heating NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 52 of 3051

SAT767B

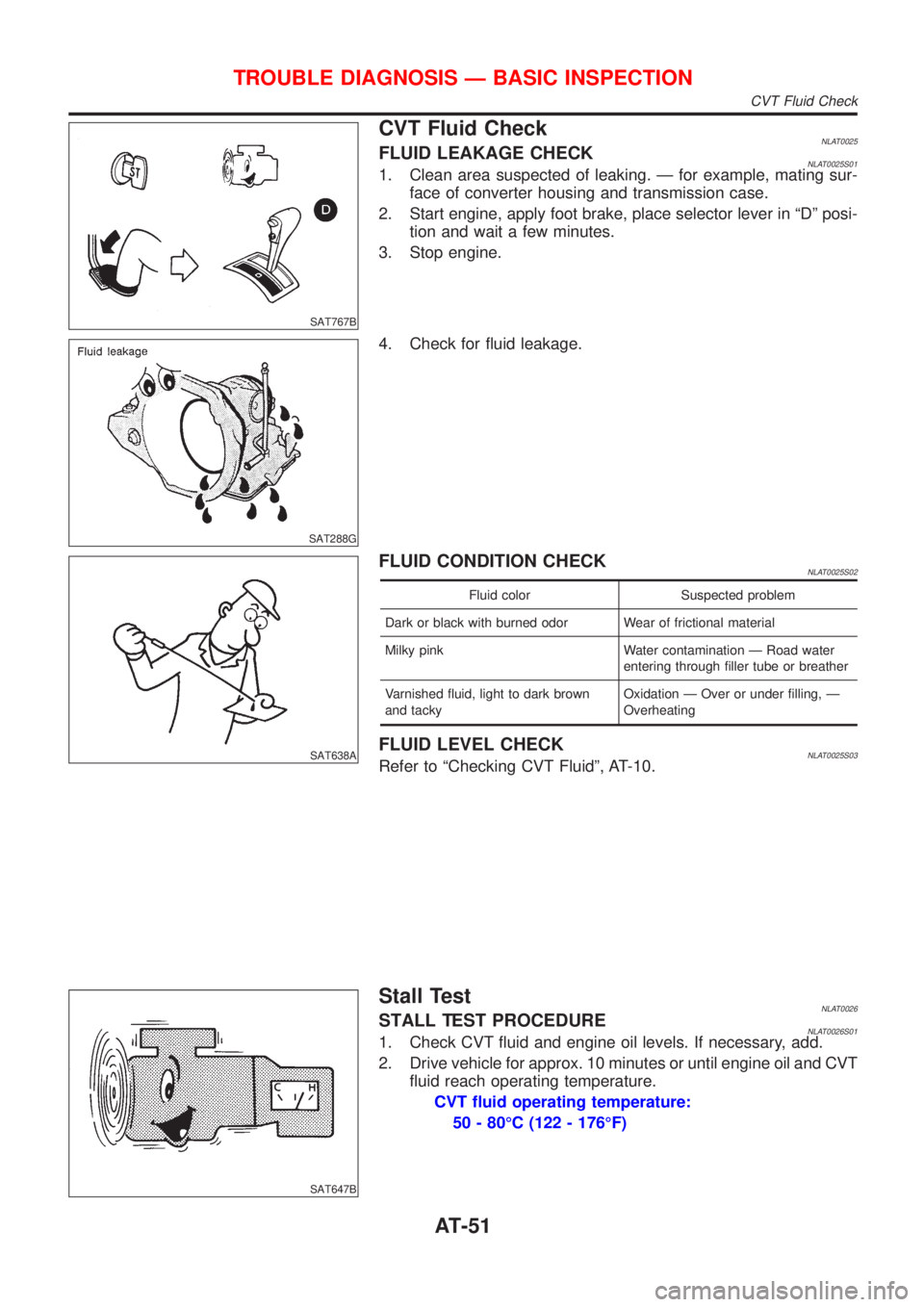

CVT Fluid CheckNLAT0025FLUID LEAKAGE CHECKNLAT0025S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

