water pump NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 253 of 3051

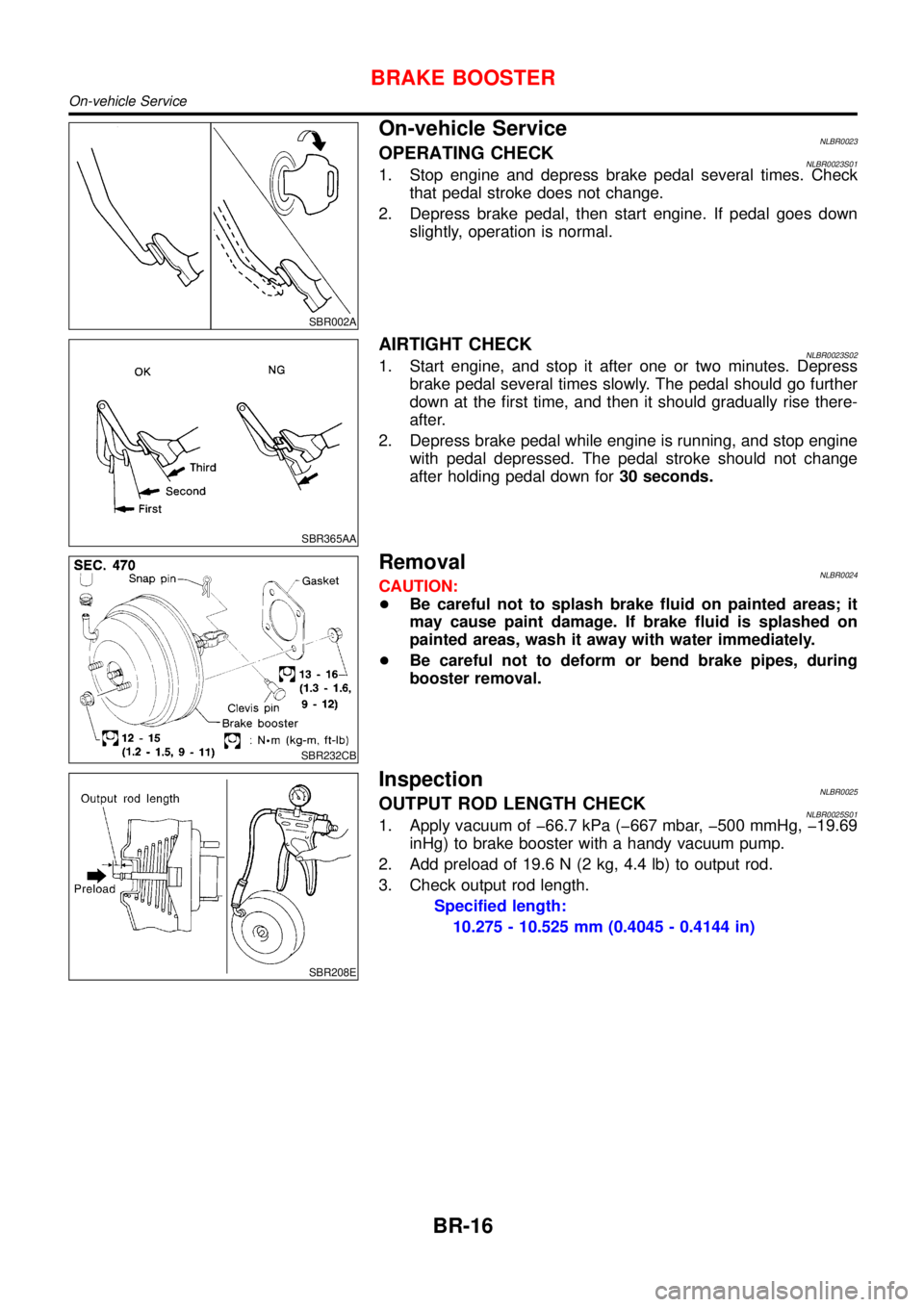

SBR002A

On-vehicle ServiceNLBR0023OPERATING CHECKNLBR0023S011. Stop engine and depress brake pedal several times. Check

that pedal stroke does not change.

2. Depress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

SBR365AA

AIRTIGHT CHECKNLBR0023S021. Start engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. The pedal should go further

down at the first time, and then it should gradually rise there-

after.

2. Depress brake pedal while engine is running, and stop engine

with pedal depressed. The pedal stroke should not change

after holding pedal down for30 seconds.

SBR232CB

RemovalNLBR0024CAUTION:

+Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

+Be careful not to deform or bend brake pipes, during

booster removal.

SBR208E

InspectionNLBR0025OUTPUT ROD LENGTH CHECKNLBR0025S011. Apply vacuum of �66.7 kPa (�667 mbar, �500 mmHg, �19.69

inHg) to brake booster with a handy vacuum pump.

