ECU NISSAN ARMADA 2017 2.G Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2017, Model line: ARMADA, Model: NISSAN ARMADA 2017 2.GPages: 614, PDF Size: 2.87 MB

Page 486 of 614

To shut off the engine in an emergency situation

while driving, perform the following procedure:

.Rapidly push the push-button ignition switch

3 consecutive times in less than 1.5

seconds, or

. Push and hold the push-button ignition

switch for more than 2 seconds.TIRE PRESSURE MONITORING SYS-

TEM (TPMS)

This vehicle is equipped with the Tire Pressure

Monitoring System (TPMS) . It monitors tire

pressure of all tires except the spare. When

the low tire pressure warning light is lit and the

CHECK TIRE PRESSURE warning appears in

the vehicle information display, one or more of

your tires is significantly under-inflated. If the

vehicle is being driven with low tire pressure, the

TPMS will activate and warn you of it by the low

tire pressure warning light. This system will

activate only when the vehicle is driven at

speeds above 16 MPH (25 km/h) . For more

details, see “Warning lights, indicator lights and

audible reminders” (P.2-10) , “TIRE PRESSURE

information” (P.4-10) and “Tire Pressure Mon-

itoring System (TPMS)” (P.5-5) .

WARNING

.If the low tire pressure warning light

illuminates or LOW PRESSURE in-

formation is displayed on the moni-

tor screen while driving, avoid

sudden steering maneuvers or

abrupt braking, reduce vehicle

speed, pull off the road to a safe

location and stop the vehicle as soon as possible. Driving with un-

der-inflated tires may permanently

damage the tires and increase the

likelihood of tire failure. Serious

vehicle damage could occur and

may lead to an accident and could

result in serious personal injury.

Check the tire pressure for all four

tires. Adjust the tire pressure to the

recommended COLD tire pressure

shown on the Tire and Loading

Information label to turn the low

tire pressure warning light OFF. If

the light still illuminates while driv-

ing after adjusting the tire pressure,

a tire may be flat. If you have a flat

tire, replace it with a spare tire as

soon as possible.

. Since the spare tire is not equipped

with the TPMS, when a spare tire is

mounted or a wheel is replaced, the

TPMS will not function and the low

tire pressure warning light will flash

for approximately 1 minute. The

light will remain on after 1 minute.

Have your tires replaced and/or

TPMS system reset as soon as

possible. It is recommended you

visit a NISSAN dealer for these

services.

In case of emergency6-3

EMERGENCY ENGINE SHUT OFF FLAT TIRE

Page 487 of 614

6-4In case of emergency

.Replacing tires with those not ori-

ginally specified by NISSAN could

affect the proper operation of the

TPMS.

. Do not inject any tire liquid or

aerosol tire sealant into the tires,

as this may cause a malfunction of

the tire pressure sensors.

CHANGING A FLAT TIRE

If you have a flat tire, follow the instructions

below.

Stopping the vehicle

1. Safely move the vehicle off the road and

away from traffic.

2. Turn on the hazard warning flashers.

3. Park on a level surface and apply the parking brake. Move the shift lever to the P (Park)

position.

4. Turn off the engine.

5. Raise the hood to warn other traffic, and to signal professional road assistance person-

nel that you need assistance.

6. Have all passengers get out of the vehicle and stand in a safe place, away from traffic

and clear of the vehicle.

WARNING

.Make sure the parking brake is

securely applied and the automatic

transmission is in the P (Park)

position.

. Never change tires when the vehicle

is on a slope, ice or slippery areas.

This is hazardous.

. Never change tires if oncoming

traffic is close to your vehicle. Wait

for professional road assistance.

