check engine NISSAN FRONTIER 1998 D22 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: FRONTIER, Model: NISSAN FRONTIER 1998 D22 / 1.GPages: 224, PDF Size: 1.7 MB

Page 155 of 224

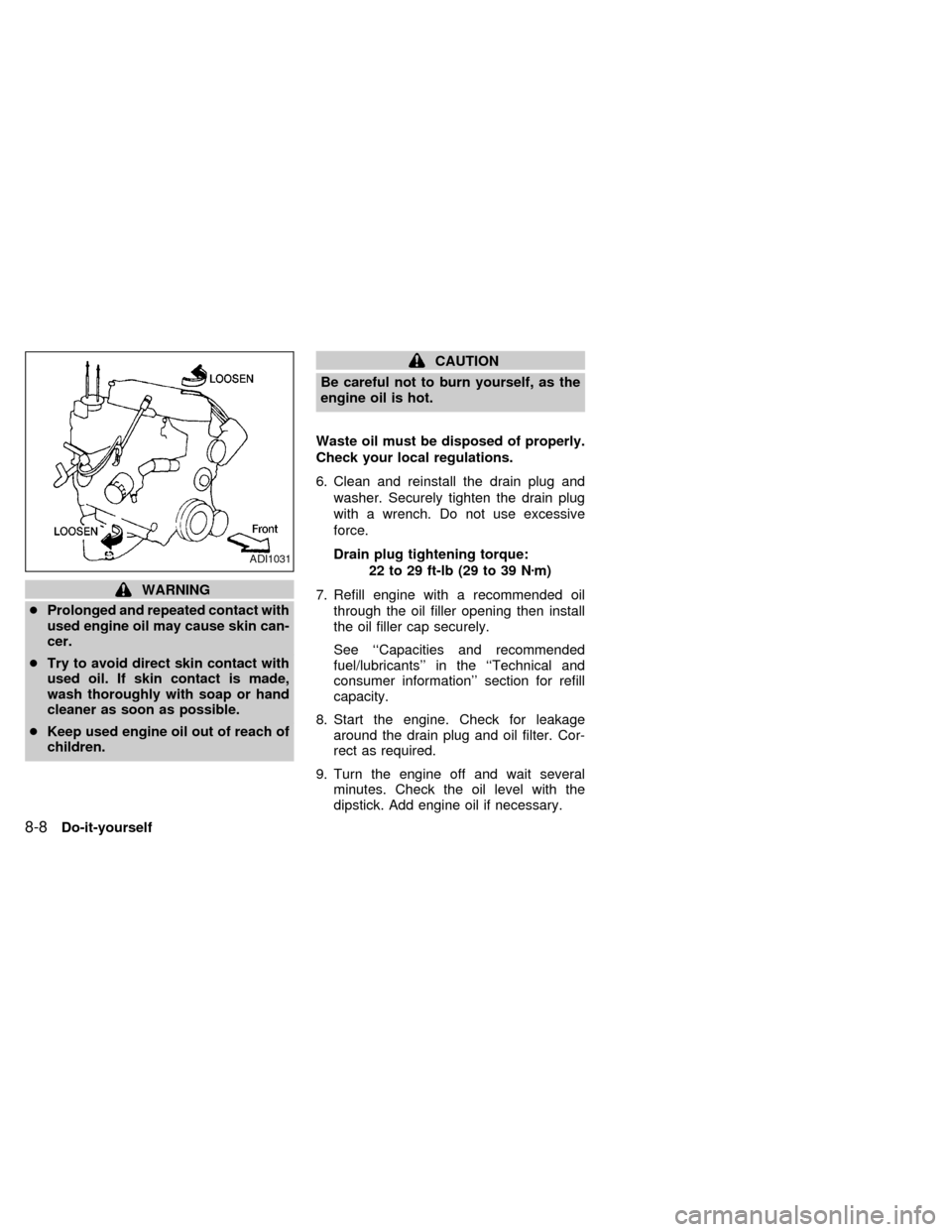

WARNING

cProlonged and repeated contact with

used engine oil may cause skin can-

cer.

cTry to avoid direct skin contact with

used oil. If skin contact is made,

wash thoroughly with soap or hand

cleaner as soon as possible.

cKeep used engine oil out of reach of

children.

CAUTION

Be careful not to burn yourself, as the

engine oil is hot.

Waste oil must be disposed of properly.

Check your local regulations.