2. Add preload of 19.6 N (2 kg, 4.4 lb) to output rod.

3. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

BRAKE BOOSTER

On-vehicle Service

BR-16

Page 549 of 3051

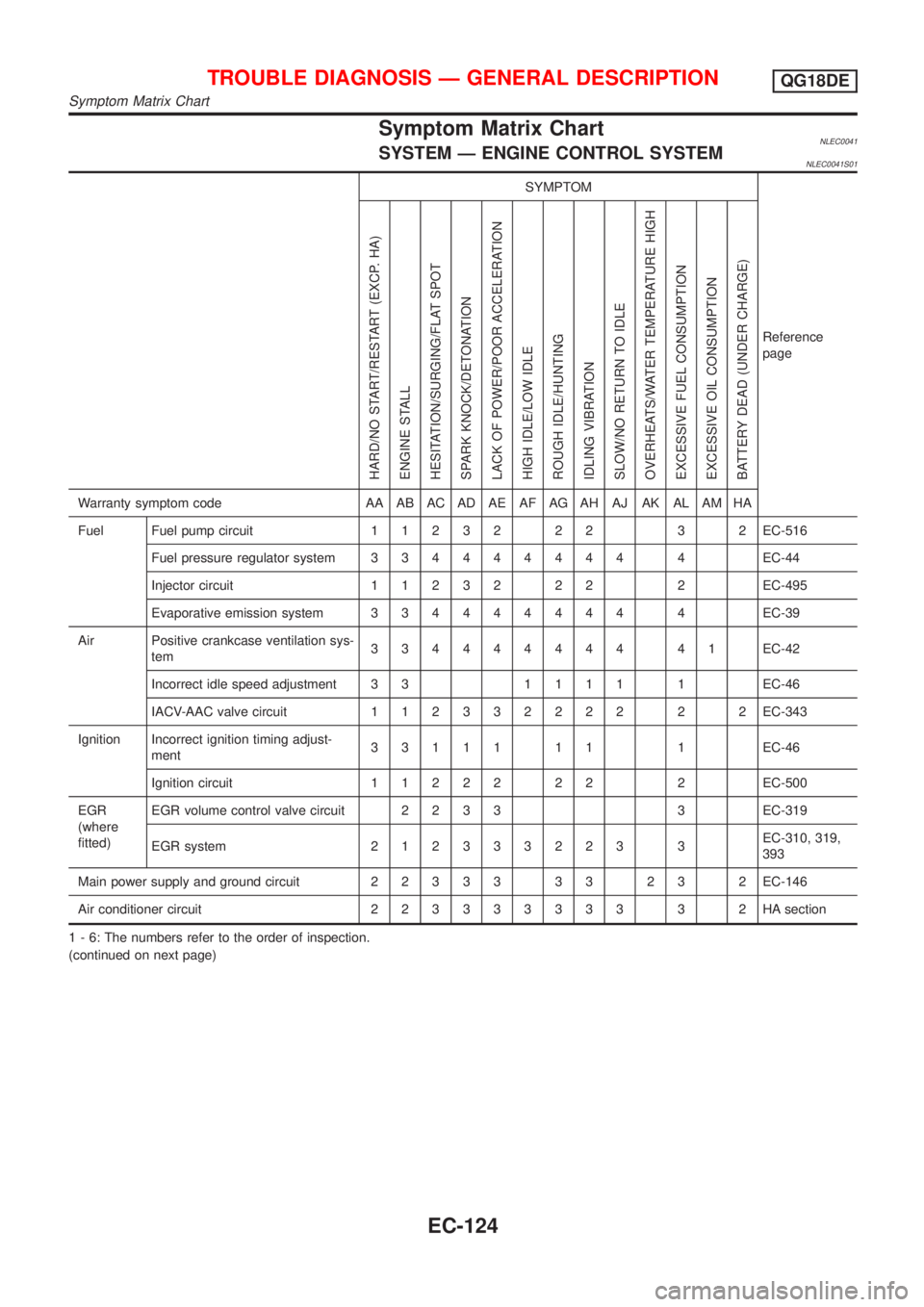

Symptom Matrix ChartNLEC0041SYSTEM Ð ENGINE CONTROL SYSTEMNLEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 22 3 2EC-516

