cooling NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1 of 3051

Release:April 2001 01)GENERALINFORMATIONGIMAINTENANCEMAENGINEMECHANICALEMENGINELUBRICATION&

COOLINGSYSTEMSLCENGINECONTROLSYSTEMECACCELERATORCONTROL,

FUEL&EXHAUSTSYSTEMSFECLUTCHCLMANUALTRANSAXLEMTAUTOMATICTRANSAXLEATFRONT&REARAXLEAXFRONT&REARSUSPENSIONSUBRAKESYSTEMBRSTEERINGSYSTEMSTRESTRAINTSYSTEMRSBODY&TRIMBTHEATER&AIRCONDITIONERHASTARTING&CHARGINGSYSTEMSSCELECTRICALSYSTEMELALPHABETICALINDEXIDXALMERATINOMODELV10SERIESQUICKREFERENCEINDEX

Page 8 of 3051

AAT470A

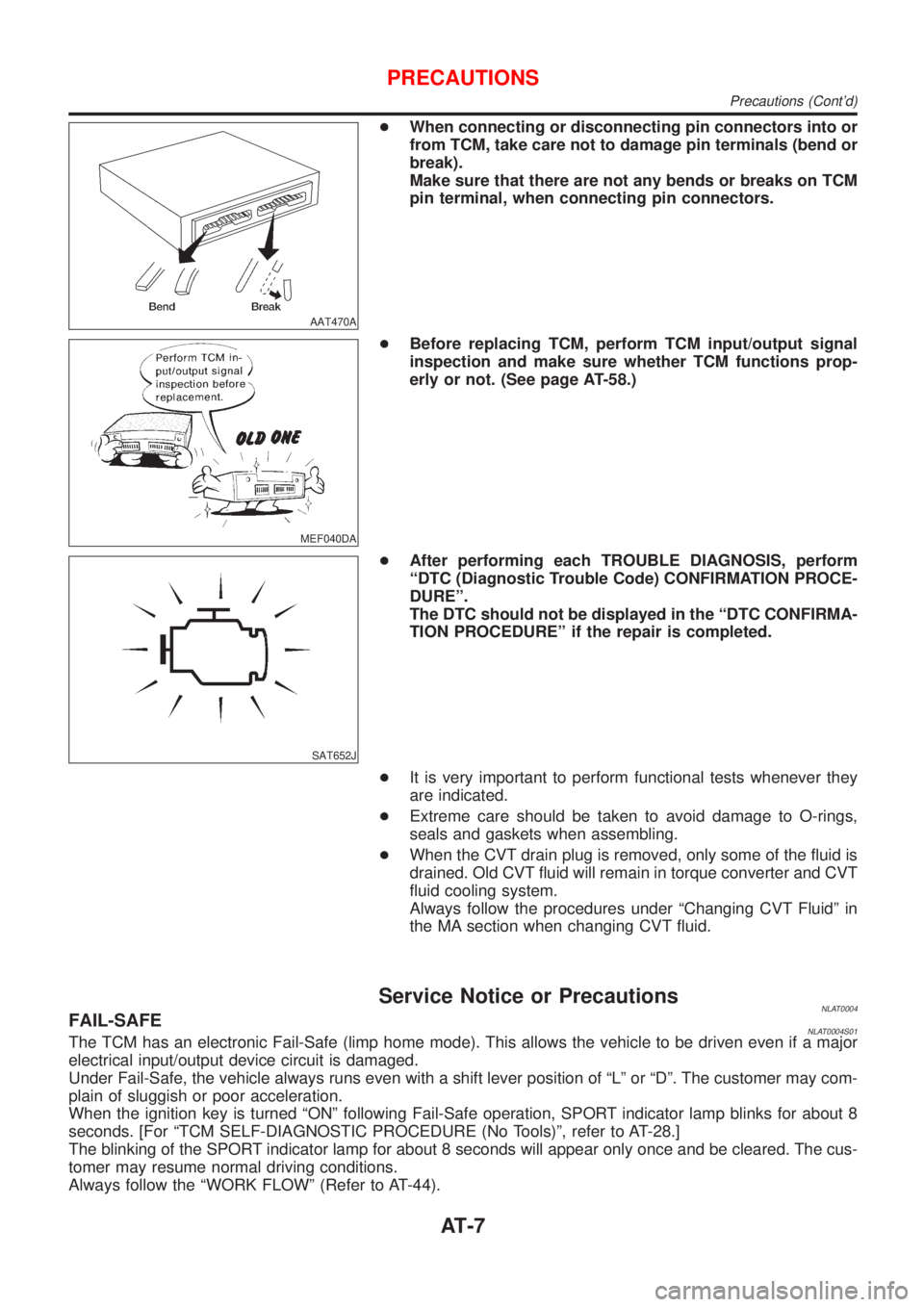

+When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

MEF040DA

+Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions prop-

erly or not. (See page AT-58.)

SAT652J

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is completed.

+It is very important to perform functional tests whenever they

are indicated.

+Extreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

+When the CVT drain plug is removed, only some of the fluid is

drained. Old CVT fluid will remain in torque converter and CVT

fluid cooling system.

Always follow the procedures under ªChanging CVT Fluidº in

the MA section when changing CVT fluid.

Service Notice or PrecautionsNLAT0004FAIL-SAFENLAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs even with a shift lever position of ªLº or ªDº. The customer may com-

plain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, SPORT indicator lamp blinks for about 8

seconds. [For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-28.]