MCE0001A

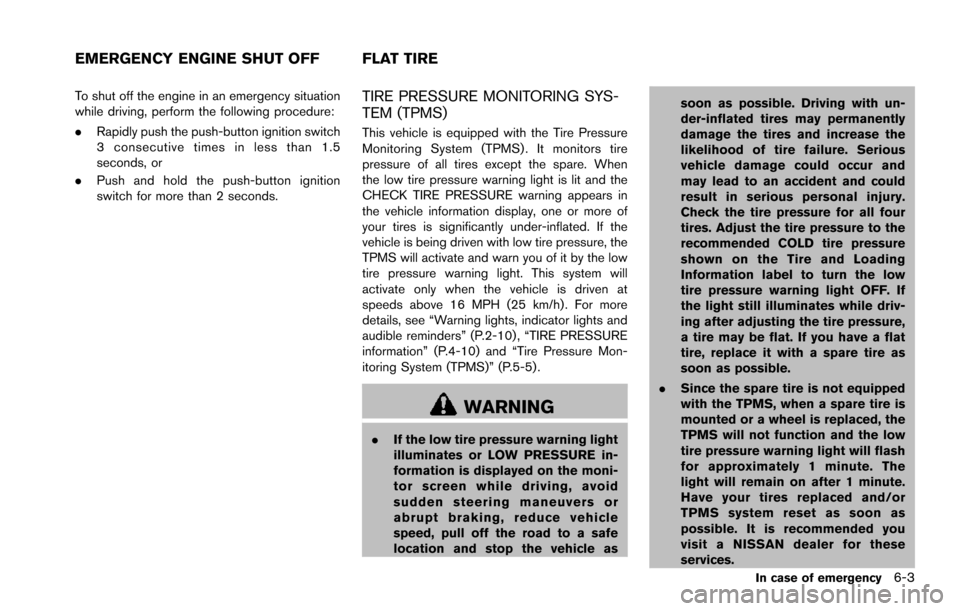

Blocking wheels

Place suitable blocks*1at both the front and

back of the wheel diagonally opposite the flat

tire to prevent the vehicle from moving when it is

jacked up.

WARNING

Be sure to block the wheel as the

vehicle may move and result in personal

injury.

Page 489 of 614

6-6In case of emergency

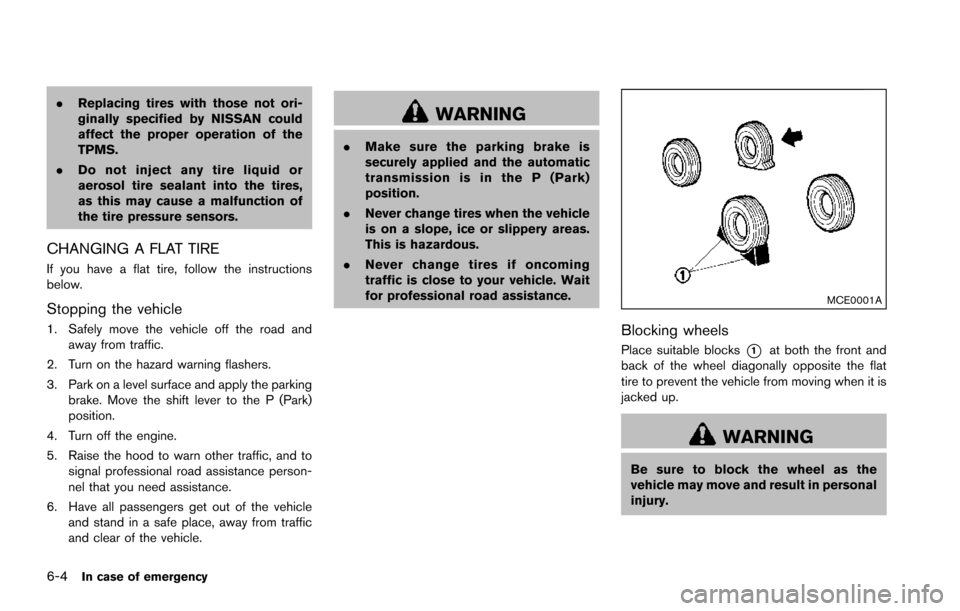

SCE0915

5. Securely screw to connect the T-shapedend of the jack rod and two extension bars

*1as illustrated.

6. Fit the square end of the jack rod into the square hole of the wheel nut wrench to form

a handle

*2. 7. Locate the oval opening above the middle of

the rear bumper.

