Sus NISSAN ARMADA 2017 2.G Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2017, Model line: ARMADA, Model: NISSAN ARMADA 2017 2.GPages: 614, PDF Size: 2.87 MB

Page 552 of 614

manufacturer’s suggestions.Use only SAE

Class S chains. Class “S” chains are used on

vehicles with restricted tire to vehicle clearance.

Vehicles that can use Class “S” chains are

designed to meet the SAE standard minimum

clearances between the tire and the closest

vehicle suspension or body component required

to accommodate the use of a winter traction

device (tire chains or cables) . The minimum

clearances are determined using the factory

equipped tire size. Other types may damage

your vehicle. Use chain tensioners when re-

commended by the tire chain manufacturer to

ensure a tight fit. Loose end links of the tire

chain must be secured or removed to prevent

the possibility of whipping action damage to the

fenders or underbody. If possible, avoid fully

loading your vehicle when using tire chains. In

addition, drive at a reduced speed. Otherwise,

your vehicle may be damaged and/or vehicle

handling and performance may be adversely

affected.

Tire chains must be installed only on the

rear wheels and not on the front wheels.

Do not use tire chains on dry roads. Driving with

tire chains in such conditions can cause damage

to the various mechanisms of the vehicle due to

some overstress.

SDI1662

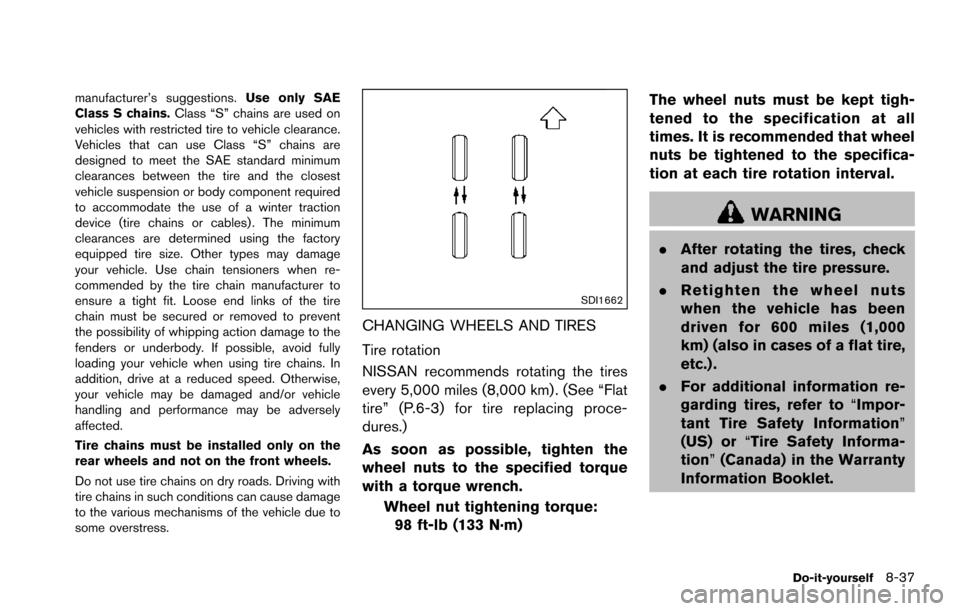

CHANGING WHEELS AND TIRES

Tire rotation

NISSAN recommends rotating the tires

every 5,000 miles (8,000 km) . (See “Flat

tire” (P.6-3) for tire replacing proce-

dures.)

As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

Wheel nut tightening torque:98 ft-lb (133 N·m) The wheel nuts must be kept tigh-

tened to the specification at all

times. It is recommended that wheel

nuts be tightened to the specifica-

tion at each tire rotation interval.

WARNING

.

After rotating the tires, check

and adjust the tire pressure.

. Retighten the wheel nuts

when the vehicle has been

driven for 600 miles (1,000

km) (also in cases of a flat tire,

etc.) .

. For additional information re-

garding tires, refer to “Impor-

tant Tire Safety Information”

(US) or “Tire Safety Informa-

tion” (Canada) in the Warranty

Information Booklet.