SAT288G

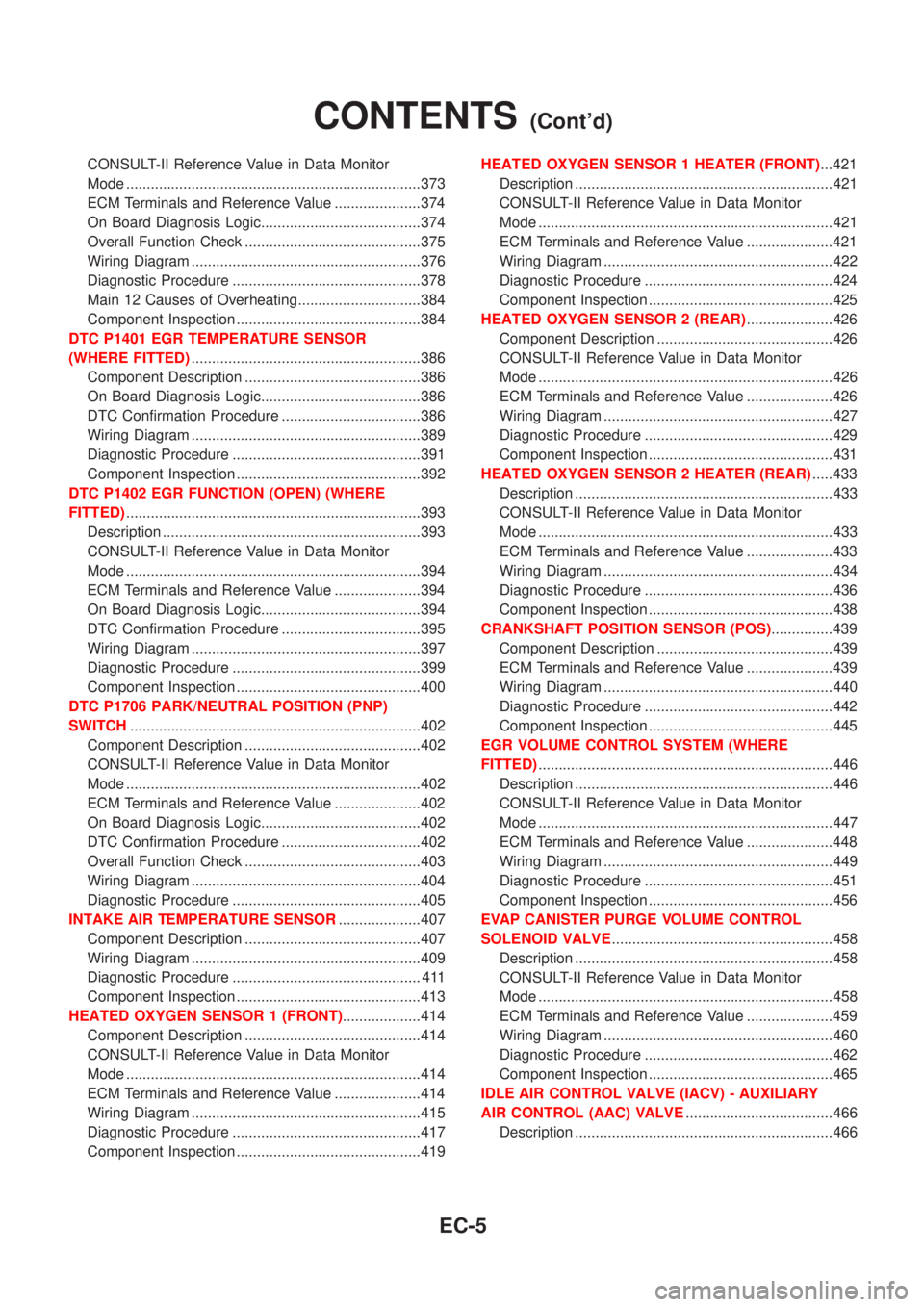

4. Check for fluid leakage.

SAT638A

FLUID CONDITION CHECKNLAT0025S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNLAT0025S03Refer to ªChecking CVT Fluidº, AT-10.

SAT647B

Stall TestNLAT0026STALL TEST PROCEDURENLAT0026S011. Check CVT fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and CVT

fluid reach operating temperature.