8. Place the T-shaped end of the jack rod through the opening and direct it towards

the spare wheel winch assembly, located

directly above the spare wheel.

SCE0916

CAUTION

Do not insert the jack rod straight as it

is designed to be inserted at an angle

as shown.

9. Seat the T-shaped end of the jack rod into the T-shaped opening of the spare wheel

winch. Apply pressure to keep the jack rod

engaged in the spare wheel winch and turn

the jack rod counterclockwise to lower the

spare wheel.

Page 490 of 614

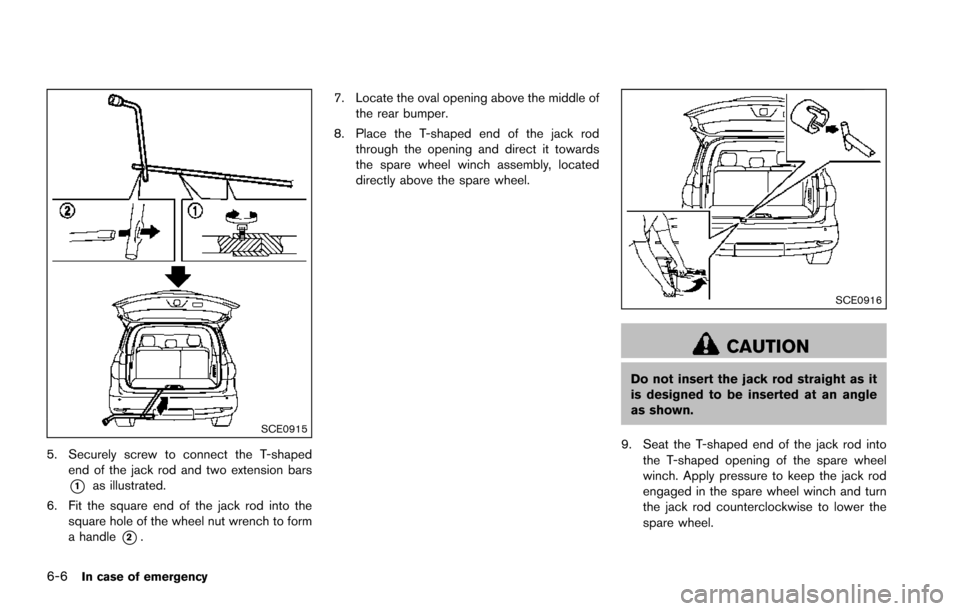

SCE0377

10. Once the spare wheel is completely low-ered, remove the jack rod and reach under

the vehicle to remove the hanging plate.

11. Carefully slide the spare wheel from under the rear of the vehicle.

After preparing the spare tire, to remove the rod,

pull out the rod while moving the rod to the right

and left with the screw of the extension facing

the side.

CAUTION

When storing the wheel, make sure that

the hanging plate is in the center of the wheel and then lift it up into the storage

area.