The blinking of the SPORT indicator lamp for about 8 seconds will appear only once and be cleared. The cus-

tomer may resume normal driving conditions.

Always follow the ªWORK FLOWº (Refer to AT-44).

PRECAUTIONS

Precautions (Cont'd)

AT-7

Page 429 of 3051

Wiring Diagram ........................................................304

Diagnostic Procedure ..............................................306

Component Inspection .............................................308

DTC P0400 EGR FUNCTION (CLOSED) (WHERE

FITTED)........................................................................310

Description ...............................................................310

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 311

ECM Terminals and Reference Value ..................... 311

On Board Diagnosis Logic....................................... 311

DTC Confirmation Procedure ..................................312

Wiring Diagram ........................................................314

Diagnostic Procedure ..............................................316

Component Inspection .............................................318

DTC P0403 EGR VOLUME CONTROL VALVE

(CIRCUIT) (WHERE FITTED)......................................319

Description ...............................................................319

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................320

ECM Terminals and Reference Value .....................320

On Board Diagnosis Logic.......................................320

DTC Confirmation Procedure ..................................320

Wiring Diagram ........................................................322

Diagnostic Procedure ..............................................324

Component Inspection .............................................326

DTC P0420 THREE WAY CATALYST FUNCTION...327

On Board Diagnosis Logic.......................................327

DTC Confirmation Procedure ..................................327

Overall Function Check ...........................................328

Diagnostic Procedure ..............................................328

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................332

Description ...............................................................332

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................332

ECM Terminals and Reference Value .....................333

On Board Diagnosis Logic.......................................333

DTC Confirmation Procedure ..................................333

Wiring Diagram ........................................................334

Diagnostic Procedure ..............................................336

Component Inspection .............................................337

DTC P0500 VEHICLE SPEED SENSOR (VSS).........338

Component Description ...........................................338

ECM Terminals and Reference Value .....................338

On Board Diagnosis Logic.......................................338

DTC Confirmation Procedure ..................................338

Wiring Diagram ........................................................340

Diagnostic Procedure ..............................................342

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............343

Description ...............................................................343CONSULT-II Reference Value in Data Monitor

Mode ........................................................................344

ECM Terminals and Reference Value .....................344

On Board Diagnosis Logic.......................................344

DTC Confirmation Procedure ..................................344

Wiring Diagram ........................................................345

Diagnostic Procedure ..............................................347

Component Inspection .............................................351

DTC P0510 CLOSED THROTTLE POSITION

SWITCH (WHERE FITTED).........................................352

Component Description ...........................................352

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................352

ECM Terminals and Reference Value .....................352

On Board Diagnosis Logic.......................................352

DTC Confirmation Procedure ..................................352

Overall Function Check ...........................................353

Wiring Diagram ........................................................354

Diagnostic Procedure ..............................................355

Component Inspection .............................................356

DTC P0605 ECM.........................................................358

Component Description ...........................................358

On Board Diagnosis Logic.......................................358

DTC Confirmation Procedure ..................................358

Diagnostic Procedure ..............................................359

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE......................................................360

Component Description ...........................................360

Operation .................................................................360

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................360

ECM Terminals and Reference Value .....................360

On Board Diagnosis Logic.......................................360

DTC Confirmation Procedure ..................................361

Wiring Diagram ........................................................362

Diagnostic Procedure ..............................................364

Component Inspection .............................................365

DTC P1131 SWIRL CONTROL VALVE SOLENOID

VALVE (CIRCUIT) (WHERE FITTED).........................366

Description ...............................................................366

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................366

ECM Terminals and Reference Value .....................367

Component Description ...........................................367

On Board Diagnosis Logic.......................................367

DTC Confirmation Procedure ..................................367

Wiring Diagram ........................................................369

Diagnostic Procedure ..............................................370

Component Inspection .............................................371

DTC P1217 OVERHEAT (COOLING SYSTEM).........373

System Description ..................................................373

CONTENTS(Cont'd)

EC-4

Page 435 of 3051

Component Inspection .............................................847

DTC P0420 THREE WAY CATALYST FUNCTION...848

On Board Diagnosis Logic.......................................848

DTC Confirmation Procedure ..................................848

Overall Function Check ...........................................849

Diagnostic Procedure ..............................................849

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................852

Description ...............................................................852

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................852

ECM Terminals and Reference Value .....................853

On Board Diagnosis Logic.......................................853

DTC Confirmation Procedure ..................................853

Wiring Diagram ........................................................854

Diagnostic Procedure ..............................................856

Component Inspection .............................................857

DTC P0500 VEHICLE SPEED SENSOR (VSS).........858

Component Description ...........................................858

ECM Terminals and Reference Value .....................858

On Board Diagnosis Logic.......................................858

DTC Confirmation Procedure ..................................858

Wiring Diagram ........................................................860

Diagnostic Procedure ..............................................862

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............863

Description ...............................................................863

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................864

ECM Terminals and Reference Value .....................864

On Board Diagnosis Logic.......................................864

DTC Confirmation Procedure ..................................864

Wiring Diagram ........................................................865

Diagnostic Procedure ..............................................867

Component Inspection .............................................871

DTC P0510 CLOSED THROTTLE POSITION

SWITCH.......................................................................872

Component Description ...........................................872

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................872

ECM Terminals and Reference Value .....................872

On Board Diagnosis Logic.......................................872

DTC Confirmation Procedure ..................................872

Overall Function Check ...........................................873

Wiring Diagram ........................................................874

Diagnostic Procedure ..............................................876

Component Inspection .............................................878

DTC P0605 ECM.........................................................880

Component Description ...........................................880

On Board Diagnosis Logic.......................................880

DTC Confirmation Procedure ..................................880

Diagnostic Procedure ..............................................881DTC P1217 OVERHEAT (COOLING SYSTEM).........882

