light NISSAN GT-R 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 48 of 230

TROUBLE DIAGNOSES

ECM (*TCM) InpuWOutput Signal Reference

Value (Cont'd)

Terminal

No.

41

NOTE: I

Signal name At

idle

rlehicle speed sen-

;or signal

dead lamp switch Light switch OFF: Approx. OV

;ignal

Light switch ON: Battery voltage

gnition power

sup- Ignition switch OFF: Approx. OV

)iY Ignition switch ON: Battery voltage

dle position switch

lB25DET.m

Mottle

opening Accelerator pedal released: Approx.

0.5V

ignal

Accelerator pedal fully depressed: Approx.

4.2V RB25DE.4WD.W

(Ignition switch ON, engine not running) ; RB25D€.AlT,

3R25Dm

Jeutral signal Selector lever in Neutral or in

N or P position: Approx. OV ParWNeutral posi- Selector lever in other positions: Approx. 4.8V

on switch)

:ull switch signal Accelerator pedal released: Approx. OV

?B20DE

(UB), Accelerator pedal fully depressed: Battery voltage

lB25DET-A/Tl (Ignition switch ON, engine not running)

- - - - -- - love voltages are measured values obtained by analog

At approx. 2,000 rpm

IRB20DE

(UB)] When driving at approx. 40 km/h: Approx. 2.4V @I

i ECL 1 7920

[RB25DE, RB25DETI

When driving at approx. 40

kmk: Approx. 2.4V %R

Approx. OV

(When accelerator pedal is depressed)

Approx.

0.N

rcuit tester.

Page 51 of 230

TROUBLE DIAGNOSES

ECM (-TCM) Input/Output Signal Reference

Terminal No.

108

- NOTE:

Signal name

CM.TCM, TCS/ABS

tegrated control signal

dultiplex communica-

&DE.m,

B25DETj

attery power supply

ijector drive signal

3attery voltage When cranking: Approx.

10.5V

Value (Cont'd)

(v) 50 40 30 20 10

0

At idle: &Wry voltage

A:

idle

Approx. 2V

rariable

air intake con-

:ol solenoid valve con- switch ON: Battery voltage (Solenoid valve

rot signal

RB20DE (UB), At idle: Approx. 0.2

- 0.3V (Solenoid valve ON) At

approx. 2,000

rpm

t

3B25DEI ' .

-urbo pressure control iO1enOid valve Battery voltage (Solenoid valve OFF)

iianal

4ir jet swirl sole- Coolant temperature below approx. 70°C: Approx.

0.9V (Solenoid valve ON)

'Oid Coolant temperature approx. 70°C and above: Battery

RB20DE (VB)] voltage (Solenold valve OFF)

[RB20DE (UB), RB25DEl

Air conditioner OFF: Battery voltage

Air conditioner ON: Battery voltage Approx.

10V

(After approx.

15 sec.)

Zanister

purge control

~alve

control signal

M 30 20 10 0

(Waveform indicates when air conditioner is

ON.)

[RB20DETJ

Air conditioner OFF: Battery voltage

Air conditioner ON: Battery voltage

4 Approx. 1OV

(After approx. 15 sec.) Slightly lower than battery voltage

t At

approx. 3,650 rpm and above [RB2ODE (UB)]

At approx. 3,500 rpm and above [RB25Dq : Battery voltage (Solenotd valve OFF)

t [When engine raced suddenly: Approx. 0.3V (Solenoid

valve ON)]

t Coolant temperature approx. 70°C and above, and

driving at approx. 3,300 rpm and above [MTT] Coolant temperature approx. 70°C and above, and

driving at approx. 3,000 rpm and above [A/T1 : Approx. 0.9V (Solenoid valve ON)

Approx.

9V

Approx. 9V

I (Waveform indicates when air conditioner is ON.)

tester.