6. Clean and reinstall the drain plug and

washer. Securely tighten the drain plug

with a wrench. Do not use excessive

force.

Drain plug tightening torque:

22 to 29 ft-lb (29 to 39 Nzm)

7. Refill engine with a recommended oil

through the oil filler opening then install

the oil filler cap securely.

See ``Capacities and recommended

fuel/lubricants'' in the ``Technical and

consumer information'' section for refill

capacity.

8. Start the engine. Check for leakage

around the drain plug and oil filter. Cor-

rect as required.

9. Turn the engine off and wait several

minutes. Check the oil level with the

dipstick. Add engine oil if necessary.

ADI1031

8-8Do-it-yourself

ZX

Page 156 of 224

CHANGING ENGINE OIL FILTER

1. Park the vehicle on a level surface and

apply the parking brake.

2. Turn the engine off.

3. Place a large drain pan under the oil

filter.

4. Loosen the oil filter with an oil filter

wrench. Then remove the oil filter by

turning it by hand.

CAUTION

Be careful not to burn yourself, as the

engine oil may be hot.

5. Wipe the engine oil filter mounting sur-

face with a clean rag.

Be sure to remove any old rubber gasket

remaining on the mounting surface of the

engine.

6. Coat the rubber gasket on the new filter

with engine oil.

7. Screw in the oil filter until a slight resis-

tance is felt, then tighten an additional

2/3 turn.

8. Start the engine and check for leakage

around the oil filter. Correct as required.

9. Turn the engine off and wait several

minutes. Check the oil level. Add engine

oil if necessary.WARNING

cWhen engine is running, keep

hands, jewelry and clothing away

from any moving parts such as cool-

ing fan and drive belts.

cAutomatic transmission fluid is poi-

sonous and should be stored care-

fully in marked containers out of the

reach of children.

TEMPERATURE CONDITIONS

FOR CHECKING ATF

cThe fluid level should be checked using

the HOT range on the dipstick after the

following conditions have been met:

Ð The engine should be warmed up to

operating temperature.

Ð The vehicle should be driven at least 5

minutes.

Ð The ATF should be warmed to between

122 and 176ÉF (50 and 80ÉC).

cThe ATF can be checked at fluid tem-

peratures of 86 to 122ÉF (30 to 50ÉC)

using the COLD range on the dipstick

after the engine is warmed up and before

ADI1032

AUTOMATIC TRANSMISSION

FLUID (ATF)