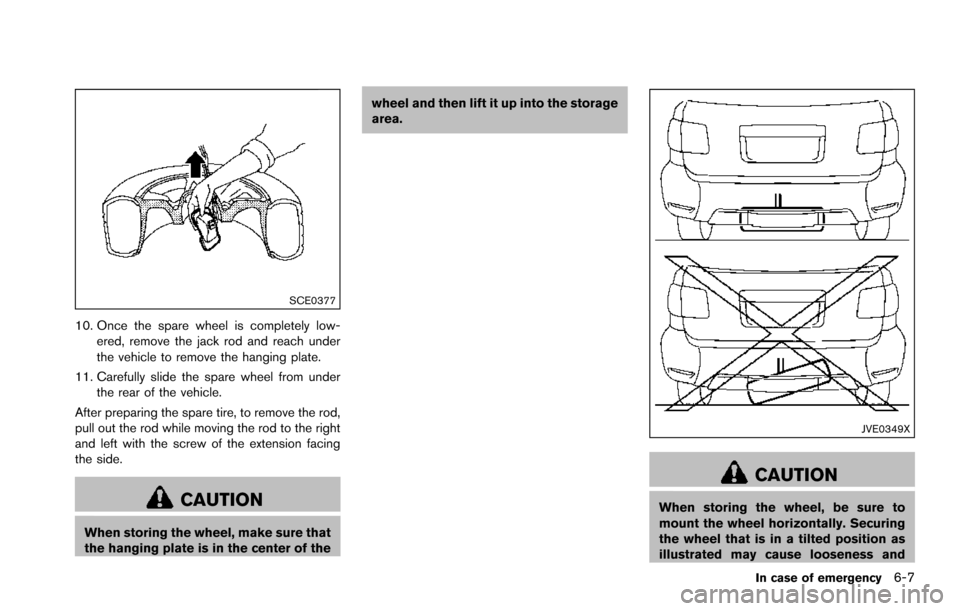

JVE0349X

CAUTION

When storing the wheel, be sure to

mount the wheel horizontally. Securing

the wheel that is in a tilted position as

illustrated may cause looseness and

In case of emergency6-7

Page 492 of 614

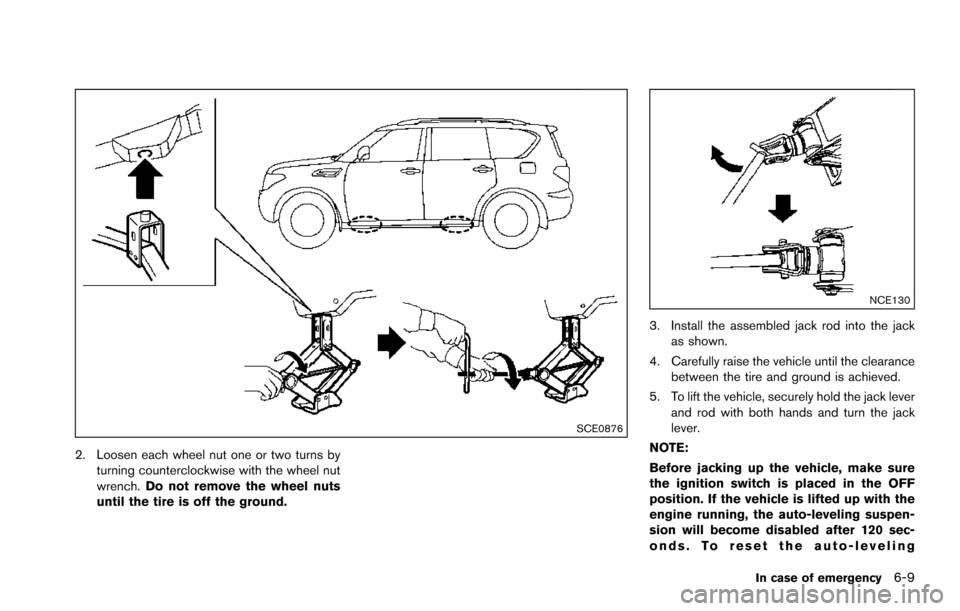

SCE0876

2. Loosen each wheel nut one or two turns byturning counterclockwise with the wheel nut

wrench. Do not remove the wheel nuts

until the tire is off the ground.

NCE130

3. Install the assembled jack rod into the jack

as shown.

4. Carefully raise the vehicle until the clearance between the tire and ground is achieved.

5. To lift the vehicle, securely hold the jack lever and rod with both hands and turn the jack

lever.

NOTE:

Before jacking up the vehicle, make sure

the ignition switch is placed in the OFF

position. If the vehicle is lifted up with the

engine running, the auto-leveling suspen-

sion will become disabled after 120 sec-

onds. To reset the auto-leveling

In case of emergency6-9

Page 493 of 614

6-10In case of emergency

suspension, cycle the ignition switch ON/

OFF one time.

