warning NISSAN GT-R 1998 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 165 of 230

ELECTRICAL SYSTEM

SECTION EL

CONTENTS

CENTRAL DOOR LOCK SYSTEM ................................. 2

Component Parts Location .......................................... 2

Circuit Diagram ............................................................ 2

Combination Meter (meter control unit) Input/

Output Signal Specifications

........................................ 2

Inspection before Trouble Diagnoses ......................... -3

Trouble Diagnoses ....................................................... 3

REMOTE CONTROL ENTRY SYSTEM .......................... 4

Component Parts Location .......................................... 4

Circuit Diagram ............................................................ 4

Remote Control Entry Control Unit Input/Output

Signal Specifications

.................................................... 5

System Check ............................................................. -5

Inspection before Trouble Diagnoses .......................... 6

Trouble Diagnoses ....................................................... 6

Component Parts inspection ....................................... 6

ID Code Entry Procedure ............................................ 7

POWER WINDOW SYSTEM ........................................... 8

System Description ..................................................... -8

Precautions ................................................................. -8

Component Parts Location .......................................... 8

Circuit Diagram ............................................................ 9

Power Window Main Switch Input/Output Signal

Specifications

............................................................... 9

Inspection before Trouble Diagnoses ........................ 11

Trouble Diagnoses .................................................... 11

SUNROOF SYSTEM ...................................................... 12

Component Parts Location ........................................ 12

Circuit Diagram .......................................................... 12

Sunroof Switch and Sunroof Motor Assembly

lnputiOutput Signal Specifications

............................. 12

AUTO LIGHT SYSTEM ................................................. 1 3

Component Parts Location ........................................ 13

Auto Light Control Unit Input/Output Signal

Specifications

............................................................. 13

Circuit Diagram ........................................................ 14

Trouble Diagnoses .................................................. I 4

..................................... XENON HEADLAMP SYSTEM 15

Trouble Diagnoses ..................................................... 15

IGNITION KEY-OPERATED ILLUMINATION

SYSTEM

................................................................... 7

Component Parts Location ........................................ 17

.......................................................... Circuit Diagram 17

Meter Control Unit InputlOutput Signal

....................................................... Specifications 1 7

METER ........................................................................\

18

Corn bination Meter .................................................... 18

Triple Meter ................................................................ 20

................................................ COMBINATION METER 21

.................................................... System Description 21

........................................ Component Parts Location 21

Diagnosis Function .................................................... 21

................................... Meter-related Circuit Diagram 22

..................................................... Trouble Diagnoses 23

Combination Meter InpuVOutput Signal

Specifications

............................................................ -25

..................................... Component Parts Inspection 26

TRIPLE METER ............................................................. 29

Special Service Tool ................................................... 29

........................................ Component Parts Location 29

Circuit Diagram .......................................................... 29

Triple Meter InputfOutput Signal Specifications ........ 30

Component Parts Inspection ..................................... 30

IGNITION KEY WARNING BUZZER AND LIGHT

WARNING BUZZER

...................................................... 31

Component Parts Location ........................................ 31

Circuit Diagram .......................................................... 31

Meter Control Unit InpuVOutput Signal

Specifications

............................................................. 31

FRONT WIPER .............................................................. 32

Component Parts Location ........................................ 32

Circuit Diagram .......................................................... 32

Front Wiper Input/Output Signal Specifications ........ 32

Page 186 of 230

COMBINATION METER

System Description

Speedometer, tachometer, odoltrip meter, fuel gauge, and

water temperature gauge are integrally controlled by the con-

trol circuit in the meter control unit.

Diagnosis function has odoltrip meter segment check, low fuel @

warning lamp check, and continuity check in the meter control

circuit and the meters (speedometer, tachometer, fuel gauge,

and water temperature gauge).

Component Parts Location

Combination meter ABS unit

ID Transfer (4WD) I H side of trunk room

I -unit connector I

/I Diagnosis Function

meter is displayed, turn the ignition switch ACC or

down the odoltrip meter switch, turn the ignition switch

/

ON.

3. Verify that 0000.0 km is displayed on the trip meter.

4. Press the odoltrip meter switch 3 times within 5 seconds.

5. All the odoltrip meter segments light up along with low fuel

warning lamp.

