4WD NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 18 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Circuit Diagram

RB20DE (UB).MTT, RB25DE, RB25DET.MTT MODELS

Fan motor

Auxtliary

electric

Ian

relay

-

Alr cmdll~oner compressor

Arr

conduoner

relay

14

Y Mallunct~on indcator lamp A 17

26 $7 = Power steenng 011

pressure sw~icr.

I

23

43 Engine Want

temwrature sensor B.

Tachometer drive signal Check connmr

To rear defogger relay

/ [RB2MWD TO starter motor *'""L'*" - > TO PNP switch

I TO Starter relay

[Except lor ' - RB25DE.4WDI

Page 20 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

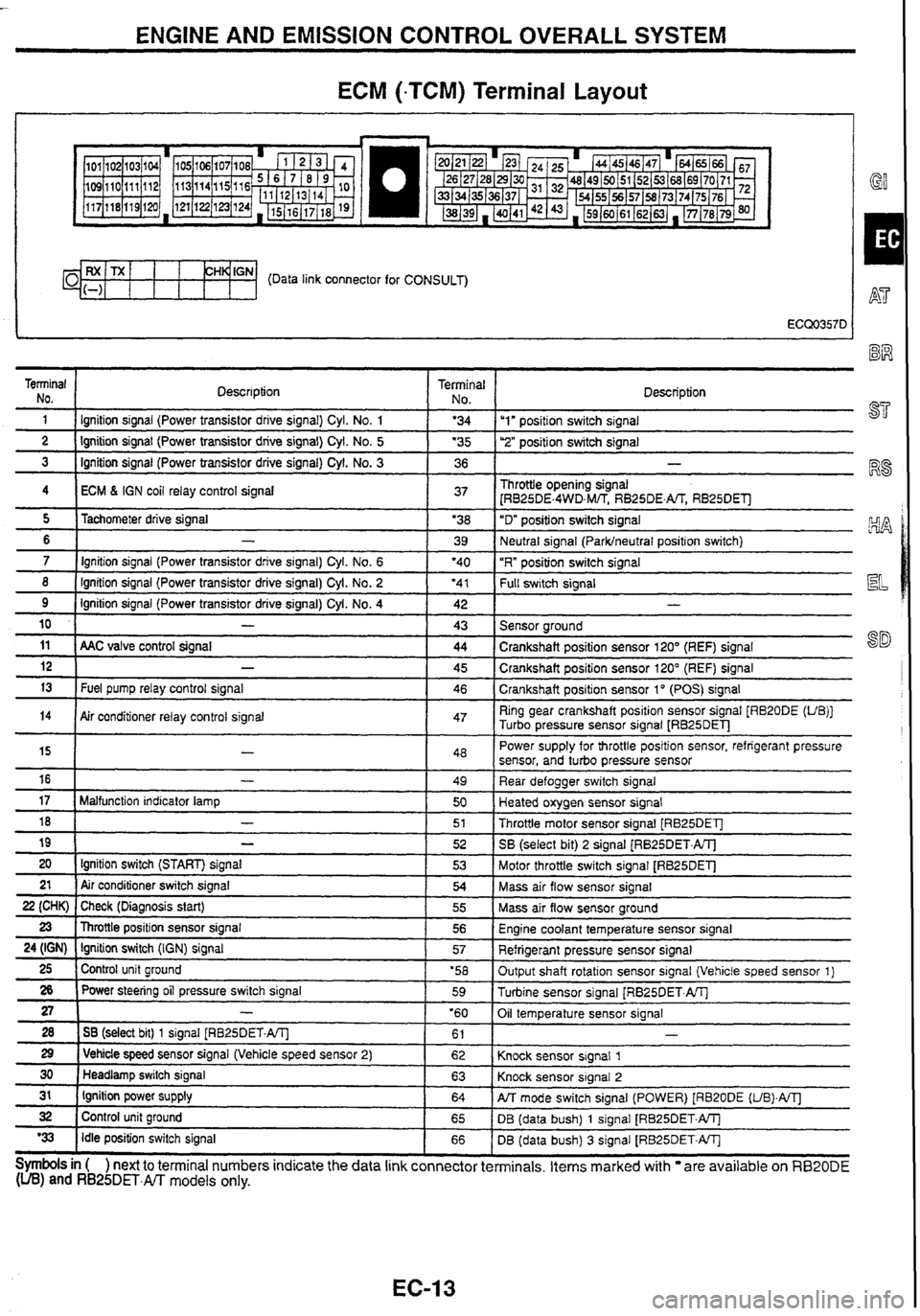

ECM (-TCM) Terminal Layout

I GY

CH~'GN- (Data link connector for CONSULT)

Terminal NO.

1 Description Terminal 1 No I Description - - 1 I lgnition

signal (Power transistor drrve signal) Cyl. No. 1 1 '34 Iu1" positron switch signal -- ---- 2 1 Ignition signal (Power transistor drive signal) Cyl. No. 5 1 '35 1 ''2" posifion switch signal - - 3 1 Ignition signal (Power transistor drive signal) Cyl. No. 3 1 36 1 -

4 I ECM 6 IGN coil relay control signal 1 37 1 Throttle opening signal

[RB25DE.4WD,M/TS RB25DE.m RB25DEll

- - - -- - - - - 8 ( Ignition signal (Power transistor drive signal) Cyl. No. 2 ( '41 1 f-k swltch signal

5

6

7

11 ( AAC valve control signal ( 44 1 Crankshaft position sensor 120' (REF) signal

Tachometer

drive signal

-

Ignition signal (Power transistor drive signal) Cyl. No. 6

9

10

'38

39

'40

Ignition signal (Power transistor drive signal)

Cyl.

No. 4

-

12

13

"D" position switch signal

Neutral signal

(Parklneutral position switch)

"R" position switch signal

14

