brakes NISSAN ALTIMA 1997 U13 / 1.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1997, Model line: ALTIMA, Model: NISSAN ALTIMA 1997 U13 / 1.GPages: 203, PDF Size: 1.64 MB

Page 14 of 203

2. If the brake fluid level is correct, have the

warning system checked by your NIS-

SAN dealer.

WARNING

cYour brake system may not be work-

ing properly if the warning light is

on. Driving could be dangerous. If

you judge it to be safe, drive care-

fully to the nearest service station

for repairs. Otherwise, have your ve-

hicle towed.

cPressing the brake pedal with the

engine stopped and/or low brake

fluid level may increase your stop-

ping distance and braking will re-

quire greater pedal effort as well as

greater pedal travel.

cIf the brake fluid level is below the

minimum mark on the brake fluid

reservoir, do not drive until the brake

system has been checked at a NIS-

SAN dealer.

Brake pad wear warning

The disc brake pads have audible wear

warnings. When a brake pad requires re-

placement, it makes a high pitched scrapingsound when the vehicle is in motion,

whether or not the brake pedal is de-

pressed. Have the brakes checked as soon

as possible if the warning sound is heard.

orAnti-lock brake

warning light

(If so equipped)

If the light comes on while the engine is

running, it may indicate something wrong with

the anti-lock portion of the brake system. Have

the system checked by your NISSAN dealer.

Turn off the engine, and start it again by

slowly turning the ignition key (quickly

doing so may cause the ABS light to stay

on when there is nothing wrong). If the

light stays on, have the system checked

by your NISSAN dealer.

If an abnormality occurs in the system, the

anti-lock function ceases but the regular

braking system continues to operate.

If the light comes on while you are driving,

contact your NISSAN dealer for repair.

Overdrive off indicator light

(Automatic transmission

models only)

This light comes on when the overdrive

switch is pushed to the OFF position.

Turn signal/hazard indicator

lights

The appropriate light flashes when the turn

signal switch is activated.

Both lights flash when the hazard switch is

turned on.

High beam indicator light

This light comes on when the headlight high

beam is on and goes out when the low

beam is selected.

Rear window defogger indi-

cator light

This light comes on when the rear defogger

switch is activated.

Cruise indicator light

This light comes on while the vehicle speed

is controlled by the cruise control system. If

the CRUISE indicator blinks, have the sys-

1-7

ZX

Page 108 of 203

WARNING

cNever leave the engine running while

the vehicle is unattended.

cNever leave children unattended in

the vehicle.The power assisted steering is designed to

use a hydraulic pump, driven by the engine,

to assist steering.

If the engine stops or drive belt breaks, you

will still have control of the vehicle. How-

ever, much greater steering effort is

needed, especially in sharp turns or at low

speeds.The brake system has two separate

hydraulic circuits. If one circuit develops a

problem, you will still have braking at two

wheels.

Vacuum assisted brake

The brake booster aids braking by using

engine vacuum. If the engine stops, you can

stop the vehicle by depressing the brake

pedal. However, greater foot pressure on

the brake pedal will be required to stop the

vehicle and the stopping distance will be

longer.

Wet brakes

When the vehicle is washed or driven

through water, the brakes may get wet. As a

result, your braking distance will be longer

and the vehicle may pull to one side during

braking.

To dry brakes, drive the vehicle at a safe

speed while lightly pressing the brake pedal

to heat-up the brakes. Do this until the

brakes return to normal. Avoid driving the

vehicle at high speeds until the brakes

function correctly.

Using the brakes

Avoid resting your foot on the brake pedal

POWER STEERING SYSTEM BRAKE SYSTEM

4-16

ZX

Page 109 of 203

while driving. This overheats the brakes,

increases wear on the brake linings and

pads, and reduces gas mileage.

To help save the brakes and to prevent the

brakes from overheating, reduce speed and

downshift to a lower gear before going down

a slope or long grade. Overheated brakes

may reduce braking performance and could

result in loss of vehicle control.