Do-it-yourself8-9

ZX

Page 157 of 224

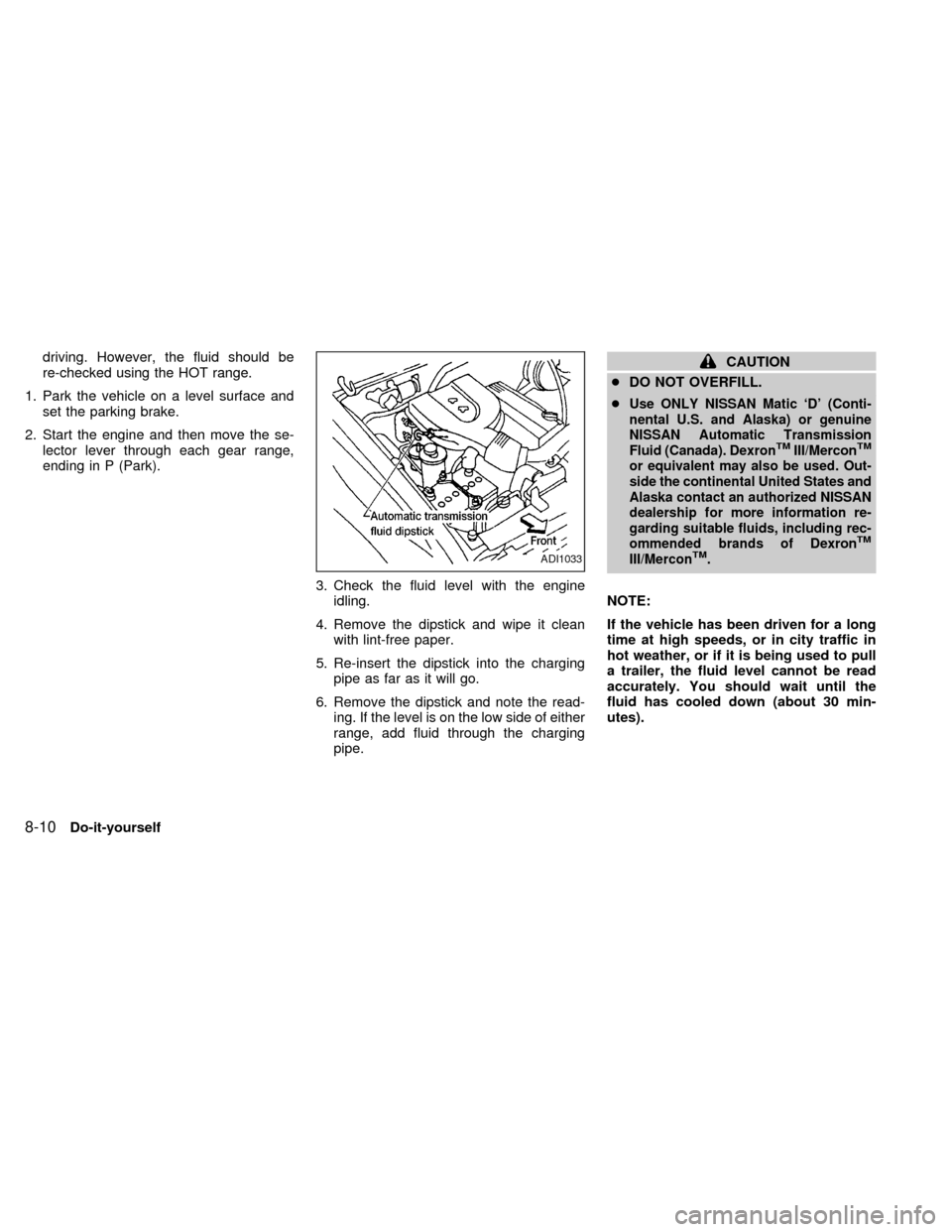

driving. However, the fluid should be

re-checked using the HOT range.

1. Park the vehicle on a level surface and

set the parking brake.

2. Start the engine and then move the se-

lector lever through each gear range,

ending in P (Park).

3. Check the fluid level with the engine

idling.

4. Remove the dipstick and wipe it clean

with lint-free paper.

5. Re-insert the dipstick into the charging

pipe as far as it will go.

6. Remove the dipstick and note the read-

ing. If the level is on the low side of either

range, add fluid through the charging

pipe.CAUTION

cDO NOT OVERFILL.

c

Use ONLY NISSAN Matic `D' (Conti-

nental U.S. and Alaska) or genuine

NISSAN Automatic Transmission

Fluid (Canada). Dexron

TMIII/MerconTM

or equivalent may also be used. Out-

side the continental United States and

Alaska contact an authorized NISSAN

dealership for more information re-

garding suitable fluids, including rec-

ommended brands of Dexron

TM

III/MerconTM.

NOTE:

If the vehicle has been driven for a long

time at high speeds, or in city traffic in

hot weather, or if it is being used to pull

a trailer, the fluid level cannot be read

accurately. You should wait until the

fluid has cooled down (about 30 min-

utes).

ADI1033

8-10Do-it-yourself

ZX

Page 159 of 224

For further brake and clutch fluid specifica-

tion information, refer to ``Capacities and

recommended fuel/lubricants'' in the ``Tech-

nical and consumer information'' section of

this manual.

WARNING

Use only new fluid from a sealed con-

tainer. Old, inferior or contaminated

fluid may damage the brake and clutch

systems. The use of improper fluids

can damage the brake system and af-

fect the vehicle's stopping ability.

CAUTION

Do not spill the fluid on any painted

surfaces. This will damage the paint. If

fluid is spilled, wash with water.USA Only

Check the window washer fluid level in the

reservoir tank and add fluid if necessary.

Add a washer solvent to the water for better

cleaning. In the winter season, add a wind-

shield washer anti-freeze. Follow the manu-

facturer's instructions for the mixture ratio.

Canada Only

Add fluid when the low washer fluid warning

light comes on. Add a washer solvent to the

water for better cleaning. In the winter sea-

son, add a windshield washer anti-freeze.Follow the manufacturer's instructions for

the mixture ratio.

CAUTION

Do not substitute engine anti-freeze

coolant for window washer solution.

This may result in damage to the paint.

