brakes NISSAN FRONTIER 2022 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2022, Model line: FRONTIER, Model: NISSAN FRONTIER 2022Pages: 556, PDF Size: 6.11 MB

Page 400 of 556

SONAR LIMITATIONS

WARNING

Listed below are the system limitations

for the sonar system. Failure to operate

the vehicle in accordance with these

system limitations could result in seri-

ous injury or death.

• The system is deactivated at speeds

above 6 mph (10 km/h). It is reacti-

vated at lower speeds.

• Inclement weather or ultrasonic

sources such as an automatic car

wash, a truck’s compressed-air

brakes or a pneumatic drill may af-

fect the function of the system; this

may include reduced performance or

a false activation.

• The system is not designed to pre-

vent contact with small or moving

objects. Always move slowly. The

system will not detect small objects

below the bumper or on the ground.

• The system may not detect the fol-

lowing objects: fluff y objects such as

snow, cloth, cotton, glass-wool, etc.;

thin objects such as rope, wire and

chain, etc.; or wedge-shaped objects. •

The system may not detect objects

at speeds above 3 mph (5 km/h) and

may not detect certain angular or

moving objects.

• Do not attach stickers (including

transparent material), install acces-

sories, or apply anything blocking

the sensors. These conditions may

reduce the ability of the system.

SYSTEM TEMPORARILY

UNAVAILABLE

When sonar blockage is detected, the sys-

tem will be deactivated automatically.

The system is not available until the condi-

tions no longer exist.

The sonar sensors may be blocked by tem-

porary ambient conditions such as splash-

ing water, mist or fog. The blocked condi-

tion may also be caused by objects such as

ice, frost or dirt obstructing the sonar

sensors.

Action to take:

When the above conditions no longer exist,

the system will resume automatically.

SYSTEM MAINTENANCE

The sonar sensorsO1are located on the

rear bumper. Always keep the area near

the sonar sensors clean.

The sonar sensors may be blocked by tem-

porary ambient conditions such as splash-

ing water, mist or fog.

The blocked condition may also be caused

by objects such as ice, frost or dirt ob-

structing the sonar sensors.

Check for and remove objects obstructing

the area around the sonar sensors.

LSD4364

5-128Starting and driving

Page 431 of 556

8 Do-it-yourself

Maintenance precautions.......................8-2

Engine compartment check locations ...........8-3

Engine cooling system ..........................8-4

Checking engine coolant level ................8-5

Changing engine coolant ....................8-5

Engine oil .......................................8-6

Checking engine oil level .....................8-6

Changing engine oil and oil filter ..............8-6

Automatic Transmission Fluid (ATF) ..............8-11

Power Steering Fluid (PSF) .......................8-11

Brake fluid ...................................... 8-12

Brake fluid ................................... 8-12

Windshield-washer fluid ........................8-13

Windshield-washer fluid reservoir ...........8-13

Battery......................................... 8-14

Jump starting ............................... 8-15

Variable voltage control system ................8-16

Drive belt ....................................... 8-16

Spark plugs .................................... 8-17

Replacing spark plugs ....................... 8-17

Air cleaner ..................................... 8-18In-cabin microfilter

.......................... 8-18

Windshield wiper blades ........................8-19

Cleaning .................................... 8-19

Replacing ................................... 8-19

Brakes ......................................... 8-20

Fuses .......................................... 8-21

Engine compartment ....................... 8-21

Passenger compartment ...................8-23

Battery replacement ........................... 8-23

NISSAN Intelligent Key® ......................8-24

Lights .......................................... 8-25

Headlights .................................. 8-25

Fog lights (if so equipped) ...................8-26

Exterior and interior lights ...................8-27

Wheels and tires ............................... 8-30

Tire pressure ................................ 8-30

Tire labeling ................................. 8-34

T

ypes of tires ................................ 8-37

Tire chains .................................. 8-38

Changing wheels and tires ..................8-39

Page 450 of 556

Be careful not to let anything get into the

washer nozzle

OD. This may cause clogging

or improper windshield–washer operation.

If something gets into the nozzle, remove it

with a needle or small pin

OC. If the brakes do not operate properly, have

the brakes checked. It is recommended

that you visit a NISSAN dealer for this

service.

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.