WARNING

While driving on a slippery surface, be

careful when braking, accelerating or

downshifting. Abrupt braking or accel-

erating could cause the wheels to skid

and result in an accident.The anti-lock brake system installed in

some models controls the brakes at each

wheel so the wheels do not lock when

braking abruptly or when braking on slip-

pery surfaces. The system detects the rota-

tion speed at each wheel and varies the

brake fluid pressure to prevent each wheel

from locking and sliding. By preventing

wheel lockup, the system helps the driver

maintain steering control and helps to mini-

mize swerving and spinning on slippery

surfaces.

Using the System

Depress the brake pedal and hold it down.

WARNING

Do not pump the brake pedal. Doing so

may result in increased stopping dis-

tances.

Normal operation

The anti-lock brake system does not oper-

ate at speeds below 3 to 6 MPH (5 to 10

km/h) to completely stop the vehicle. (The

speeds vary according to road conditions.)

When the anti-lock system senses that one

or more wheels are close to locking up, theactuator (under the hood) rapidly applies

and releases hydraulic pressure (like pump-

ing the brakes very quickly). While the ac-

tuator is working, you may feel a pulsation in

the brake pedal and hear a noise or vibra-

tion from the actuator under the hood. This

is normal and indicates that the anti-lock

system is working properly. However, the

pulsation may indicate that road conditions

are hazardous and extra care is required

while driving.

Self-test feature

The anti-lock brake system is sophisticated,

with electronic sensors, electric pumps, and

hydraulic solenoids controlled by a com-

puter. The computer has a built-in diagnos-

tic feature that tests the system each time

you start the engine and move the vehicle at

a low speed in forward or reverse. When the

self-test occurs, you may hear a ``clunk''

noise and/or feel a pulsation in the brake

pedal. This is normal and is not an indica-

tion of any malfunction. If the computer

senses any malfunction, it switches the anti-

lock brake system OFF and turns on the

ABS brake warning light in the dashboard.

The brake system then operates normally,

but without anti-lock assistance.

ANTI-LOCK BRAKE SYSTEM

(ABS) (If so equipped)