Symbols in ( ) next to terminal numbers indicate the data link connector terminals. Items marked with are available on RB20DE (UB) and RB25DET.m models only.

42

43

-

Fuel pump relay control signal

15

16

17

18

19

20 21

22 (CHK)

23

24 (IGN)

25

26

27

28

29

30

31

32

'33

- -

Sensor around

Air conditioner relay control signal 45

46

-

-

Malfunction indicator lamp

-

-

Ignition switch (START) signal

Air conditioner switch signal

Check (Diagnosis start)

Throttle position sensor signal

Ignition switch

(IGN) signal

Control unit ground

Power steering oil pressure switch signal

-

1 SB (select bit) 1 signal [RB25DET.A/Tl

1 Vehicle speed sensor signal (Vehicle speed sensor 2)

Headlamp switch signal

Ignition power supply

Control unit ground

Idle position switch signal Crankshaft

position sensor 120" (REF) signal

Crankshaft position sensor 1

" (POS) signal

47 Ring gear crankshaft position sensor signal [RB20DE (UB)]

Turbo pressure sensor signal

LRB25DEl-J

48

49

50

51

52

53

54

55

56

57

'58 59

'60 61

62

63

64

65

66 Power

supply for throttle position sensor, refrigerant pressure

sensor, and turbo pressure sensor

Rear defogger switch signal

Heated oxygen sensor signal

Throttle motor sensor signal [RB25DET]

SB

(select bit)

2 signal (RB25DET.ATJ

Motor throttle switch signal

[RB25DET]

Mass air flow sensor signal

Mass air flow sensor ground

Engine coolant temperature sensor signal

Refrigerant pressure sensor signal

Output shaft rotation sensor signal (Vehicle speed sensor 1)

Turbine sensor signal

[RB25DET.AlTj

Oil temperature sensor signal

Knock sensor signal

1

Knock sensor signal 2

PJT mode switch signal (POWER) [RB20DE (UB).A/Tl

DB (data bush) 1 signal [RB25DET.W

DB (data bush)