The front and rear disc-type brakes self-

adjust every time the brake pedal is

applied.

WARNING

Have your brake system checked if the

brake pedal height does not return to

normal. It is recommended that you

visit a NISSAN dealer for this service.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, a high pitched

scraping or screeching sound will be heard

when the vehicle is in motion. The noise will

be heard whether or not the brake pedal is

depressed. Have the brakes checked as

soon as possible if the wear indicator

sound is heard. Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brake

noise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

Proper brake inspection intervals should

be followed.

For additional information re-

garding brake inspections, see the appro-

priate maintenance schedule information

in the "Maintenance and schedules" sec-

tion of this manual.LDI2710

BRAKES

8-20Do-it-yourself

Page 477 of 556

Doors and engine hood:Check that the

doors and engine hood operate properly.

Also ensure that all latches lock securely.

Lubricate hinges, latches, latch pins, rollers

and links if necessary. Make sure that the

secondary latch keeps the hood from

opening when the primary latch is

released.

When driving in areas using road salt or

other corrosive materials, check lubrica-

tion frequently.

Check that the gas stays or struts properly

and securely hold the hood, trunk, or rear

hatch fully open. If the hood, trunk, or rear

hatch is not held open, have the gas stays

or struts replaced.

Lights*: Clean the headlights on a regular

basis. Make sure that the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and in-

stalled securely. Also check headlight aim.

Road wheel nuts (lug nuts)*: When check-

ing the tires, make sure no wheel nuts are

missing, and check for any loose wheel

nuts. Tighten if necessary.

Tire rotation*: Rotate tires at the specified

interval shown in the maintenance

schedule. Tires*:

Check the pressure with a gauge

of ten and always prior to long distance

trips. If necessary, adjust the pressure in all

tires, including the spare, to the pressure

specified. Check carefully for damage, cuts

or excessive wear.

Tire Pressure Monitoring System (TPMS)

tire pressure sensor: It is recommended

that you replace the tire pressure sensor

assembly when the tires are replaced due

to wear or age.

Wheel alignment and balance:

If the ve-

hicle should pull to either side while driving

on a straight and level road, or if you detect

uneven or abnormal tire wear, there may be

a need for wheel alignment. If the steering

wheel or seat vibrates at normal highway

speeds, wheel balancing may be needed.

For additional information regarding tires,

refer to “Important Tire Safety Information”

(US) or “Tire Safety Information” (Canada) in

the Warranty Information Booklet.

Windshield: Clean the windshield on a

regular basis. Check the windshield at least

every six months for cracks or other dam-

age. Have a damaged windshield repaired

by a qualified repair facility. It is recom-

mended that you have a damaged wind-

shield repaired by a NISSAN dealer, or a NISSAN Certified Collision Center. To locate

a collision center in your area, refer to

http://collision.nissanusa.com.

Windshield wiper blades*:

Check for

cracks or wear if they do not wipe properly.

Inside the vehicle

The maintenance items listed here should

be checked on a regular basis, such as

when performing scheduled maintenance,

cleaning the vehicle, etc.

Accelerator pedal: Check the pedal for

smooth operation and make sure the

pedal does not catch or require uneven

effort. Keep the floor mat away from the

pedal.

Automatic transmission P (Park) mecha-

nism: On a fairly steep hill check that the

vehicle is held securely with the shif t lever

in the P (Park) position without applying any

brakes.

Brake pedal: Check the pedal for smooth

operation. If the brake pedal suddenly goes

down further than normal, the pedal feels

spongy or the vehicle seems to take longer

to stop, have your vehicle checked imme-

diately. It is recommended that you visit a

NISSAN dealer for this service. Keep the

floor mat away from the pedal.

Maintenance and schedules9-3

Page 478 of 556

Brakes:Check that the brakes do not pull

the vehicle to one side when applied.

Parking brake: Check the parking brake

operation regularly. The vehicle should be

securely held on a fairly steep hill with only

the parking brake applied. If the parking

brake needs adjustment, it is recom-

mended that you visit a NISSAN dealer for

this service.

Seats: Check seat position controls such

as seat adjusters, seatback recliner, etc., to

ensure they operate smoothly and all

latches lock securely in every position.