System Description ..................................................882

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................882

ECM Terminals and Reference Value .....................883

On Board Diagnosis Logic.......................................883

Overall Function Check ...........................................884

Wiring Diagram ........................................................885

Diagnostic Procedure ..............................................887

Main 12 Causes of Overheating..............................898

Component Inspection .............................................898

DTC P1320 IGNITION SIGNAL...................................900

Component Description ...........................................900

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................900

ECM Terminals and Reference Value .....................900

On Board Diagnosis Logic.......................................901

DTC Confirmation Procedure ..................................901

Wiring Diagram ........................................................903

Diagnostic Procedure ..............................................905

Component Inspection .............................................907

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)..................................................909

Component Description ...........................................909

ECM Terminals and Reference Value .....................909

On Board Diagnosis Logic.......................................910

DTC Confirmation Procedure ..................................910

Wiring Diagram ........................................................ 911

Diagnostic Procedure ..............................................913

Component Inspection .............................................914

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................915

Component Description ...........................................915

On Board Diagnosis Logic.......................................915

DTC Confirmation Procedure ..................................915

Wiring Diagram ........................................................918

Diagnostic Procedure ..............................................919

Component Inspection .............................................920

DTC P1402 EGR FUNCTION (OPEN) (WHERE

FITTED)........................................................................921

Description ...............................................................921

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................922

ECM Terminals and Reference Value .....................922

On Board Diagnosis Logic.......................................922

DTC Confirmation Procedure ..................................923

Wiring Diagram ........................................................925

Diagnostic Procedure ..............................................926

DTC P1605 A/T DIAGNOSIS COMMUNICATION

LINE.............................................................................928

System Description ..................................................928

ECM Terminals and Reference Value .....................928

CONTENTS(Cont'd)