Page 71 of 230

TROUBLE DIAGNOSES

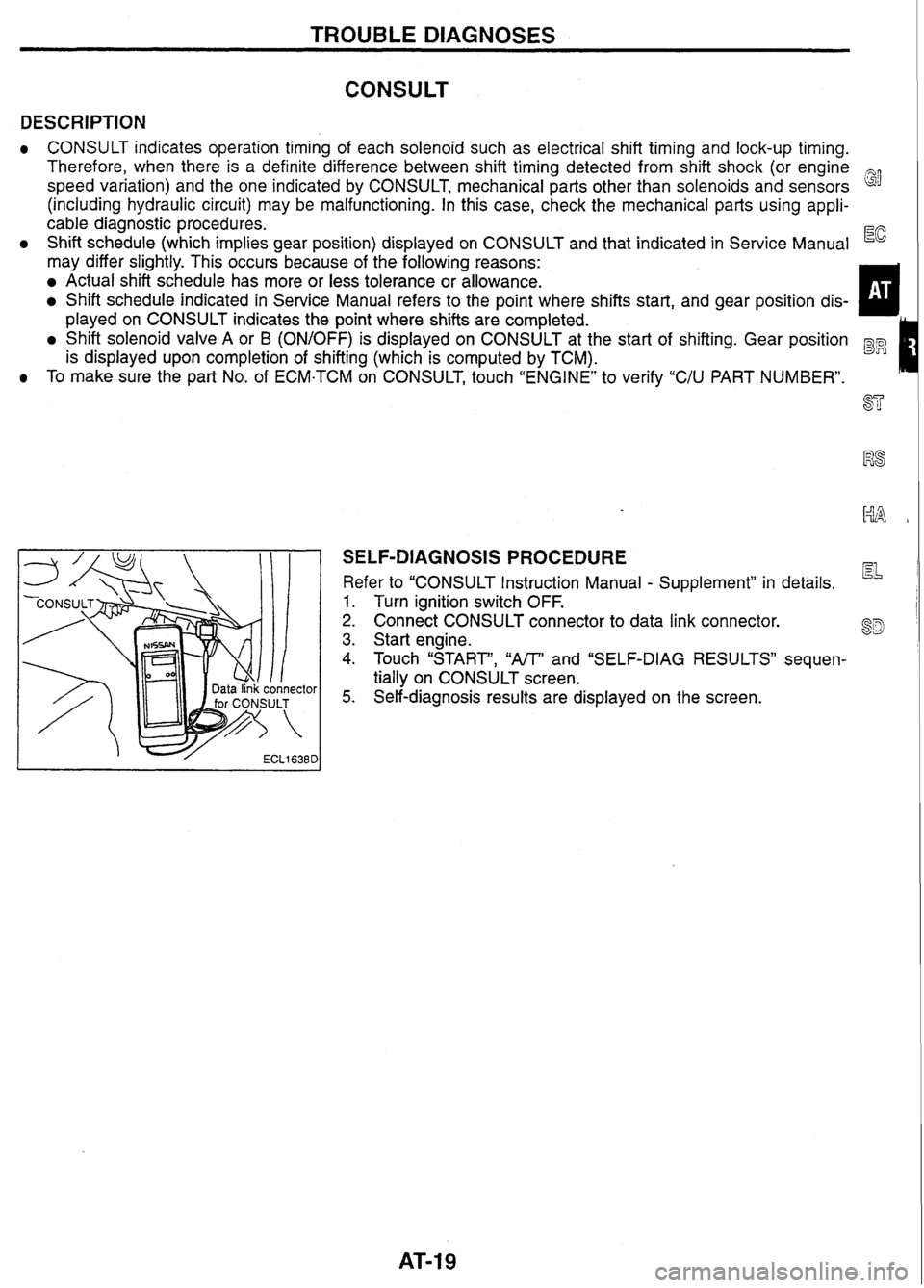

DESCRIPTION

CONSULT indicates operation timing of each solenoid such as electrical shift timing and lock-up timing.

Therefore, when there is a definite difference between shift timing detected from shift shock (or engine

speed variation) and the one indicated by CONSULT, mechanical parts other than solenoids and sensors

(including hydraulic circuit) may be malfunctioning. In this case, check the mechanical parts using appli-

cable diagnostic procedures.

Shift schedule (which implies gear position) displayed on CONSULT and that indicated in Service Manual

may differ slightly. This occurs because of the following reasons:

Actual shift schedule has more or less tolerance or allowance.

Shift schedule indicated in Service Manual refers to the point where shifts start, and gear position dis-

played on CONSULT indicates the point where shifts are completed.