EL-21

SEGMENT CHECK AND LOW FUEL WARNING LAMP

CHECK

Page 187 of 230

COMBINATION METER

Diagnosis Function

(Cont'd)

METER CIRCUIT CHECK

After the segment check, press the odohrip meter switch to

verify that meters operate as shown below. (Low fuel warning

lamp goes off at this point.)

i

ELF0967D I It takes 1 minute for the meters to become stable.

DIAGNOSIS FUNCTION CANCELLATION

Turn the ignition switch ACC or OFF.

Meter-related Circuit Diagram

I I TO oil pressure W.L

Page 188 of 230

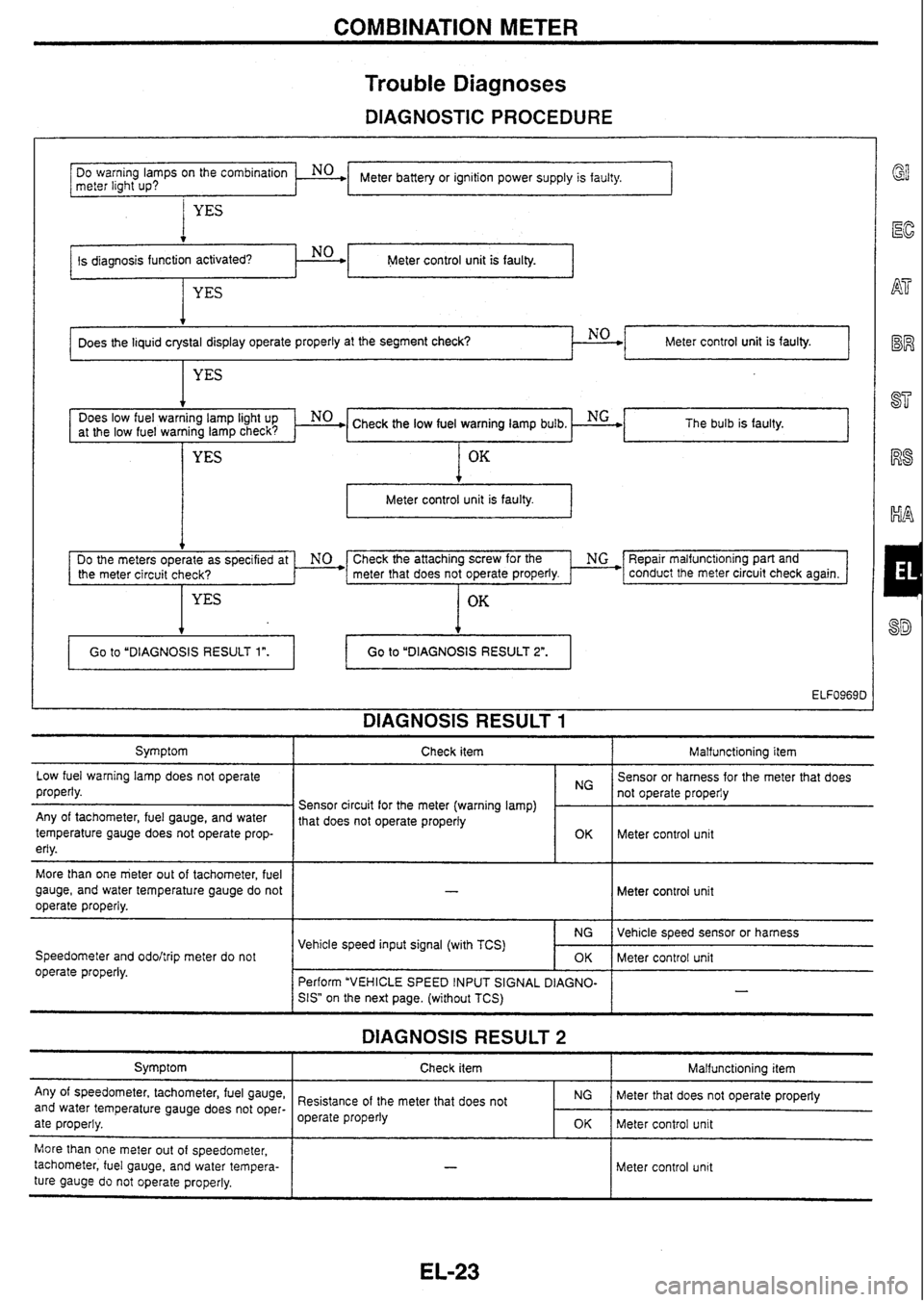

COMBINATION METER

Trouble

Diagnoses

DIAGNOSTIC PROCEDURE

I YES

Meter control unit is faulty.