EC-10

Page 459 of 3051

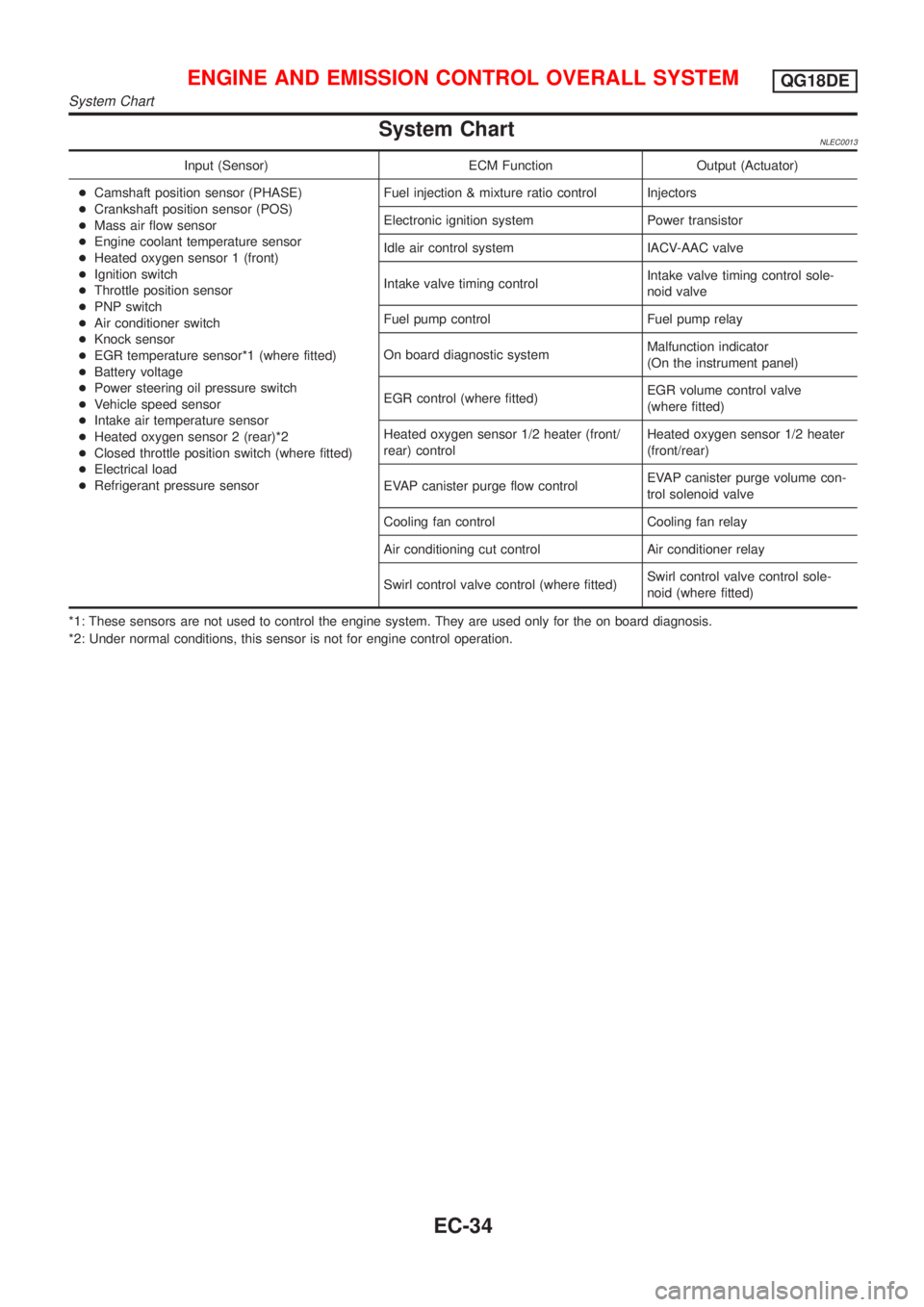

System ChartNLEC0013

Input (Sensor) ECM Function Output (Actuator)

+Camshaft position sensor (PHASE)

+Crankshaft position sensor (POS)

+Mass air flow sensor

+Engine coolant temperature sensor

+Heated oxygen sensor 1 (front)

+Ignition switch

+Throttle position sensor

+PNP switch

+Air conditioner switch

+Knock sensor

+EGR temperature sensor*1 (where fitted)

+Battery voltage

+Power steering oil pressure switch

+Vehicle speed sensor

+Intake air temperature sensor

+Heated oxygen sensor 2 (rear)*2

+Closed throttle position switch (where fitted)

+Electrical load

+Refrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Intake valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

On board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control (where fitted)EGR volume control valve

(where fitted)

Heated oxygen sensor 1/2 heater (front/

rear) controlHeated oxygen sensor 1/2 heater

(front/rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Swirl control valve control (where fitted)Swirl control valve control sole-

noid (where fitted)

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG18DE

System Chart

EC-34

Page 472 of 3051

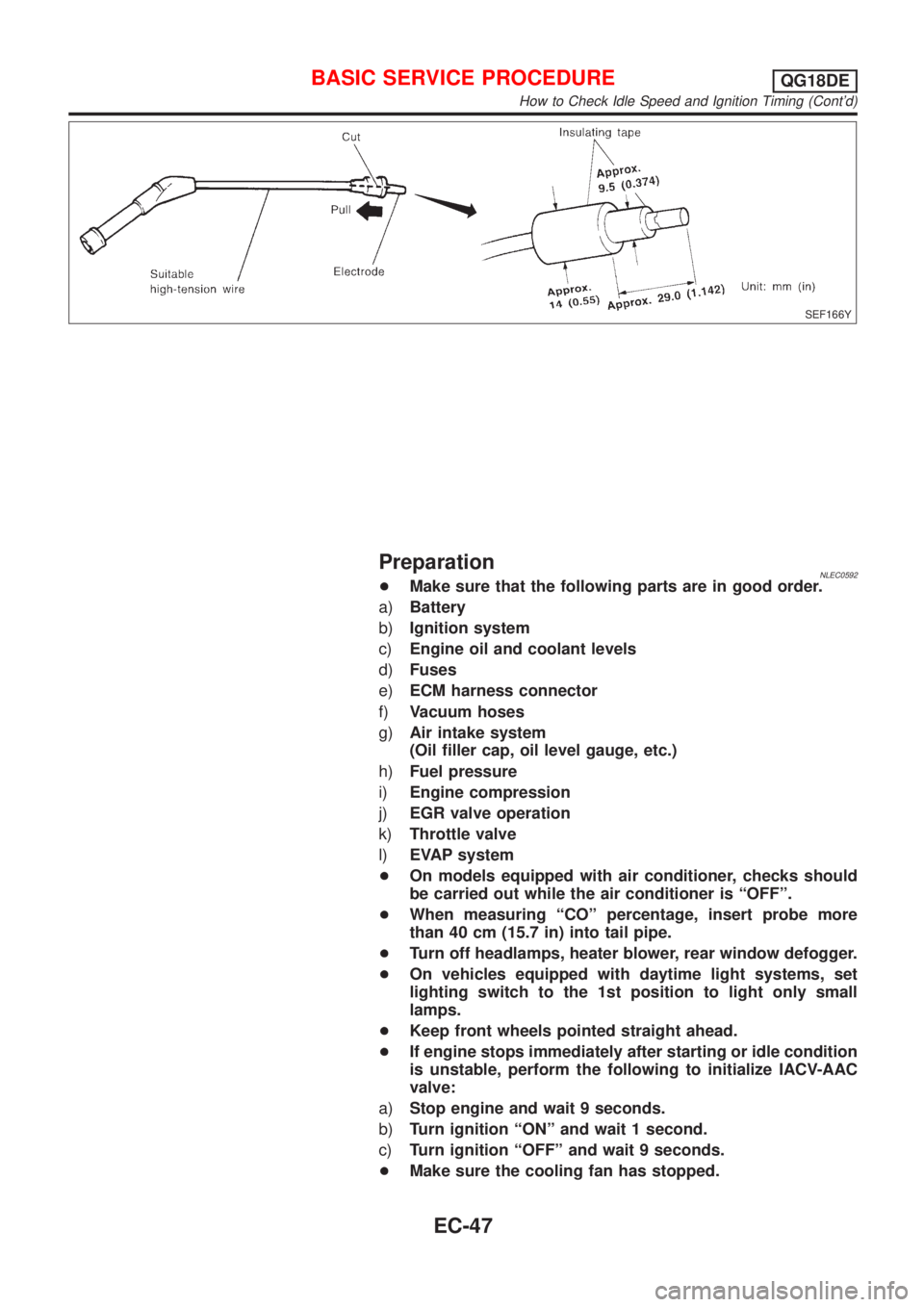

SEF166Y

PreparationNLEC0592+Make sure that the following parts are in good order.