Fuel pressure regulator system334444444 4EC-44

Injector circuit11232 22 2EC-495

Evaporative emission system334444444 4EC-39

Air Positive crankcase ventilation sys-

tem334444444 41EC-42

Incorrect idle speed adjustment 3 31111 1EC-46

IACV-AAC valve circuit112332222 2 2EC-343

Ignition Incorrect ignition timing adjust-

ment33111 11 1EC-46

Ignition circuit11222 22 2EC-500

EGR

(where

fitted)EGR volume control valve circuit2233 3EC-319

EGR system212333223 3EC-310, 319,

393

Main power supply and ground circuit22333 33 23 2EC-146

Air conditioner circuit223333333 3 2HAsection

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG18DE

Symptom Matrix Chart

EC-124

Page 552 of 3051

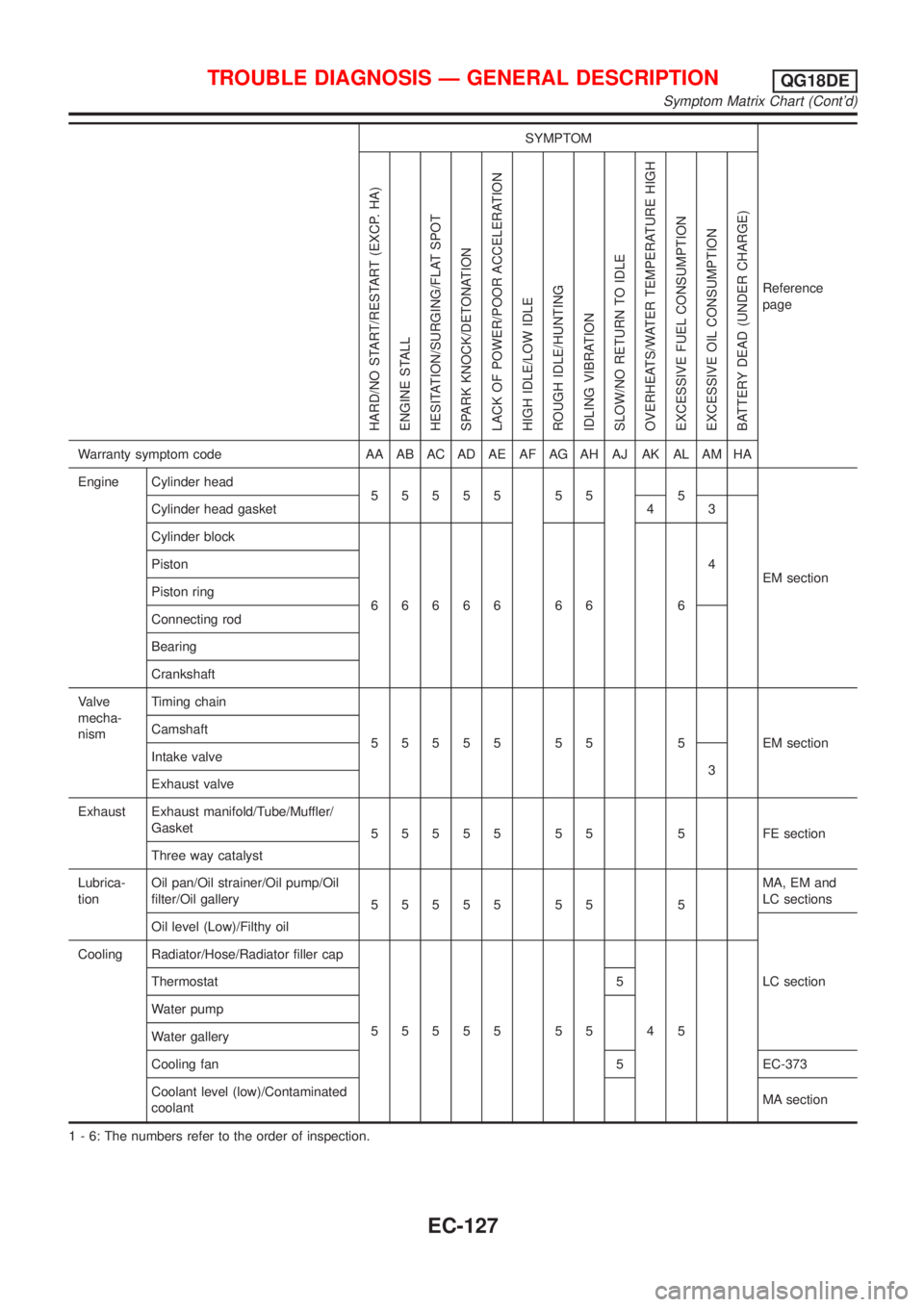

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 55 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 66 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nismTiming chain

55555 55 5 EMsection Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5 FEsection

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 55 5MA, EM and

LC sections

Oil level (Low)/Filthy oil

LC section Cooling Radiator/Hose/Radiator filler cap

55555 55 45 Thermostat 5

Water pump

Water gallery

Cooling fan 5 EC-373

Coolant level (low)/Contaminated

coolantMA section

1 - 6: The numbers refer to the order of inspection.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG18DE

Symptom Matrix Chart (Cont'd)

EC-127

Page 806 of 3051

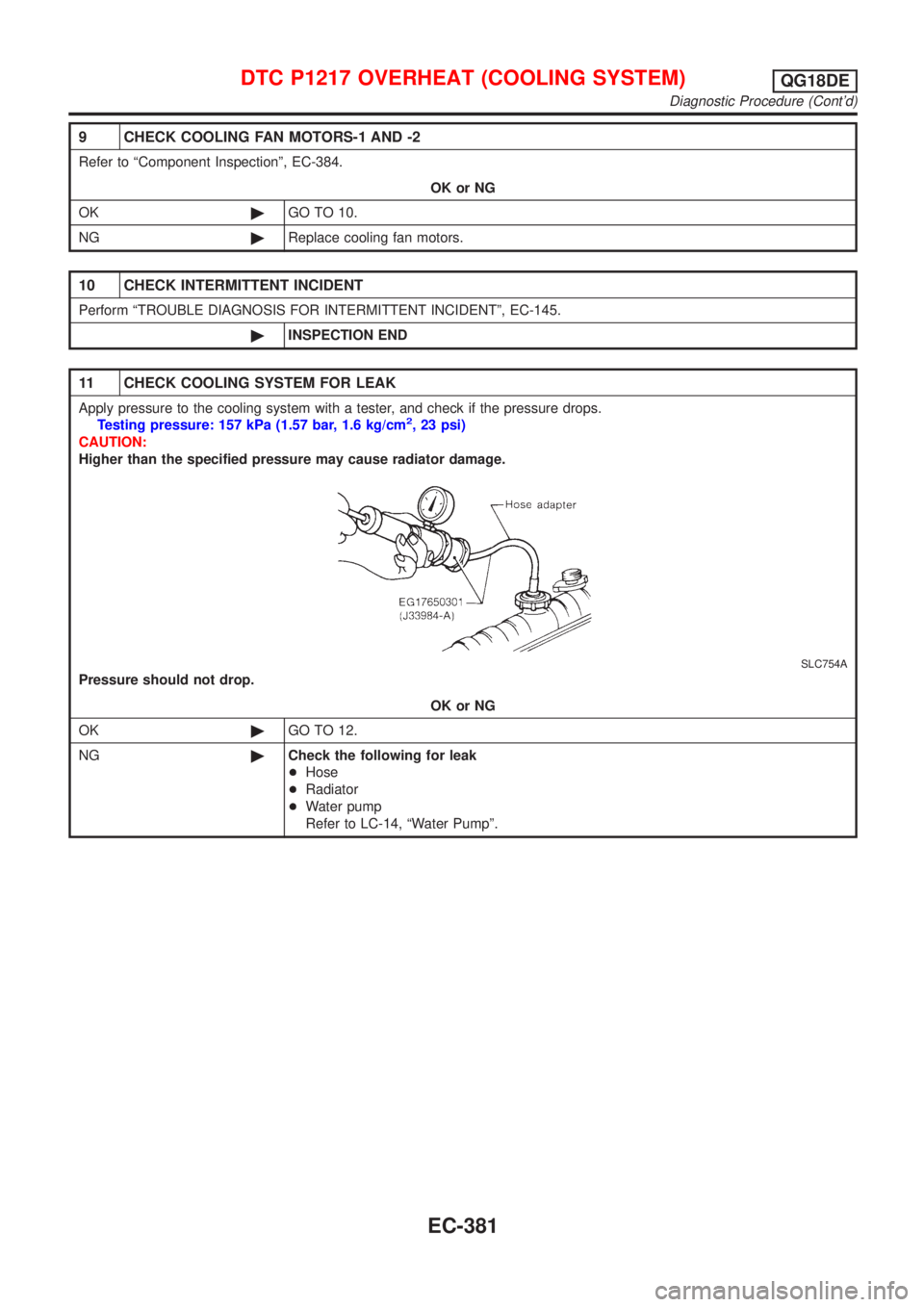

9 CHECK COOLING FAN MOTORS-1 AND -2

Refer to ªComponent Inspectionº, EC-384.

OK or NG

OK©GO TO 10.

NG©Replace cooling fan motors.

10 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-145.

©INSPECTION END

11 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 12.