Do-it-yourself8-37

Page 561 of 614

9-6Maintenance and schedules

Exhaust system:

Visually inspect the exhaust pipes, muffler and

hangers for leaks, cracks, deterioration, and

damage. Tighten connections or replace parts

as necessary.

Propeller shaft(s):

Check for damage, looseness, and grease

leakage.

In-cabin microfilter:

Replace at specified intervals. When driving for

prolonged periods in dusty conditions, replace

the filter more frequently.

Steering gear and linkage, axle and sus-

pension parts:

Check for damage, looseness, and leakage of oil

or grease. Under severe driving conditions,

inspect more frequently.

Tire rotation:

Tires should be rotated every 5,000 miles

(8,000km) . When rotating tires, check for

damage and uneven wear. Replace if necessary.

Transmission fluid/oil, differential oil:

Visually inspect for signs of leakage at specified

intervals.Off-road maintenance:

Check the following items frequently whenever

you drive off-road through deep sand, mud or

water:

.

Brake pads and rotors

. Brake linings and drums

. Brake lines and hoses

. Differential, transmission and transfer case

oil

. Steering linkage

. Propeller shaft(s) and front drive shafts

. Engine air filter

. Clutch housing drain (AWD only) To help ensure smooth, safe and economical

driving, NISSAN provides two maintenance

schedules that may be used, depending upon

the conditions in which you usually drive. These

schedules contain both distance and time

intervals, up to 120,000 miles (192,000 km)/

144 months. For most people, the odometer

reading will indicate when service is needed.

However, if you drive very little, your vehicle

should be serviced at the regular time intervals

shown in the schedule.

After 120,000 miles (192,000 km)/144

months, continue maintenance at the

same mileage/time intervals.

ADDITIONAL MAINTENANCE ITEMS

FOR SEVERE OPERATING CONDI-

TIONS

Additional maintenance items for severe

operating conditions;

should be performed

on vehicles that are driven under especially

demanding conditions. Additional maintenance

items should be performed if you primarily

operate your vehicle under the following condi-

tions:

. Repeated short trips of less than 5 miles (8

km) .

. Repeated short trips of less than 10 miles

(16 km) with outside temperatures remain-

ing below freezing.

MAINTENANCE SCHEDULES

Page 566 of 614

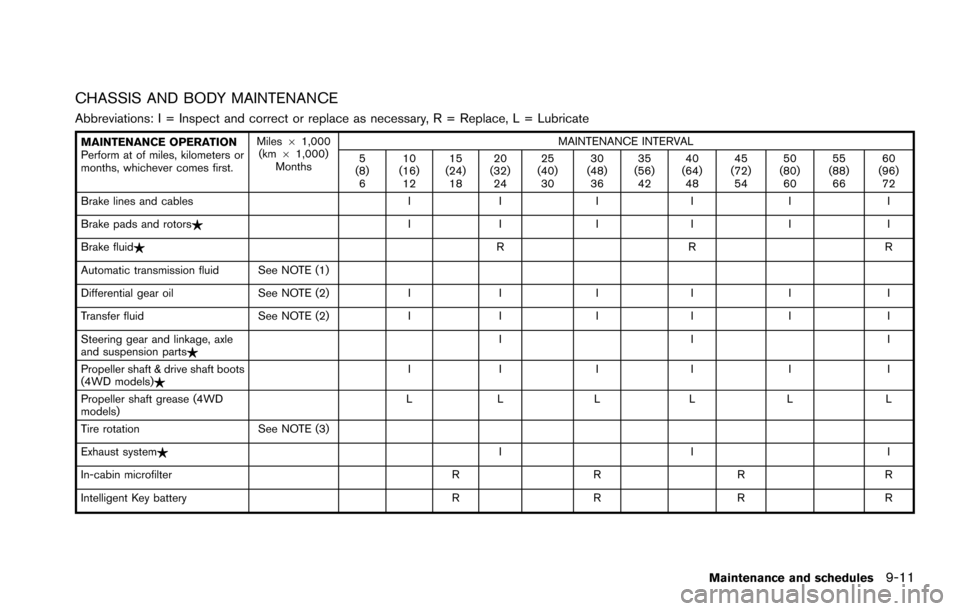

CHASSIS AND BODY MAINTENANCE

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate

MAINTENANCE OPERATION

Perform at of miles, kilometers or

months, whichever comes first.Miles

61,000

(km 61,000)