Check that the head restraints/headrests

move up and down smoothly and the locks

(if so equipped) hold securely in all latched

positions.

Seat belts: Check that all parts of the seat

belt system (for example, buckles, anchors,

adjusters and retractors) operate properly

and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying,

wear or damage.

Steering wheel: Check for changes in the

steering system, such as excessive free

play, hard steering or strange noises.

Warning lights and chimes: Make sure all

warning lights and chimes are operating

properly. Windshield defroster:

Check that the air

comes out of the defroster outlets properly

and in sufficient quantity when operating

the heater or air conditioner.

Windshield wiper and washer*: Check

that the wipers and washer operate prop-

erly and that the wipers do not streak.

Under the hood and vehicle

The maintenance items listed here should

be checked periodically (for example, each

time you check the engine oil or refuel).

Battery (for maintenance free batter-

ies)*: This vehicle is equipped with a sealed

maintenance free battery. It is recom-

mended that you visit a NISSAN dealer for

service.

NOTE:

Care should be taken to avoid situations

that can lead to potential battery dis-

charge and potential no-start conditions

such as:

1. Installation or extended use of elec- tronic accessories that consume bat-

tery power when the engine is not

running (Phone chargers, GPS, DVD

players, etc.). 2. Vehicle is not driven regularly and/or

only driven short distances.

In these cases, the battery may need to

be charged to maintain battery health.

Brake fluid level*: Make sure that the fluid

level is between the MAX and MIN lines on

the reservoir.

Engine coolant level*: Check the coolant

level when the engine is cold.

Engine drive belts*: Check engine drive

belts for wear, fraying or cracking and for

proper tension. Replace any damaged

drive belts.