a)Battery

b)Ignition system

c)Engine oil and coolant levels

d)Fuses

e)ECM harness connector

f)Vacuum hoses

g)Air intake system

(Oil filler cap, oil level gauge, etc.)

h)Fuel pressure

i)Engine compression

j)EGR valve operation

k)Throttle valve

l)EVAP system

+On models equipped with air conditioner, checks should

be carried out while the air conditioner is ªOFFº.

+When measuring ªCOº percentage, insert probe more

than 40 cm (15.7 in) into tail pipe.

+Turn off headlamps, heater blower, rear window defogger.

+On vehicles equipped with daytime light systems, set

lighting switch to the 1st position to light only small

lamps.

+Keep front wheels pointed straight ahead.

+If engine stops immediately after starting or idle condition

is unstable, perform the following to initialize IACV-AAC

valve:

a)Stop engine and wait 9 seconds.

b)Turn ignition ªONº and wait 1 second.

c)Turn ignition ªOFFº and wait 9 seconds.

+Make sure the cooling fan has stopped.

BASIC SERVICE PROCEDUREQG18DE

How to Check Idle Speed and Ignition Timing (Cont'd)

EC-47

Page 482 of 3051

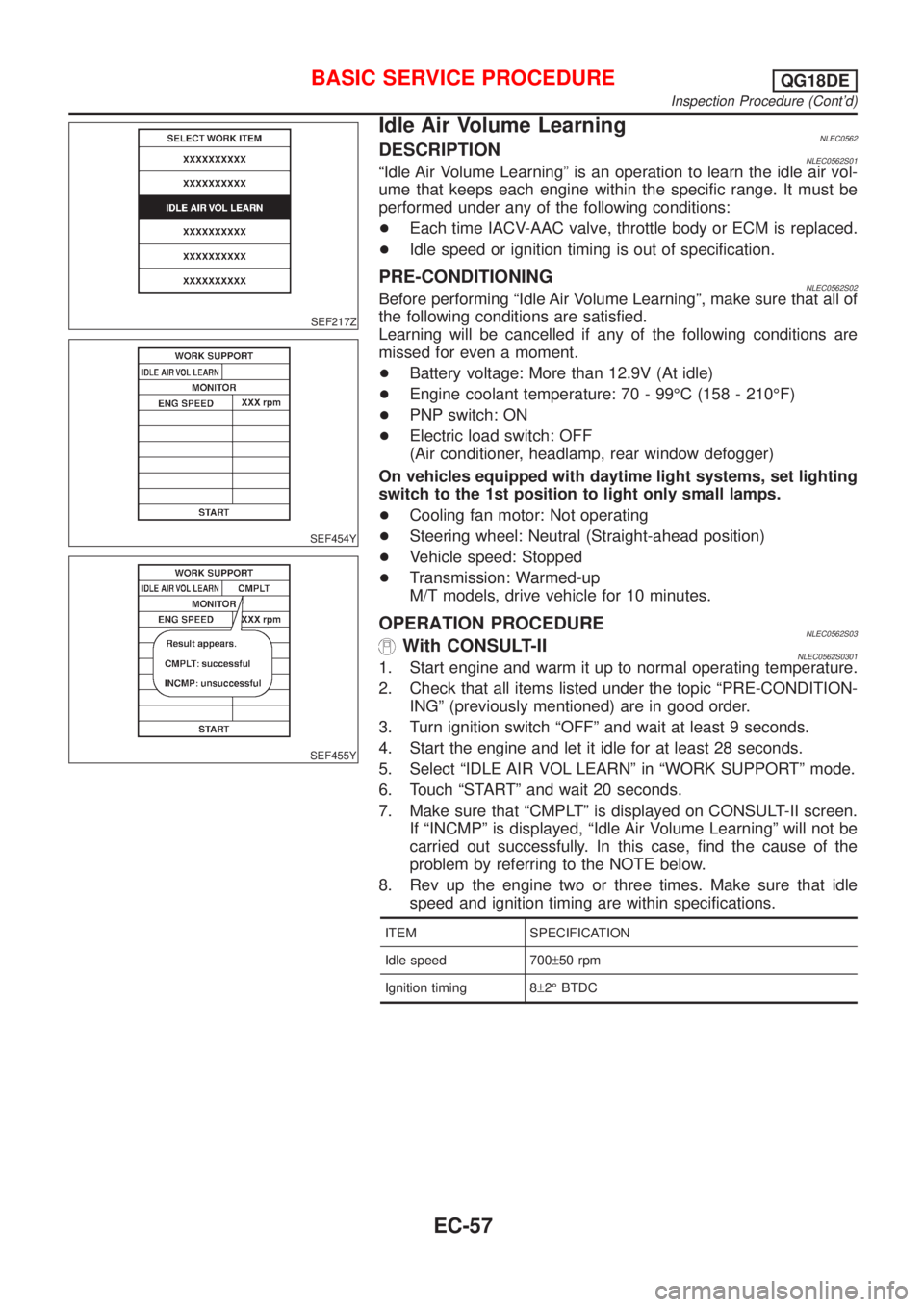

SEF217Z

SEF454Y

SEF455Y

Idle Air Volume LearningNLEC0562DESCRIPTIONNLEC0562S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

+Each time IACV-AAC valve, throttle body or ECM is replaced.