CVT fluid operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

CVT Fluid Check

AT-51

Page 430 of 3051

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................373

ECM Terminals and Reference Value .....................374

On Board Diagnosis Logic.......................................374

Overall Function Check ...........................................375

Wiring Diagram ........................................................376

Diagnostic Procedure ..............................................378

Main 12 Causes of Overheating..............................384

Component Inspection .............................................384

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................386

Component Description ...........................................386

On Board Diagnosis Logic.......................................386

DTC Confirmation Procedure ..................................386

Wiring Diagram ........................................................389

Diagnostic Procedure ..............................................391

Component Inspection .............................................392

DTC P1402 EGR FUNCTION (OPEN) (WHERE

FITTED)........................................................................393

Description ...............................................................393

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................394

ECM Terminals and Reference Value .....................394

On Board Diagnosis Logic.......................................394

DTC Confirmation Procedure ..................................395

Wiring Diagram ........................................................397

Diagnostic Procedure ..............................................399

Component Inspection .............................................400

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................402

Component Description ...........................................402

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................402

ECM Terminals and Reference Value .....................402

On Board Diagnosis Logic.......................................402

DTC Confirmation Procedure ..................................402

Overall Function Check ...........................................403

Wiring Diagram ........................................................404

Diagnostic Procedure ..............................................405

INTAKE AIR TEMPERATURE SENSOR....................407

Component Description ...........................................407

Wiring Diagram ........................................................409

Diagnostic Procedure .............................................. 411

Component Inspection .............................................413

HEATED OXYGEN SENSOR 1 (FRONT)...................414

Component Description ...........................................414

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................414

ECM Terminals and Reference Value .....................414

Wiring Diagram ........................................................415

Diagnostic Procedure ..............................................417

Component Inspection .............................................419HEATED OXYGEN SENSOR 1 HEATER (FRONT)...421

Description ...............................................................421

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................421

ECM Terminals and Reference Value .....................421

Wiring Diagram ........................................................422

Diagnostic Procedure ..............................................424

Component Inspection .............................................425

HEATED OXYGEN SENSOR 2 (REAR).....................426

Component Description ...........................................426

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................426

ECM Terminals and Reference Value .....................426

Wiring Diagram ........................................................427

Diagnostic Procedure ..............................................429

Component Inspection .............................................431

HEATED OXYGEN SENSOR 2 HEATER (REAR).....433

Description ...............................................................433

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................433

ECM Terminals and Reference Value .....................433

Wiring Diagram ........................................................434

Diagnostic Procedure ..............................................436

Component Inspection .............................................438

CRANKSHAFT POSITION SENSOR (POS)...............439

Component Description ...........................................439

ECM Terminals and Reference Value .....................439

Wiring Diagram ........................................................440

Diagnostic Procedure ..............................................442

Component Inspection .............................................445

EGR VOLUME CONTROL SYSTEM (WHERE

FITTED)........................................................................446

Description ...............................................................446

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................447

ECM Terminals and Reference Value .....................448

Wiring Diagram ........................................................449

Diagnostic Procedure ..............................................451

Component Inspection .............................................456

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE......................................................458

Description ...............................................................458

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................458

ECM Terminals and Reference Value .....................459

Wiring Diagram ........................................................460

Diagnostic Procedure ..............................................462

Component Inspection .............................................465

IDLE AIR CONTROL VALVE (IACV) - AUXILIARY

AIR CONTROL (AAC) VALVE....................................466

Description ...............................................................466

CONTENTS(Cont'd)

EC-5

Page 435 of 3051

Component Inspection .............................................847

DTC P0420 THREE WAY CATALYST FUNCTION...848

On Board Diagnosis Logic.......................................848

DTC Confirmation Procedure ..................................848

Overall Function Check ...........................................849

Diagnostic Procedure ..............................................849

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................852

Description ...............................................................852

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................852

ECM Terminals and Reference Value .....................853

On Board Diagnosis Logic.......................................853

DTC Confirmation Procedure ..................................853

Wiring Diagram ........................................................854

Diagnostic Procedure ..............................................856

Component Inspection .............................................857

DTC P0500 VEHICLE SPEED SENSOR (VSS).........858

Component Description ...........................................858

ECM Terminals and Reference Value .....................858

On Board Diagnosis Logic.......................................858

DTC Confirmation Procedure ..................................858

Wiring Diagram ........................................................860

Diagnostic Procedure ..............................................862

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............863

Description ...............................................................863

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................864

ECM Terminals and Reference Value .....................864

On Board Diagnosis Logic.......................................864

DTC Confirmation Procedure ..................................864

Wiring Diagram ........................................................865

Diagnostic Procedure ..............................................867

Component Inspection .............................................871

DTC P0510 CLOSED THROTTLE POSITION

SWITCH.......................................................................872

Component Description ...........................................872

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................872

ECM Terminals and Reference Value .....................872

On Board Diagnosis Logic.......................................872

DTC Confirmation Procedure ..................................872

Overall Function Check ...........................................873

Wiring Diagram ........................................................874

Diagnostic Procedure ..............................................876

Component Inspection .............................................878

DTC P0605 ECM.........................................................880

Component Description ...........................................880

On Board Diagnosis Logic.......................................880

DTC Confirmation Procedure ..................................880

Diagnostic Procedure ..............................................881DTC P1217 OVERHEAT (COOLING SYSTEM).........882