Months MAINTENANCE INTERVAL

5

(8) 6 10

(16) 12 15

(24) 18 20

(32) 24 25

(40) 30 30

(48) 36 35

(56) 42 40

(64) 48 45

(72) 54 50

(80) 60 55

(88) 66 60

(96) 72

Brake lines and cables II II I I

Brake pads and rotors$ II I I I I

Brake fluid$ RR R

Automatic transmission fluid See NOTE (1)

Differential gear oil See NOTE (2)II II I I

Transfer fluid See NOTE (2)II II I I

Steering gear and linkage, axle

and suspension parts$ II I

Propeller shaft & drive shaft boots

(4WD models)$ II I I I I

Propeller shaft grease (4WD

models) LL L L L L

Tire rotation See NOTE (3)

Exhaust system$ II I

In-cabin microfilter RR R R

Intelligent Key battery RR R R

Maintenance and schedules9-11

Page 567 of 614

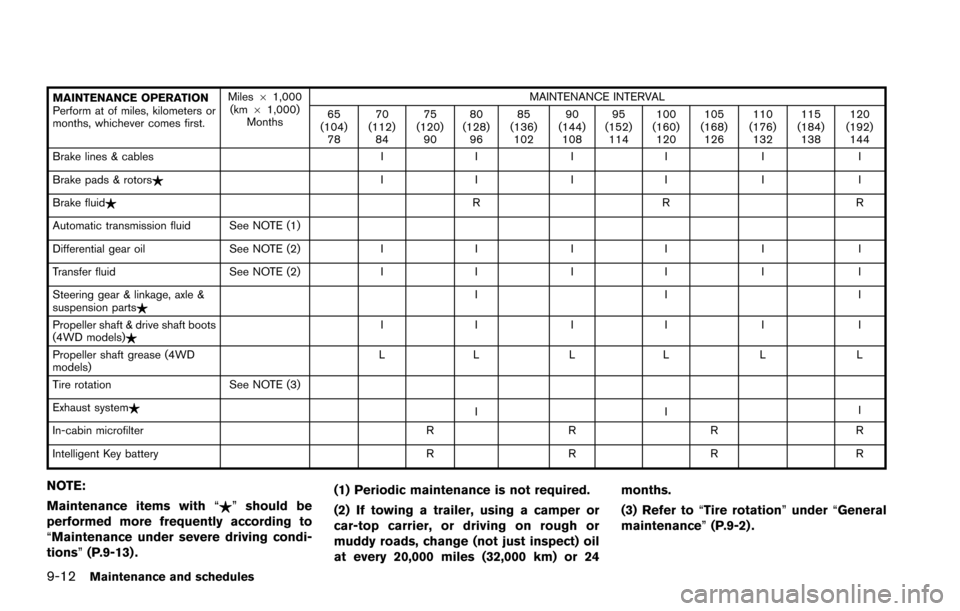

9-12Maintenance and schedules

MAINTENANCE OPERATION

Perform at of miles, kilometers or

months, whichever comes first.Miles

61,000

(km 61,000)

Months MAINTENANCE INTERVAL

65

(104) 78 70

(112) 84 75

(120) 90 80

(128) 96 85

(136) 102 90

(144) 108 95

(152) 114 100

(160) 120 105

(168) 126 110

(176) 132 115

(184) 138 120

(192) 144

Brake lines & cables II II I I

Brake pads & rotors$ II II I I

Brake fluid$ RR R

Automatic transmission fluid See NOTE (1)

Differential gear oil See NOTE (2)II II I I

Transfer fluid See NOTE (2)II II I I

Steering gear & linkage, axle &

suspension parts$ II I

Propeller shaft & drive shaft boots

(4WD models)$ II II I I

Propeller shaft grease (4WD

models) LL LL L L

Tire rotation See NOTE (3)

Exhaust system$ III

In-cabin microfilter RRR R

Intelligent Key battery RRR R

NOTE:

Maintenance items with “$”should be

performed more frequently according to

“Maintenance under severe driving condi-

tions” (P.9-13) . (1) Periodic maintenance is not required.