4-17

ZX

Page 148 of 203

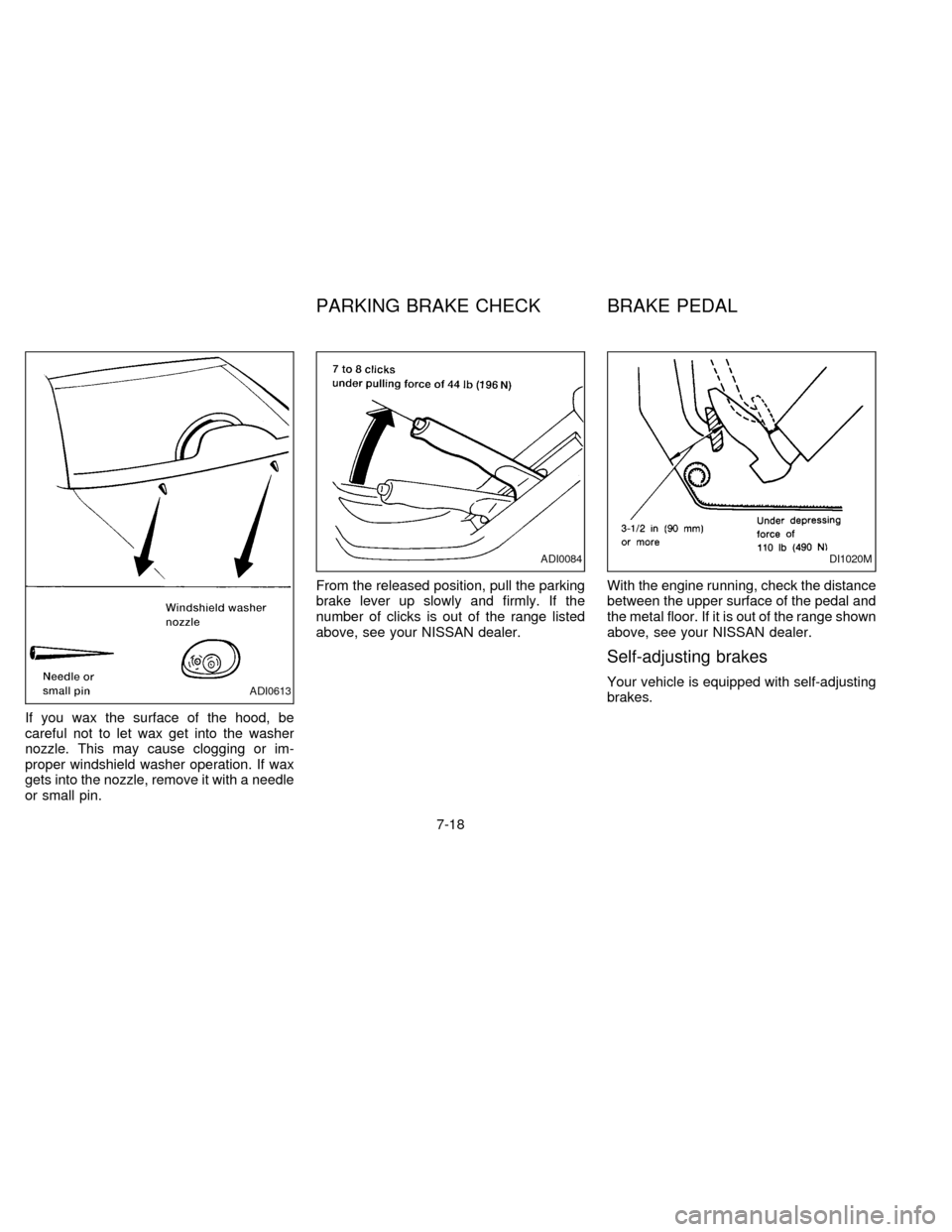

If you wax the surface of the hood, be

careful not to let wax get into the washer

nozzle. This may cause clogging or im-

proper windshield washer operation. If wax

gets into the nozzle, remove it with a needle

or small pin.From the released position, pull the parking

brake lever up slowly and firmly. If the

number of clicks is out of the range listed

above, see your NISSAN dealer.With the engine running, check the distance

between the upper surface of the pedal and

the metal floor. If it is out of the range shown

above, see your NISSAN dealer.

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.ADI0613

ADI0084DI1020M

PARKING BRAKE CHECK BRAKE PEDAL

7-18

ZX

Page 149 of 203

The front (and rear, if equipped) disc-type

brakes self-adjust every time the brake

pedal is applied. The rear drum- type brakes

also self-adjust every time the brake pedal

is applied.

If the brake pedal goes down farther than

normal, it may be due to a lack of adjust-

ment of the rear drum brakes. Apply the

parking brake several times.

WARNING

See your NISSAN dealer and have it

checked if the brake pedal height does

not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it makes a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear

indicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brakenoise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise from

the rear drum brakes, have them inspected

as soon as possible by your NISSAN

dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance Schedule'' section of this

manual.Check the brake booster function as fol-

lows:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to the

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keep the pedal depressed for

about 30 seconds. The pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, see

your NISSAN dealer.

BRAKE BOOSTER

7-19

ZX

Page 167 of 203

Tire rotation*Ð Tires should be rotated

every 7,500 miles (12,000 km).

Wheel alignment and balanceÐIfthe

vehicle should pull to either side while driv-

ing on a straight and level road, or if you

detect uneven or abnormal tire wear, there

may be a need for wheel alignment.

If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing

may be needed.

Windshield wiper blades*Ð Check for

cracks or wear if they do not wipe properly.

Doors and engine hoodÐ Check that all

doors and the engine hood operate prop-

erly. Also ensure all latches lock securely.

Lubricate hinges, latches, rollers and links if

necessary. Make sure the secondary latch

keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or

other corrosive materials, check lubrication

frequently.

Lights*Ð Make sure the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and installed

securely. Also check headlight aim.INSIDE THE VEHICLE

The maintenance items listed here should

be checked on a regular basis, such as

when performing periodic maintenance,

cleaning the vehicle, etc.