9-4Maintenance and schedules

Page 529 of 556

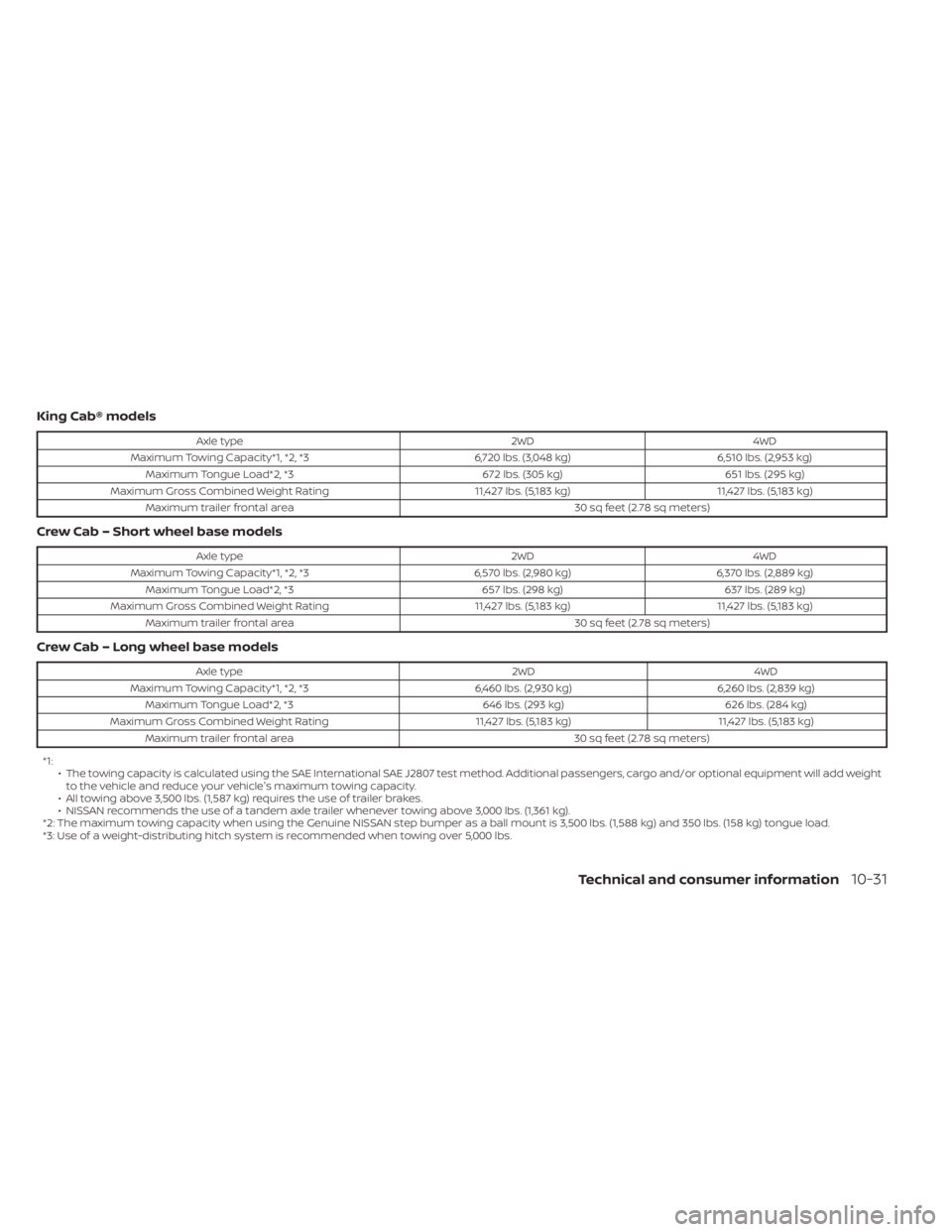

King Cab® models

Axle type2WD4WD

Maximum Towing Capacity*1, *2, *3 6,720 lbs. (3,048 kg)6,510 lbs. (2,953 kg)

Maximum Tongue Load*2, *3 672 lbs. (305 kg)651 lbs. (295 kg)

Maximum Gross Combined Weight Rating 11,427 lbs. (5,183 kg)11,427 lbs. (5,183 kg)

Maximum trailer frontal area 30 sq feet (2.78 sq meters)

Crew Cab – Short wheel base models

Axle type2WD4WD

Maximum Towing Capacity*1, *2, *3 6,570 lbs. (2,980 kg)6,370 lbs. (2,889 kg)

Maximum Tongue Load*2, *3 657 lbs. (298 kg)637 lbs. (289 kg)

Maximum Gross Combined Weight Rating 11,427 lbs. (5,183 kg)11,427 lbs. (5,183 kg)

Maximum trailer frontal area 30 sq feet (2.78 sq meters)

Crew Cab – Long wheel base models

Axle type2WD4WD

Maximum Towing Capacity*1, *2, *3 6,460 lbs. (2,930 kg)6,260 lbs. (2,839 kg)

Maximum Tongue Load*2, *3 646 lbs. (293 kg)626 lbs. (284 kg)

Maximum Gross Combined Weight Rating 11,427 lbs. (5,183 kg)11,427 lbs. (5,183 kg)

Maximum trailer frontal area 30 sq feet (2.78 sq meters)

*1: • The towing capacity is calculated using the SAE International SAE J2807 test method. Additional passengers, cargo and/or optional equipment will a dd weight

to the vehicle and reduce your vehicle's maximum towing capacity.

• All towing above 3,500 lbs. (1,587 kg) requires the use of trailer brakes.

• NISSAN recommends the use of a tandem axle trailer whenever towing above 3,000 lbs. (1,361 kg).

*2: The maximum towing capacity when using the Genuine NISSAN step bumper as a ball mount is 3,500 lbs. (1,588 kg) and 350 lbs. (158 kg) tongue load.

*3: Use of a weight-distributing hitch system is recommended when towing over 5,000 lbs.