Shift solenoid valve A or B (ON/OFF) is displayed on CONSULT at the start of shifting. Gear position

is displayed upon completion of shifting (which is computed by TCM).

To make sure the part No. of ECM-TCM on CONSULT, touch "ENGINE" to verify "C/U PART NUMBER".

SELF-DIAGNOSIS PROCEDURE

Refer to "CONSULT Instruction Manual - Supplement" in details.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector.

3. Start engine.

4. Touch "START', "NT and "SELF-DIAG RESULTS" sequen-

tially on CONSULT screen.

5. Self-diagnosis results are displayed on the screen.

Page 75 of 230

TROUBLE DIAGNOSES

Self-diagnosis

DESCRIPTION

If malfunction should occur in electrical systems, turning ignition switch ON lights M mode switch POWER

indicator lamp

(M-AT Dual matic AfT warning lamp) for 2 seconds, and then flashes the indicator lamp for 8 Gc

seconds. If malfunction does not occur, A/T mode switch POWER indicator lamp (M-AT Dual matic A/T warn-

ing lamp) is turned on for

2 seconds upon turning ignition switch ON. To locate and display the malfunction-

ing part, output the trouble information memory and flash

A/T mode switch POWER indicator lamp (M-AT Dual

matic

A/T warning lamp) by inputting self-diagnostic startup signal.

SELF-DIAGNOSIS PROCEDURE

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Move A/T mode switch to AUTO, and turn overdrive control switch to O/D ON.

4. Turn ignition switch ON with selector lever in "Pn position, and ensure POWER indicator lamp is turned on

for

2 seconds.

5. Turn ignition switch OFF.

6. Move selector lever to "D" position.

7. Turn overdrive control switch O/D OFF.

8. Turn ignition switch ON.

9. Move selector lever to "2" position.

10. Turn overdrive control switch OID ON.

11. Move selector lever to "I" position.

12. Turn overdrive control switch O/D OFF.

13. Depress accelerator pedal fully, and release it.

14. Read flashing status of POWER indicator lamp to complete self-diagnosis procedures.

M-AT

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Turn ignition switch ON with selector lever in "P" position, and ensure dual matic PJT warning lamp is turned

on for

2 seconds.

4. Turn ignition switch OFF.

5. Depress brake pedal, release accelerator pedal, and then move selector lever to "D" position.

6. Turn ignition switch ON.

7. Release brake pedal, and move selector lever to "3" position.

8. While depressing brake pedal with left foot, depress accelerator pedal fully with right foot, and move

selector lever to

"2" position.

9. Read dual matic A/T warning lamp indication to complete self-diagnosis procedures.

Page 86 of 230

ANTI-LOCK BRAKE SYSTEM

Precautions for Trouble Diagnosis

After performing trouble diagnosis, be sure to erase trouble stored in memory. Refer to "CONSULT' (next

page) or "SELF-DIAGNOSIS"

(BR-15).

As for the concerns that are difficult to duplicate, move harnesses or harness connectors by hand to check

if there is any poor mating of connector halves or faulty connection.

Do not force to open a connector terminal when using a circuit tester for inspection.

Read GI section thoroughly in advance and make sure of all the general precautions.

Basic Inspection

BASIC INSPECTION 1 - Brake fluid level and leakage AT

1. Check brake fluid level in reservoir tank. Replenish brake fluid if necessary.

2. Check for leakage at or around brake piping and ABS actuator. If leakage or seepage is noted, proceed

as follows:

If ABS actuator connectors are loose, tighten to specified torque. Recheck to ensure that leakage is no

longer present.

If flare nut threads at piping connectors or actuator threads are damaged, replace faulty parts with new 87

ones. Recheck to ensure that leakage is no longer present.

If brake fluid leaks through areas other than actuator connectors, wipe off using a clean cloth. Recheck

for leakage or seepage. If necessary, replace faulty parts with new ones.

R8

If brake fluid leaks at or seeps through ABS actuator, wipe off using a clean cloth. Recheck for leakage

or seepage. If necessary, replace

ABS actuator with new one.

CAUTION: HA

ABS actuator cannot be disassembled. Do not attempt to disassemble it.