NG©Check the following for leak

+Hose

+Radiator

+Water pump

Refer to LC-14, ªWater Pumpº.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure (Cont'd)

EC-381

Page 1073 of 3051

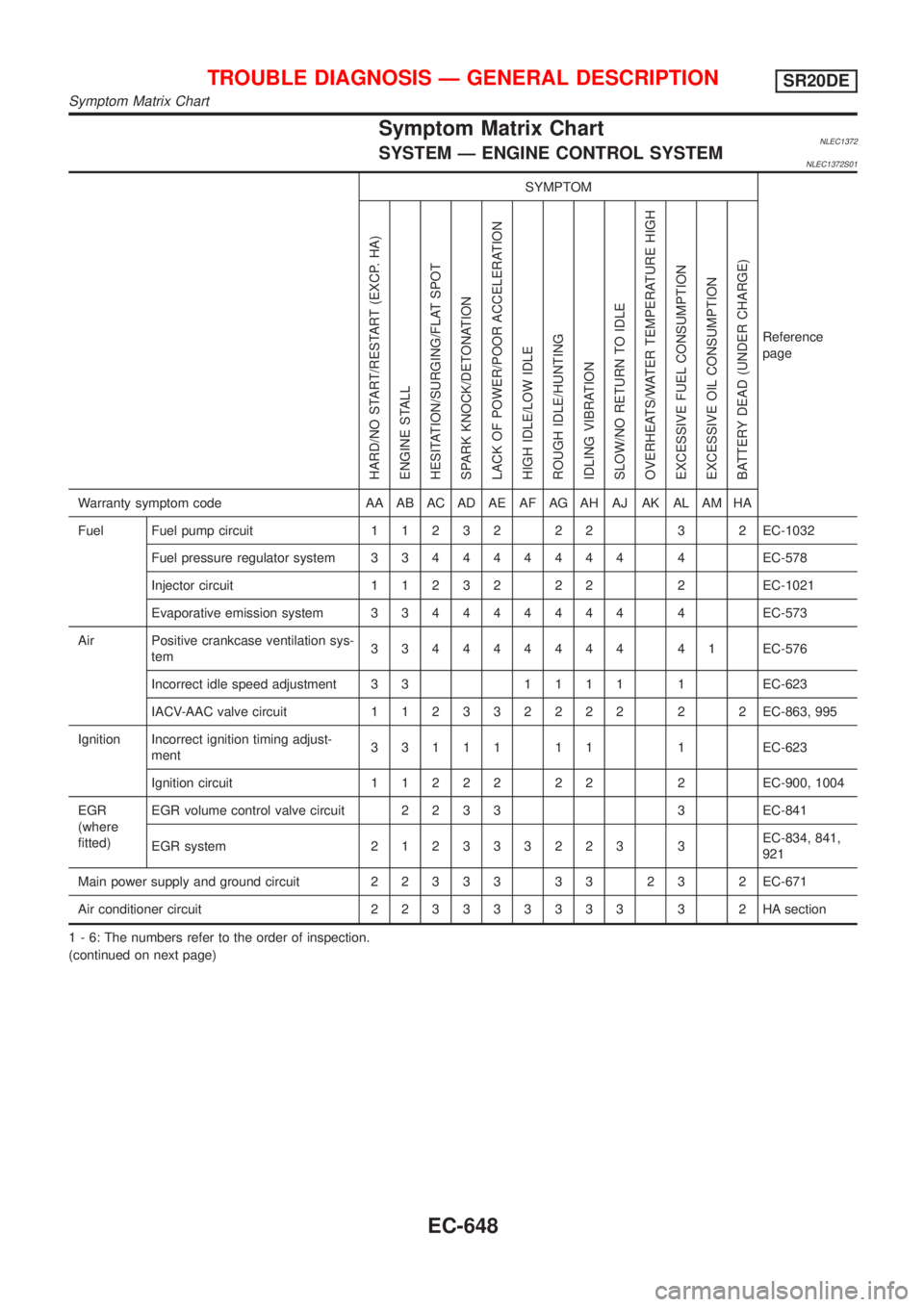

Symptom Matrix ChartNLEC1372SYSTEM Ð ENGINE CONTROL SYSTEMNLEC1372S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 22 3 2EC-1032

