NISSAN GT-R 1998 Service Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 1 of 230

SERVICEMANUAL

Page 2 of 230

NISSAN

MODEL R34 SERIES

FOREWORD

This Sewice Manual contains infor-

mation concerning necessary ser-

vice procedures and relevant data

for the model

R34 series.

All information, illustrations and

specifications contained in this Ser-

vice Manual are based on the latest

product information available at the

time of publication. If your NISSAN

model differs from the specifications

contained in this

Sewice Manual,

consult your NISSAN distributor for

information.

The right is resewed to make

changes in specifications and meth-

ods at any time without notice.

QUICK REFERENCE INDEX I

0 1998 KISSAN MOTOR CO., LTD. Printed in Japan

A11 rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Motor Company Ltd.. Tokyo, Japan.

Page 3 of 230

HOW TO USE THIS MANUAL

b This Service Manual only contains the service data specifications and trouble diagnosis informa-

tion such as self-diagnosis,

CONSULT, circuit diagram and so on.

b For other information not specified in this manual, refer to Japanese version Service Manual (Pub.

No. A006029) and wiring diagram manual (Pub. No.

WD8EOR34JO).

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the technician and the efficient

functioning of the vehicle.

The service methods in this Service Manual are described in such a manner that the service may be

performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the tools and parts available.

Accordingly, anyone using service procedures,

took or parts which are not specifically recommended

by

NISSAN must first be completely satisfied that neither personal safety nor the vehicle's safety will

be jeopardized by the service method selected.

Page 4 of 230

GENERAL INFORMATION

SECTION

GI

CONTENTS

CONSULT CHECKING SYSTEM .................................... 2 IDENTIFICATION INFORMATION ................................... 3

Function and System Application ................................ 2 Model Variation ............................................................ 3

Lithium Battery Replacement ..................................... .2 Vehicle Identification Number ...................................... 4

.................................................... Checking Equipment 2 Vehicle Identification Plate ........................................... 4