BASIC INSPECTION 2 - Loose power line terminal

Check battery terminals (positive and negative) and battery mounting (ground) for looseness.

BASIC INSPECTION 3 - ABS warning lamp

1. Turn ignition switch "ON" to ensure that ABS warning lamp lights up for approximately 1 second. If ABS

warning lamp does not light, check ABS warning lamp circuit.

2. After driving vehicle at approx. 30 km/h for approx. 1 minute, check to ensure that ABS warning lamp

remains off. If ABS warning lamp lights, perform self-diagnosis procedures.

3. After performing self-diagnosis procedures, be sure to erase trouble stored in memory.

Page 89 of 230

![NISSAN GT-R 1998 User Guide

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost NISSAN GT-R 1998 User Guide

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost](/img/5/57354/w960_57354-88.png)

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnostic

item is detected when

...

Control unit,

control

unit

power supply

and ground

circuit

Check item

ABS control unit battery voltage

is abnormally high.

ABS control unit battery voltage is abnormally low.

. ABS MOTOR

[LOCK FAILURE] Control

unit

power supply

circuit ABS motor speed is abnormally low. AES motor,

motor relay

and circuit

1 I

'1 : ABS warning lamp turns on if a wheel or wheels spin for I0 to 80 seconds (depending on the wheel speed) with the vehicle

stuck in snow. ice, or mud. This is a normal condition.

'2: After repairing short-circuited sensor, turning ignition switch ON lights up ABS warning lamp. Check that ABS warning lamp

turns

off when the vehicle is driven at approx. 30 krnh for approx. 1 minute as shown in the self-diagnosis procedure. NOTE: If "ABSn is not displayed on "SELECT SYSTEM" screen, check ABS control unit and data link connector circuit, and make sure

of the CONSULT card number.

DATA MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector for CON-

SULT.

3. Turn ignition switch ON.

4. Touch "START' on CONSULT screen.

5. Touch "ABS" on CONSULT screen.

If "START" is touched immediately after engine is started

or ignition switch is turned on,

"ABS" may not be dis-

played on "SELECT SYSTEM" screen. To display "ABS",

repeat the data monitor procedure from the beginning.

6. Touch "DATA MONITORn.

7. Touch "SETTING" to set recording condition.

8. Touch "AUTO TRIG", "LONG TIME" and then "ENTER".

9. Return to "SELECT MONITOR ITEM" screen and touch "CIU

INPUT ITEM", "ALL SIGNALS" or 'SELECTION FROM

MENU". Refer to "DATA MONITOR MODE" on the next page.

10. Touch "START'.

11. Display data monitor.

12. If necessary, sequentially touch "REC START, "REC STOP",

"DATA DISPLAY", "NUMBER PRINT' and "PRINT' to print out

the data.

Page 95 of 230

ANTI-LOCK BRAKE SYSTEM

Self-diagnosis (Cont'd)