Technical and consumer information10-31

Page 531 of 556

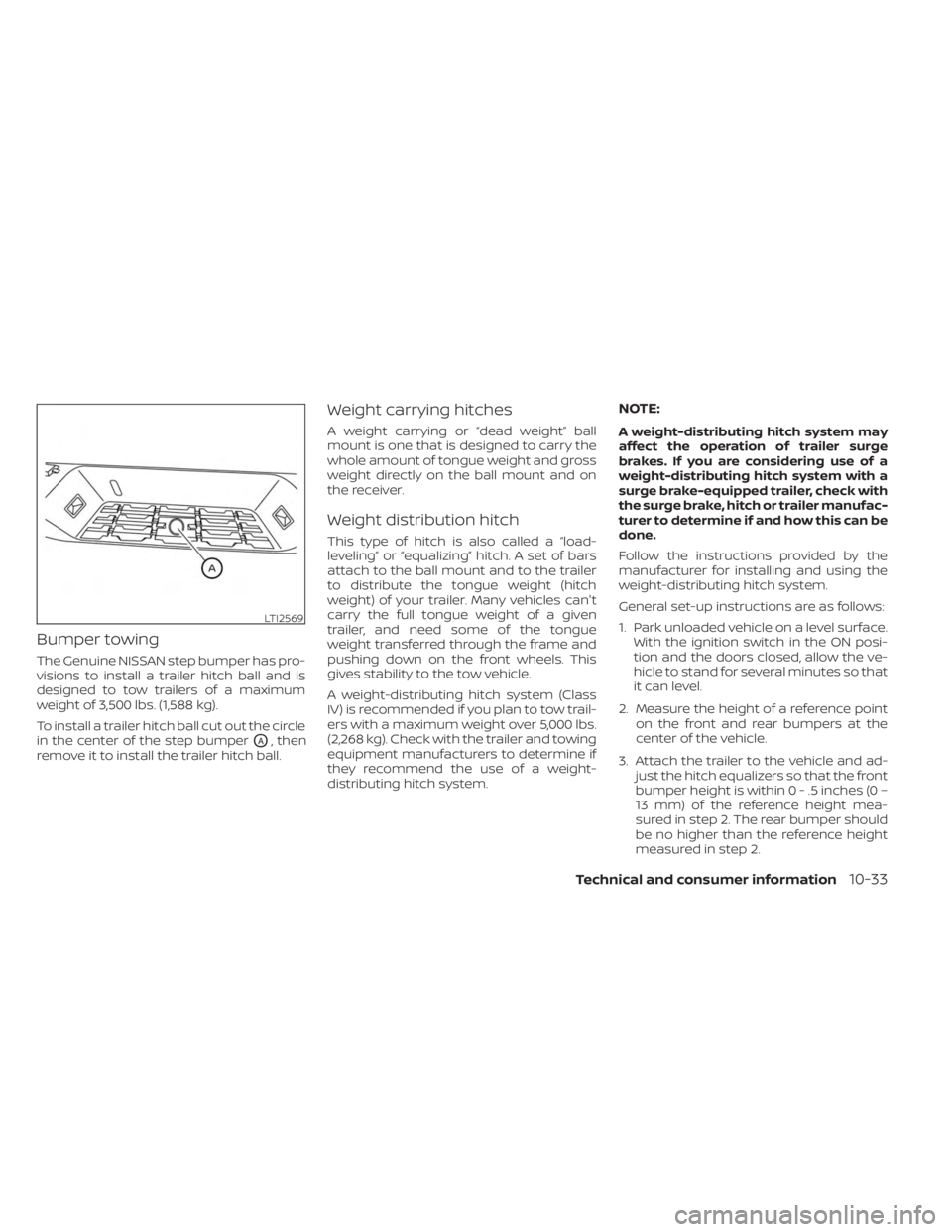

Bumper towing

The Genuine NISSAN step bumper has pro-

visions to install a trailer hitch ball and is

designed to tow trailers of a maximum

weight of 3,500 lbs. (1,588 kg).

To install a trailer hitch ball cut out the circle

in the center of the step bumper

OA, then

remove it to install the trailer hitch ball.

Weight carrying hitches

A weight carrying or “dead weight” ball

mount is one that is designed to carry the

whole amount of tongue weight and gross

weight directly on the ball mount and on

the receiver.

Weight distribution hitch

This type of hitch is also called a “load-

leveling” or “equalizing” hitch. A set of bars

attach to the ball mount and to the trailer

to distribute the tongue weight (hitch

weight) of your trailer. Many vehicles can't

carry the full tongue weight of a given

trailer, and need some of the tongue

weight transferred through the frame and

pushing down on the front wheels. This

gives stability to the tow vehicle.

A weight-distributing hitch system (Class

IV) is recommended if you plan to tow trail-

ers with a maximum weight over 5,000 lbs.

(2,268 kg). Check with the trailer and towing

equipment manufacturers to determine if

they recommend the use of a weight-

distributing hitch system.