Fuel pressure regulator system334444444 4EC-578

Injector circuit11232 22 2EC-1021

Evaporative emission system334444444 4EC-573

Air Positive crankcase ventilation sys-

tem334444444 41EC-576

Incorrect idle speed adjustment 3 31111 1EC-623

IACV-AAC valve circuit112332222 2 2EC-863, 995

Ignition Incorrect ignition timing adjust-

ment33111 11 1EC-623

Ignition circuit11222 22 2EC-900, 1004

EGR

(where

fitted)EGR volume control valve circuit2233 3EC-841

EGR system212333223 3EC-834, 841,

921

Main power supply and ground circuit22333 33 23 2EC-671

Air conditioner circuit223333333 3 2HAsection

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

Symptom Matrix Chart

EC-648

Page 1076 of 3051

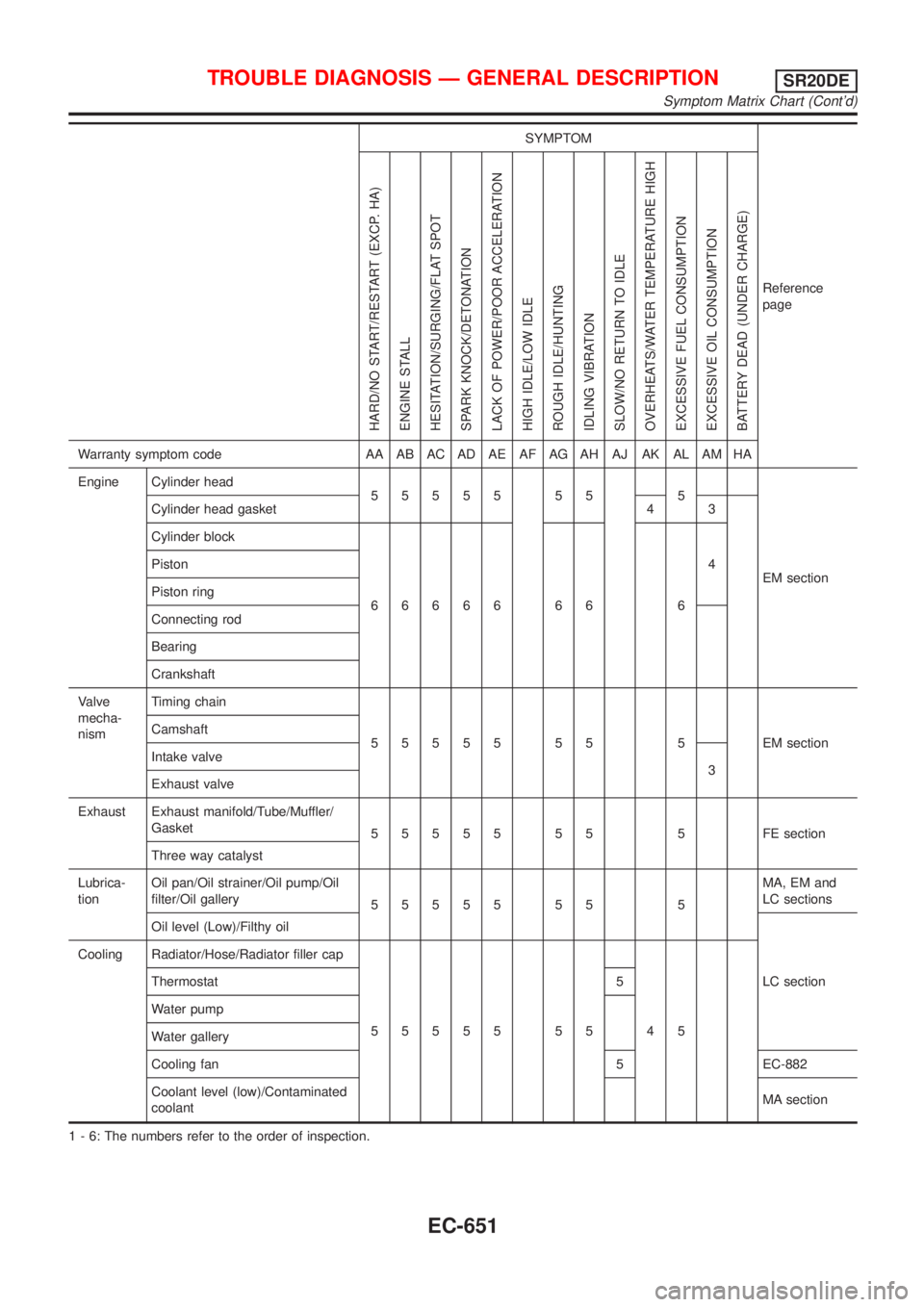

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 55 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 66 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mecha-

nismTiming chain

55555 55 5 EMsection Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5 FEsection

Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 55 5MA, EM and

LC sections

Oil level (Low)/Filthy oil

LC section Cooling Radiator/Hose/Radiator filler cap

55555 55 45 Thermostat 5

Water pump

Water gallery

Cooling fan 5 EC-882

Coolant level (low)/Contaminated

coolantMA section

1 - 6: The numbers refer to the order of inspection.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONSR20DE

Symptom Matrix Chart (Cont'd)