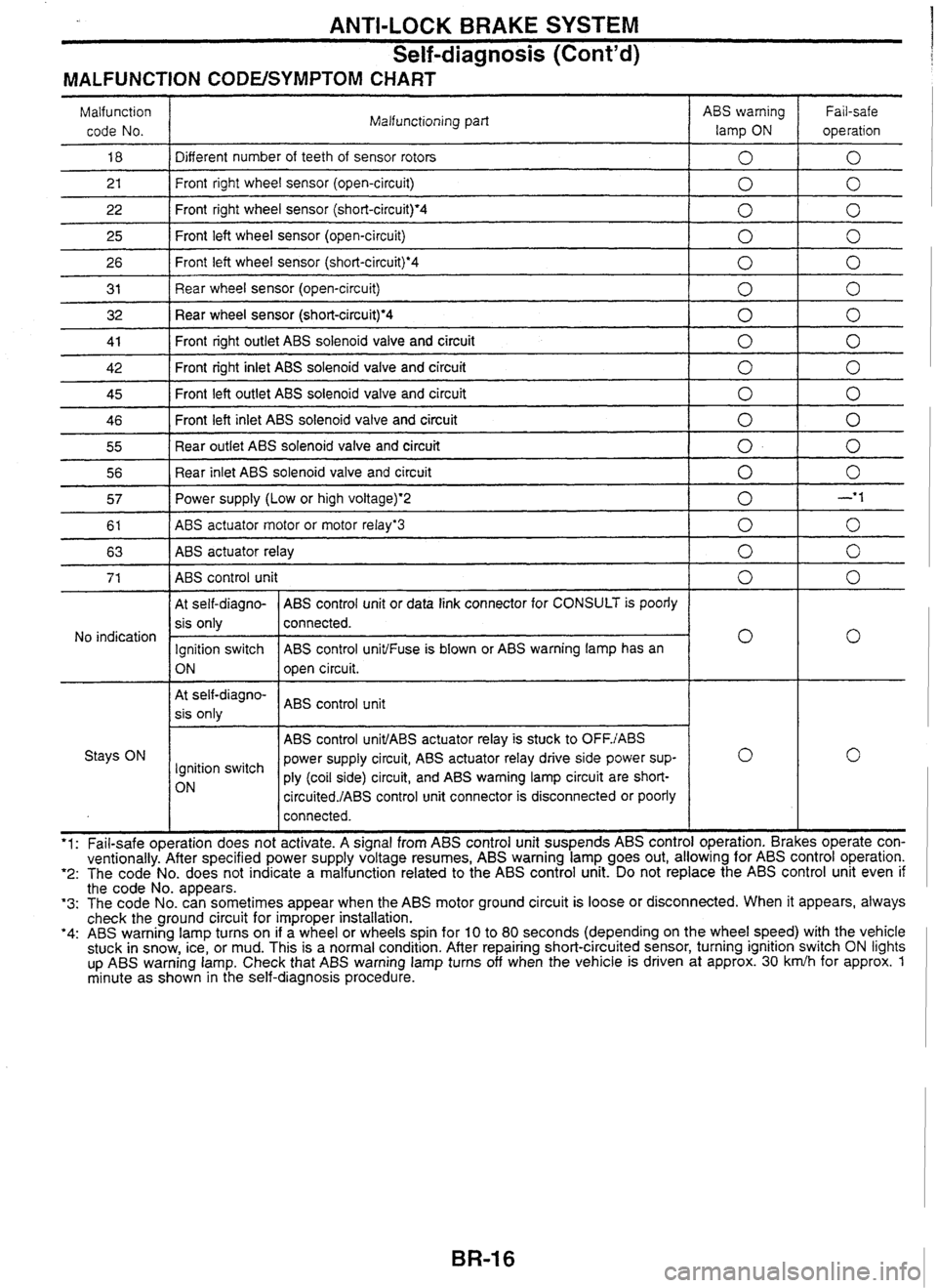

MALFUNCTION CODEISYMPTOM CHART

Malfunction code No. Malfunctioning

part ABS warning

lamp

ON

Fail-safe

operation

18 1 Different number of teeth of sensor rotors 1010

2 1

26 I Front left wheel sensor (short-circuiQ.4 1010

- --

22

25

3 1 I Rear wheel sensor (open-circuit) 1010

Front right wheel sensor (open-circuit)

32 Rear wheel sensor (short-circuit)'4 1 0 1 0

Front right wheel sensor (short-circuit)'4

Front left wheel sensor (open-circuit)

41

I Front right outlet ABS solenoid valve and circuit 1010

0 0

0

0

0

0

- -

42

-- - -

46 Front left inlet ABS solenoid valve and circuit 0 1 0

45 Front

left outlet ABS solenoid valve and circuit

55

1 Rear outlet ABS solenoid valve and circuit 1010

Front right inlet ABS solenoid valve and circuit

56

1 Rear inlet ABS solenoid valve and circuit 1010

0

57 1 Power supply (Low or high voltage)*2 I 0 I -'I

0

0

0

I At self-diagno- ( ABS control unit or data link connector for CONSULT is poorly 1 I

61

63

At self-diagno-

I ABS control unit

sis only

ABS

actuator motor or motor relayg3

ABS

actuator relay

No indication

I I ABS control unit1ABS actuator relay is stuck to OFFJABS I Stays ON power supply circuit, ABS actuator relay drive side power sup-

lgnition switch

ply (coil side) circuit, and ABS warning lamp circuit are

short-

circuited./ABS control unit connector is disconnected or poorly

0

0

I

sis only

Ignition switch

ON

I I connected. I I

0

0

connected.

