brake light NISSAN FRONTIER 2010 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: FRONTIER, Model: NISSAN FRONTIER 2010Pages: 373, PDF Size: 6.21 MB

Page 254 of 373

cIf wheels or tires other than the recom-

mended ones are used, the Vehicle Dy-

namic Control system may not operate

properly and the Vehicle Dynamic Con-

trol off indicator light may come on.

cThe Vehicle Dynamic Control system is

not a substitute for winter tires or tire

chains on a snow covered road.WARNING

cNever rely solely on the hill descent

control system to control vehicle speed

when driving on steep down hill grades.

Always drive carefully and attentively

when using the hill descent control sys-

tem and decelerate the vehicle speed

by depressing the brake pedal if neces-

sary. Be especially careful when driving

on frozen, muddy or an extremely steep

downhill roads. Failure to control ve-

hicle speed may result in a loss of con-

trol of the vehicle and possible serious

injury or death.

cThe hill descent control may not control

the vehicle speed on a hill under all load

or road conditions. Always be prepared

to depress the brake pedal to control

vehicle speed. Failure to do so may re-

sult in a collision or serious personal

injury.

The hill descent control system helps maintain

vehicle speed when driving under 15-21 mph

(25-35 km/h) on steeper downhill grades. Hill

descent control is useful when engine braking

alone in 4H or 4L cannot control vehicle speed.

Hill descent control applies the vehicle brakes to

control vehicle speed allowing the driver to con-centrate on steering while reducing the burden of

brake and accelerator operation.

cWhen additional braking is required on

steep downhill roads activate the hill de-

scent control system by pushing the switch

ON, see “Hill descent control switch” in the

“Instruments and controls” section.

cOnce the system is activated the indicator

light will remain on in the instrument panel,

see “Hill descent control system on indicator

light” in the “Instruments and controls” sec-

tion.

If the accelerator or brake pedal is depressed

while the hill descent control system is on, the

system will stop operating temporarily. As soon

as the accelerator or brake pedal is released, the

hill descent control system begins to function

again if the hill descent control operating condi-

tions are fulfilled.

For the best results, when descending steep

downhill grades, the hill descent control switch

should be ON and the shift selector in 2 (Second

gear) or 1 (Low gear) for engine braking.

HILL DESCENT CONTROL SYSTEM (if

so equipped)

5-36Starting and driving

Page 261 of 373

TIRE PRESSURE MONITORING

SYSTEM (TPMS)

This vehicle is equipped with the Tire Pressure

Monitoring System (TPMS) . It monitors tire pres-

sure of all tires except the spare. When the low

tire pressure warning light is lit, one or more of

your tires is significantly under-inflated. If the

vehicle is being driven with low tire pressure, the

TPMS will activate and warn you of it by the low

tire pressure warning light. This system will acti-

vate only when the vehicle is driven at speeds

above 16 MPH (25 km/h) . For more details, refer

to “Warning/indicator lights and audible remind-

ers” in the “Instruments and controls” section,

and “Tire Pressure Monitoring System (TPMS)”

in the “Starting and driving” section.

WARNING

cIf the low tire pressure warning light

illuminates while driving, avoid sudden

steering maneuvers or abrupt braking,

reduce vehicle speed, pull off the road

to a safe location and stop the vehicle

as soon as possible. Driving with under-

inflated tires may permanently damage

the tires and increase the likelihood of

tire failure. Serious vehicle damage

could occur and may lead to an acci-

dent and could result in serious per-

sonal injury. Check the tire pressure for

all four tires. Adjust the tire pressure to

the recommended COLD tire pressure

shown on the Tire and Loading Informa-

tion label to turn the low tire pressure

warning light OFF. If you have a flat tire,

replace it with a spare tire as soon as

possible.

cWhen a spare tire is mounted or a wheel

is replaced, the TPMS will not function

and the low tire pressure warning light

will flash for approximately 1 minute.

The light will remain on after 1 minute.

Contact your NISSAN dealer as soon as

possible for tire replacement and/or

system resetting.cReplacing tires with those not originally

specified by NISSAN could affect the

proper operation of the TPMS.

cDo not inject any tire liquid or aerosol

tire sealant into the tires, as this may

cause a malfunction of the tire pressure

sensors.