Page 5 of 230

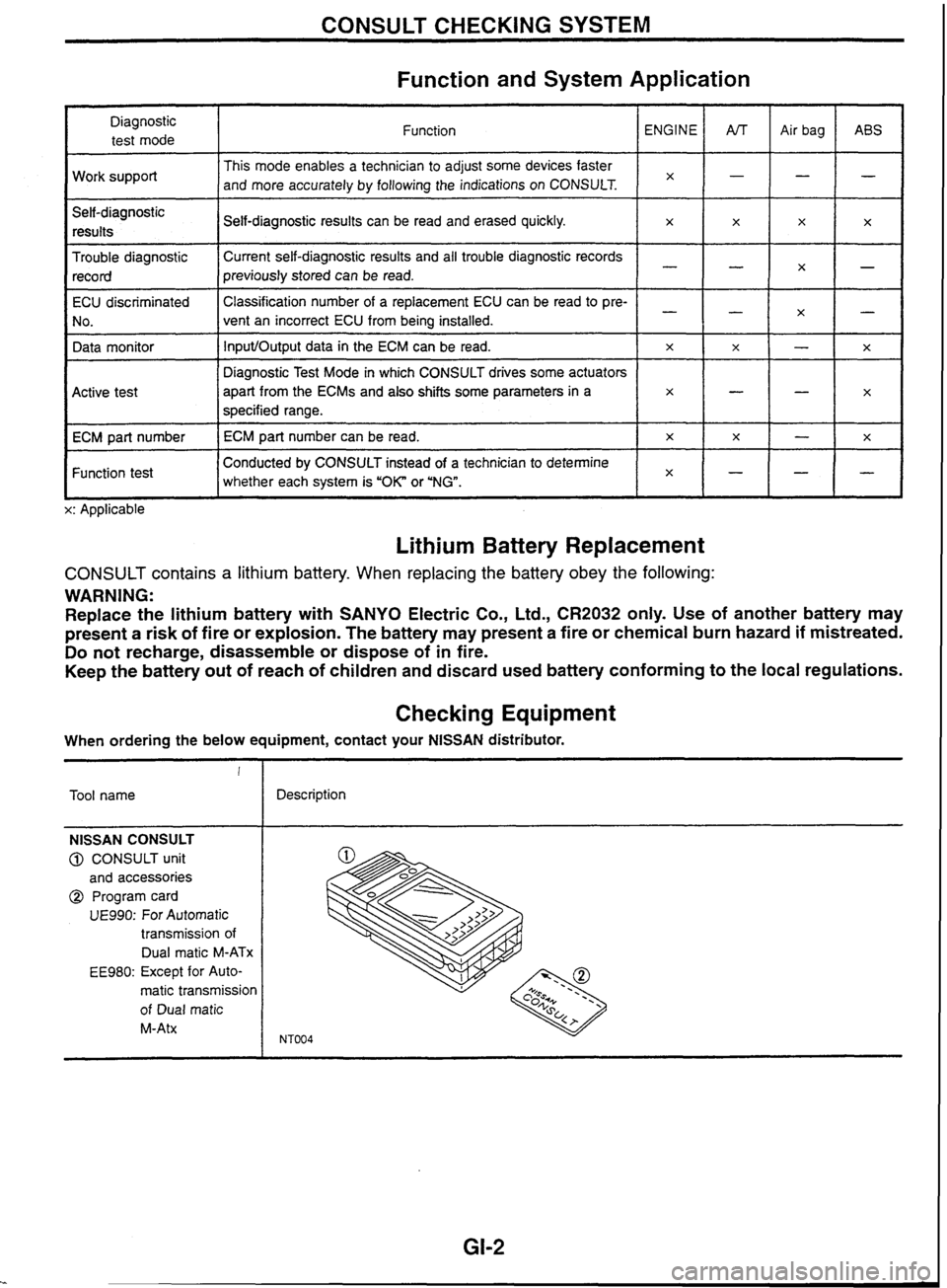

CONSULT CHECKING SYSTEM

Function and System Application

Diagnostic test mode

Work support

Self-diagnostic results

Trouble diagnostic record Function

This mode enables a technician to adjust some devices faster

and more accurately by following the indications on CONSULT.

ECU discriminated

No.

Data monitor

I I whether each system is "OK" or 'NG". lxH-1-

Conducted by CONSULT instead of a technician to determine

Function test Self-diagnostic

results can be read and erased quickly.

Current self-diagnostic results and all trouble diagnostic records

previously stored can be read.

Active test

ECM part number

L x: Applicable ENGINE

x

Classification

number of a replacement ECU can be read to pre-

vent an incorrect ECU from being installed.

InputIOutput data in the ECM can be read.

Lithium Battery Replacement

x

Diagnostic Test Mode in which CONSULT drives some actuators

apart from the

ECMs and also shifts some parameters

in a

specified range.

ECM part number can be read.

CONSULT contains a lithium battery. When replacing the battery obey the following:

WARNING:

Replace the lithium battery with SANYO Electric Co., Ltd.,

CR2032 only. Use of another battery may

present

a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mistreated.

Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

AfT

-

-

x

Checking Equipment

x

-

x

x

When ordering the below equipment, contact your NlSSAN distributor. Air

bag

-

-

-

x

!