ABS control

unit1Fuse is blown or ABS warning lamp has an

open circuit.

- -- '1: Fail-safe operation does not activate. A signal from ABS control unit suspends ABS control operation. Brakes operate con-

ventionally. After specified power supply voltage resumes, ABS warning lamp goes out, allowing for ABS control operation. '2: The code No. does not indicate a malfunction related to the ABS control unit. Do not replace the ABS control unit even if the code No. appears. '3: The code No. can sometimes appear when the ABS motor ground circuit is loose or disconnected. When it appears, always

check the ground circuit for improper installation.

'4: ABS warning lamp turns on if a wheel or wheels spin for 10 to 80 seconds (depending on the wheel speed) with the vehicle

stuck in snow, ice, or mud. This is a normal condition. After repairing short-circuited sensor, turning ignition switch ON lights

up

ABS warning lamp. Check that ABS warning lamp turns off when the vehicle is driven at approx. 30 krnlh for approx. 1 minute as shown in the self-diagnosis procedure.

Page 96 of 230

TCSIABS SYSTEM

System

Description

ABS FUNCTION

During ABS operation, the brake pedal pulsates along with a mechanical noise. This ensures that the ABS

is working properly. mP

When starting up the engine or immediately after the vehicle starts to run, the brake pedal pulsates and G'

a motor noise from the engine compartment can be heard. They are caused by the ABS operation check

and should not be considered abnormal.

A vehicle with the ABS may stop in a longer distance than a vehicle without the ABS when the brake is

EC

applied on a bad road, gravel road, or deep fresh snow.

TCS FUNCTION

TCS/ABS control unit monitors the speed of the driving wheels through 4 wheel speed sensors. If driving

wheel slip is detected, fuel to the engine is cut

ol

and the throttle valve is adjusted so that the engine

a

torque is reduced. On vehicles with automatic transmission, transmission shift schedule is also changed

to control the rear wheel driving torque, which results

in the reduction of wheel slip. This system enables

the throttle valve to be controlled so that optimum engine torque can be achieved in accordance with the

driver's acceleration request.

The driver may not feel satisfied with acceleration on some road surfaces. This poor acceleration occurs

because the operating TCS gives priority to maintaining optimum traction. Therefore, this condition should

R8

be considered normal.

When shiftdown is made or the acceleration pedal is depressed while the vehicle is driven on the road

surface that has different friction coefficients, the TCS may operate temporarily.

r-- 4 Lrd[-i

On vehicles with manual transmission, the SLlP indicator lamp and the TCS OFF indicator lamp may light

up when the engine is about to stall in the conditions shown below.

If the lamps go off when engine speed

increases, there is no problem in the system.

At start, the engine almost stalls and the engine speed is much lower than the idle speed.

The vehicle is driven at an extremely low speed with a high-speed gear engaged.

The clutch has been engaged until the vehicle almost stops. 8D

FAIL-SAFE FUNCTION

ABS system

If any malfunction is detected in the system, the ABS warning lamp, the TCS OFF indicator lamp and the SLlP

indicator lamp in the instrument panel is turned on with the TCSIABS deactivated and the vehicle's brake sys-

tem reverts to normal operation.

TCS system

If any malfunction is detected in the system, both the SLlP indicator lamp and the TCS indicator lamp on the

instrument panel light up and the TCS is shut down. The vehicle operates in the same manner as a vehicle

without the

TCS, while the ABS is operational.

If there is a malfunction in the throttle control system, the TCS becomes inoperative while the ABS

remains functional.

When fail-safe operation is activated, perform the self-diagnosis procedure for the TCSIABS first.

Refer to

BR-27 for details.

Page 105 of 230

TCSlABS SYSTEM

Precautions for Trouble

Diagnosis

After performing trouble diagnosis, be sure to erase trouble stored in memory.

Refer to "CONSULT for

TCS/ABS Control Unit Control System"

(BR-27), "Self-diagnosis for TCSIABS

Control Unit Control System"

(BR-34), "CONSULT for Throttle Control Unit Control System" (BR-37) or

"Self-diagnosis for Throttle Control Unit Control System"

(BR-41).