CHANGING A FLAT TIRE

If you have a flat tire, follow the instructions be-

low:

Stopping the vehicle

1. Safely move the vehicle off the road and

away from traffic.

2. Turn on the hazard warning flashers.

3. Park on a level surface and apply the parking

brake. Shift the manual transmission into R

(Reverse) , or the automatic transmission

into P (Park) .

4. Turn off the engine.

5. Raise the hood to warn other traffic and to

signal professional road assistance person-

nel that you need assistance.

6. Have all passengers get out of the vehicle

and stand in a safe place, away from traffic

and clear of the vehicle.

FLAT TIRE

In case of emergency6-3

Page 268 of 373

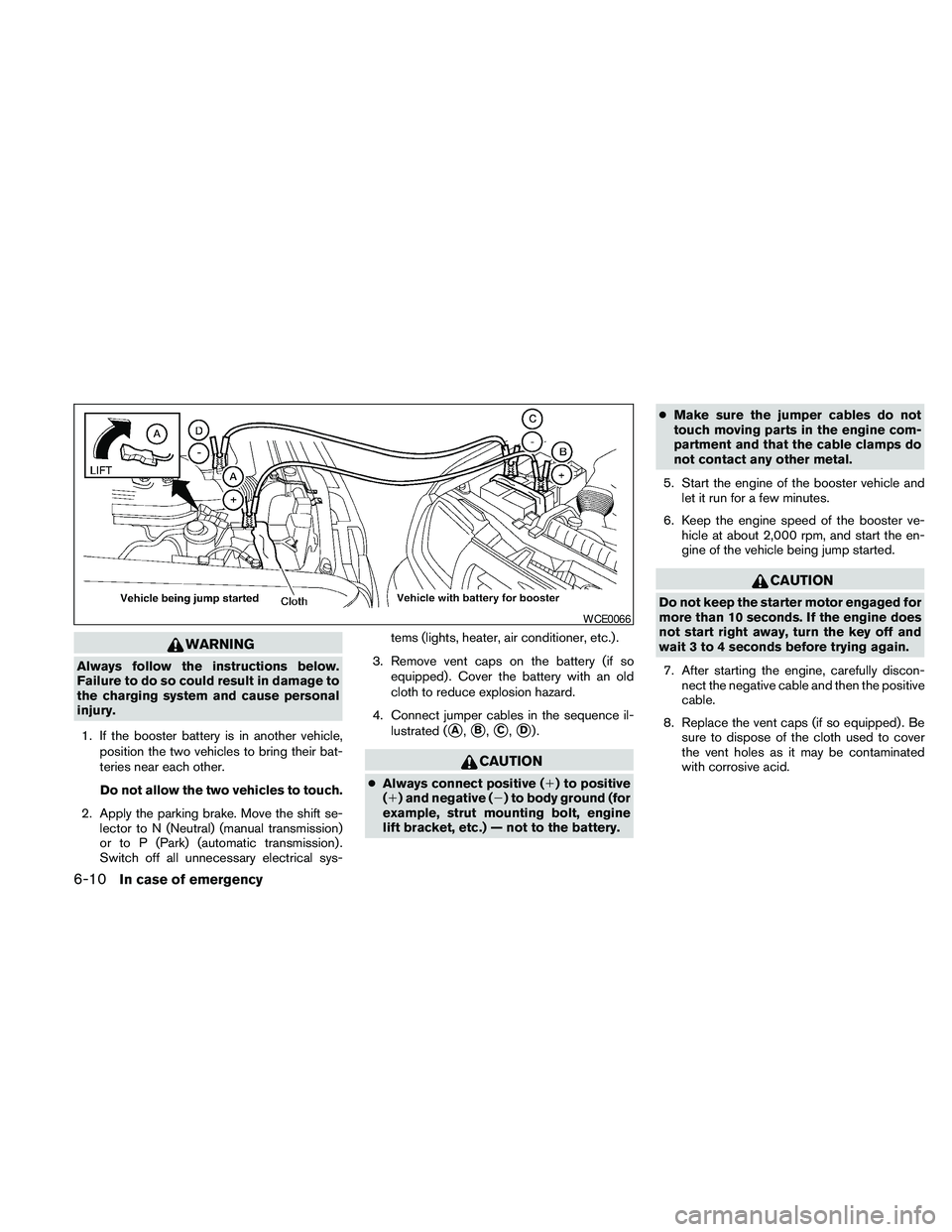

WARNING

Always follow the instructions below.