Warning lights and chimesÐ Make sure

all warning lights and buzzers/chimes are

operating properly.

Windshield wiper and washer*Ð Check

that the wipers and washer operate properly

and that the wipers do not streak.

Windshield defrosterÐ Check that the air

comes out of the defroster outlets properly

and in sufficient quantity when operating the

heater or air conditioner.

Steering wheelÐ Check for changes in

the steering conditions, such as excessive

freeplay, hard steering or strange noises.

SeatsÐ Check seat position controls such

as seat adjusters, seatback recliner, etc. to

ensure they operate smoothly and all

latches lock securely in every position.

Check that the head restraints move up and

down smoothly and the locks (if so

equipped) hold securely in all latched posi-

tions.Seat beltsÐ Check that all parts of the seat

belt system (for example, buckles, anchors,

adjusters and retractors) operate properly

and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying,

wear or damage.

Accelerator pedalÐ Check the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort.

Keep the floor mats away from the pedal.

Clutch pedal*Ð Make sure the pedal

operates smoothly and check that it has the

proper free travel.

BrakesÐ Check that the brakes do not pull

the vehicle to one side when applied.

Brake pedal*Ð Check the pedal for

smooth operation and make sure it has the

proper distance under it when depressed

fully. Check the brake booster function. Be

certain to keep floor mats away from the

pedal.

Parking brake*Ð Check that the lever has

the proper travel and confirm that your

vehicle is held securely on a fairly steep hill

with only the parking brake applied.

8-3

ZX

Page 168 of 203

Automatic transmission ``Park'' mecha-

nismÐ On a fairly steep hill check that your

vehicle is held securely with the gearshift

lever in the P position without applying any

brakes.

UNDER THE HOOD AND

VEHICLE

The maintenance items listed here should

be checked periodically, such as each time

you check the engine oil or refuel.

Additional information on the items

marked with ª*º can be found in the

ªDo-It-Yourself operationsº section.

Windshield washer fluid*Ð Check that

there is adequate fluid in the tank.

Engine coolant level*Ð Check the cool-

ant level when the engine is cold.

Radiator and hosesÐ Check the front of

the radiator and clean off any dirt, insects,

leaves, etc., that may have accumulated.

Make sure the hoses have no cracks, de-

formation, rot or loose connections.

Brake and clutch fluid levels*Ð Make

sure that the brake and clutch fluid level is

between the MAX and MIN lines on the

reservoir.Battery*Ð Check the fluid level in each

cell. It should be between the MAX and MIN

lines.

Engine drive belts*Ð Make sure that no

belt is frayed, worn, cracked or oily.

Engine oil level*Ð Check the level after

parking the vehicle on a level spot and

turning off the engine. Wait a few minutes

for the oil to drain back into the oil pan.

Power steering fluid level* and linesÐ

Check the level when the fluid is cold and

the engine is turned off. Check the lines for

proper attachment, leaks, cracks, etc.

Automatic transmission fluid level*Ð

Check the level after putting the shift lever in

P with the engine idling.

Exhaust systemÐ Make sure there are no

cracks, holes, loose joints or supports. If the

sound of the exhaust seems unusual or

there is a smell of exhaust fumes, immedi-

ately have the exhaust system inspected by

a qualified individual. (See the carbon mon-

oxide warning in the ``Starting and driving''

section.)

UnderbodyÐ The underbody is frequently

exposed to corrosive substances such asthose used on icy roads or to control dust. It

is very important to remove these sub-

stances, otherwise rust forms on the floor

pan, frame, fuel lines and around the ex-

haust system. At the end of winter, the

underbody should be thoroughly flushed

with plain water, being careful to clean

those areas where mud and dirt may accu-

mulate. See the ``Appearance and interior

care'' section for additional information.

Fluid leaksÐ Check under the vehicle for

fuel, oil, water or other fluid leaks after the

vehicle has been parked for a while. Water

dripping from the air conditioner after use is

normal. If you should notice any leaks or if

gasoline fumes are evident, check for the

cause and have it corrected immediately.