Meter battery or ignition power supply is faulty.

DO

warning

lamps

on

the

meter light

up?

. No .

at the low fuel warning lamp check? The bulb

is faulty.

t

Meter control unit is faulty. I

Does the liquid crystal display operate properly at the segment check? NO

Check the attaching screw for the ' NG *F3epair malfunct~oning part and

the meter circuit check? meter that

does not operate properly. * conduct the meter circuit check again.

OK

Meter control unit is faulty.

YES

DIAGNOSIS RESULT 1

4

Symptom I Check item I Malfunctioning item

Go

to "DIAGNOSIS RESULT

1".

Low fuel warning lamp does not operate

properly. Go to

"DIAGNOSIS RESULT

2".

Any of tachometer, fuel gauge, and water

temperature gauge does not operate prop-

erly.

More than one meter out of tachometer, fuel

gauge, and water temperature gauge do not

operate properly.

Speedometer and

odohrip meter do not

operate properly. Sensor

or harness for the meter that does

Sensor circuit for the meter (warning lamp)

1 1: 1 not operate properiy

1 that does not operate properly

~ Meter control unit

Meter control unit

DIAGNOSIS RESULT 2

Symptom

Any of speedometer, tachometer, fuel gauge,

and water temperature gauge does not oper-

ate properly. Vehicle

speed sensor or harness

Meter control unit

-

Vehicle speed input signal (with TCS)

Check item

I Malfunctioning item

NG

OK

Perform "VEHICLE SPEED INPUT SIGNAL

DIAGNO-

SIS"

on the next page. (without TCS)

More than one meter out of speedometer,

tachometer, fuel gauge, and water tempera-

ture gauge

do not operate properly. Resistance

of the meter that does not

operate properly

Meter control unit

NG

OK

- -

Meter that does not operate properly

Meter control unit

Page 189 of 230

COMBINATION METER

Trouble Diagnoses (Cont'd)

VEHICLE SPEED INPUT SIGNAL DIAGNOSIS

I Connector

WARNING LAMP CHECK Does ABS warning lamp remain ON with

ignition switch ON?

ABS I

Perform ABS self-diagnosis

and check faulty circuit.

Refer to

BR section ("ABS

SYSTEMn).

Continuity exists.

Terminal No. 19 and ground:

No continuity

. -- I I

HARNESS CHECK ' Disconnect ABS control unit connector

(TK24)

and meter connector (TK20

Brown).

Terminals No. 19 - 24:

OK

El f

Meter control unit connector on vehicle

NG+'

I - = 'ELF0970D

El

@EM

Meter control unit connector on vehicle rn

rm-1 ffee

1

L / - - -

ELFo971D -

ABS control unit to meter

harness is faulty.

Meter control unit

is faulty. VEHICLE SPEED INPUT SIGNAL

CHECK 1 Connect meter connector (TK20 Brown). Terminal No. 19 and around:

'2

" Approx. 9V

OK

r9 v

VEHICLE SPEED INPUT SIGNAL

CHECK 2 Connect ABS control unit connector

(TK24).

Start the engine and drive the vehicle. Terminal No. 19 and ground:

Specification

Refer to "Combination Meter InpuffOutput

Signal Specificationsn on the next page.

OK

Meter control unit is faulty.

5' Pelform ABS self-diagnosis and check faulty circuit.

Refer to BR section ("ABS

SYSTEMn).