Failure to do so could result in damage to

the charging system and cause personal

injury.

1. If the booster battery is in another vehicle,

position the two vehicles to bring their bat-

teries near each other.

Do not allow the two vehicles to touch.

2. Apply the parking brake. Move the shift se-

lector to N (Neutral) (manual transmission)

or to P (Park) (automatic transmission) .

Switch off all unnecessary electrical sys-tems (lights, heater, air conditioner, etc.) .

3. Remove vent caps on the battery (if so

equipped) . Cover the battery with an old

cloth to reduce explosion hazard.

4. Connect jumper cables in the sequence il-

lustrated (

sA,sB,sC,sD).

CAUTION

cAlways connect positive (1) to positive

(1) and negative (2) to body ground (for

example, strut mounting bolt, engine

lift bracket, etc.) — not to the battery.cMake sure the jumper cables do not

touch moving parts in the engine com-

partment and that the cable clamps do

not contact any other metal.

5. Start the engine of the booster vehicle and

let it run for a few minutes.

6. Keep the engine speed of the booster ve-

hicle at about 2,000 rpm, and start the en-

gine of the vehicle being jump started.

CAUTION

Do not keep the starter motor engaged for

more than 10 seconds. If the engine does

not start right away, turn the key off and

wait 3 to 4 seconds before trying again.

7. After starting the engine, carefully discon-

nect the negative cable and then the positive

cable.

8. Replace the vent caps (if so equipped) . Be

sure to dispose of the cloth used to cover

the vent holes as it may be contaminated

with corrosive acid.

WCE0066

6-10In case of emergency

Page 281 of 373

8 Maintenance and do-it-yourself

Maintenance requirements..........................8-2

General maintenance..............................8-2

Explanation of general maintenance items.........8-2

Maintenance precautions...........................8-5

Engine compartment check locations................8-6

Engine cooling system.............................8-8

Checking engine coolant level...................8-8

Changing engine coolant........................8-9

Engine oil.........................................8-9

Checking engine oil level........................8-9

Changing engine oil...........................8-11

Changing engine oil filter.......................8-12

5-speed automatic transmission fluid...............8-13

Power steering fluid...............................8-13

Brake and clutch fluid.............................8-14

Brake fluid....................................8-14

Clutch fluid...................................8-14

Window washer fluid.............................8-15

Window washer fluid reservoir..................8-15

Battery..........................................8-15

Jump starting.................................8-17

Variable voltage control system.....................8-17

Drive belt........................................8-18Spark plugs......................................8-19

Replacing spark plugs.........................8-19

Air cleaner.......................................8-20

In-cabin microfilter (if so equipped)..............8-20

Windshield wiper blades..........................8-22

Cleaning.....................................8-22

Replacing....................................8-22

Brakes..........................................8-23

Fuses...........................................8-24

Engine compartment...........................8-24

Passenger compartment.......................8-25

Battery replacement..............................8-26

Keyfob (if so equipped)........................8-27

Lights...........................................8-28

Headlights....................................8-28

Exterior and interior lights.......................8-30

Wheels and tires.................................8-32

Tire pressure..................................8-32

Tire labeling...................................8-36

Types of tires..................................8-38

Tire chains....................................8-39

Changing wheels and tires.....................8-39

Page 283 of 373

When driving in areas using road salt or other

corrosive materials, check lubrication frequently.

Lights*Clean the headlights on a regular basis.

Make sure that the headlights, stop lights, tail

lights, turn signal lights, and other lights are all

operating properly and installed securely. Also

check headlight aim.

Road wheel nuts (lug nuts)*When checking

the tires, make sure no wheel nuts are missing,

and check for any loose wheel nuts. Tighten if

necessary.

Tire rotation*Tires should be rotated every

7,500 miles (12,000 km) .