Tool name ABS

-

x

X

-

x

NISSAN CONSULT

@ CONSULT unit

and accessories

@ Program card

UE990: For Automatic

transmission of

Dual

rnatic M-ATx

EE980: Except for Auto-

matic transmission

of Dual

matic

M-Atx

x

-

--

X

-

Description

-

x

-

-

x

x

Page 6 of 230

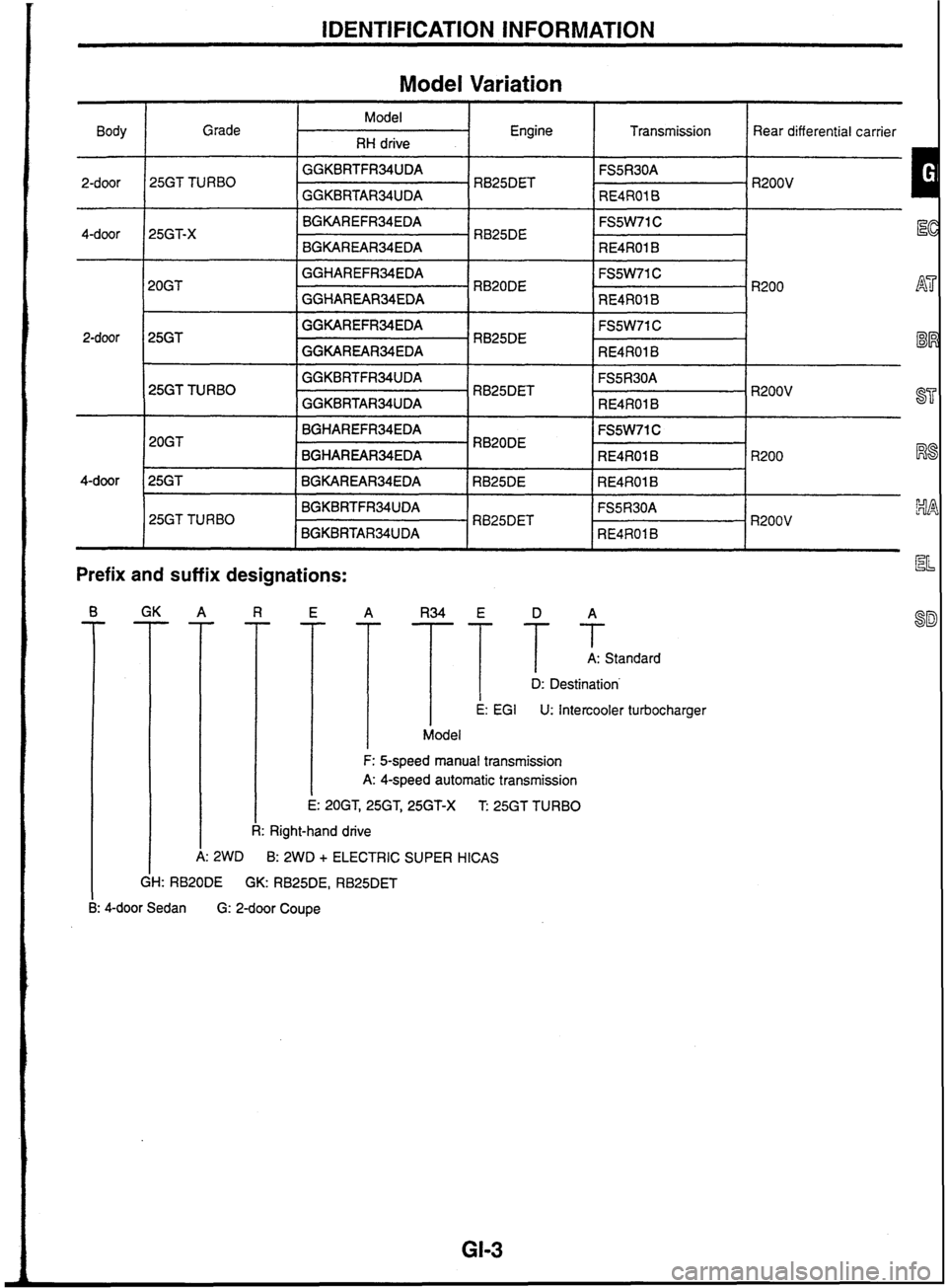

IDENTIFICATION INFORMATION

Model Variation

Model

Body Grade Engine Transmission Rear differential carrier

RH drive

GGKBRTFR34UDA FS5R30A

2-door 25GT TURBO

RB25DET

. R200V

GGKBRTAR34UDA

RE4RO1

B

RB20DE

GGHAREARMEDA

1 GGKAREFRMEDA 1 RB25DE

GGKAREARMEDA

GGKBRTFRMUDA

25GT TURBO

RB25DET R200V

GGKBRTARMUDA

RE4RO1 B

BGHAREFR34EDA FS5W71 C

20GT

RB20DE

BGHAREARMEDA RE4RO1 B R200

i%

I

BGKBRTFR34UDA FS5R30A $#i 25GT TURBO RB25DET

R200V

BGKBRTAR34UDA RE4RO1 B

Prefix and suffix designations:

A: Standard

- 1 TEG, TDestlon' U: intercooler turbocharger

Model

F:

&speed

manual transmission

A: 4-speed automatic transmission

20GT,

25GT,

25GT-X T: 25GT TURBO

k: Right-hand drive

2WD B: 2WD

+ ELECTRIC SUPER HlCAS

GH:

RB20DE

GK:

RB25DE, RB25DET

4-door Sedan G: 2-door Coupe

Page 7 of 230

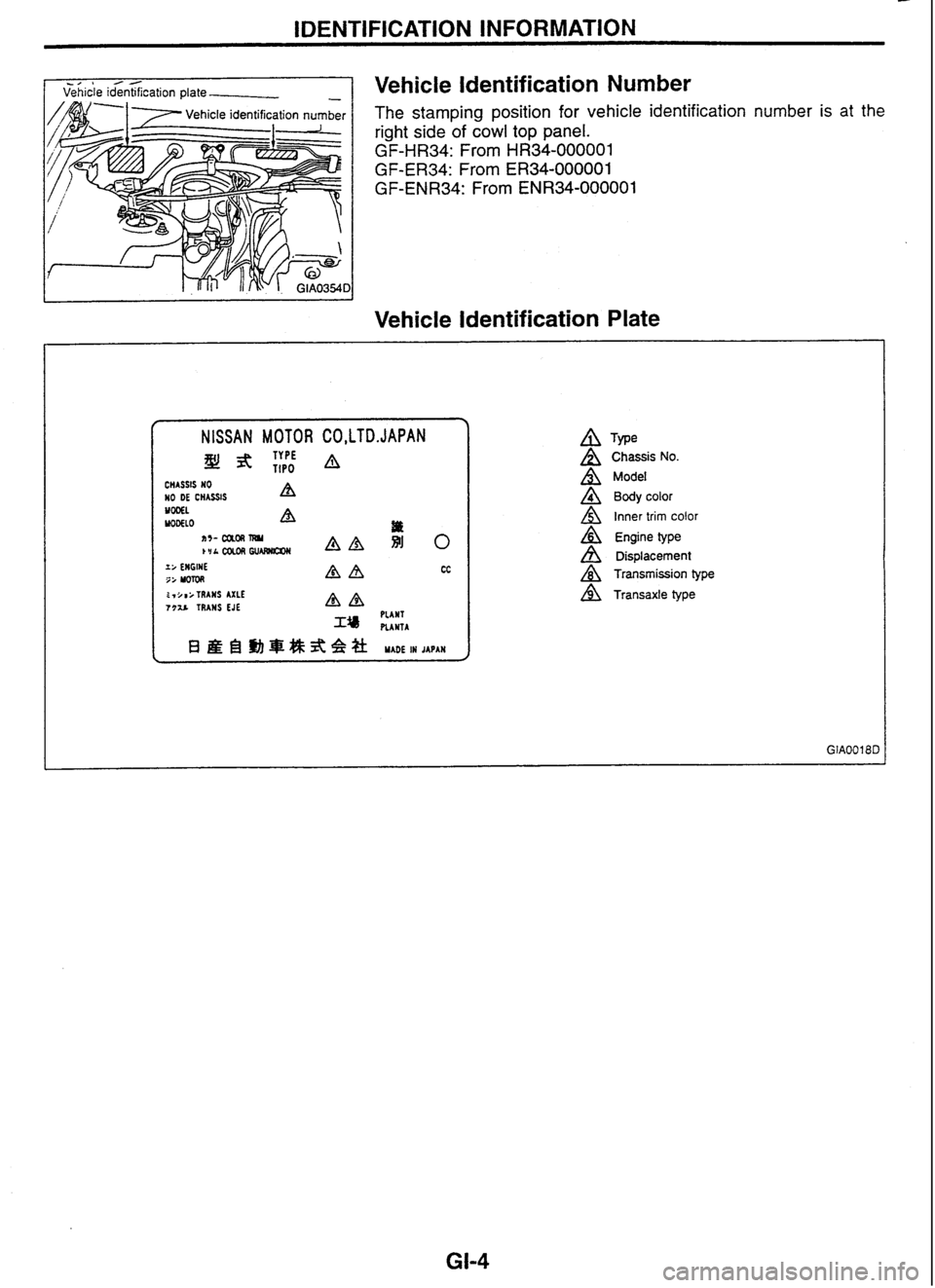

IDENTIFICATION INFORMATION

-2 L .I Vehicle identification plate Vehicle Identification Number

The stamping position for vehicle identification number is at the

right side of cowl top panel.