NOTE:

A weight-distributing hitch system may

affect the operation of trailer surge

brakes. If you are considering use of a

weight-distributing hitch system with a

surge brake-equipped trailer, check with

the surge brake, hitch or trailer manufac-

turer to determine if and how this can be

done.

Follow the instructions provided by the

manufacturer for installing and using the

weight-distributing hitch system.

General set-up instructions are as follows:

1. Park unloaded vehicle on a level surface. With the ignition switch in the ON posi-

tion and the doors closed, allow the ve-

hicle to stand for several minutes so that

it can level.

2. Measure the height of a reference point on the front and rear bumpers at the

center of the vehicle.

3. Attach the trailer to the vehicle and ad- just the hitch equalizers so that the front

bumper height is within0-.5inches (0 –

13 mm) of the reference height mea-

sured in step 2. The rear bumper should

be no higher than the reference height

measured in step 2.

LTI2569

Technical and consumer information10-33

Page 533 of 556

WARNING

• Do not use axle-mounted hitches.

• Do not modif y the vehicle exhaust

system, brake system, etc. to install a

trailer hitch.

• To reduce the possibility of addi-

tional damage if your vehicle is

struck from the rear, where practical,

remove the receiver when not in use.

• Regularly check that all trailer hitch

mounting bolts are securely

mounted.

Tire pressures

• When towing a trailer, inflate the

vehicle tires to the recommended

cold tire pressure indicated on the

Tire and Loading Information label.

• Trailer tire condition, size, load rat- ing and proper inflation pressure

should be in accordance with the

trailer and tire manufacturer's

specifications.

Safety chains

Always use suitable safety chains between

your vehicle and the trailer. The safety chains

should be crossed and should be attached

to the hitch, not to the vehicle bumper or

axle. The safety chains can be attached to

the bumper if the hitch ball is mounted to the

bumper. Be sure to leave enough slack in the

chains to permit turning corners.

Trailer lights

CAUTION

When splicing into the vehicle electrical

system, a commercially available

power-type module/converter must

be used to provide power for all trailer

lighting. This unit uses the vehicle bat-

tery as a direct power source for all

trailer lights while using the vehicle tail

light, stop light and turn signal circuits

as a signal source. The module/

converter must draw no more than 15

milliamps from the stop and tail lamp

circuits. Using a module/converter that

exceeds these power requirements

may damage the vehicle's electrical

system. See a reputable trailer dealer

to obtain the proper equipment and to

have it installed. Trailer lights should comply with federal

and/or local regulations. For assistance in

hooking up trailer lights, it is recommended

that you visit a NISSAN dealer or reputable

trailer dealer. Vehicles equipped with the

optional trailer tow package are equipped

with a 7-pin trailer harness connector. A flat

4–pin harness is available from your dealer

for vehicles without a tow package. If your

trailer is equipped with a flat 4-pin connec-

tor, an adapter will be needed to connect

the trailer lights to the vehicle. Adapters are

available at auto parts stores and hitch

retailers.

Trailer brakes

If your trailer is equipped with a braking

system, make sure it conforms to federal

and/or local regulations and that it is prop-

erly installed.

Vehicles equipped with a 7–pin trailer har-

ness connector are pre-wired for a trailer

brake controller. It is recommended that

you visit a NISSAN dealer for a trailer brake

adapter harness.

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Technical and consumer information10-35

Page 534 of 556

When towing a trailer load of 3,500 lbs.

(1587 kg) or more, trailers with a brake

system MUST be used.However, most

states require a separate braking system

on trailers with a loaded weight above a

specific amount. Make sure the trailer

meets the local regulations and the regu-

lations where you plan to tow.

Several types of braking systems are

available.

Surge Brakes -The surge brake actuator is

mounted on the trailer tongue with a hy-

draulic line running to each trailer wheel.

Surge brakes are activated by the trailer

pushing against the hitch ball when the

tow vehicle is braking. Hydraulic surge

brakes are common on rental trailers and

some boat trailers. In this type of system,

there is no hydraulic or electric connection

for brake operation between the tow ve-

hicle and the trailer.

Electric Trailer Brakes -Electric braking

systems are activated by an electronic sig-

nal sent from a trailer brake controller (spe-

cial brake-sensing module). If electric trailer

brakes are used, see “Electric trailer brake

controller" (P. 10-36).. Have a professional supplier of towing

equipment make sure the trailer brakes are

properly installed and demonstrate proper

brake function testing.