Tires*Check the pressure with a gauge often

and always prior to long distance trips. If neces-

sary, adjust the pressure in all tires, including the

spare, to the pressure specified. Check carefully

for damage, cuts or excessive wear.

Tire Pressure Monitoring System (TPMS)

transmitter componentsReplace the TPMS

transmitter grommet seal, valve core and cap

when the tires are replaced due to wear or age.

Wheel alignment and balanceIf the vehicle

should pull to either side while driving on a

straight and level road, or if you detect uneven or

abnormal tire wear, there may be a need for wheelalignment. If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing may be

needed.

cFor additional information regarding tires,

refer to “Important Tire Safety Information”

(US) or “Tire Safety Information” (Canada) in

the Warranty Information Booklet.

WindshieldClean the windshield on a regular

basis. Check the windshield at least every six

months for cracks or other damage. Have a dam-

aged windshield repaired by a qualified repair

facility.

Windshield wiper blades*Check for cracks or

wear if they do not wipe properly.

Inside the vehicle

The maintenance items listed here should be

checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the ve-

hicle, etc.

Additional information on the following

items with an “*” is found later in this sec-

tion.

Accelerator pedalCheck the pedal for smooth

operation and make sure the pedal does not bind

or require uneven effort. Keep the floor mat away

from the pedal.Automatic transmission P (Park) position

mechanismOn a fairly steep hill check that your

vehicle is held securely with the shift selector in

the P (Park) position without applying any brakes.

Brake pedalCheck the pedal for smooth opera-

tion. If the brake pedal suddenly goes down fur-

ther than normal, the pedal feels spongy or the

vehicle seems to take longer to stop, see a

NISSAN dealer immediately. Keep the floor mat

away from the pedal.

BrakesCheck that the brakes do not pull the

vehicle to one side when applied.

Parking brakeCheck the parking brake opera-

tion regularly. The vehicle should be securely held

on a fairly steep hill with only the parking brake

applied. If the parking brake needs adjustment,

see a NISSAN dealer.

Seats

Check seat position controls such as seat

adjusters, seatback recliner, etc. to ensure they op-

erate smoothly and all latches lock securely in every

position. Check that the head restraints and head-

rests move up and down smoothly and the locks (if

so equipped) hold securely in all latched positions.

Seat beltsCheck that all parts of the seat belt

system (for example, buckles, anchors, adjusters

and retractors) operate properly and smoothly,

and are installed securely. Check the belt web-

bing for cuts, fraying, wear or damage.

Maintenance and do-it-yourself8-3

Page 284 of 373

Steering wheelCheck for changes in the steer-

ing system, such as excessive freeplay, hard

steering or strange noises.

Warning lights and chimesMake sure all

warning lights and chimes are operating properly.

Windshield wiper and washer*Check that

the wipers and washer operate properly and that

the wipers do not streak.

Windshield defrosterCheck that the air

comes out of the defroster outlets properly and in

sufficient quantity when operating the heater or

air conditioner.

Under the hood and vehicle

The maintenance items listed here should be

checked periodically (for example, each time you

check the engine oil or refuel) .

Battery*Check the fluid level in each cell. It

should be between the MAX and MIN lines. Ve-

hicles operated in high temperatures or under

severe conditions require frequent checks of the

battery fluid level.

Brake and clutch fluid levels*Make sure that

the brake and clutch fluid level is between the

MIN and MAX lines on the reservoir.

Engine coolant level*Check the coolant level

when the engine is cold.Engine drive belts*Make sure the drive belts

are not frayed, worn, cracked or oily.

Engine oil level*Check the level after parking

the vehicle on a level surface with the engine off.

Wait more than 10 minutes for the oil to drain

back into the oil pan.

Exhaust systemMake sure there are no loose

supports, cracks or holes. If the sound of the

exhaust seems unusual or there is a smell of

exhaust fumes, immediately have the exhaust

system inspected by a NISSAN dealer. See the

carbon monoxide warning in the “Starting and

driving” section of this manual.

Fluid leaksCheck under the vehicle for fuel, oil,

water or other fluid leaks after the vehicle has

been parked for a while. Water dripping from the

air conditioner after use is normal. If you should

notice any leaks or if gasoline fumes are evident,

check for the cause and have it corrected imme-

diately.