+Idle speed or ignition timing is out of specification.

PRE-CONDITIONINGNLEC0562S02Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

+Battery voltage: More than 12.9V (At idle)

+Engine coolant temperature: 70 - 99ÉC (158 - 210ÉF)

+PNP switch: ON

+Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting

switch to the 1st position to light only small lamps.

+Cooling fan motor: Not operating

+Steering wheel: Neutral (Straight-ahead position)

+Vehicle speed: Stopped

+Transmission: Warmed-up

M/T models, drive vehicle for 10 minutes.

OPERATION PROCEDURENLEC0562S03With CONSULT-IINLEC0562S03011. Start engine and warm it up to normal operating temperature.

2. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

3. Turn ignition switch ªOFFº and wait at least 9 seconds.

4. Start the engine and let it idle for at least 28 seconds.

5. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

6. Touch ªSTARTº and wait 20 seconds.

7. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

8. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 700±50 rpm

Ignition timing 8±2É BTDC

BASIC SERVICE PROCEDUREQG18DE

Inspection Procedure (Cont'd)

EC-57

Page 509 of 3051

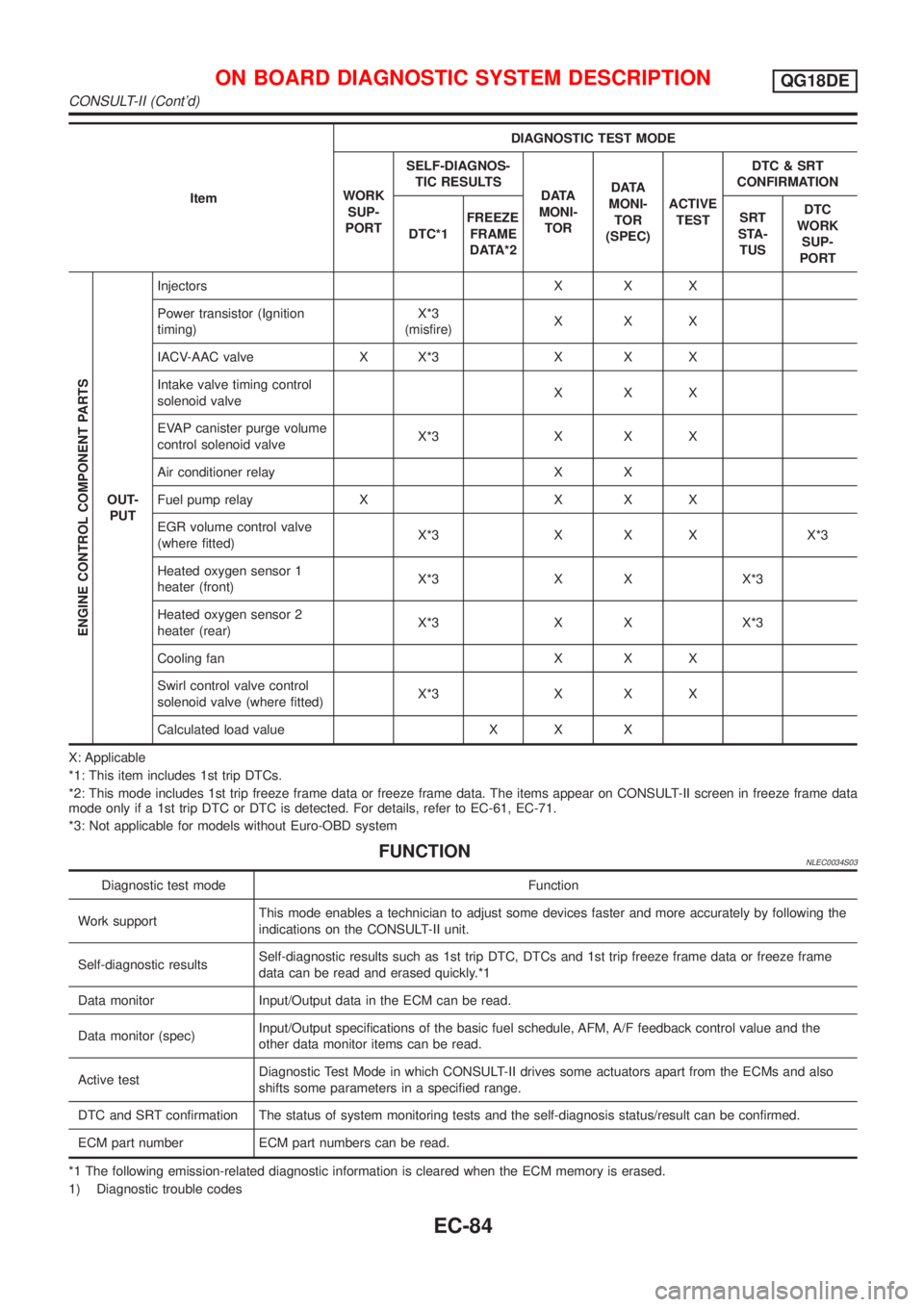

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOS-

TIC RESULTS

D ATA

MONI-

TORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STA-

TUSDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

OUT-

PUTInjectors X X X

Power transistor (Ignition

timing)X*3

(misfire)XXX

IACV-AAC valve X X*3 X X X

Intake valve timing control

solenoid valveXXX

EVAP canister purge volume

control solenoid valveX*3 X X X

Air conditioner relay X X

Fuel pump relay X X X X

EGR volume control valve

(where fitted)X*3 X X X X*3

Heated oxygen sensor 1

heater (front)X*3 X X X*3

Heated oxygen sensor 2

heater (rear)X*3 X X X*3

Cooling fan X X X

Swirl control valve control

solenoid valve (where fitted)X*3 X X X

Calculated load value X X X

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-II screen in freeze frame data