ADI1034

WINDOW WASHER FLUID

8-12Do-it-yourself

ZX

Page 160 of 224

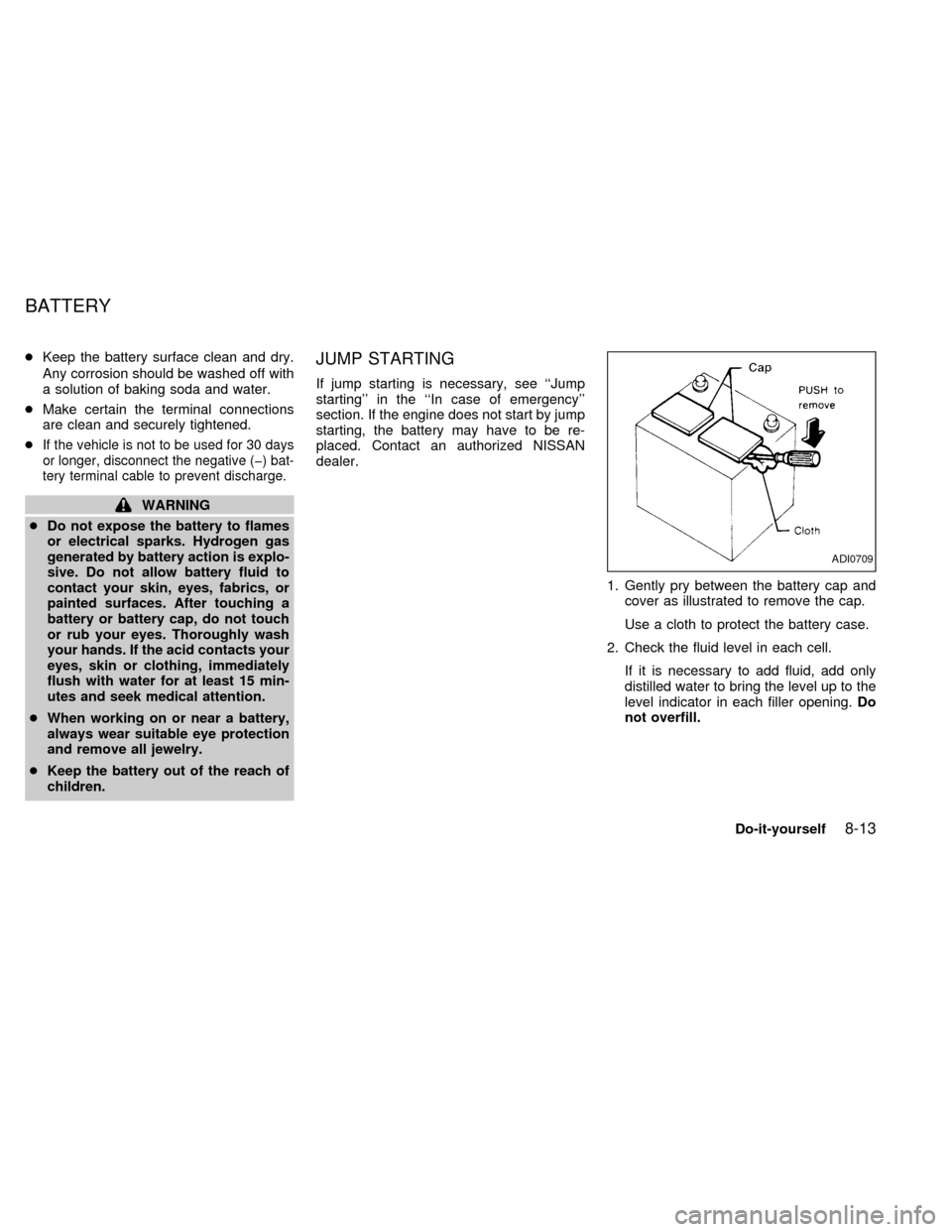

cKeep the battery surface clean and dry.

Any corrosion should be washed off with

a solution of baking soda and water.

cMake certain the terminal connections

are clean and securely tightened.

c

If the vehicle is not to be used for 30 days

or longer, disconnect the negative (þ) bat-

tery terminal cable to prevent discharge.

WARNING

cDo not expose the battery to flames

or electrical sparks. Hydrogen gas

generated by battery action is explo-

sive. Do not allow battery fluid to

contact your skin, eyes, fabrics, or

painted surfaces. After touching a

battery or battery cap, do not touch

or rub your eyes. Thoroughly wash

your hands. If the acid contacts your

eyes, skin or clothing, immediately

flush with water for at least 15 min-

utes and seek medical attention.

cWhen working on or near a battery,

always wear suitable eye protection

and remove all jewelry.

cKeep the battery out of the reach of

children.