EC-651

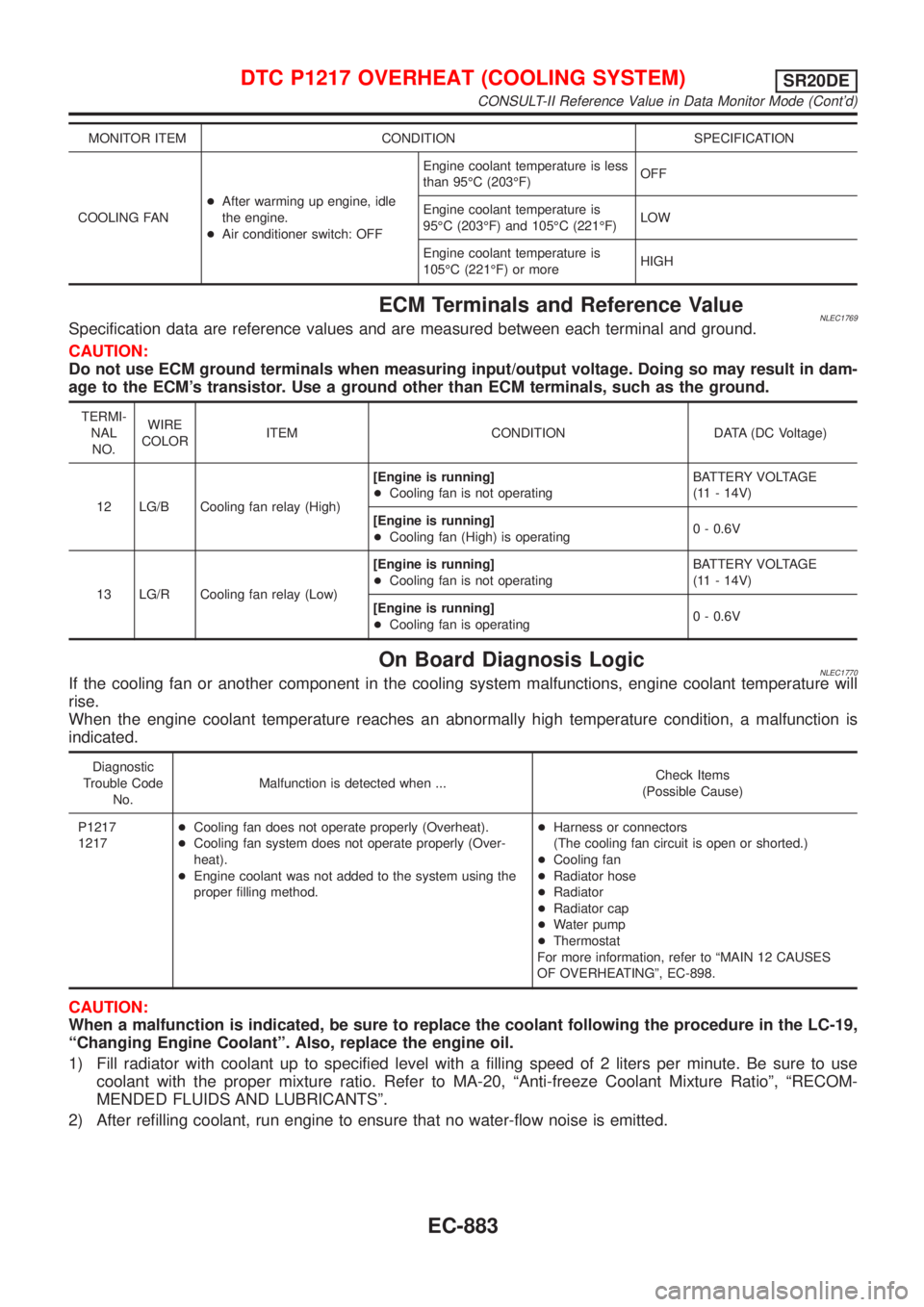

Page 1308 of 3051

MONITOR ITEM CONDITION SPECIFICATION

COOLING FAN+After warming up engine, idle

the engine.

+Air conditioner switch: OFFEngine coolant temperature is less

than 95ÉC (203ÉF)OFF

Engine coolant temperature is

95ÉC (203ÉF) and 105ÉC (221ÉF)LOW

Engine coolant temperature is

105ÉC (221ÉF) or moreHIGH

ECM Terminals and Reference ValueNLEC1769Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

12 LG/B Cooling fan relay (High)[Engine is running]

+Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Cooling fan (High) is operating0 - 0.6V

13 LG/R Cooling fan relay (Low)[Engine is running]

+Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Cooling fan is operating0 - 0.6V

On Board Diagnosis LogicNLEC1770If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Diagnostic

Trouble Code

No.Malfunction is detected when ...Check Items

(Possible Cause)

P1217

1217+Cooling fan does not operate properly (Overheat).

+Cooling fan system does not operate properly (Over-

heat).

+Engine coolant was not added to the system using the

proper filling method.+Harness or connectors

(The cooling fan circuit is open or shorted.)

+Cooling fan

+Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

For more information, refer to ªMAIN 12 CAUSES

OF OVERHEATINGº, EC-898.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the LC-19,

ªChanging Engine Coolantº. Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use

coolant with the proper mixture ratio. Refer to MA-20, ªAnti-freeze Coolant Mixture Ratioº, ªRECOM-

MENDED FLUIDS AND LUBRICANTSº.

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-883

Page 1314 of 3051

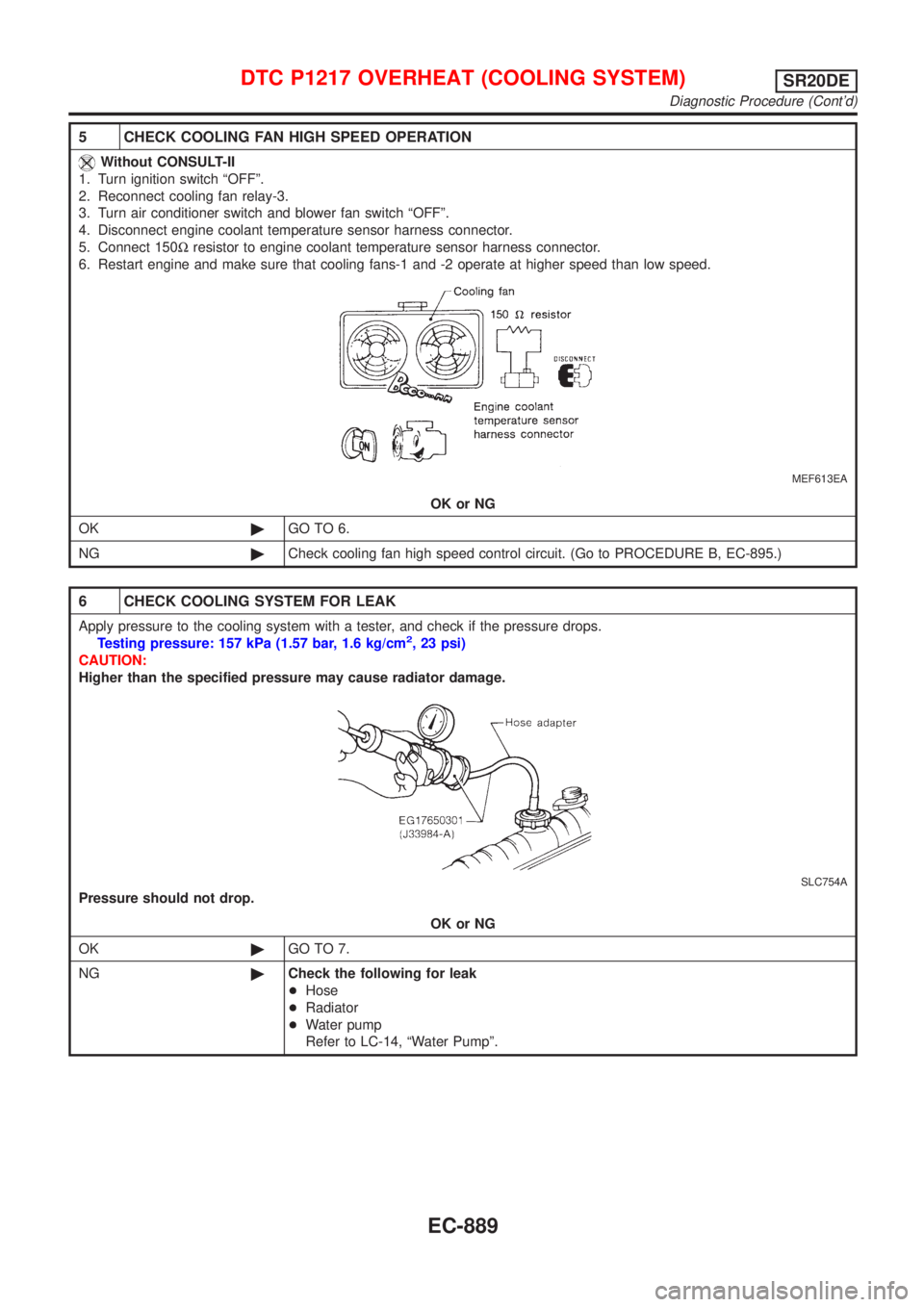

5 CHECK COOLING FAN HIGH SPEED OPERATION

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Reconnect cooling fan relay-3.