8-4

ZX

Page 191 of 203

hitch, trailer tongue load and any other

optional equipment. In addition, front or rear

gross axle weight must not exceed the

gross axle weight rating (GAWR) shown on

the F.M.V.S.S. certification label.

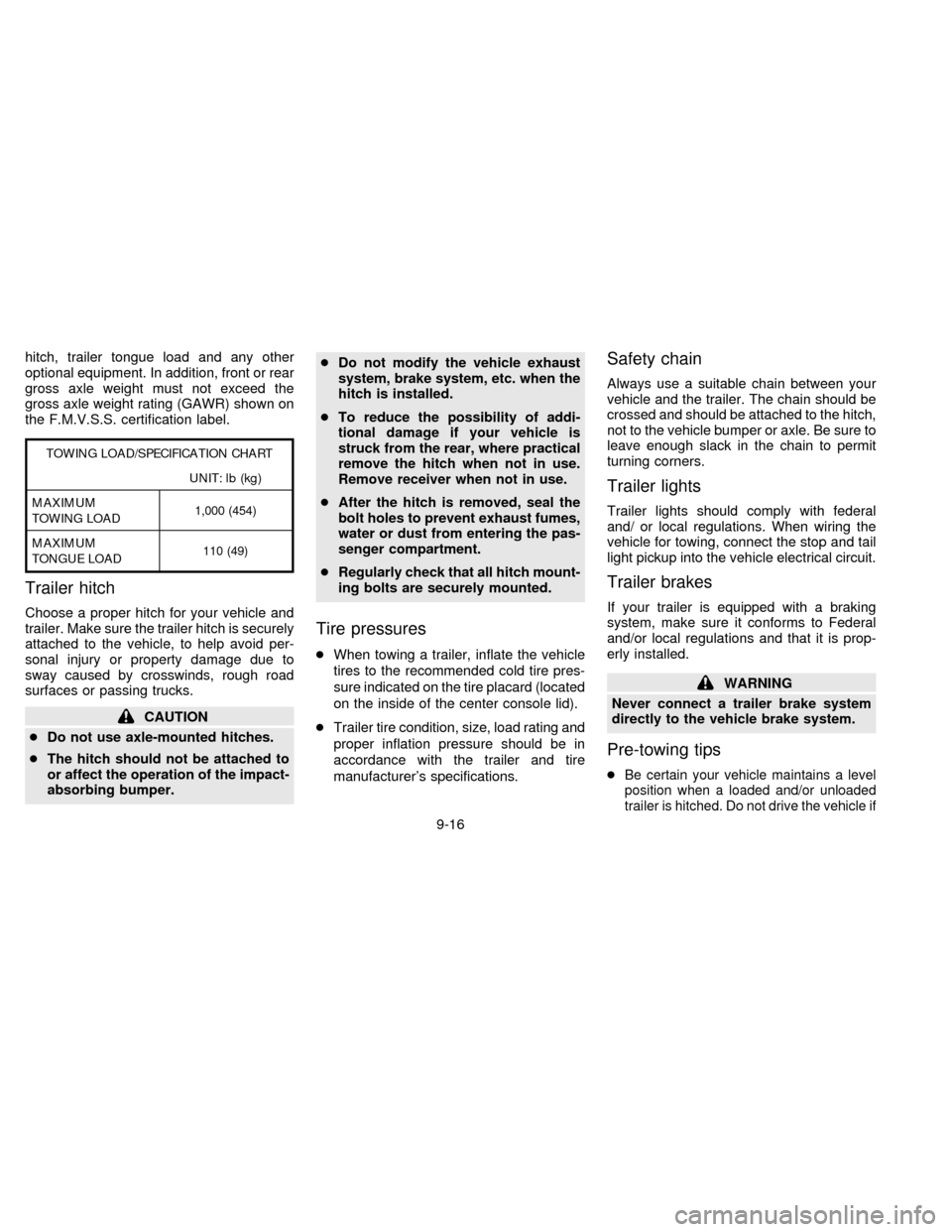

TOWING LOAD/SPECIFICATION CHART

UNIT: lb (kg)

MAXIMUM

TOWING LOAD1,000 (454)

MAXIMUM

TONGUE LOAD110 (49)

Trailer hitch

Choose a proper hitch for your vehicle and

trailer. Make sure the trailer hitch is securely

attached to the vehicle, to help avoid per-

sonal injury or property damage due to

sway caused by crosswinds, rough road

surfaces or passing trucks.