The concerns that are difficult to duplicate may be caused by faulty electrical connections. Move harnesses

or harness connectors by hand to check if there is any poor mating of connector halves or faulty connec-

tion. Do not force to open a connector terminal when using a circuit tester for inspection.

Read GI section thoroughly in advance and make sure of all the general precautions.

Basic Inspection

BASIC INSPECTION 1 - Brake fluid level and leakage

1. Check brake fluid level in reservoir tank. Replenish brake fluid if necessary.

2. Check for leakage at or around brake piping and ABS actuator. If leakage or seepage is noted, proceed

as follows:

If ABS actuator connectors are loose, tighten to specified torque. Recheck to ensure that leakage is no

longer present.

If flare nut threads at piping connectors or actuator threads are damaged, replace faulty parts with new

ones. Recheck to ensure that leakage is no longer present.

If brake fluid leaks through areas other than actuator connectors, wipe off using a clean cloth. Recheck

for leakage or seepage. If necessary, replace faulty parts with new ones.

If brake fluid leaks at or seeps through ABS actuator, wipe off using a clean cloth.

Recheck for leakage or seepage. If necessary, replace ABS actuator with new one.

CAUTION:

ABS actuator cannot be disassembled. Do not attempt to disassemble it.

3. Check brake disc rotors and pads for proper operation.

BASIC INSPECTION 2 - Loose power line terminal

Check battery terminals (positive and negative) and battery mounting (ground) for looseness. If necessary,

tighten to specified torque. Check the battery for lower voltage.

BASIC INSPECTION 3 - SLlP indicator lamp, TCS OFF indicator lamp and ABS warning

lamp

Turn ignition switch "ON" to ensure that TCS OFF indicator lamp lights up. If TCS OFF indicator lamp does

not light, check TCS OFF indicator lamp circuit.

Turn ignition switch

"ON" to ensure that SLlP indicator lamp lights

up. If SLlP indicator lamp does not light,

check SLlP indicator lamp circuit.

Turn ignition switch "ON" to ensure that ABS warning lamp lights up. If ABS warning lamp does not light,

check ABS warning lamp circuit.

Check that the SLlP indicator lamp and the ABS warning lamp go off approx.

1 second after the engine

has started. If either of the lamps still remains on, perform the self-diagnosis for TCSIABS control unit

control system and the self-diagnosis for throttle control unit control system.

After driving vehicle at approx. 30

km/h

for approx.

1 minute, check to ensure that the SLlP indicator lamp

and the ABS warning lamp are off. If either of the lamps still remains on, perform the self-diagnosis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

Check that the TCS OFF indicator lamp turns ON and OFF when the TCS OFF switch is turned to

ON

and OFF respectively, with the engine running. If the lamp status does not correspond to the switch

position, check the TCS OFF switch circuit.

Check that the TCS OFF indicator lamp goes off when the engine has started with the TCS OFF switch

OFF. If the TCS

OFF indicator lamp does not go off even 10 seconds after the engine has started, per-

form the self-diagnosis for TCSIABS control unit control system and the self-diagnosis for throttle control

unit control system.

After driving vehicle at approx.

30 kmlh for approx. 1 minute with the TCS OFF switch OFF, check to ensure

that the TCS OFF indicator lamp is off. If the TCS OFF indicator lamp lights up, perform the

self-diagno-

sis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

After performing self-diagnosis procedures, be sure to erase trouble stored in memory.