System Description ..................................................882

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................882

ECM Terminals and Reference Value .....................883

On Board Diagnosis Logic.......................................883

Overall Function Check ...........................................884

Wiring Diagram ........................................................885

Diagnostic Procedure ..............................................887

Main 12 Causes of Overheating..............................898

Component Inspection .............................................898

DTC P1320 IGNITION SIGNAL...................................900

Component Description ...........................................900

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................900

ECM Terminals and Reference Value .....................900

On Board Diagnosis Logic.......................................901

DTC Confirmation Procedure ..................................901

Wiring Diagram ........................................................903

Diagnostic Procedure ..............................................905

Component Inspection .............................................907

DTC P1336 CRANKSHAFT POSITION SENSOR

(CKPS) (OBD) (COG)..................................................909

Component Description ...........................................909

ECM Terminals and Reference Value .....................909

On Board Diagnosis Logic.......................................910

DTC Confirmation Procedure ..................................910

Wiring Diagram ........................................................ 911

Diagnostic Procedure ..............................................913

Component Inspection .............................................914

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................915

Component Description ...........................................915

On Board Diagnosis Logic.......................................915

DTC Confirmation Procedure ..................................915

Wiring Diagram ........................................................918

Diagnostic Procedure ..............................................919

Component Inspection .............................................920

DTC P1402 EGR FUNCTION (OPEN) (WHERE

FITTED)........................................................................921

Description ...............................................................921

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................922

ECM Terminals and Reference Value .....................922

On Board Diagnosis Logic.......................................922

DTC Confirmation Procedure ..................................923

Wiring Diagram ........................................................925

Diagnostic Procedure ..............................................926

DTC P1605 A/T DIAGNOSIS COMMUNICATION

LINE.............................................................................928

System Description ..................................................928

ECM Terminals and Reference Value .....................928

CONTENTS(Cont'd)

EC-10

Page 438 of 3051

TROUBLE DIAGNOSIS - INTRODUCTION.............. 1107

Introduction ............................................................ 1107

Work Flow .............................................................. 1109

TROUBLE DIAGNOSIS - BASIC INSPECTION.......1111

Basic Inspection.....................................................1111

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION........................................................... 1116

Symptom Matrix Chart ........................................... 1116

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1126

Major Sensor Reference Graph in Data Monitor

Mode ...................................................................... 1128

ECM Terminals and Reference Value ................... 1129

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT................................................................... 1135

Description ............................................................. 1135

Diagnostic Procedure ............................................ 1135

TROUBLE DIAGNOSIS FOR POWER SUPPLY...... 1136

Main Power Supply and Ground Circuit ................ 1136

DTC P0100 MASS AIR FLOW SEN......................... 1143

Component Description ......................................... 1143

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1143

ECM Terminals and Reference Value ................... 1143

On Board Diagnosis Logic..................................... 1143

DTC Confirmation Procedure ................................ 1144

Wiring Diagram ...................................................... 1145

Diagnostic Procedure ............................................ 1147

DTC P0115 COOLANT TEMP SEN.......................... 1150

Description ............................................................. 1150

On Board Diagnosis Logic..................................... 1150

DTC Confirmation Procedure ................................ 1150

Wiring Diagram ...................................................... 1152

Diagnostic Procedure ............................................ 1153

DTC P0120 ACCEL POS SENSOR.......................... 1155

Description ............................................................. 1155

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1155

ECM Terminals and Reference Value ................... 1155

On Board Diagnosis Logic..................................... 1156

DTC Confirmation Procedure ................................ 1156

Wiring Diagram ...................................................... 1157

Diagnostic Procedure ............................................ 1159

DTC P0335 CRANK POS SEN (TDC)...................... 1166

Description ............................................................. 1166

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1166

ECM Terminals and Reference Value ................... 1166

On Board Diagnosis Logic..................................... 1166

DTC Confirmation Procedure ................................ 1167

Wiring Diagram ...................................................... 1168

Diagnostic Procedure ............................................ 1169DTC P0500 VEHICLE SPEED SEN.......................... 1172