JUMP STARTING

If jump starting is necessary, see ``Jump

starting'' in the ``In case of emergency''

section. If the engine does not start by jump

starting, the battery may have to be re-

placed. Contact an authorized NISSAN

dealer.

1. Gently pry between the battery cap and

cover as illustrated to remove the cap.

Use a cloth to protect the battery case.

2. Check the fluid level in each cell.

If it is necessary to add fluid, add only

distilled water to bring the level up to the

level indicator in each filler opening.Do

not overfill.

ADI0709

BATTERY

Do-it-yourself8-13

ZX

Page 161 of 224

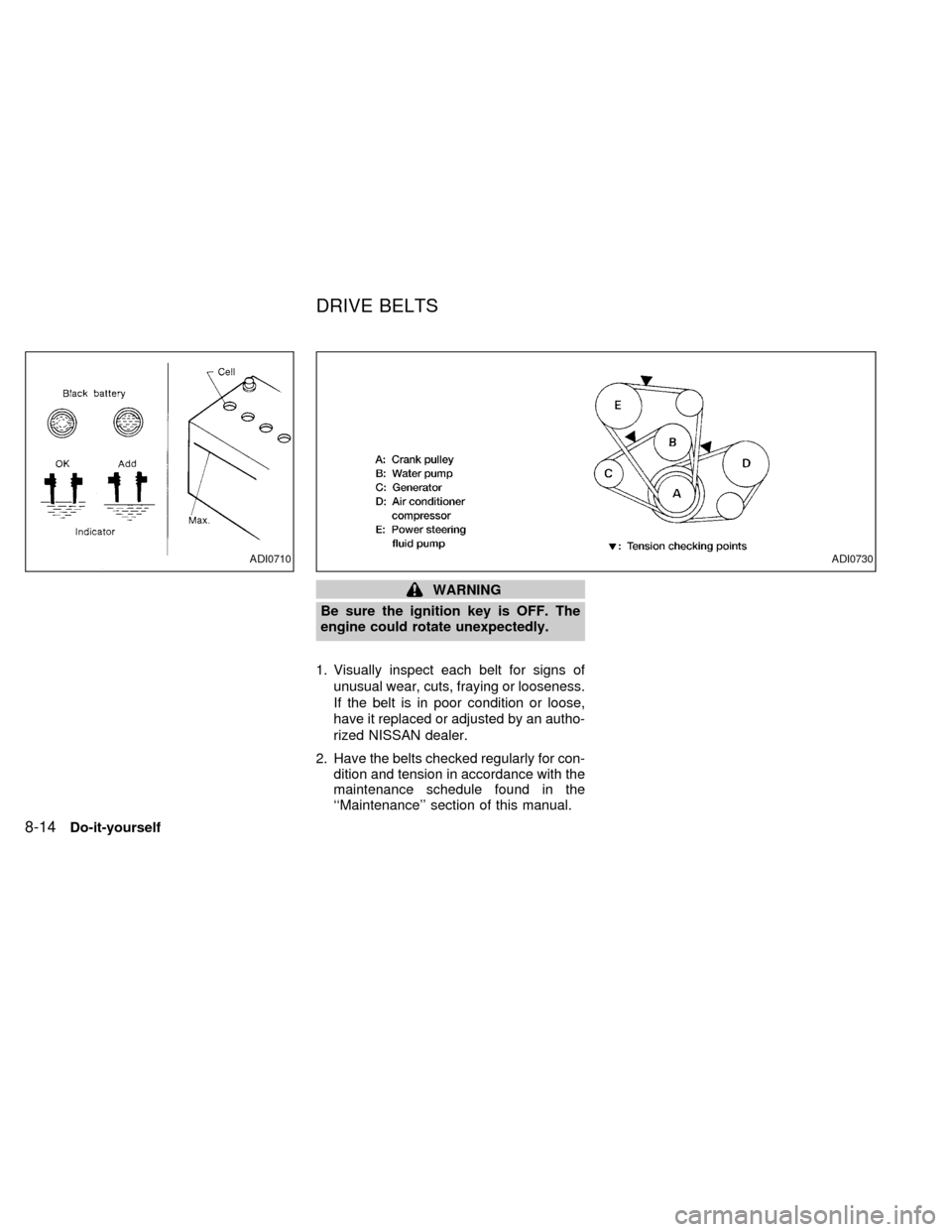

WARNING

Be sure the ignition key is OFF. The

engine could rotate unexpectedly.