3. Turn air conditioner switch and blower fan switch ªOFFº.

4. Disconnect engine coolant temperature sensor harness connector.

5. Connect 150Wresistor to engine coolant temperature sensor harness connector.

6. Restart engine and make sure that cooling fans-1 and -2 operate at higher speed than low speed.

MEF613EA

OK or NG

OK©GO TO 6.

NG©Check cooling fan high speed control circuit. (Go to PROCEDURE B, EC-895.)

6 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 7.

NG©Check the following for leak

+Hose

+Radiator

+Water pump

Refer to LC-14, ªWater Pumpº.

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

Diagnostic Procedure (Cont'd)

EC-889

Page 1493 of 3051

SAT652J

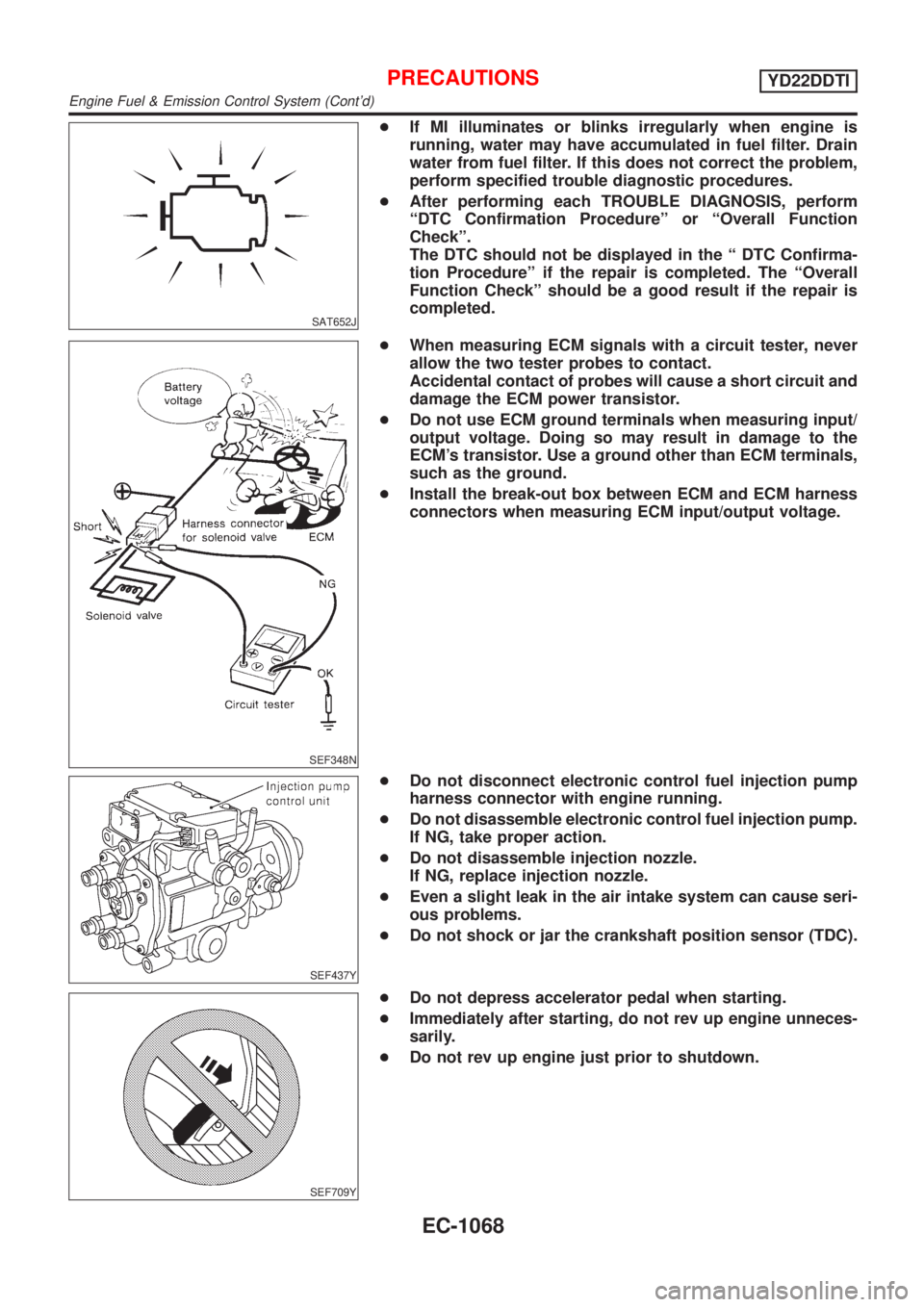

+If MI illuminates or blinks irregularly when engine is

running, water may have accumulated in fuel filter. Drain

water from fuel filter. If this does not correct the problem,

perform specified trouble diagnostic procedures.

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC Confirmation Procedureº or ªOverall Function

Checkº.

The DTC should not be displayed in the ª DTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

SEF348N

+When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

+Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than ECM terminals,

such as the ground.

+Install the break-out box between ECM and ECM harness

connectors when measuring ECM input/output voltage.

SEF437Y

+Do not disconnect electronic control fuel injection pump

harness connector with engine running.

+Do not disassemble electronic control fuel injection pump.

If NG, take proper action.

+Do not disassemble injection nozzle.

If NG, replace injection nozzle.

+Even a slight leak in the air intake system can cause seri-

ous problems.

+Do not shock or jar the crankshaft position sensor (TDC).

SEF709Y

+Do not depress accelerator pedal when starting.

+Immediately after starting, do not rev up engine unneces-

sarily.

+Do not rev up engine just prior to shutdown.