(2) If towing a trailer, using a camper or

car-top carrier, or driving on rough or

muddy roads, change (not just inspect) oil

at every 20,000 miles (32,000 km) or 24 months.

(3) Refer to

“Tire rotation” under“General

maintenance” (P.9-2) .

Page 568 of 614

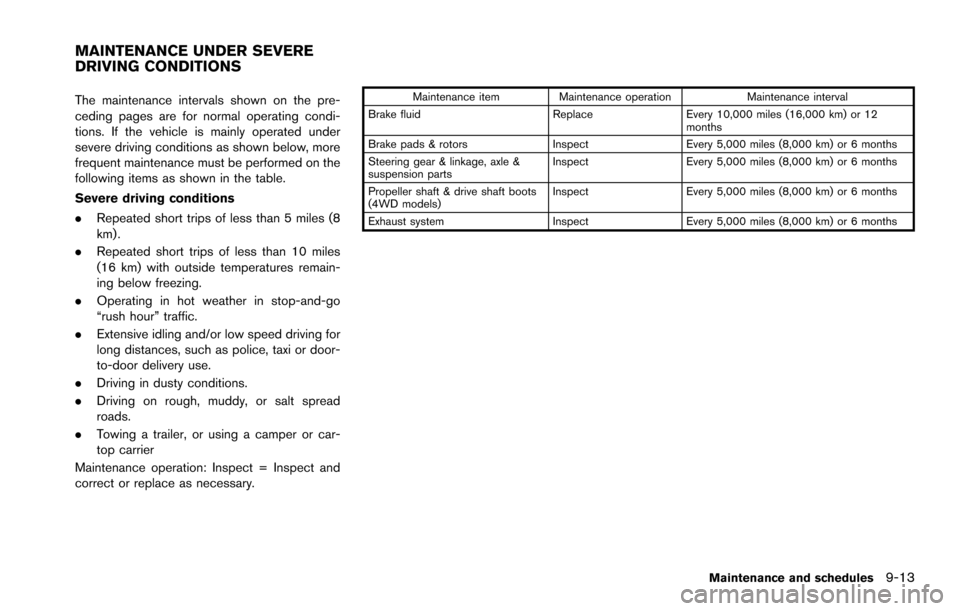

The maintenance intervals shown on the pre-

ceding pages are for normal operating condi-

tions. If the vehicle is mainly operated under

severe driving conditions as shown below, more

frequent maintenance must be performed on the

following items as shown in the table.

Severe driving conditions

.Repeated short trips of less than 5 miles (8

km) .

. Repeated short trips of less than 10 miles

(16 km) with outside temperatures remain-

ing below freezing.

. Operating in hot weather in stop-and-go

“rush hour” traffic.

. Extensive idling and/or low speed driving for

long distances, such as police, taxi or door-

to-door delivery use.

. Driving in dusty conditions.

. Driving on rough, muddy, or salt spread

roads.

. Towing a trailer, or using a camper or car-

top carrier

Maintenance operation: Inspect = Inspect and

correct or replace as necessary.Maintenance item Maintenance operation Maintenance interval