Description ............................................................. 1172

ECM Terminals and Reference Value ................... 1172

On Board Diagnosis Logic..................................... 1172

Overall Function Check ......................................... 1172

Wiring Diagram ...................................................... 1174

Diagnostic Procedure ............................................ 1176

DTC P0571 BRAKE SW............................................ 1177

Description ............................................................. 1177

ECM Terminals and Reference Value ................... 1177

On Board Diagnosis Logic..................................... 1177

DTC Confirmation Procedure ................................ 1177

Wiring Diagram ...................................................... 1179

Diagnostic Procedure ............................................ 1181

DTC P1107 ECM 10.................................................. 1185

Description ............................................................. 1185

On Board Diagnosis Logic..................................... 1185

DTC Confirmation Procedure ................................ 1185

Diagnostic Procedure ............................................ 1186

DTC P1180 P9.FUEL TEMP SEN............................. 1187

Description ............................................................. 1187

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1187

ECM Terminals and Reference Value ................... 1188

On Board Diagnosis Logic..................................... 1188

DTC Confirmation Procedure ................................ 1188

Wiring Diagram ...................................................... 1190

Diagnostic Procedure ............................................ 1192

DTC P1202 FUEL CUT SYSTEM2........................... 1194

Description ............................................................. 1194

CONSULT-II Reference Value in Data Monitor

Mode ...................................................................... 1194

ECM Terminals and Reference Value ................... 1195

On Board Diagnosis Logic..................................... 1195

DTC Confirmation Procedure ................................ 1195

Wiring Diagram ...................................................... 1197

Diagnostic Procedure ............................................ 1199

DTC P1217 OVER HEAT..........................................1201

Description .............................................................1201

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1201

ECM Terminals and Reference Value ...................1201

On Board Diagnosis Logic.....................................1202

Overall Function Check .........................................1203

Wiring Diagram ......................................................1204

Diagnostic Procedure ............................................1206

Main 12 Causes of Overheating............................1217

DTC P1241 P7.F/INJ TIMG FB.................................1218

Description .............................................................1218

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................1218

ECM Terminals and Reference Value ...................1219

CONTENTS(Cont'd)

EC-13

Page 710 of 3051

On Board Diagnosis LogicNLEC0202When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the CKP

sensor signal to vary, the ECM can determine that a misfire is occurring.

Sensor Input Signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the first trip that a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MI will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level that will not damage the TWC, the MI will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MI will blink.

When the misfire condition decreases to a level that will not damage the TWC, the MI will remain on.

If another misfire condition occurs that can damage the TWC, the MI will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MI will only light

when the misfire is detected on a second trip. During this condition, the ECM monitors the CKP sensor

signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0300

0300+Multiple cylinders misfire.+Improper spark plug

+Insufficient compression

+Incorrect fuel pressure

+EGR volume control valve

+The injector circuit is open or shorted

+Injectors

+Intake air leak

+Insufficient ignition spark

+Lack of fuel

+Heated oxygen sensor 1 (front) P0301

0301+No. 1 cylinder misfires.

P0302

0302+No. 2 cylinder misfires.

P0303

0303+No. 3 cylinder misfires.

P0304

0304+No. 4 cylinder misfires.

SEF058Y

DTC Confirmation ProcedureNLEC0203CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº, and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and warm it up to normal operating temperature.