PRECAUTIONSYD22DDTI

Engine Fuel & Emission Control System (Cont'd)

EC-1068

Page 1519 of 3051

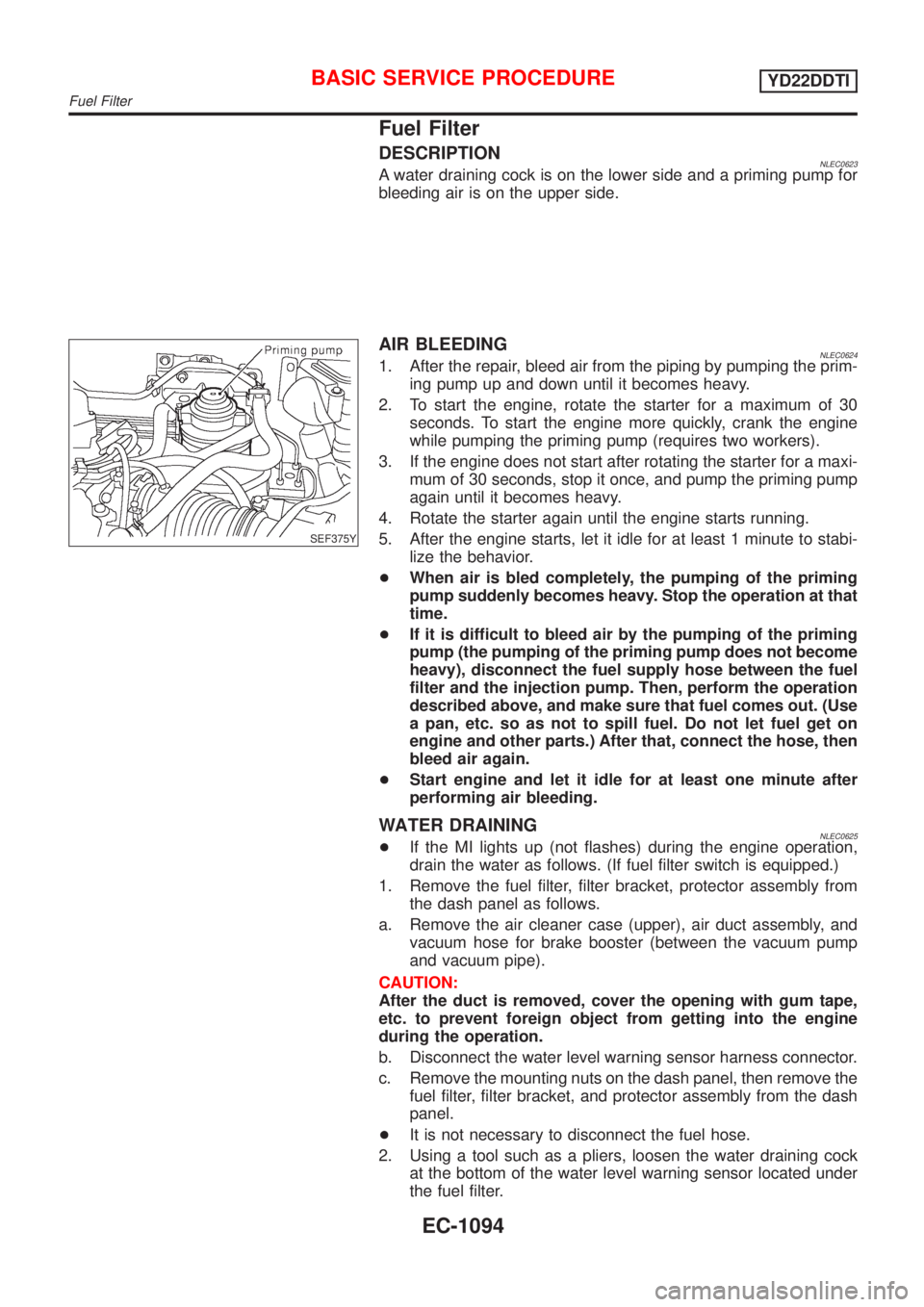

Fuel Filter

DESCRIPTIONNLEC0623A water draining cock is on the lower side and a priming pump for

bleeding air is on the upper side.

SEF375Y

AIR BLEEDINGNLEC06241. After the repair, bleed air from the piping by pumping the prim-

ing pump up and down until it becomes heavy.

2. To start the engine, rotate the starter for a maximum of 30

seconds. To start the engine more quickly, crank the engine

while pumping the priming pump (requires two workers).

3. If the engine does not start after rotating the starter for a maxi-

mum of 30 seconds, stop it once, and pump the priming pump

again until it becomes heavy.

4. Rotate the starter again until the engine starts running.

5. After the engine starts, let it idle for at least 1 minute to stabi-

lize the behavior.

+When air is bled completely, the pumping of the priming

pump suddenly becomes heavy. Stop the operation at that

time.

+If it is difficult to bleed air by the pumping of the priming

pump (the pumping of the priming pump does not become

heavy), disconnect the fuel supply hose between the fuel

filter and the injection pump. Then, perform the operation

described above, and make sure that fuel comes out. (Use

a pan, etc. so as not to spill fuel. Do not let fuel get on

engine and other parts.) After that, connect the hose, then

bleed air again.

+Start engine and let it idle for at least one minute after

performing air bleeding.

WATER DRAININGNLEC0625+If the MI lights up (not flashes) during the engine operation,

drain the water as follows. (If fuel filter switch is equipped.)

1. Remove the fuel filter, filter bracket, protector assembly from

the dash panel as follows.

a. Remove the air cleaner case (upper), air duct assembly, and

vacuum hose for brake booster (between the vacuum pump

and vacuum pipe).

CAUTION:

After the duct is removed, cover the opening with gum tape,

etc. to prevent foreign object from getting into the engine

during the operation.

b. Disconnect the water level warning sensor harness connector.

c. Remove the mounting nuts on the dash panel, then remove the

fuel filter, filter bracket, and protector assembly from the dash

panel.

+It is not necessary to disconnect the fuel hose.

2. Using a tool such as a pliers, loosen the water draining cock

at the bottom of the water level warning sensor located under

the fuel filter.

BASIC SERVICE PROCEDUREYD22DDTI

Fuel Filter

EC-1094