Page 193 of 230

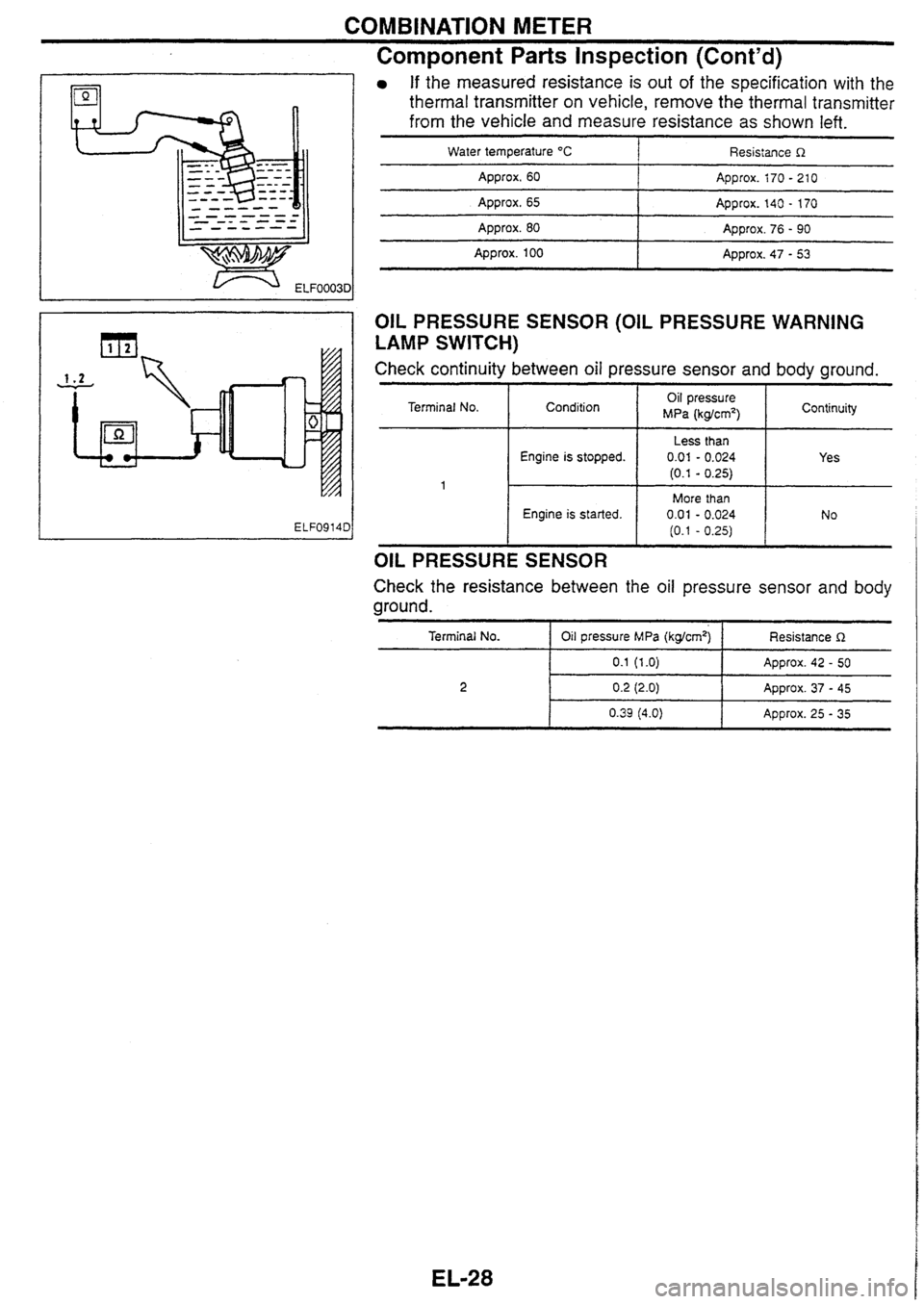

COMBINATION METER

Component Parts Inspection (Cont'd)

If the measured resistance is out of the specification with the

thermal transmitter on vehicle, remove the thermal transmitter

from the vehicle and measure resistance as

shown left.