3 signal [RB25DET.W

Page 43 of 230

TROUBLE DlAGNOSES

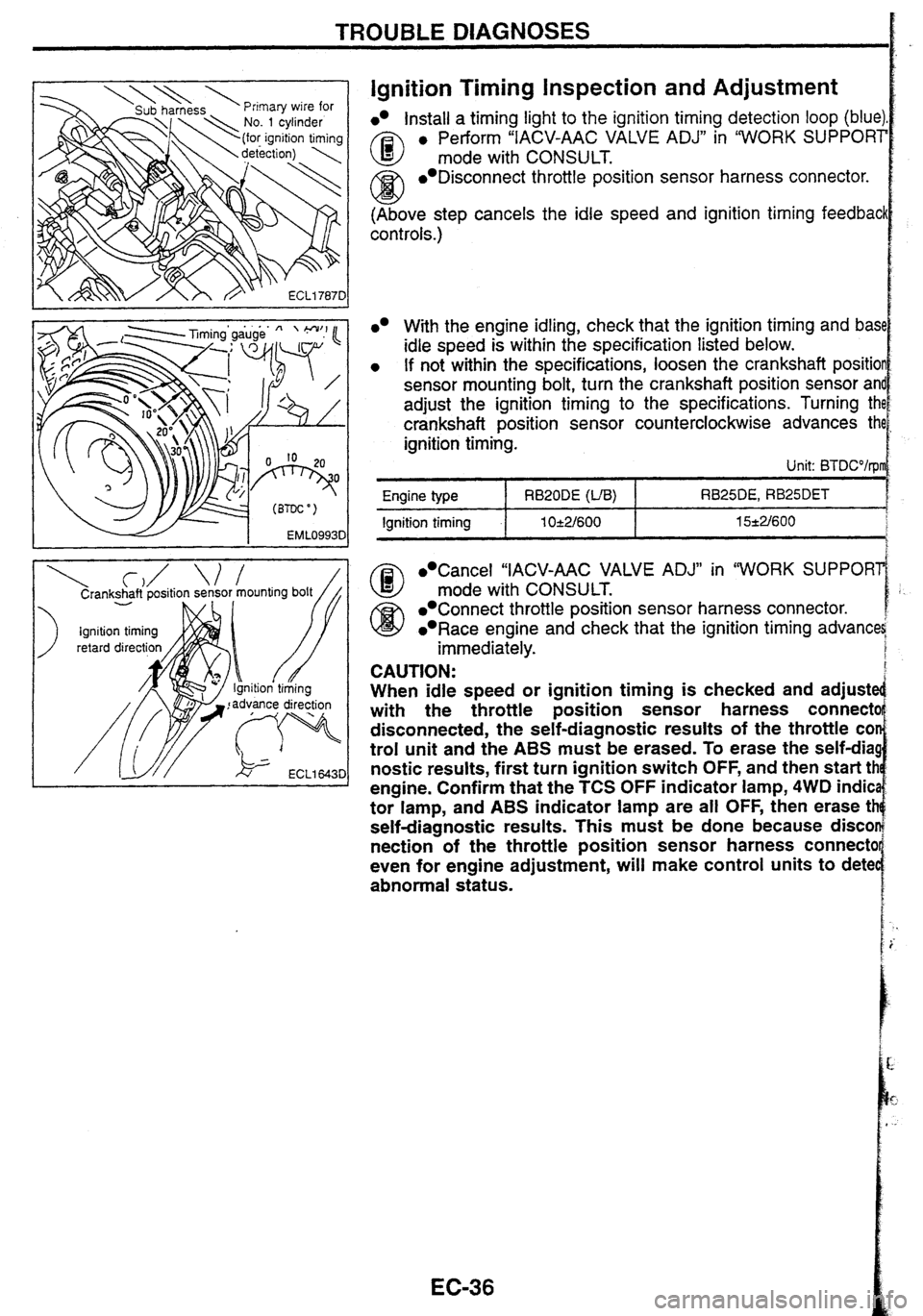

Ignition Timing inspection and Adjustment

lnstall a timing light to the ignition timing detection loop (blue)

A3 e Perform "IACV-AAC VALVE ADJ" in "WORK SUPPORT

mode with CONSULT.