Power steering fluid level* and linesCheck

the level when the fluid is cold, with the engine

off. Check the lines for proper attachment, leaks,

cracks, etc.Radiator and hosesCheck the front of the

radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure the

hoses have no cracks, deformation, rot or loose

connections.

UnderbodyThe underbody is frequently ex-

posed to corrosive substances such as those

used on icy roads or to control dust. It is very

important to remove these substances from the

underbody, otherwise rust may form on the floor

pan, frame, fuel lines and exhaust system. At the

end of winter, the underbody should be thor-

oughly flushed with plain water, in those areas

where mud and dirt may have accumulated. See

the “Appearance and care” section of this

manual.

Windshield washer fluid*Check that there is

adequate fluid in the reservoir.

8-4Maintenance and do-it-yourself

Page 294 of 373

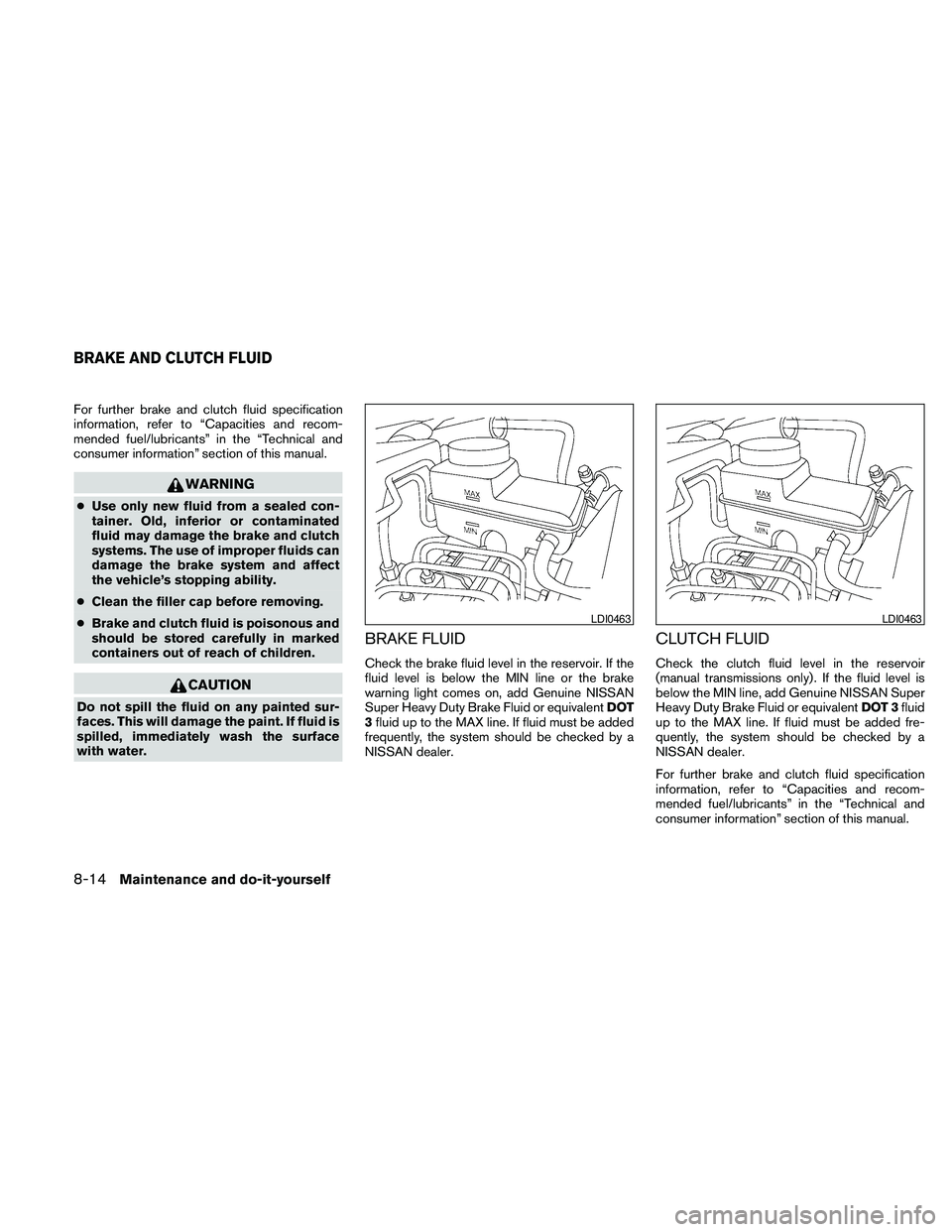

For further brake and clutch fluid specification

information, refer to “Capacities and recom-

mended fuel/lubricants” in the “Technical and

consumer information” section of this manual.

WARNING

cUse only new fluid from a sealed con-

tainer. Old, inferior or contaminated

fluid may damage the brake and clutch

systems. The use of improper fluids can

damage the brake system and affect

the vehicle’s stopping ability.

cClean the filler cap before removing.

cBrake and clutch fluid is poisonous and

should be stored carefully in marked

containers out of reach of children.

CAUTION

Do not spill the fluid on any painted sur-

faces. This will damage the paint. If fluid is

spilled, immediately wash the surface

with water.

BRAKE FLUID

Check the brake fluid level in the reservoir. If the

fluid level is below the MIN line or the brake

warning light comes on, add Genuine NISSAN

Super Heavy Duty Brake Fluid or equivalentDOT

3fluid up to the MAX line. If fluid must be added

frequently, the system should be checked by a

NISSAN dealer.

CLUTCH FLUID

Check the clutch fluid level in the reservoir

(manual transmissions only) . If the fluid level is

below the MIN line, add Genuine NISSAN Super

Heavy Duty Brake Fluid or equivalentDOT 3fluid

up to the MAX line. If fluid must be added fre-

quently, the system should be checked by a

NISSAN dealer.

For further brake and clutch fluid specification

information, refer to “Capacities and recom-

mended fuel/lubricants” in the “Technical and

consumer information” section of this manual.