1. Visually inspect each belt for signs of

unusual wear, cuts, fraying or looseness.

If the belt is in poor condition or loose,

have it replaced or adjusted by an autho-

rized NISSAN dealer.

2. Have the belts checked regularly for con-

dition and tension in accordance with the

maintenance schedule found in the

``Maintenance'' section of this manual.

ADI0710ADI0730

DRIVE BELTS

8-14Do-it-yourself

ZX

Page 162 of 224

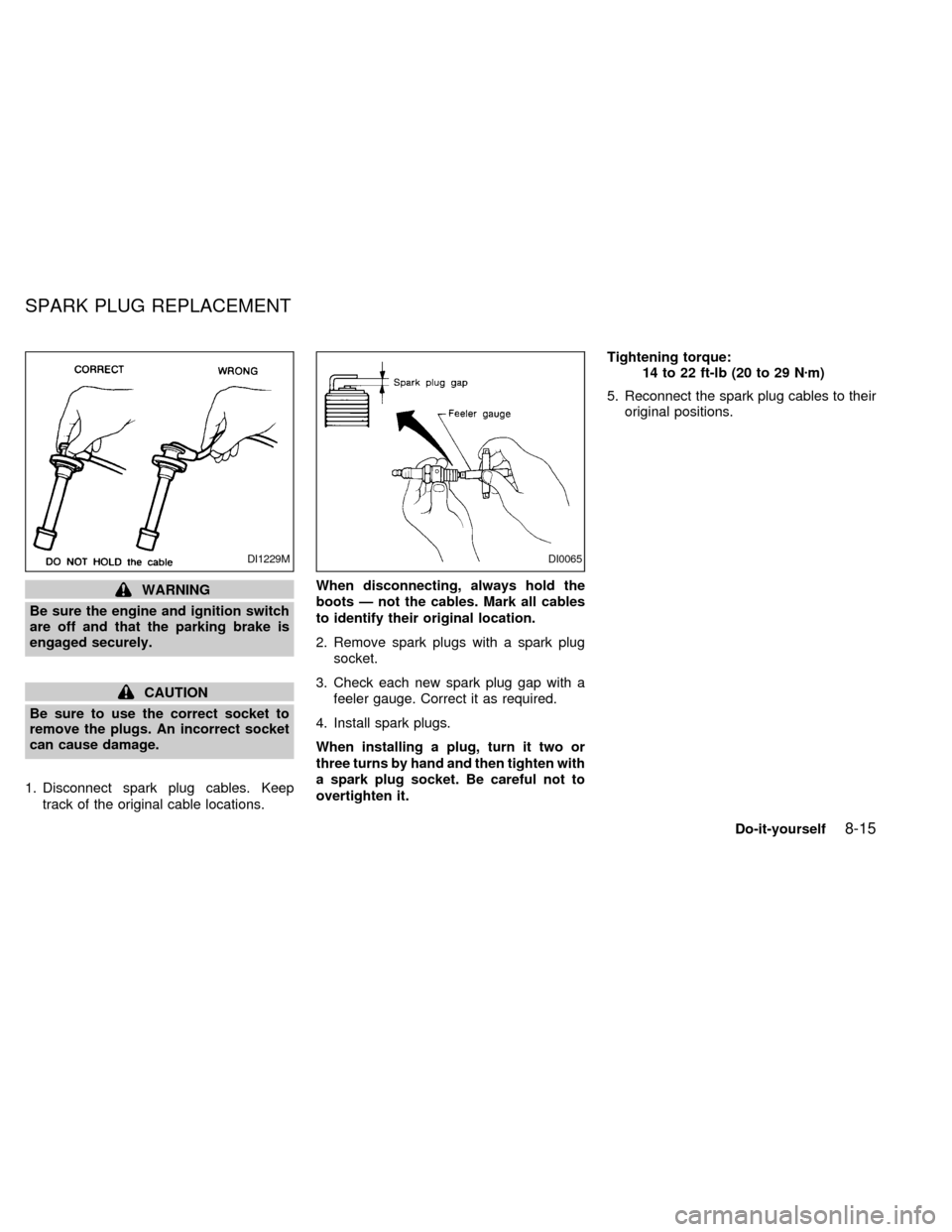

WARNING

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

CAUTION

Be sure to use the correct socket to

remove the plugs. An incorrect socket

can cause damage.