GF-HR34: From HR34-000001

GF-ER34:

From ER34-000001

GF-ENR34:

From ENR34-000001

--

Vehicle Identification Plate

-- -

NISSAN MOTOR CO,LTD.JAPAN

CHASSlS NO YO DE CHASSIS A MOOEL WDELO A n7- me4 W I

~YLCOLOAWUIWQW( AA 0

z; ENGINE QA cc 2; Mom 2 I ;mi TRANS AXLE T77.b TRANS EJE A& PLANT

nrwrr

A TYP~ A Chassis No.

A Model

A ~ody color

A Inner trim color

A Engine type

Displacement

A Transmission type

A Transaxle type

Page 8 of 230

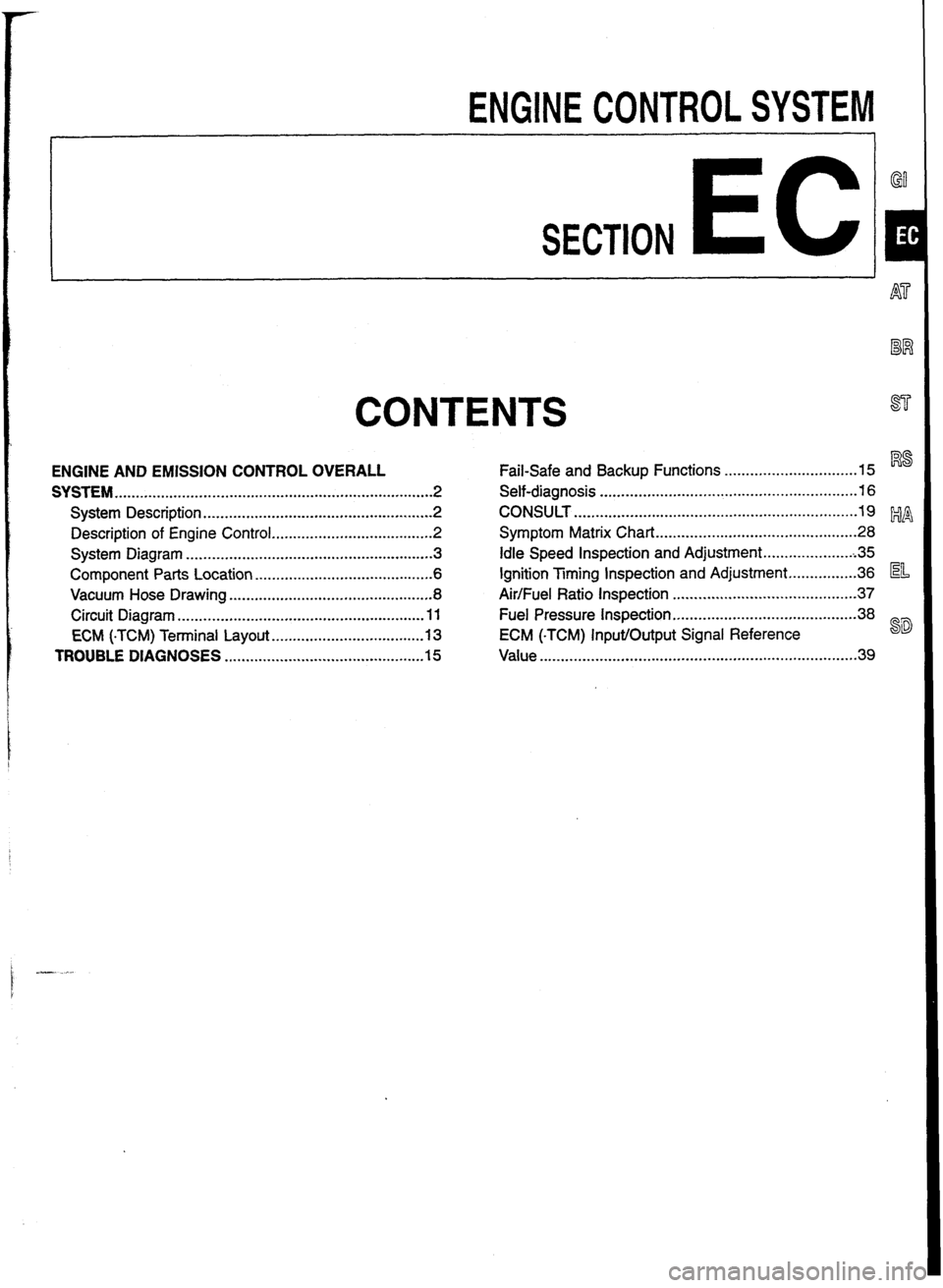

ENGINE CONTROL SYSTEM

SECTION EC

CONTENTS

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM..