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

QG18DE

On Board Diagnosis Logic

EC-285

Page 799 of 3051

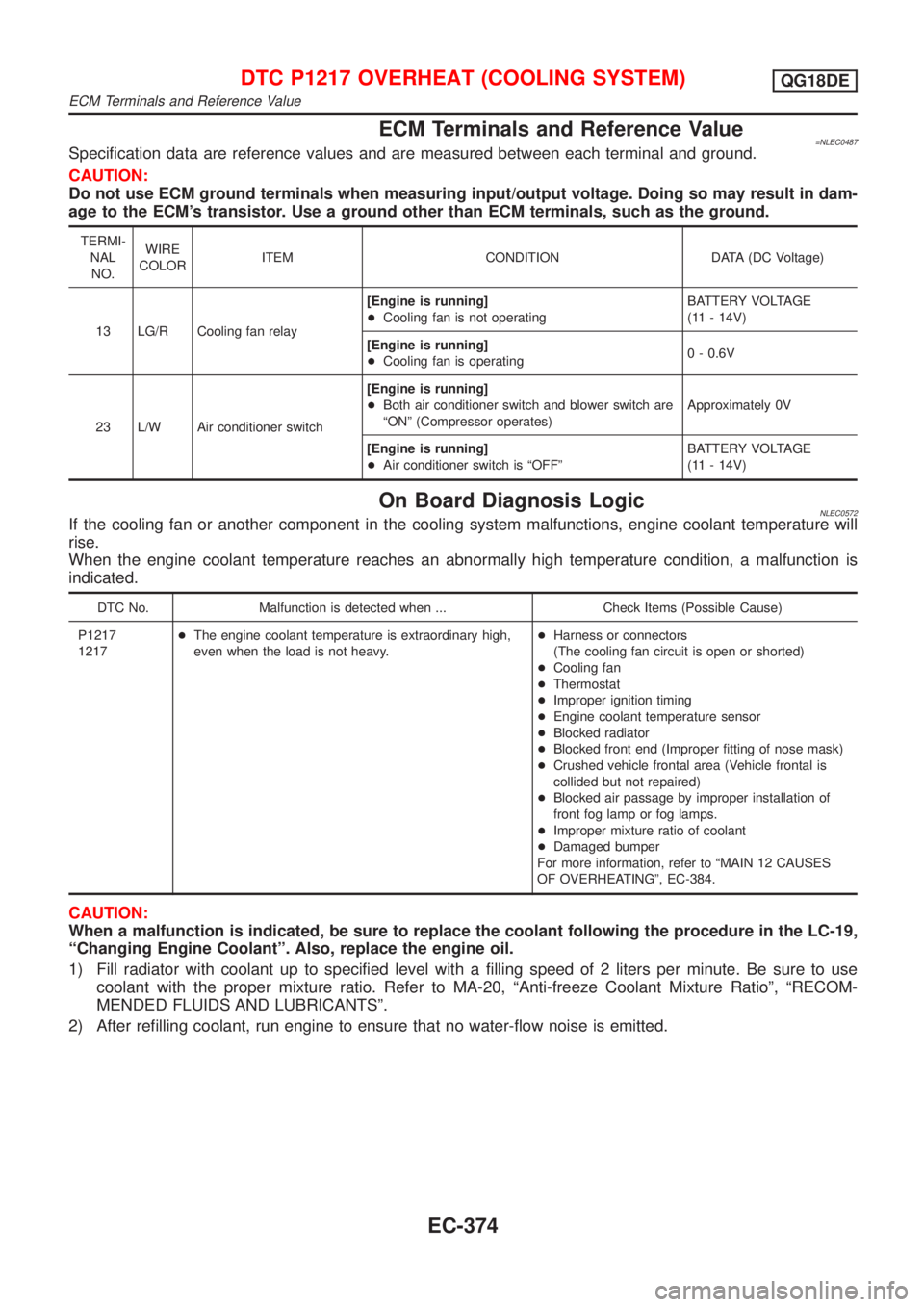

ECM Terminals and Reference Value=NLEC0487Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

13 LG/R Cooling fan relay[Engine is running]

+Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Cooling fan is operating0 - 0.6V

23 L/W Air conditioner switch[Engine is running]

+Both air conditioner switch and blower switch are

ªONº (Compressor operates)Approximately 0V

[Engine is running]

+Air conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNLEC0572If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1217

1217+The engine coolant temperature is extraordinary high,

even when the load is not heavy.+Harness or connectors

(The cooling fan circuit is open or shorted)

+Cooling fan

+Thermostat

+Improper ignition timing

+Engine coolant temperature sensor

+Blocked radiator

+Blocked front end (Improper fitting of nose mask)

+Crushed vehicle frontal area (Vehicle frontal is

collided but not repaired)

+Blocked air passage by improper installation of

front fog lamp or fog lamps.

+Improper mixture ratio of coolant

+Damaged bumper

For more information, refer to ªMAIN 12 CAUSES

OF OVERHEATINGº, EC-384.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the LC-19,

ªChanging Engine Coolantº. Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use

coolant with the proper mixture ratio. Refer to MA-20, ªAnti-freeze Coolant Mixture Ratioº, ªRECOM-

MENDED FLUIDS AND LUBRICANTSº.

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

ECM Terminals and Reference Value

EC-374

Page 808 of 3051

15 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-384.