Brake fluid ReplaceEvery 10,000 miles (16,000 km) or 12

months

Brake pads & rotors InspectEvery 5,000 miles (8,000 km) or 6 months

Steering gear & linkage, axle &

suspension parts Inspect

Every 5,000 miles (8,000 km) or 6 months

Propeller shaft & drive shaft boots

(4WD models) Inspect

Every 5,000 miles (8,000 km) or 6 months

Exhaust system InspectEvery 5,000 miles (8,000 km) or 6 months

Maintenance and schedules9-13

MAINTENANCE UNDER SEVERE

DRIVING CONDITIONS

Page 573 of 614

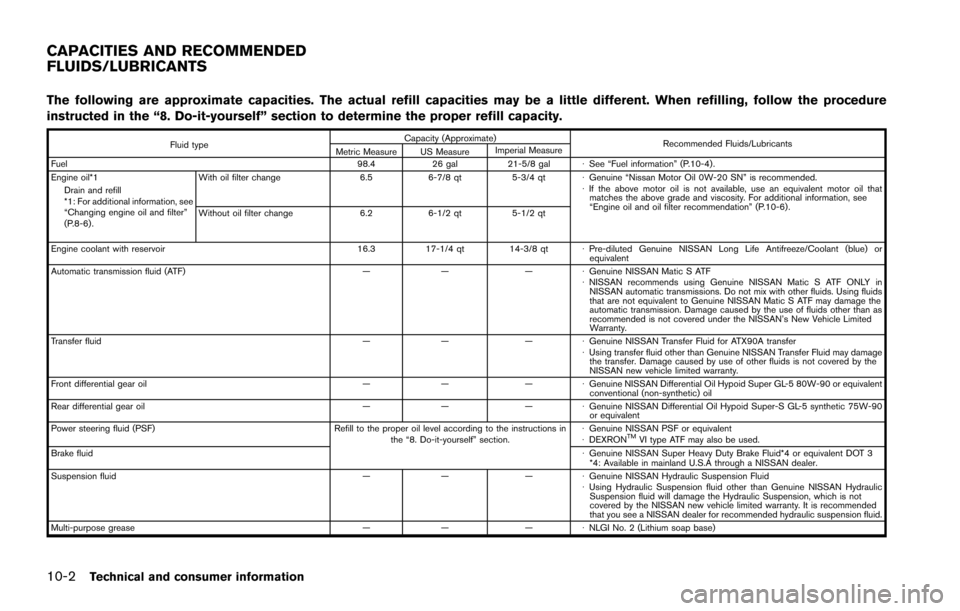

10-2Technical and consumer information

The following are approximate capacities. The actual refill capacities may be a little different. When refilling, follow the procedure

instructed in the “8. Do-it-yourself” section to determine the proper refill capacity.

Fluid typeCapacity (Approximate)

Recommended Fluids/Lubricants

Metric Measure US Measure Imperial Measure

Fuel 98.426 gal 21-5/8 gal�ÂSee “Fuel information” (P.10-4).

Engine oil*1 With oil filter change 6.56-7/8 qt 5-3/4 qt�ÂGenuine “Nissan Motor Oil 0W-20 SN” is recommended.

� If the above motor oil is not available, use an equivalent motor oil that

matches the above grade and viscosity. For additional information, see

“Engine oil and oil filter recommendation” (P.10-6).

Drain and refill

*1: For additional information, see

“Changing engine oil and filter”

(P.8-6) .

Without oil filter change

6.26-1/2 qt 5-1/2 qt

Engine coolant with reservoir 16.317-1/4 qt 14-3/8 qt �ÂPre-diluted Genuine NISSAN Long Life Antifreeze/Coolant (blue) or

equivalent

Automatic transmission fluid (ATF) —— —�ÂGenuine NISSAN Matic S ATF

� NISSAN recommends using Genuine NISSAN Matic S ATF ONLY in

NISSAN automatic transmissions. Do not mix with other fluids. Using fluids

that are not equivalent to Genuine NISSAN Matic S ATF may damage the

automatic transmission. Damage caused by the use of fluids other than as

recommended is not covered under the NISSAN’s New Vehicle Limited

Warranty.

Transfer fluid —— —�ÂGenuine NISSAN Transfer Fluid for ATX90A transfer

� Using transfer fluid other than Genuine NISSAN Transfer Fluid may damage

the transfer. Damage caused by use of other fluids is not covered by the

NISSAN new vehicle limited warranty.

Front differential gear oil —— —�ÂGenuine NISSAN Differential Oil Hypoid Super GL-5 80W-90 or equivalent

conventional (non-synthetic) oil

Rear differential gear oil —— —�ÂGenuine NISSAN Differential Oil Hypoid Super-S GL-5 synthetic 75W-90

or equivalent

Power steering fluid (PSF) Refill to the proper oil level according to the instructions in

the “8. Do-it-yourself” section. �Â

Genuine NISSAN PSF or equivalent

� DEXRON

TMVI type ATF may also be used.