LDI0463LDI0463

BRAKE AND CLUTCH FLUID

8-14Maintenance and do-it-yourself

Page 303 of 373

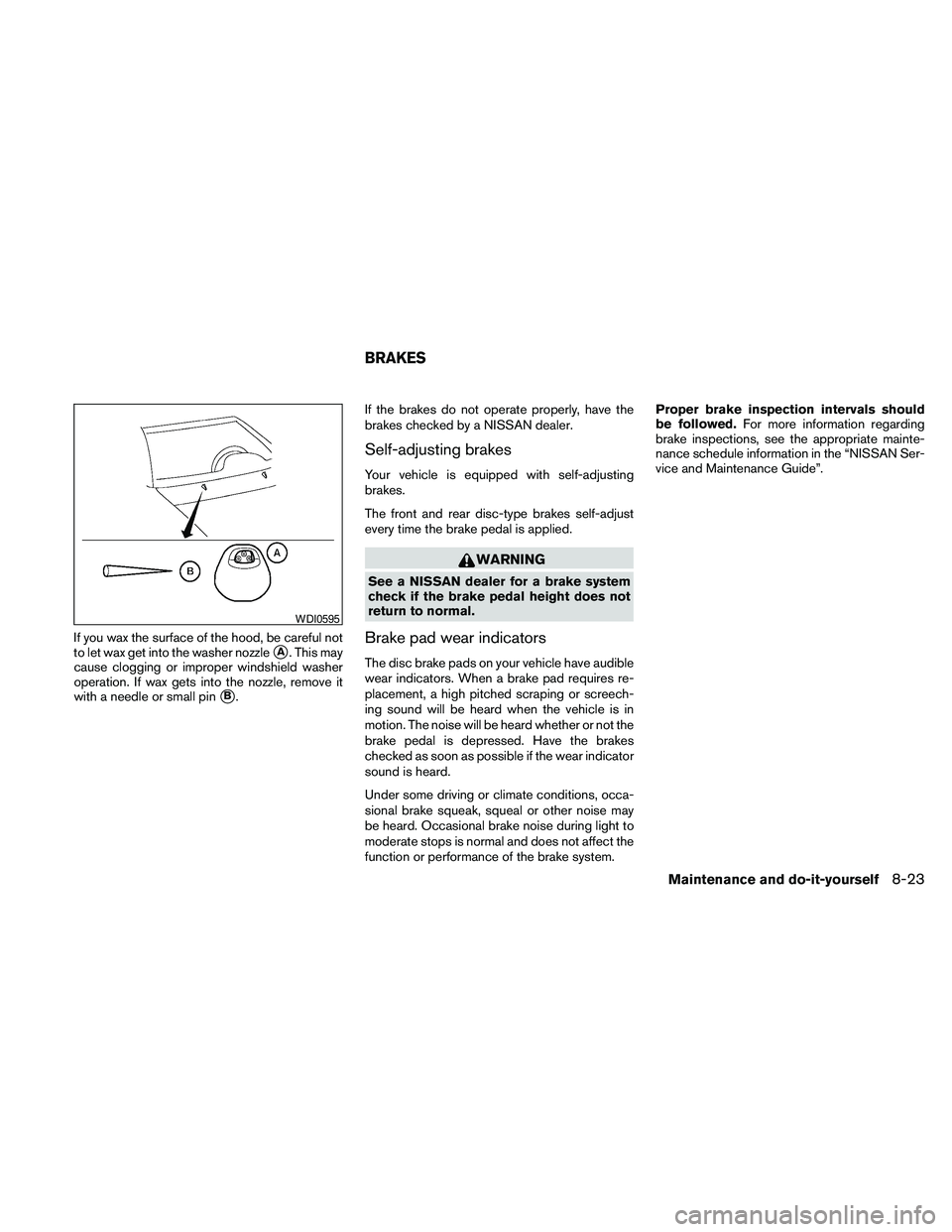

If you wax the surface of the hood, be careful not

to let wax get into the washer nozzle

sA. This may

cause clogging or improper windshield washer

operation. If wax gets into the nozzle, remove it

with a needle or small pin

sB.If the brakes do not operate properly, have the

brakes checked by a NISSAN dealer.

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.

The front and rear disc-type brakes self-adjust

every time the brake pedal is applied.

WARNING

See a NISSAN dealer for a brake system

check if the brake pedal height does not

return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have audible

wear indicators. When a brake pad requires re-

placement, a high pitched scraping or screech-

ing sound will be heard when the vehicle is in

motion. The noise will be heard whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear indicator

sound is heard.

Under some driving or climate conditions, occa-

sional brake squeak, squeal or other noise may

be heard. Occasional brake noise during light to

moderate stops is normal and does not affect the

function or performance of the brake system.Proper brake inspection intervals should

be followed.For more information regarding

brake inspections, see the appropriate mainte-

nance schedule information in the “NISSAN Ser-

vice and Maintenance Guide”.

WDI0595

BRAKES

Maintenance and do-it-yourself8-23

Page 321 of 373

Replacing wheels and tires

When replacing a tire, use the same size, tread

design, speed rating and load carrying capacity