Water temperature "C 1 Resistance R

Approx. 60 I Approx. i70 - 21 0

Approx. 65 I Approx. 140 - 170

Approx. 80 I Approx. 76 - 90

I

- - -- Appro~. 100 Approx. 47 - 53

OIL PRESSURE SENSOR (OIL PRESSURE WARNING

LAMP SWITCH)

Check continuity between oil pressure sensor and body ground.

Terminal No.

OIL PRESSURE SENSOR

Engine is stopped.

Engine is started.

Check the resistance between the oil pressure sensor and body

ground.

Condition

Terminal No.

I Oil pressure MPa (kgkmq-1 Resistance R

Oil pressure

MPa (kg/cm2) 1 Continuity

Less than

0.01 - 0.024

(0.1 - 0.25)

More than 0.01 - 0.024

(0.1 - 0.25)

0.2 (2.0) Approx. 37 - 45

Yes

No

Page 196 of 230

IGNITION KEY WARNING BUZZER AND LIGHT WARNING BUZZER

I Behind combination meter

Meter control unit Component Parts Location

J

Circuit Diagram

Meter Control Unit

InputlOutput Signal

Specifications

Terminal No.

Driver door switch signal

Signal

name

OFF Measuring condition

Ignition switch

I Measuring method Specification

Driver door switch

29

ON (Open)

OFF (Closed)

42

Approx. OV

Approx. 12V

Ignition power supply

54

55

Key-in detection switch

signal 1 OFF

ON

Lighting switch signal

Ground Approx. 12V

Remove

the ignition key.

Insert the ignition key. Approx. OV

Approx. 12V

Approx. 12V

Approx. OV

Approx. OV

I

OFF

ON Lighting

switch: 1 ST ON

OFF

-

Page 228 of 230

BRAKE

BRAKING FORCE

More than 10% of axle

weight

REAR DlSC BRAKE

Total braking force of rear wheels

Variation between right and left of

each wheel Brake

type

Less than 8% of axle weight ADllVC

9.3

Brake

pad

Disc rotor

Total

braking force OPZ11V

11.5

Standard

thickness (New) mm

Wear limit of thickness mm

Standard thickness (New) mm

Wear limit of thickness mm

Runout limit mm

More than 50%

of vehicle

weight at inspected

Note: The braking force when both front wheels are locked up can be considered to meet the total braking force.

2.0

16

14

BRAKE PEDAL

18

16

PARKING BRAKE

Free play (at pedal top surface)

mm I 3 - 11 Less than

0.07 Type DS17HD I

Brake

lining

Depressed pedal height under force

of 490 N (50 kg)

(from dash panel top surface)

mm

Brake

pedal height

(from dash panel top surface)

mm

Standard inner diameter

I (New) mm I

Standard thickness (New) mrn

Wear limit of thickness

mm M/T: 163 - 173 IVT: 170 - 180

172 dia. 3.0 1.5

M/T: More

than 85 A. More than 90 . . Drum I

I

Wear limit of inner diameter

mm I 173 dia.

Clearance between the edge of stop

lamp switch screw and pedal stopper

mm Operating

stroke

[under force of 196 N (20

kg)] 5 - 7 notches

CHECK VALVE I

I

Maximum stroke

19 notches

Number of notches when brake warning

lamp turns on

TIGHTENING TORQUE

Unit: N.m (kg-m)

Within 1 notch

Vacuum leakage

[at

vacuum Of 66'7 kPa (-500 mmHg)]

BRAKE BOOSTER

Within 1.3 kPa (10 mmHg) of

vacuum for 15 seconds

Master cylinder fixing nut

I 12 - 14 (1.2 - 1.5)

Vacuum leakage

[at vacuum of 66.7

kPa

(-500

mmHg)l

Within 3.3

kPa

(25

mmHg)

of

vacuum for 15 seconds Front

caliper mounting bolt

Brake tube flare nut -- - 152 - 154 (15.5 - 15.8)

15

- 17 (1.5 - 1.8)

FRONT DlSC BRAKE

Input rod standard length at installed

mm

Brake type

I AD25VB I CUSVD [OPZ~~VC

140

Standard thickness

Wear limit of

thickness

Standard thickness

mm

1 22 1 26 1 30

Disc rotor Wear limit of

thickness

Runout

limit Less than 0.07