....................................................................... \

..2

System Description ...................................................... 2

Description of Engine Control ...................................... 2

System Diagram

.......................................................... 3

Component Parts Location .......................................... 6

Vacuum Hose Drawing ................................................ 8

Circuit Diagram

........................................................ 11

.................................... ECM (.EM) Terminal Layout 13

TROUBLE DIAGNOSES ............................................... 15

Fail-safe and Backup Functions 15 RS ...............................

Self-diagnosis .......................................................... 16

CONSULT .................................................................. I9 MA ............................................... Symptom Matrix Chart 28

Idle Speed Inspection and Adjustment

..................... ;35

................ Ignition Timing Inspection and Adjustment 36

AirIFuel Ratio Inspection ........................................... 37

Fuel Pressure Inspection ........................................... 38

ECM (.TCM) InpuVOutput Signal Reference 9D

........................................................................\

. Value .39

Page 9 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

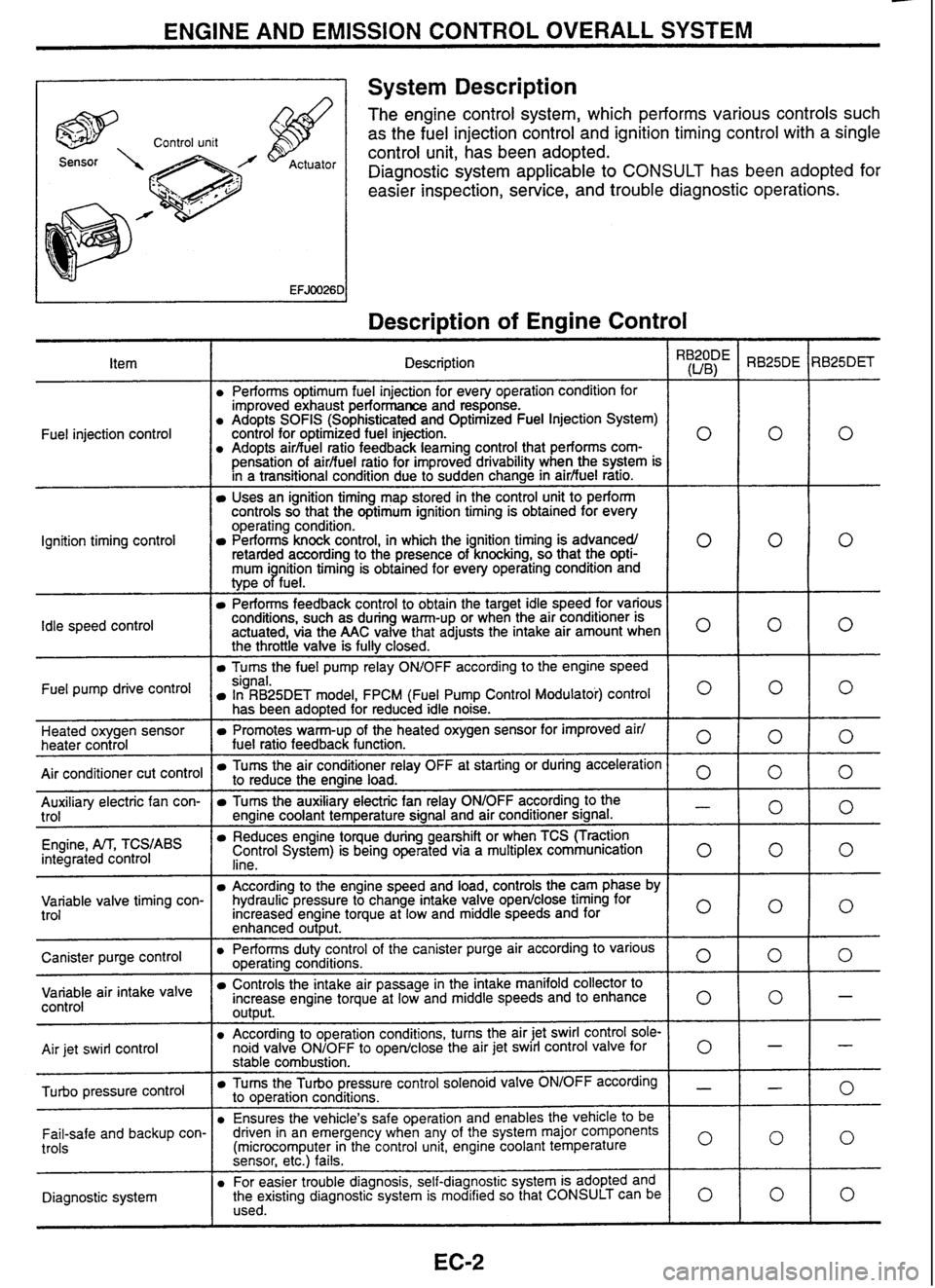

A 1 System Description

The engine control system, which performs various controls such

as the fuel injection control and ignition timing control with a single

control unit, has been adopted.

Diagnostic system applicable to

CONSULT has been adopted for

easier inspection, service, and trouble diagnostic operations.

Description of Engine Control

I

Description \,

Performs optimum fuel injection for every operation condition for

improved exhaust performance and response.

Adopts

SOFlS (Sophisticated and Optimized Fuel Injection System)

control for optimized fuel injection.

Adopts

airbuel ratio feedback

learning control that performs

com-

0

pensation of airfiuel ratio for improved drivability when the system is

in a transitional condiiion due to sudden change in

airfiuel ratro.

Uses an ignition timing map stored in the control unit to perform

controls so that the optimum ignition timing is obtained for every

operating condition.

Performs knock control, in which the ignition timing is advancedl