1. Disconnect spark plug cables. Keep

track of the original cable locations.When disconnecting, always hold the

boots Ð not the cables. Mark all cables

to identify their original location.

2. Remove spark plugs with a spark plug

socket.

3. Check each new spark plug gap with a

feeler gauge. Correct it as required.

4. Install spark plugs.

When installing a plug, turn it two or

three turns by hand and then tighten with

a spark plug socket. Be careful not to

overtighten it.Tightening torque:

14 to 22 ft-lb (20 to 29 Nzm)

5. Reconnect the spark plug cables to their

original positions.

DI1229MDI0065

SPARK PLUG REPLACEMENT

Do-it-yourself8-15

ZX

Page 166 of 224

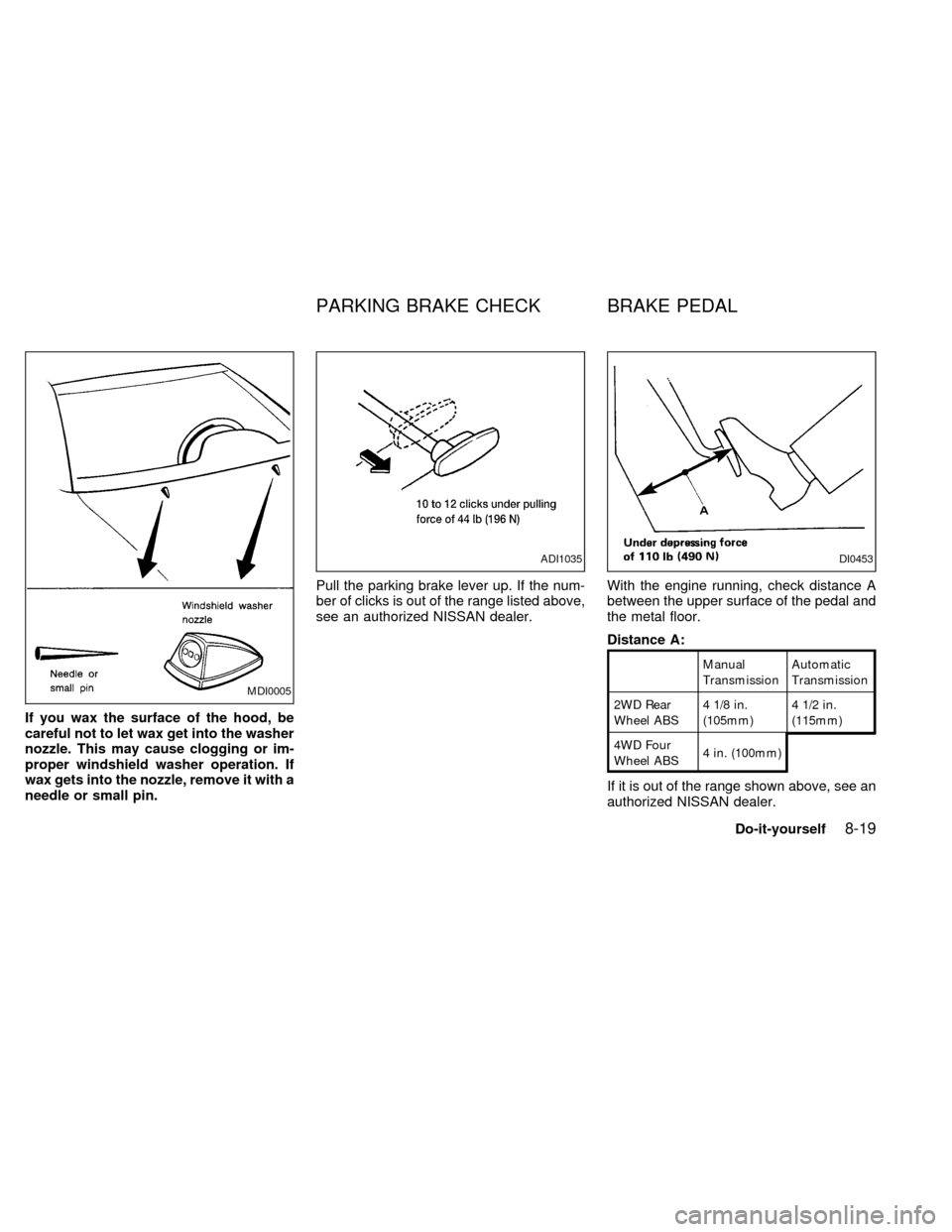

If you wax the surface of the hood, be

careful not to let wax get into the washer

nozzle. This may cause clogging or im-

proper windshield washer operation. If

wax gets into the nozzle, remove it with a

needle or small pin.Pull the parking brake lever up. If the num-

ber of clicks is out of the range listed above,

see an authorized NISSAN dealer.With the engine running, check distance A

between the upper surface of the pedal and

the metal floor.