mode only if a 1st trip DTC or DTC is detected. For details, refer to EC-61, EC-71.

*3: Not applicable for models without Euro-OBD system

FUNCTIONNLEC0034S03

Diagnostic test mode Function

Work supportThis mode enables a technician to adjust some devices faster and more accurately by following the

indications on the CONSULT-II unit.

Self-diagnostic resultsSelf-diagnostic results such as 1st trip DTC, DTCs and 1st trip freeze frame data or freeze frame

data can be read and erased quickly.*1

Data monitor Input/Output data in the ECM can be read.

Data monitor (spec)Input/Output specifications of the basic fuel schedule, AFM, A/F feedback control value and the

other data monitor items can be read.

Active testDiagnostic Test Mode in which CONSULT-II drives some actuators apart from the ECMs and also

shifts some parameters in a specified range.

DTC and SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECM part number ECM part numbers can be read.

*1 The following emission-related diagnostic information is cleared when the ECM memory is erased.

1) Diagnostic trouble codes

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-84

Page 513 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

CAL/LD VALUE [%]+ªCalculated load valueº indicates the value of

the current airflow divided by peak airflow.

ABSOL TH.P/S [%]+ª NISSAN ALMERA TINO 2001 Service Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

CAL/LD VALUE [%]+ªCalculated load valueº indicates the value of

the current airflow divided by peak airflow.

ABSOL TH.P/S [%]+ª](/img/5/57352/w960_57352-512.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

CAL/LD VALUE [%]+ªCalculated load valueº indicates the value of

the current airflow divided by peak airflow.

ABSOL TH.P/S [%]+ªAbsolute throttle position sensorº indicates

the throttle opening computed by ECM

according to the signal voltage of the throttle

position sensor.

MASS AIRFLOW

[gm/s]+Indicates the mass airflow computed by ECM

according to the signal voltage of the mass

air flow sensor.

IACV-AAC/V [step]j+Indicates the IACV-AAC valve control value

computed by ECM according to the input sig-

nals.

PURG VOL C/V [%]+Indicates the EVAP canister purge volume

control solenoid valve computed by the ECM

according to the inpuct signals.

+The opening becomes larger as the value

increases.

EGR VOL CON/V

[step]

(where fitted)j+Indicates the EGR volume control valve com-

puted by the ECM according to the input sig-

nals.

+The opening becomes larger as the value

increases.

SWRL CONT S/V

[ON/OFF]

(where fitted)+The control condition of the swirl control

valve control solenoid valve (determined by

ECM according to the input signals) is indi-

cated.

+ON ... Swirl control valve is closed.

OFF ... Swirl control valve is opened.

INT/V SOL-B1

[ON/OFF]+The control condition of the valve timing sole-

noid valve (determined by ECM according to

the input signal) is indicated.

ON ... Intake valve timing control operating

OFF ... Intake valve timing control not operat-

ing

AIR COND RLY

[ON/OFF]j+Indicates the air conditioner relay control con-

dition determined by ECM according to the

input signals.

FUEL PUMP RLY

[ON/OFF]j+Indicates the fuel pump relay control condi-

tion determined by ECM according to the

input signals.

COOLING FAN

[ON/OFF]j+Indicates [ON/OFF] control condition of the

cooling fan determined by ECM according to

the input signals.

HO2S1 HTR (B1)

[ON/OFF]+Indicates [ON/OFF] condition of heated oxy-

gen sensor 1 heater (front) determined by

ECM according to the input signals.

HO2S2 HTR (B1)

[ON/OFF]+Indicates [ON/OFF] condition of heated oxy-

gen sensor 2 heater (rear) determined by

ECM according to the input signals.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-88