retarded according to the presence of knocking, so that the

opti- 0

mum i nition timing is obtained for every operating condition and

type

oPfue1.

Performs feedback control to obtain the target idle speed for various

conditions, such as during warm-up or when the air conditioner is

actuated, via the

AAC valve that adjusts the intake air amount when

O

the throttle valve is fully closed.

Turns the fuel pump relay OWOFF according to the engine speed

Fuel

injection control

Ignition timing control

Idle

speed

control

Fuel pump drive signal. In RB25DET model, FPCM (Fuel Pump Control Modulatoi) control O

has been adopted for reduced idle noise.

Heated oxygen sensor

heater control

Air conditioner cut control

Promotes warm-up of the heated oxygen sensor for improved air1

fuel ratio feedback function. 0

Tums the air conditioner relay OFF at starting or during acceleration to reduce the engine load. 0 -- Auxiliary electric fan con-

trol

Engine,

M, TCS,ABS integrated control

Tums the auxiliary electric fan relay ONIOFF according to the - engine coolant temperature signal and air conditioner signal.

Reduces engine toque during gearshift or when TCS (Traction

Control System) is being operated via a multiplex communication

lino 0

- -

Variable valve timing con-

trol According to the engine speed and load, controls the cam phase by

hydraulic pressure to change intake valve

open/close timing for

Increased engine torque at low and middle speeds and for

enhanced

out~ut.

I o I

Canister purge control air

intake valve control

Air

jet swirl control Performs duty

control of the canister purge air according to various ooeratina conditions.

0 -r-~ e-- ---

-

Controls the intake air passage in the intake manifold collector to

increase engine torque at low and middle speeds and to enhance

output. 0

According to operation conditions, turns the air jet swirl control sole-

noid valve ONIOFF to openlclose the air jet swirl control valve

for 0

pressure control

stable combustion.

Tums the Turbo pressure control solenoid valve ONIOFF according - to operation conditions.

Ensures the vehicle's safe operation and enables the vehicle

to be

Fail-safe and backup con-

trols

Diagnostic system driven

in an emergency when any of the system major components

(microcomputer in the control unit, engine coolant temperature

0

sensor, etc.) fails.

For easier trouble diagnosis, self-diagnostic system is adopted and

the existing diagnostic system is modified so that CONSULT can be

0 used.