©INSPECTION END

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Diagnostic Procedure (Cont'd)

EC-383

Page 809 of 3051

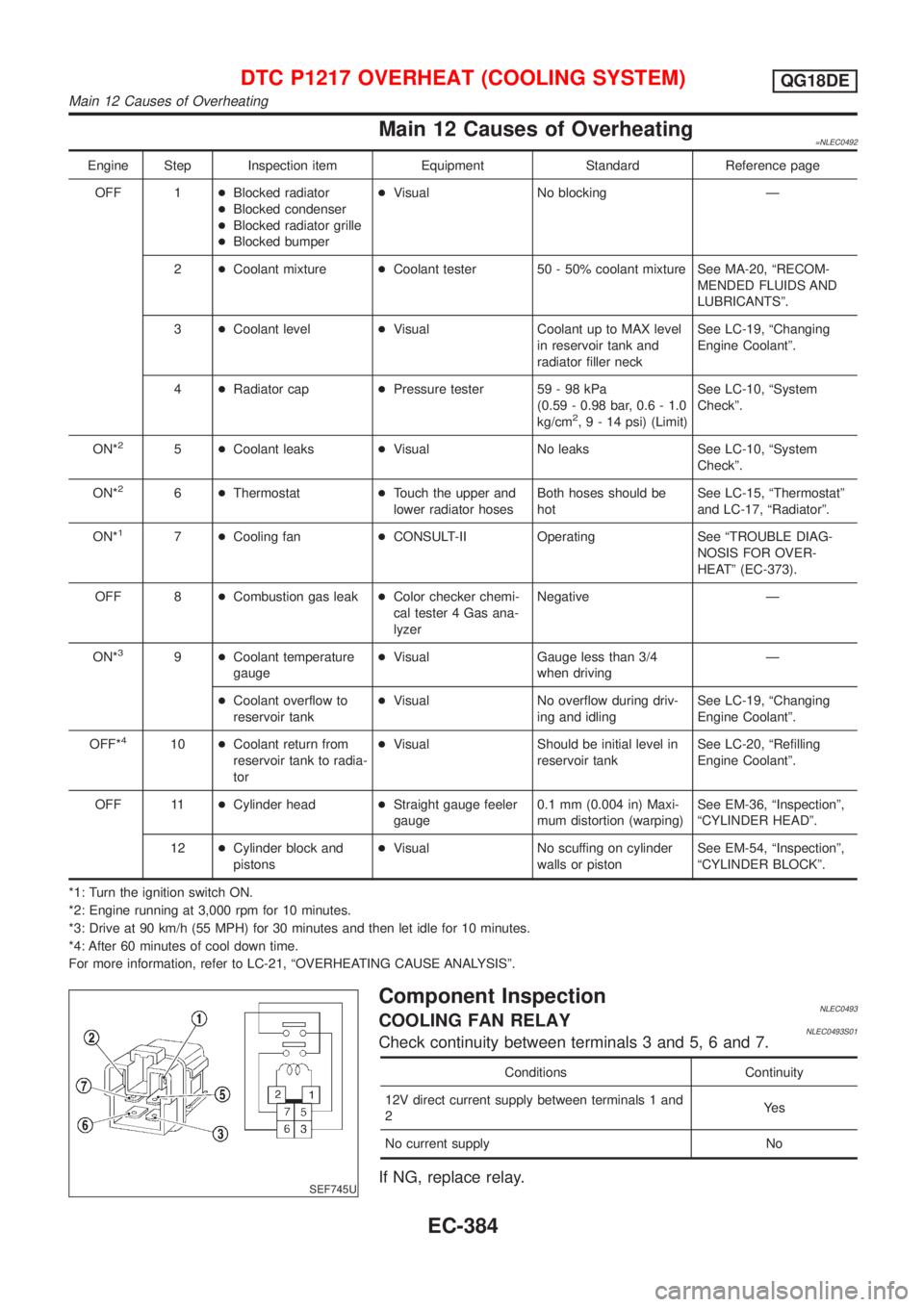

Main 12 Causes of Overheating=NLEC0492

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 50 - 50% coolant mixture See MA-20, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee LC-19, ªChanging

Engine Coolantº.

4+Radiator cap+Pressure tester 59 - 98 kPa

(0.59 - 0.98 bar, 0.6 - 1.0

kg/cm

2,9-14psi) (Limit)See LC-10, ªSystem

Checkº.

ON*

25+Coolant leaks+Visual No leaks See LC-10, ªSystem

Checkº.

ON*

26+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-15, ªThermostatº

and LC-17, ªRadiatorº.

ON*

17+Cooling fan+CONSULT-II Operating See ªTROUBLE DIAG-

NOSIS FOR OVER-

HEATº (EC-373).