as originally equipped. Recommended types and

sizes are shown in “Wheels and tires” in the

“Technical and consumer information” section of

this manual.

WARNING

cThe use of tires other than those recom-

mended or the mixed use of tires of

different brands, construction (bias,

bias-belted or radial) , or tread patterns

can adversely affect the ride, braking,

handling, VDC system, ground clear-

ance, body-to-tire clearance, tire chain

clearance, speedometer calibration,

headlight aim and bumper height.

Some of these effects may lead to acci-

dents and could result in serious per-

sonal injury.

cIf your vehicle was originally equipped

with 4 tires that were the same size and

you are only replacing 2 of the 4 tires,

install the new tires on the rear axle.

Placing new tires on the front axle may

cause loss of vehicle control in some

driving conditions and cause an acci-

dent and personal injury.cIf the wheels are changed for any rea-

son, always replace with wheels which

have the same off-set dimension.

Wheels of a different off-set could

cause premature tire wear, degrade ve-

hicle handling characteristics, affect

the VDC system and/or interference

with the brake discs/drums. Such inter-

ference can lead to decreased braking

efficiency and/or early brake pad/shoe

wear. Refer to “Wheels and tires” in the

“Technical and consumer information”

section of this manual for wheel off-set

dimensions.

cWhen a spare tire is mounted or a wheel

is replaced, tire pressure will not be

indicated, the TPMS will not function

and the low tire pressure warning light

will flash for approximately 1 minute.