Brake fluid �ÂGenuine NISSAN Super Heavy Duty Brake Fluid*4 or equivalent DOT 3

*4: Available in mainland U.S.A through a NISSAN dealer.

Suspension fluid —— —�ÂGenuine NISSAN Hydraulic Suspension Fluid

� Using Hydraulic Suspension fluid other than Genuine NISSAN Hydraulic

Suspension fluid will damage the Hydraulic Suspension, which is not

covered by the NISSAN new vehicle limited warranty. It is recommended

that you see a NISSAN dealer for recommended hydraulic suspension fluid.

Multi-purpose grease —— —�ÂNLGI No. 2 (Lithium soap base)

CAPACITIES AND RECOMMENDED

FLUIDS/LUBRICANTS

Page 576 of 614

.E-15 fuel contains more than 10%

oxygenate. E-15 fuel will adversely

affect the emission control devices

and systems of the vehicle and should

not be used. Damage caused by such

fuel is not covered by the NISSAN new

vehicle limited warranty.

. If a methanol blend is used, it should

contain no more than 5% methanol

(methyl alcohol, wood alcohol) . It

should also contain a suitable amount

of appropriate cosolvents and corro-

sion inhibitors. If not properly formu-

lated with appropriate cosolvents and

corrosion inhibitors, such methanol

blends may cause fuel system damage

and/or vehicle performance problems.

At this time, sufficient data is not

available to ensure that all methanol

blends are suitable for use in NISSAN

vehicles.

If any undesirable driveability problems such as

engine stalling or hard hot starting are experi-

enced after using oxygenate-blend fuels, im-

mediately change to a non-oxygenate fuel or a

fuel with a low blend of MTBE.

Take care not to spill gasoline during

refueling. Gasoline containing oxygenates

can cause paint damage.E-15 fuel

E-15 fuel is a mixture of approximately 15% fuel

ethanol and 85% unleaded gasoline. E-15 can

only be used in vehicles designed to run on E-

15 fuel. Do not use E-15 in your vehicle. U.S.

government regulations require fuel ethanol

dispensing pumps to be identified with small,

square, orange and black label with the common

abbreviation or the appropriate percentage for

that region.

E-85 fuel

E-85 fuel is a mixture of approximately 85% fuel

ethanol and 15% unleaded gasoline. E-85 can

only be used in a Flexible Fuel Vehicle (FFV) . Do

not use E-85 fuel in your vehicle. U.S. govern-

ment regulations require fuel ethanol dispensing

pumps to be identified by a small, square,

orange and black label with the common

abbreviation or the appropriate percentage for

that region.

Fuel containing MMT

MMT, or methylcyclopentadienyl manganese

tricarbonyl, is an octane boosting additive.

NISSAN does not recommend the use of fuel

containing MMT. Such fuel may adversely affect

vehicle performance, including the emissions

control system. Note that while some fuel pumps

label MMT content, not all do, so you may have to consult your gasoline retailer for more details.

Aftermarket fuel additives

NISSAN does not recommend the use of any

aftermarket fuel additives (Example: fuel injector

cleaner, octane booster, intake valve deposit

removers, etc.) which are sold commercially.

Many of these additives intended for gum,

varnish or deposit removal may contain active

solvent or similar ingredients that can be harmful

to the fuel system and engine.

Octane rating tips

Using unleaded gasoline with an octane

rating lower than recommended above can

cause persistent, heavy spark knock.

(Spark knock is a metallic rapping noise.)

If severe, this can lead to engine damage.

If you detect a persistent heavy spark

knock even when using gasoline of the

stated octane rating, or if you hear steady

spark knock while holding a steady speed

on level roads, it is recommended you have

a NISSAN dealer correct the condition.

Failure to correct the condition is misuse

of the vehicle, for which NISSAN is not

responsible.

Incorrect ignition timing will result in knocking,

after-run or overheating. This in turn may cause

excessive fuel consumption or damage to the

Technical and consumer information10-5

Page 597 of 614

10-26Technical and consumer information

Several types of braking systems are available.