OFF 8+Combustion gas leak+Color checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to

reservoir tank+Visual No overflow during driv-

ing and idlingSee LC-19, ªChanging

Engine Coolantº.

OFF*

410+Coolant return from

reservoir tank to radia-

tor+Visual Should be initial level in

reservoir tankSee LC-20, ªRefilling

Engine Coolantº.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-36, ªInspectionº,

ªCYLINDER HEADº.

12+Cylinder block and

pistons+Visual No scuffing on cylinder

walls or pistonSee EM-54, ªInspectionº,

ªCYLINDER BLOCKº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC-21, ªOVERHEATING CAUSE ANALYSISº.

SEF745U

Component InspectionNLEC0493COOLING FAN RELAYNLEC0493S01Check continuity between terminals 3 and 5, 6 and 7.

Conditions Continuity

12V direct current supply between terminals 1 and

2Ye s

No current supply No

If NG, replace relay.

DTC P1217 OVERHEAT (COOLING SYSTEM)QG18DE

Main 12 Causes of Overheating

EC-384

Page 1233 of 3051

On Board Diagnosis LogicNLEC1752When a misfire occurs, engine speed will fluctuate (vary). If the engine speed fluctuates enough to cause the

CKP sensor to vary, ECM can detect a misfire.

Sensor Input Signal to ECM ECM function

Crankshaft position sensor (OBD) Engine speed On board diagnosis of misfire

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the first rip that a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MI will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor (OBD) signal every 200 engine revo-

lutions for a change.

When the misfire condition decreases to a level that will not damage the TWC, the MI will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MI will blink.

When the misfire condition decreases to a level that will not damage the TWC, the MI will remain on.

If another misfire condition occurs that can damage the TWC, the MI will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not cause damage to the TWC (but will affect vehicle emissions), the MI

will only light when the misfire is detected on a second trip. During this condition, the ECM monitors the

CKP sensor (OBD) signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on-multiple cylinders.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0300+Multiple cylinders misfire.+Improper spark plug

+Insufficient compression

+Incorrect fuel pressure

+EGR volume control valve

+The injector circuit is open or shorted

+Injectors

+Intake air leak

+The ignition secondary circuit is open or shorted

+Lack of fuel

+Drive plate

+Heated oxygen sensor 1 (front)

+Incorrect distributor roter P0301+No. 1 cylinder misfires.

P0302+No. 2 cylinder misfires.

P0303+No. 3 cylinder misfires.

P0304+No. 4 cylinder misfires.

SEF058Y

DTC Confirmation ProcedureNLEC1522CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº, and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Start engine again and drive at 1,500 - 3,000 rpm for at least

3 minutes.

Hold the accelerator pedal as steady as possible.

NOTE:

Refer to the freeze frame data for the test driving conditions.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-809.

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

SR20DE

On Board Diagnosis Logic

EC-808

Page 1308 of 3051

MONITOR ITEM CONDITION SPECIFICATION

COOLING FAN+After warming up engine, idle

the engine.

+Air conditioner switch: OFFEngine coolant temperature is less

than 95ÉC (203ÉF)OFF

Engine coolant temperature is

95ÉC (203ÉF) and 105ÉC (221ÉF)LOW

Engine coolant temperature is

105ÉC (221ÉF) or moreHIGH

ECM Terminals and Reference ValueNLEC1769Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

12 LG/B Cooling fan relay (High)[Engine is running]

+Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Cooling fan (High) is operating0 - 0.6V

13 LG/R Cooling fan relay (Low)[Engine is running]

+Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Cooling fan is operating0 - 0.6V

On Board Diagnosis LogicNLEC1770If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Diagnostic

Trouble Code

No.Malfunction is detected when ...Check Items

(Possible Cause)

P1217

1217+Cooling fan does not operate properly (Overheat).

+Cooling fan system does not operate properly (Over-

heat).

+Engine coolant was not added to the system using the

proper filling method.+Harness or connectors

(The cooling fan circuit is open or shorted.)

+Cooling fan

+Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

For more information, refer to ªMAIN 12 CAUSES

OF OVERHEATINGº, EC-898.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the LC-19,

ªChanging Engine Coolantº. Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to use

coolant with the proper mixture ratio. Refer to MA-20, ªAnti-freeze Coolant Mixture Ratioº, ªRECOM-

MENDED FLUIDS AND LUBRICANTSº.

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC P1217 OVERHEAT (COOLING SYSTEM)SR20DE

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-883