Page 515 of 3051

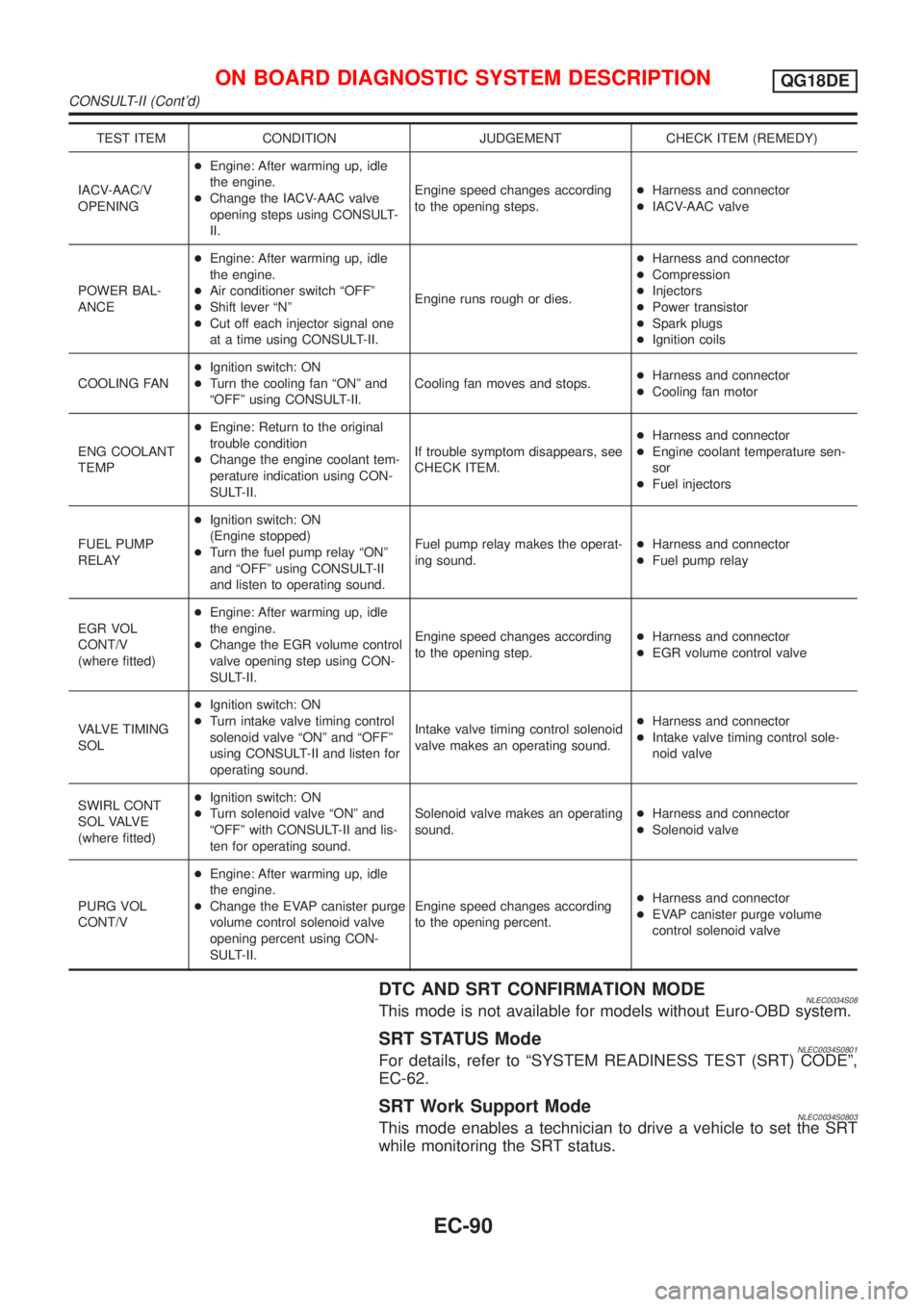

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

IACV-AAC/V

OPENING+Engine: After warming up, idle

the engine.

+Change the IACV-AAC valve

opening steps using CONSULT-

II.Engine speed changes according

to the opening steps.+Harness and connector

+IACV-AAC valve

POWER BAL-

ANCE+Engine: After warming up, idle

the engine.

+Air conditioner switch ªOFFº

+Shift lever ªNº

+Cut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.+Harness and connector

+Compression

+Injectors

+Power transistor

+Spark plugs

+Ignition coils

COOLING FAN+Ignition switch: ON

+Turn the cooling fan ªONº and

ªOFFº using CONSULT-II.Cooling fan moves and stops.+Harness and connector

+Cooling fan motor

ENG COOLANT

TEMP+Engine: Return to the original

trouble condition

+Change the engine coolant tem-

perature indication using CON-

SULT-II.If trouble symptom disappears, see

CHECK ITEM.+Harness and connector

+Engine coolant temperature sen-

sor

+Fuel injectors

FUEL PUMP

RELAY+Ignition switch: ON

(Engine stopped)

+Turn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.+Harness and connector

+Fuel pump relay

EGR VOL

CONT/V

(where fitted)+Engine: After warming up, idle

the engine.

+Change the EGR volume control

valve opening step using CON-

SULT-II.Engine speed changes according

to the opening step.+Harness and connector

+EGR volume control valve

VALVE TIMING

SOL+Ignition switch: ON

+Turn intake valve timing control

solenoid valve ªONº and ªOFFº

using CONSULT-II and listen for

operating sound.Intake valve timing control solenoid

valve makes an operating sound.+Harness and connector

+Intake valve timing control sole-

noid valve

SWIRL CONT

S O L VA LV E

(where fitted)+Ignition switch: ON

+Turn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.+Harness and connector

+Solenoid valve

PURG VOL

CONT/V+Engine: After warming up, idle

the engine.

+Change the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.+Harness and connector

+EVAP canister purge volume

control solenoid valve

DTC AND SRT CONFIRMATION MODENLEC0034S08This mode is not available for models without Euro-OBD system.

SRT STATUS ModeNLEC0034S0801For details, refer to ªSYSTEM READINESS TEST (SRT) CODEº,

EC-62.

SRT Work Support ModeNLEC0034S0803This mode enables a technician to drive a vehicle to set the SRT

while monitoring the SRT status.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG18DE

CONSULT-II (Cont'd)

EC-90