Page 151 of 230

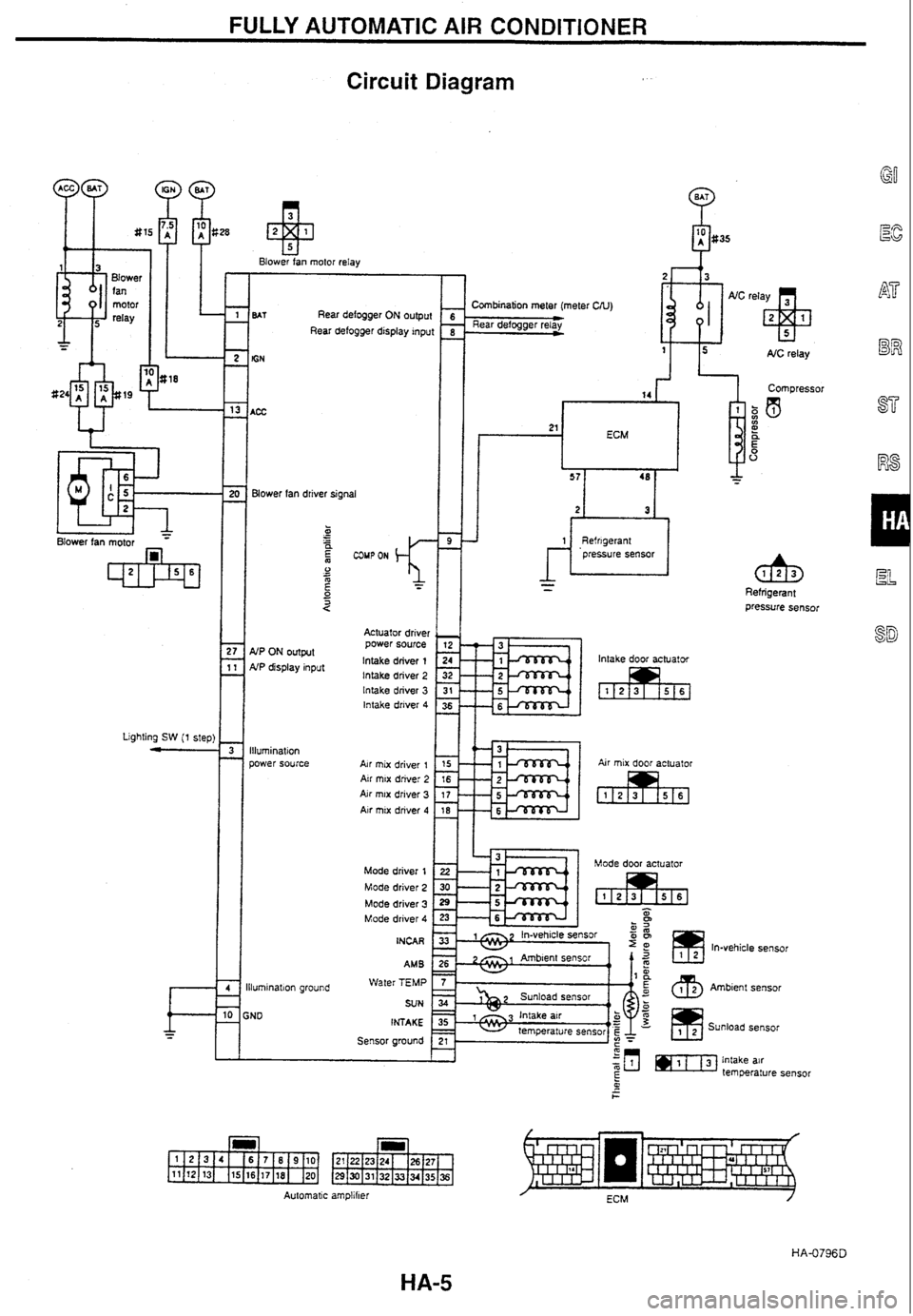

FULLY AUTOMATIC AIR CONDITIONER

Circuit

Diagram

Blower tan motor relay

Rear defogger

A Combination meter (meter UU) output * I Rear defogger relay - Rear defogger display inpui

I Compressor

Blower

fan driver signal Refrigerant Pressure sensor

Actuator driver power source

lntake driver

1 lntake driver 2 lntake driver 3 lntake driver 4

lntake door actuator NP ON output NP display input

Lighting

SW (1 step)

Y-lkEka Air mix door actuator

Illumination

power

source

Air mix driver 1 Air mrx drive: 2 Air mix driver 3 Air mix driver 4

Mode driver 1 1 Mode driver 2 Mode driver 3 Mode driver 4

INCAR In-vehicle sensor

Ambienl sensor

Sunload sensor

AM B

Water TEMP

SUN

INTAKE

Sensor around

lluminatron

groun:!

iND

Automatic

amp!iher