The light will remain on after 1 minute.

Contact your NISSAN dealer as soon as

possible for tire replacement and/or

system resetting.

cReplacing tires with those not originally

specified by NISSAN could affect the

proper operation of the TPMS.cDo not install a damaged or deformed

wheel or tire even if it has been re-

paired. Such wheels or tires could have

structural damage and could fail with-

out warning.

cThe use of retread tires is not

recommended.

cFor additional information regarding

tires, refer to “Important Tire Safety In-

formation” (US) or “Tire Safety Informa-

tion” (Canada) in the Warranty Informa-

tion Booklet.

Four-wheel drive models

CAUTION

Always use tires of the same type, size,

brand, construction (bias, bias-belted or

radial) , and tread pattern on all four

wheels. Failure to do so may result in a

circumference difference between tires

on the front and rear axles which will

cause excessive tire wear and may dam-

age the transmission, transfer case and

differential gears.

If excessive tire wear is found, it is recommended

that all four tires be replaced with tires of the

same size, brand, construction and tread pattern.

Maintenance and do-it-yourself8-41

Page 356 of 373

Trailer lights

CAUTION

When splicing into the vehicle electrical

system, a commercially available power-

type module/converter must be used to

provide power for all trailer lighting. This

unit uses the vehicle battery as a direct

power source for all trailer lights while

using the vehicle tail light, stoplight and

turn signal circuits as a signal source. The

module/converter must draw no more

that 15 milliamps from the stop and tail

lamp circuits. Using a module/converter

that exceeds these power requirements

may damage the vehicle’s electrical sys-

tem. See a reputable trailer dealer to ob-

tain the proper equipment and to have it

installed.

Trailer lights should comply with federal and/or

local regulations. For assistance in hooking up

trailer lights, contact a NISSAN dealer or repu-

table trailer dealer. Vehicles equipped with the

optional trailer tow package are equipped with a

7-pin trailer harness connector. A flat 4–pin har-

ness is available from your dealer for vehicles

without a tow package. If your trailer is equipped

with a flat 4-pin connector, an adapter will beneeded to connect the trailer lights to the vehicle.

Adapters are available at auto parts stores and

hitch retailers.Trailer brakes

If your trailer is equipped with a braking system,

make sure it conforms to federal and/or local

regulations and that it is properly installed.

Vehicles equipped with a 7–pin trailer harness

connector are pre-wired for a trailer brake con-

troller. See a NISSAN dealer for a trailer brake

adapter harness.

WARNING

Never connect a trailer brake system di-

rectly to the vehicle brake system.

When towing a trailer load of 3,500 lbs.

(1587 kg) or more, trailers with a brake

system MUST be used.However, most states

require a separate braking system on trailers with

a loaded weight above a specific amount. Make

sure the trailer meets the local regulations and

the regulations where you plan to tow.

Several types of braking systems are available.

Surge Brakes -The surge brake actuator is

mounted on the trailer tongue with a hydraulic line

running to each trailer wheel. Surge brakes are

activated by the trailer pushing against the hitchball when the tow vehicle is braking. Hydraulic

surge brakes are common on rental trailers and

some boat trailers. In this type of system, there is

no hydraulic or electric connection for brake op-

eration between the tow vehicle and the trailer.

Electric Trailer Brakes -Electric braking sys-

tems are activated by an electronic signal sent

from a trailer brake controller (special brake-

sensing module) . If electric trailer brakes are

used, see9Electric trailer brake controller9in this

section.

Have a professional supplier of towing equip-

ment make sure the trailer brakes are properly

installed and demonstrate proper brake function

testing.

Electric trailer brake controller

Trailers equipped with electric brakes may re-

quire the installation of an aftermarket trailer

brake controller.

A Genuine NISSAN jumper harness is available

that is specifically designed to be used when

installing an aftermarket brake controller.

Install the aftermarket electric trailer brake con-

troller according to the manufacturer’s instruc-

tions.

9-32Technical and consumer information