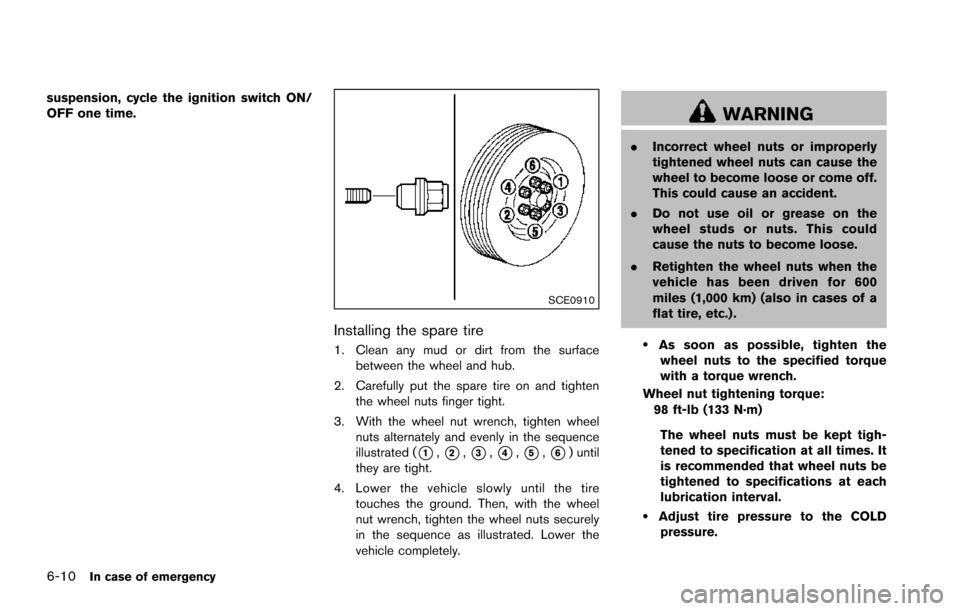

SCE0910

Installing the spare tire

1. Clean any mud or dirt from the surfacebetween the wheel and hub.

2. Carefully put the spare tire on and tighten the wheel nuts finger tight.

3. With the wheel nut wrench, tighten wheel nuts alternately and evenly in the sequence

illustrated (

*1,*2,*3,*4,*5,*6) until

they are tight.

4. Lower the vehicle slowly until the tire touches the ground. Then, with the wheel

nut wrench, tighten the wheel nuts securely

in the sequence as illustrated. Lower the

vehicle completely.

WARNING

.Incorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to become loose or come off.

This could cause an accident.

. Do not use oil or grease on the

wheel studs or nuts. This could

cause the nuts to become loose.

. Retighten the wheel nuts when the

vehicle has been driven for 600

miles (1,000 km) (also in cases of a

flat tire, etc.) .

.As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

Wheel nut tightening torque: 98 ft-lb (133 N·m)

The wheel nuts must be kept tigh-

tened to specification at all times. It

is recommended that wheel nuts be

tightened to specifications at each

lubrication interval.

.Adjust tire pressure to the COLDpressure.

Page 494 of 614

COLD pressure:

After the vehicle has been parked

for three hours or more or driven

less than 1 mile (1.6 km) .

COLD tire pressures are shown on

the Tire and Loading Information

label affixed to the driver side center

pillar.

After adjusting tire pressure to the COLD tire

pressure, the display of the tire pressure

information may show higher pressure than the

COLD tire pressure after the vehicle has been

driven more than 1 mile (1.6 km). This is

because the tire pressurizes as the tire tem-

perature rises. This does not indicate a system

malfunction.

Stowing the damaged tire and tools

1. Securely store the damaged tire, jack and tools in the storage area.

2. Close the cargo floor cover.

3. Replace the cargo floor board.

4. Close the liftgate.

WARNING

Always make sure that the spare tire

and jacking equipment are properly

secured after use. Such items can

become dangerous projectiles in an

accident or sudden stop.