Surge Brakes -The surge brake actuator is

mounted on the trailer tongue with a hydraulic

line running to each trailer wheel. Surge brakes

are activated by the trailer pushing against the

hitch ball when the tow vehicle is braking.

Hydraulic surge brakes are common on rental

trailers and some boat trailers. In this type of

system, there is no hydraulic or electric connec-

tion for brake operation between the tow vehicle

and the trailer.

Electric Trailer Brakes - Electric braking

systems are activated by an electronic signal

sent from a trailer brake controller (special brake

sensing module) .

Have a professional supplier of towing equip-

ment make sure the trailer brakes are properly

installed and demonstrate proper brake function

testing.

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

. Be certain your vehicle maintains a level

position when a loaded or unloaded trailer is

hitched. Do not drive the vehicle if it has an

abnormal nose-up or nose-down condition;

check for improper tongue load, overload,

worn suspension or other possible causes

of either condition.

. Always secure items in the trailer to prevent

load shift while driving.

. Keep the cargo load as low as possible in

the trailer to keep the trailer center of gravity

low.

. Load the trailer so approximately 60% of the

trailer load is in the front half and 40% is in

the back half. Also make sure the load is

balanced side to side.

. Check your hitch, trailer tire pressure,

vehicle tire pressure, trailer light operation,

and trailer wheel lug nuts every time you

attach a trailer to the vehicle.

. Be certain your rearview mirrors conform to

all federal, state or local regulations. If not,

install any mirrors required for towing before

driving the vehicle.

. Determine the overall height of the vehicle

and trailer so the required clearance is

known.

Trailer towing tips

In order to gain skill and an understanding of the

vehicle’s behavior, you should practice turning,

stopping and backing up in an area which is free

from traffic. Steering stability, and braking

performance will be somewhat different than

under normal driving conditions.

.Always secure items in the trailer to prevent

load shift while driving.

. Lock the trailer hitch coupler with a pin or

lock to prevent the coupler from inadver-

tently becoming unlatched.

. Avoid abrupt starts, acceleration or stops.

. Avoid sharp turns or lane changes.

. Always drive your vehicle at a moderate

speed. Some states or provinces have

specific speed limits for vehicles that are

towing trailers. Obey the local speed limits.

. When backing up, hold the bottom of the

steering wheel with one hand. Move your

hand in the direction in which you want the

trailer to go. Make small corrections and

back up slowly. If possible, have someone

guide you when you are backing up.

Always block the wheels on both vehicle and

trailer when parking. Parking on a slope is not

recommended; however, if you must do so:

Page 601 of 614

10-30Technical and consumer information

WARNING

The traction grade assigned to this tire

is based on straight-ahead braking

traction tests, and does not include

acceleration, cornering, hydroplaning,

or peak traction characteristics.

TEMPERATURE A, B AND C

The temperature grades A (the highest) , B, and

C, representing the tire’s resistance to the

generation of heat and its ability to dissipate

heat when tested under controlled conditions on

a specified indoor laboratory test wheel. Sus-

tained high temperature can cause the material

of the tire to degenerate and reduce tire life, and

excessive temperature can lead to sudden tire

failure. The grade C corresponds to a level of

performance which all passenger car tires must

meet under the Federal Motor Vehicle Safety

Standard No. 109. Grades B and A represent

higher levels of performance on the laboratory

test wheel than the minimum required by law.

WARNING

The temperature grade for this tire is

established for a tire that is properly

inflated and not overloaded. Excessive

speed, under-inflation, or excessive

loading, either separately or in combi-

nation, can cause heat build-up and

possible tire failure.Your NISSAN is covered by the following

emission warranties.

For USA:

.

Emission Defects Warranty

. Emissions Performance Warranty

Details of these warranties may be found with

other vehicle warranties in your Warranty In-

formation Booklet that comes with your

NISSAN. If you did not receive a Warranty

Information Booklet, or it has become lost, you

may obtain a replacement by writing to:

. NISSAN Division

Nissan North America, Inc.

Consumer Affairs Department

P.O. Box 685003

Franklin, TN 37068-5003

EMISSION CONTROL SYSTEM

WARRANTY