/Ci3 Disconnect throttle position sensor harness connector.

w (Above step cancels the idle speed and ignition timing feedbacl

cont rots.)

Cancel "IACV-AAC VALVE ADJ" in "WORK SUPPORl

@ mode with CONSULT.

Connect throttle position sensor harness connector.

Race engine and check that the ignition timing advana

immediately.

With the engine idling, check that the ignition timing and bas1

idle speed is within the specification listed below.

If not within the specifications, loosen the crankshaft positio

sensor mounting bolt, turn the crankshaft position sensor

an

adjust the ignition timing to the specifications. Turning th

crankshaft position sensor counterclockwise advances th

ignition timing.

Unit: BTDCO/rpl

CAUTION:

When idle speed or ignition timing is checked and adjuste

with the throttle position sensor harness

connectc

disconnected, the self-diagnostic results of the throttle

COI

trol unit and the ABS must be erased. To erase the self-dia!

nostic

results, first turn ignition switch OFF, and then start tt

engine. Confirm that the

TCS OFF indicator lamp, 4WD indic

tor lamp, and

ABS indicator lamp are all OFF, then erase tt

self-diagnostic results. This must be done because disco

nection

of the throttle position sensor harness connectc

even for engine adjustment,

will make control units to dete

abnormal status.

RB25DE, RB25DET

15*2/600 Engine type

Ignition timing

RB20DE (VB)

1 O-e2/600

Page 48 of 230

TROUBLE DIAGNOSES

ECM (*TCM) InpuWOutput Signal Reference

Value (Cont'd)

Terminal

No.

41

NOTE: I

Signal name At

idle

rlehicle speed sen-

;or signal

dead lamp switch Light switch OFF: Approx. OV

;ignal

Light switch ON: Battery voltage

gnition power

sup- Ignition switch OFF: Approx. OV

)iY Ignition switch ON: Battery voltage

dle position switch

lB25DET.m

Mottle

opening Accelerator pedal released: Approx.

0.5V

ignal

Accelerator pedal fully depressed: Approx.

4.2V RB25DE.4WD.W

(Ignition switch ON, engine not running) ; RB25D€.AlT,

3R25Dm

Jeutral signal Selector lever in Neutral or in

N or P position: Approx. OV ParWNeutral posi- Selector lever in other positions: Approx. 4.8V

on switch)

:ull switch signal Accelerator pedal released: Approx. OV

?B20DE

(UB), Accelerator pedal fully depressed: Battery voltage

lB25DET-A/Tl (Ignition switch ON, engine not running)

- - - - -- - love voltages are measured values obtained by analog

At approx. 2,000 rpm

IRB20DE

(UB)] When driving at approx. 40 km/h: Approx. 2.4V @I

i ECL 1 7920

[RB25DE, RB25DETI

When driving at approx. 40

kmk: Approx. 2.4V %R

Approx. OV

(When accelerator pedal is depressed)

Approx.

0.N

rcuit tester.

Page 186 of 230

COMBINATION METER

System Description

Speedometer, tachometer, odoltrip meter, fuel gauge, and

water temperature gauge are integrally controlled by the con-

trol circuit in the meter control unit.

Diagnosis function has odoltrip meter segment check, low fuel @

warning lamp check, and continuity check in the meter control

circuit and the meters (speedometer, tachometer, fuel gauge,

and water temperature gauge).

Component Parts Location

Combination meter ABS unit

ID Transfer (4WD) I H side of trunk room

I -unit connector I

/I Diagnosis Function

meter is displayed, turn the ignition switch ACC or

down the odoltrip meter switch, turn the ignition switch

/

ON.

3. Verify that 0000.0 km is displayed on the trip meter.

4. Press the odoltrip meter switch 3 times within 5 seconds.

5. All the odoltrip meter segments light up along with low fuel

warning lamp.

EL-21

SEGMENT CHECK AND LOW FUEL WARNING LAMP

CHECK