In case of emergency6-11

Page 500 of 614

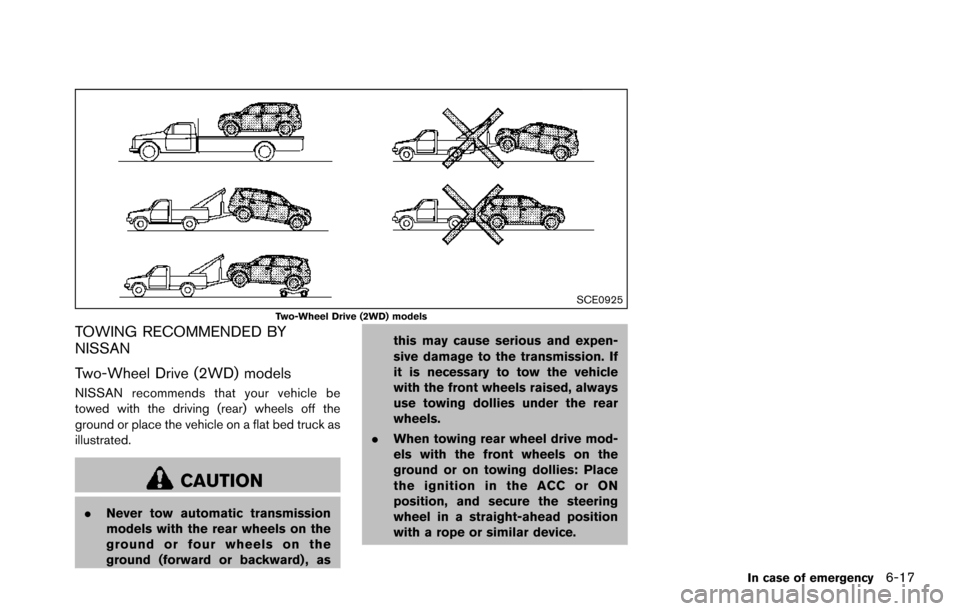

SCE0925Two-Wheel Drive (2WD) models

TOWING RECOMMENDED BY

NISSAN

Two-Wheel Drive (2WD) models

NISSAN recommends that your vehicle be

towed with the driving (rear) wheels off the

ground or place the vehicle on a flat bed truck as

illustrated.

CAUTION

.Never tow automatic transmission

models with the rear wheels on the

ground or four wheels on the

ground (forward or backward) , as this may cause serious and expen-

sive damage to the transmission. If

it is necessary to tow the vehicle

with the front wheels raised, always

use towing dollies under the rear

wheels.

. When towing rear wheel drive mod-

els with the front wheels on the

ground or on towing dollies: Place

the ignition in the ACC or ON

position, and secure the steering

wheel in a straight-ahead position

with a rope or similar device.

In case of emergency6-17

Page 505 of 614

6-22In case of emergency

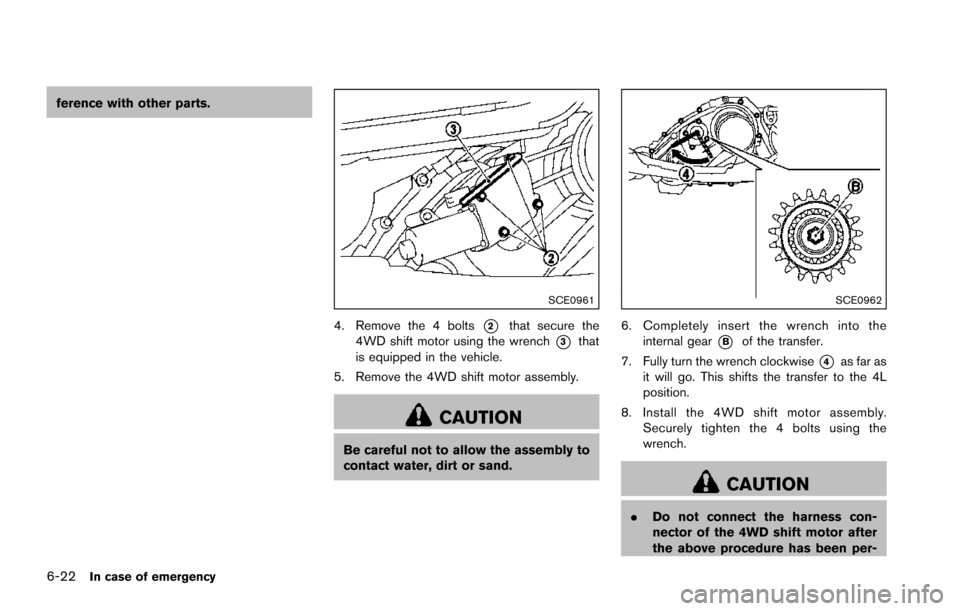

ference with other parts.