Distance A:

Manual

TransmissionAutomatic

Transmission

2WD Rear

Wheel ABS4 1/8 in.

(105mm)4 1/2 in.

(115mm)

4WD Four

Wheel ABS4 in. (100mm)

If it is out of the range shown above, see an

authorized NISSAN dealer.

MDI0005

ADI1035DI0453

PARKING BRAKE CHECK BRAKE PEDAL

Do-it-yourself8-19

ZX

Page 167 of 224

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.

The front disc-type brakes self-adjust every

time the brake pedal is applied. The rear

drum-type brakes on two-wheel drive trucks

self-adjust every time the parking brake is

applied. The rear drum-type brakes on four-

wheel drive trucks self-adjust every time the

brake pedal is applied. If the brake pedal

goes down farther than normal, it may be

due to a lack of adjustment of the rear drum

brakes. Apply the parking brake several

times.

WARNING

If the brake pedal height does not re-

turn to normal, see an authorized NIS-

SAN dealer and have it checked.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it will make a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakeschecked as soon as possible if the wear

indicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brake

noise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise from

the rear drum brakes, have them inspected

as soon as possible by an authorized NIS-

SAN dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance Schedule'' section of this

manual.Check the brake booster function with the

following steps:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keeping the pedal depressed for

about 30 seconds, the pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, have

the brakes checked by an authorized NIS-

SAN dealer.

BRAKE BOOSTER

8-20Do-it-yourself

ZX

Page 179 of 224

Your new NISSAN has been designed to

have minimum maintenance requirements

with longer service intervals to save you

both time and money. However, some day-

to-day and regular maintenance is essential

to maintain your NISSAN's good mechani-

cal condition, as well as its emission and

engine performance.

It is the owner's responsibility to make sure

that the specified maintenance, as well as

general maintenance, is performed.

As the vehicle owner, you are the only one

who can ensure that your vehicle receives

proper maintenance. You are a vital link in

the maintenance chain.

General maintenance

General maintenance includes those items

which should be checked during normal

day-to-day operation of the vehicle. They

are essential if your vehicle is to continue to

operate properly. It is your responsibility to

perform these maintenance procedures

regularly as prescribed.

These checks or inspections can be done

by yourself, a qualified technician or, if you

prefer, an authorized NISSAN dealer.

Periodic maintenance

The maintenance items listed under peri-

odic maintenance in this section are re-

quired to be serviced at regular intervals.

However, under severe driving conditions,

additional or more frequent maintenance

will be required.

Where to go for service

If maintenance service is required or your

vehicle appears to malfunction, have the

systems checked and tuned by an autho-

rized NISSAN dealer.

NISSAN technicians are well-trained spe-

cialists who and are kept up to date with the

latest service information through technical

bulletins, service tips, and in-dealership

training programs. They are completely

qualified to work on NISSAN vehicles

beforethey work on your vehicle, rather

than after they have worked on it.

You can be confident that an authorized

NISSAN dealer's service department per-

forms the best job to meet the maintenance

requirements on your vehicle Ð in a reliable

and economic way.During the normal day-to-day operation of

the vehicle, general maintenance should be

performed regularly as prescribed in this

section. If you detect any unusual sounds,

vibrations or smells, be sure to check for the

cause or have an authorized NISSAN

dealer do it promptly. In addition, you should

notify an authorized NISSAN dealer if you

think that repairs are required.

When performing any checks or mainte-

nance work, closely observe the precau-

tions in the ``Do-it-yourself'' section of this

manual.

OUTSIDE THE VEHICLE

The maintenance items listed here should

be performed from time to time, unless

otherwise specified.

Additional information on the following

items with ``*'' is found in the ``Do-it-

yourself'' section of this manual.

Tires*Check the pressure with a gauge

periodically when at a service station, in-

cluding the spare, and adjust to the speci-

fied pressure if necessary. Check carefully

for damage, cuts or excessive wear.

Wheel nuts*When checking the tires, make

GENERAL MAINTENANCE

9-2Maintenance

ZX