CAUTION

cDo not use axle-mounted hitches.

cThe hitch should not be attached to

or affect the operation of the impact-

absorbing bumper.cDo not modify the vehicle exhaust

system, brake system, etc. when the

hitch is installed.

cTo reduce the possibility of addi-

tional damage if your vehicle is

struck from the rear, where practical

remove the hitch when not in use.

Remove receiver when not in use.

cAfter the hitch is removed, seal the

bolt holes to prevent exhaust fumes,

water or dust from entering the pas-

senger compartment.

cRegularly check that all hitch mount-

ing bolts are securely mounted.

Tire pressures

cWhen towing a trailer, inflate the vehicle

tires to the recommended cold tire pres-

sure indicated on the tire placard (located

on the inside of the center console lid).

cTrailer tire condition, size, load rating and

proper inflation pressure should be in

accordance with the trailer and tire

manufacturer's specifications.

Safety chain

Always use a suitable chain between your

vehicle and the trailer. The chain should be

crossed and should be attached to the hitch,

not to the vehicle bumper or axle. Be sure to

leave enough slack in the chain to permit

turning corners.

Trailer lights

Trailer lights should comply with federal

and/ or local regulations. When wiring the

vehicle for towing, connect the stop and tail

light pickup into the vehicle electrical circuit.

Trailer brakes

If your trailer is equipped with a braking

system, make sure it conforms to Federal

and/or local regulations and that it is prop-

erly installed.

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

cBe certain your vehicle maintains a level

position when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle if

9-16

ZX

Page 193 of 203

cTo maintain engine braking efficiency

and electrical charging performance, do

not use fifth gear (manual transmission)

or overdrive (automatic transmission).

cAvoid holding the brake pedal down too

long or too frequently. This could cause

the brakes to overheat, resulting in re-

duced braking efficiency.

When towing a trailer, change the trans-

mission fluid more frequently.

See the Maintenance Schedule.DOT (Department of Transportation) Qual-

ity Grades: All passenger car tires must

conform to federal safety requirements in

addition to these grades.

Treadwear

Treadwear grade is a comparative rating

based on tire wear rate when tested under

controlled conditions on specified govern-

ment test courses. For example, a tire

graded 150 would wear one and a half

(1-1/2) times as well on the government

course as a tire graded 100. However,

relative tire performance depends on actual

driving conditions, and may vary signifi-

cantly from the norm due to variations in

driving habits, service practices and differ-

ences in road characteristics and climate.

Traction A, B and C

Traction grades are A (the highest), B and

C. They represent a tire's ability to stop on

wet pavement as measured under con-

trolled conditions, on specified government

test surfaces of asphalt and concrete. A tire

marked with a C may have poor traction

performance.

WARNING

The traction grade assigned to your

vehicle tires is based on straight line

braking traction tests and does not

include cornering (turning) traction.

Temperature A, B and C

Temperature grades are A (the highest), B,

and C. They represent a tire's resistance to

heat build-up, and its ability to dissipate

heat when tested under controlled condi-

tions on a specified indoor laboratory test

wheel. Sustained high temperature can

cause tire material to degenerate, reducing

tire life. Excessive temperatures can lead to

sudden tire failure. Grade C corresponds to

a performance level which all passenger car

tires must meet under the Federal Motor

Vehicle Safety Standard No. 109. Grades A

and B represent higher levels of perfor-

mance on laboratory test wheels than the

minimum required by law.

WARNING

The temperature grade for this tire is

established for a tire that is properly

UNIFORM TIRE QUALITY

GRADING

9-18

ZX