SCE0961

4. Remove the 4 bolts*2that secure the

4WD shift motor using the wrench

*3that

is equipped in the vehicle.

5. Remove the 4WD shift motor assembly.

CAUTION

Be careful not to allow the assembly to

contact water, dirt or sand.

SCE0962

6. Completely insert the wrench into the internal gear

*Bof the transfer.

7. Fully turn the wrench clockwise

*4as far as

it will go. This shifts the transfer to the 4L

position.

8. Install the 4WD shift motor assembly. Securely tighten the 4 bolts using the

wrench.

CAUTION

.Do not connect the harness con-

nector of the 4WD shift motor after

the above procedure has been per-

Page 513 of 614

7-6Appearance and care

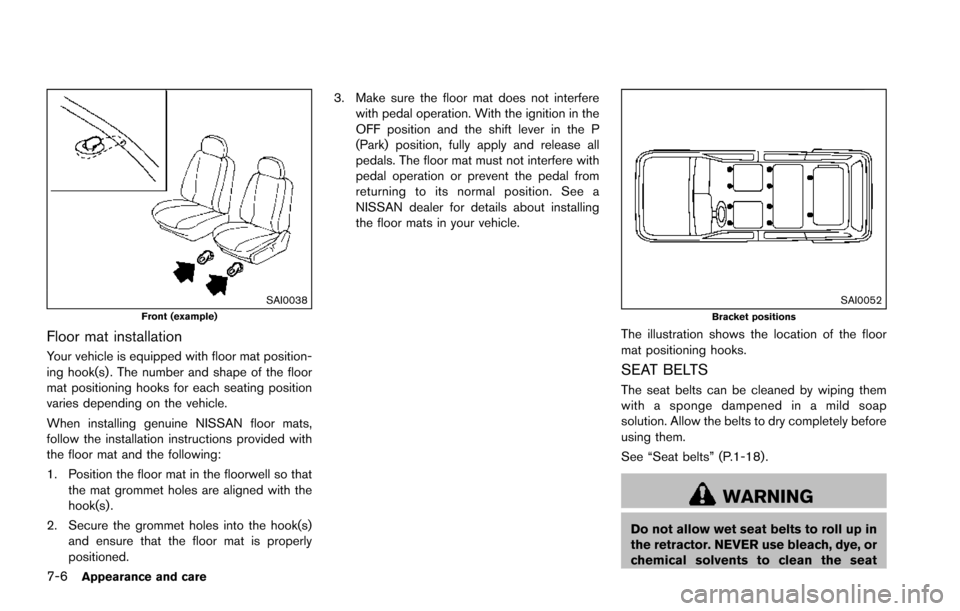

SAI0038Front (example)

Floor mat installation

Your vehicle is equipped with floor mat position-

ing hook(s) . The number and shape of the floor

mat positioning hooks for each seating position

varies depending on the vehicle.

When installing genuine NISSAN floor mats,

follow the installation instructions provided with

the floor mat and the following:

1. Position the floor mat in the floorwell so thatthe mat grommet holes are aligned with the

hook(s) .

2. Secure the grommet holes into the hook(s) and ensure that the floor mat is properly

positioned. 3. Make sure the floor mat does not interfere

with pedal operation. With the ignition in the

OFF position and the shift lever in the P

(Park) position, fully apply and release all

pedals. The floor mat must not interfere with

pedal operation or prevent the pedal from

returning to its normal position. See a

NISSAN dealer for details about installing

the floor mats in your vehicle.

SAI0052Bracket positions

The illustration shows the location of the floor

mat positioning hooks.

SEAT BELTS

The seat belts can be cleaned by wiping them

with a sponge dampened in a mild soap

solution. Allow the belts to dry completely before

using them.

See “Seat belts” (P.1-18).

WARNING

Do not allow wet seat belts to roll up in

the retractor. NEVER use bleach, dye, or

chemical solvents to clean the seat