Page 10 of 230

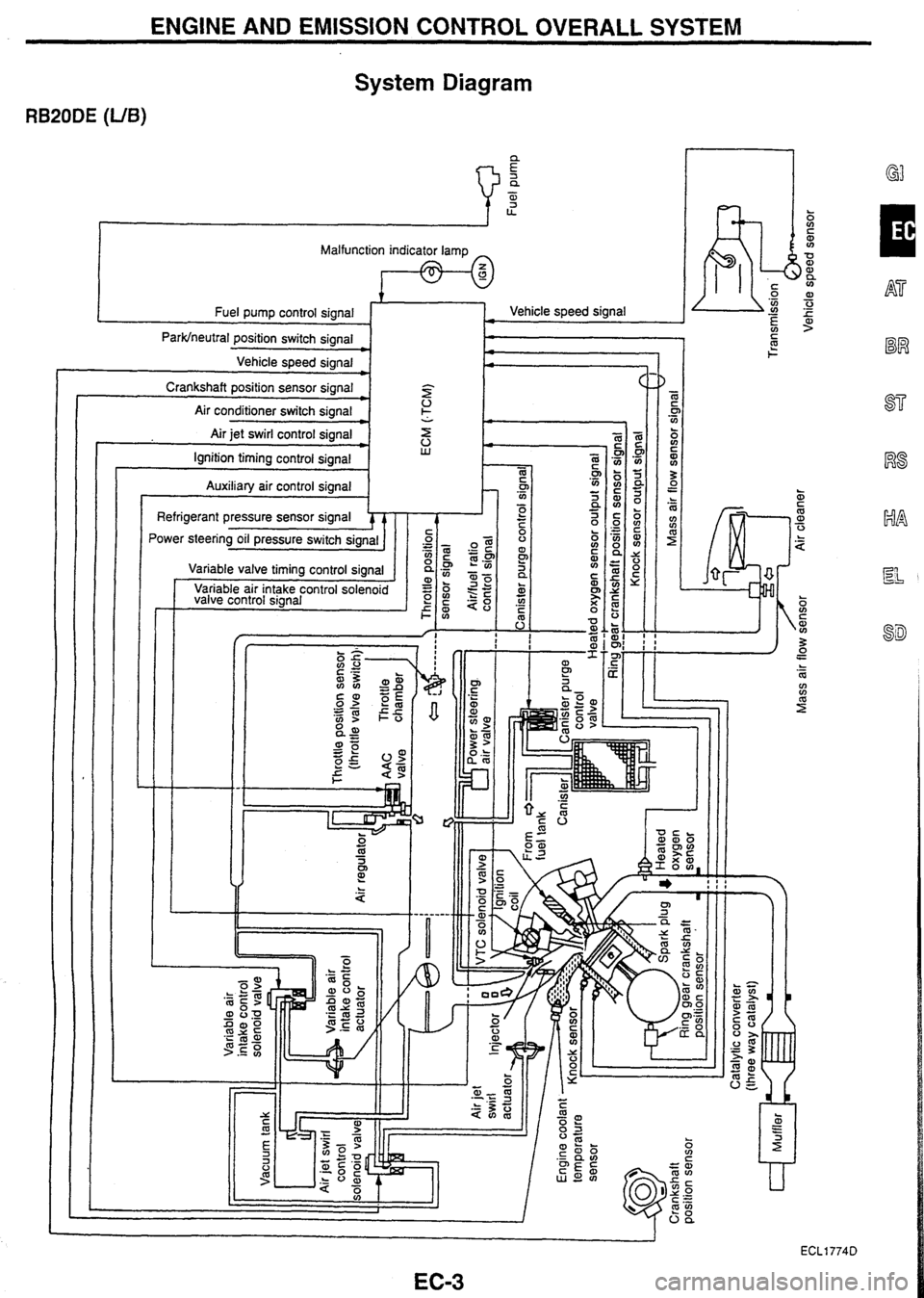

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

RB20DE (UB)

System Diagram

c !! I-

a

5 a - w 2 LL

Malfunction indicator lamp

-!

Fuel pump control signal

Parwneutral position switch signal

C

Vehicle speed signal - - 5 Vehicle speed signal -