDE AND FLOOR TRIM”for details.

9. Remove bolts securing rear seat belt retractor, then remove seat belt and seat belt retractor.

NRS128

SEAT BELTS

Rear Seat Belt (Cont’d)

RS-10

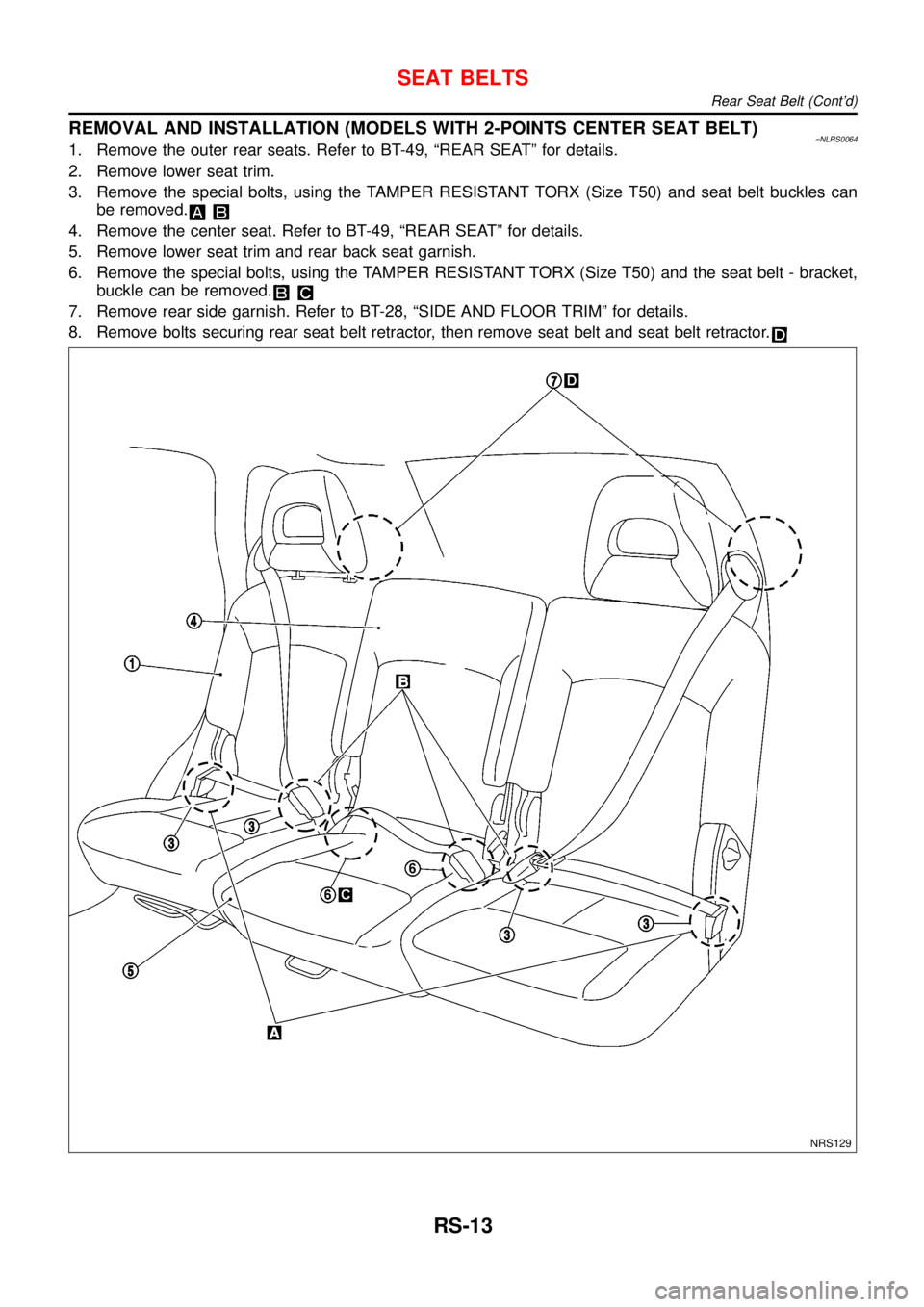

Page 2904 of 3051

REMOVAL AND INSTALLATION (MODELS WITH 2-POINTS CENTER SEAT BELT)=NLRS00641. Remove the outer rear seats. Refer to BT-49,“REAR SEAT”for details.

2. Remove lower seat trim.

3. Remove the special bolts, using the TAMPER RESISTANT TORX (Size T50) and seat belt buckles can

be removed.

4. Remove the center seat. Refer to BT-49,“REAR SEAT”for details.

5. Remove lower seat trim and rear back seat garnish.

6. Remove the special bolts, using the TAMPER RESISTANT TORX (Size T50) and the seat belt - bracket,

buckle can be removed.

7. Remove rear side garnish. Refer to BT-28,“SIDE AND FLOOR TRIM”for details.

8. Remove bolts securing rear seat belt retractor, then remove seat belt and seat belt retractor.

NRS129

SEAT BELTS

Rear Seat Belt (Cont’d)

RS-13