Electric trailer brake controller

Trailers equipped with electric brakes may

require the installation of an af termarket

trailer brake controller.

A Genuine NISSAN jumper harness is avail-

able that is specifically designed to be used

when installing an af termarket brake

controller.

Install the af termarket electric trailer brake

controller according to the manufacturer's

instructions.

Pre-towing tips

• Be certain your vehicle maintains a level

position when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle if

it has an abnormal nose-up or nose-

down condition; check for improper

tongue load, overload, worn suspension

or other possible causes of either

condition.

• Always secure items in the trailer to pre- vent load shif t while driving. • Keep the cargo load as low as possible in

the trailer to keep the trailer center of

gravity low.

• Load the trailer so approximately 60% of the trailer load is in the front half and 40%

is in the back half. Also make sure the load

is balanced side to side.

• Check your hitch, trailer tire pressure, ve- hicle tire pressure, trailer light operation,

and trailer wheel lug nuts every time you

attach a trailer to the vehicle.

• Be certain your rearview mirrors conform to all federal, state or local regulations. If

not, install any mirrors required for towing

before driving the vehicle.

• Determine the overall height of the ve- hicle and trailer so the required clearance

is known.Trailer towing tips

In order to gain skill and an understanding

of the vehicle's behavior, you should prac-

tice turning, stopping and backing up in an

area which is free from traffic. Steering sta-

bility and braking performance will be

somewhat different than under normal

driving conditions.

• Always secure items in the trailer to pre-vent load shif t while driving.

10-36Technical and consumer information

Page 535 of 556

• Lock the trailer hitch coupler with a pin orlock to prevent the coupler from inadver-

tently becoming unlatched.

• Avoid abrupt starts, acceleration or stops.

• Avoid sharp turns or lane changes.

• Always drive your vehicle at a moderate speed.

• When backing up, hold the bottom of the steering wheel with one hand. Move your

hand in the direction in which you want

the trailer to go. Make small corrections

and back up slowly. If possible, have

someone guide you when you are back-

ing up.

Always block the wheels on both vehicle

and trailer when parking. Parking on a

slope is not recommended; however, if you

must do so:

CAUTION

If you move the shif t lever to the P

(Park) position before blocking the

wheels and applying the parking brake,

transmission damage could occur. 1. Apply and hold the brake pedal.

2. Have someone place blocks on the

downhill side of the vehicle and trailer

wheels.

3. Af ter the wheel blocks are in place, slowly release the brake pedal until the

blocks absorb the vehicle load.

4. Apply the parking brake.

5. Shif t the transmission into P (Park).

6. Make sure the 4WD shif t indicator light (if so equipped) indicates the transfer case

is in 4H, 4LO, or 2WD and that the ATP

light is off. If the 4WD shif t indicator light

is flashing, or the ATP light is ON, make

sure the transmission is in P (Park) and

turn the 4WD switch to 2WD or 4H. For

additional information, see “Automatic

transmission park warning light” (P. 2-11)

and “Using 4-wheel drive (4WD)” (P. 5-109).

7. Turn off the engine.

To drive away:

1. Start the vehicle.

2. Apply and hold the brake pedal.

3. Shif t the transmission into gear.

4. Release the parking brake. 5. Drive slowly until the vehicle and trailer

are clear from the blocks.

6. Apply and hold the brake pedal.

7. Have someone retrieve and store the blocks.

• While going downhill, the weight of the trailer pushing on the tow vehicle may

decrease overall stability. Therefore, to

maintain adequate control, reduce your

speed and shif t to a lower gear. Avoid

long or repeated use of the brakes when

descending a hill, as this reduces their

effectiveness and could cause overheat-

ing. Shif ting to a lower gear instead pro-

vides “engine braking” and reduces the

need to brake as frequently.

• If the engine coolant temperature rises to a high temperature, see “If your vehicle

overheats” (P. 6-13).

• Trailer towing requires more fuel than normal circumstances.

• Avoid towing a trailer for your vehicle's first 500 miles (805 km).

• For the first 500 miles (805 km) that you do tow, do not drive over 50 mph (80

km/h).

Technical and consumer information10-37