ESP NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 9 of 230

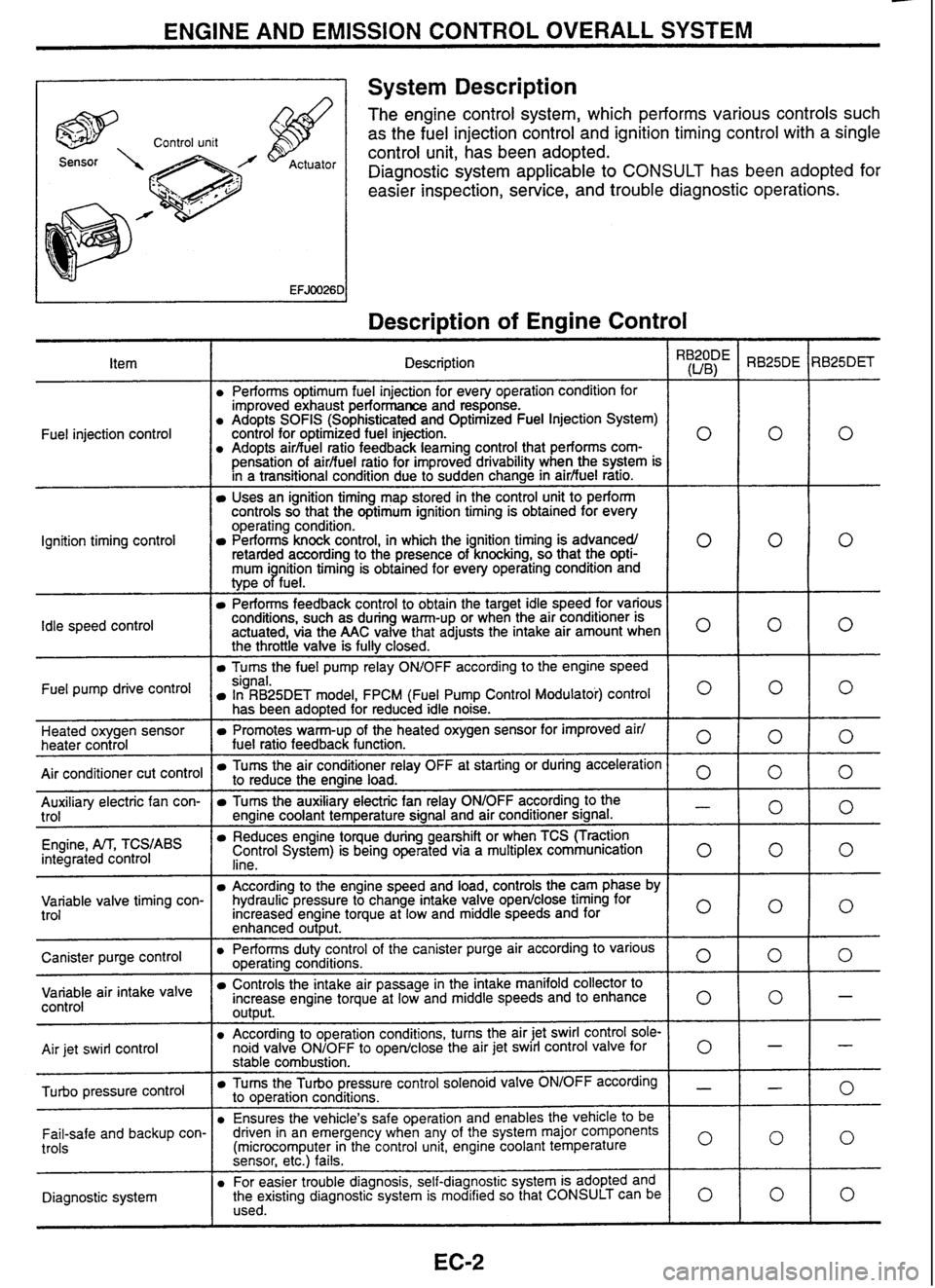

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

A 1 System Description

The engine control system, which performs various controls such

as the fuel injection control and ignition timing control with a single

control unit, has been adopted.

Diagnostic system applicable to

CONSULT has been adopted for

easier inspection, service, and trouble diagnostic operations.

Description of Engine Control

I

Description \,

Performs optimum fuel injection for every operation condition for

improved exhaust performance and response.

Adopts

SOFlS (Sophisticated and Optimized Fuel Injection System)

control for optimized fuel injection.

Adopts

airbuel ratio feedback

learning control that performs

com-

0

pensation of airfiuel ratio for improved drivability when the system is

in a transitional condiiion due to sudden change in

airfiuel ratro.

Uses an ignition timing map stored in the control unit to perform

controls so that the optimum ignition timing is obtained for every

operating condition.

Performs knock control, in which the ignition timing is advancedl

retarded according to the presence of knocking, so that the

opti- 0

mum i nition timing is obtained for every operating condition and

type

oPfue1.

Performs feedback control to obtain the target idle speed for various

conditions, such as during warm-up or when the air conditioner is

actuated, via the

AAC valve that adjusts the intake air amount when

O

the throttle valve is fully closed.

Turns the fuel pump relay OWOFF according to the engine speed

Fuel

injection control

Ignition timing control

Idle

speed

control

Fuel pump drive signal. In RB25DET model, FPCM (Fuel Pump Control Modulatoi) control O

has been adopted for reduced idle noise.

Heated oxygen sensor

heater control

Air conditioner cut control

Promotes warm-up of the heated oxygen sensor for improved air1

fuel ratio feedback function. 0

Tums the air conditioner relay OFF at starting or during acceleration to reduce the engine load. 0 -- Auxiliary electric fan con-

trol

Engine,

M, TCS,ABS integrated control

Tums the auxiliary electric fan relay ONIOFF according to the - engine coolant temperature signal and air conditioner signal.

Reduces engine toque during gearshift or when TCS (Traction

Control System) is being operated via a multiplex communication

lino 0

- -

Variable valve timing con-

trol According to the engine speed and load, controls the cam phase by

hydraulic pressure to change intake valve

open/close timing for

Increased engine torque at low and middle speeds and for

enhanced

out~ut.

I o I

Canister purge control air

intake valve control

Air

jet swirl control Performs duty

control of the canister purge air according to various ooeratina conditions.

0 -r-~ e-- ---

-

Controls the intake air passage in the intake manifold collector to

increase engine torque at low and middle speeds and to enhance

output. 0

According to operation conditions, turns the air jet swirl control sole-

noid valve ONIOFF to openlclose the air jet swirl control valve

for 0

pressure control

stable combustion.

Tums the Turbo pressure control solenoid valve ONIOFF according - to operation conditions.

Ensures the vehicle's safe operation and enables the vehicle

to be

Fail-safe and backup con-

trols

Diagnostic system driven

in an emergency when any of the system major components

(microcomputer in the control unit, engine coolant temperature

0

sensor, etc.) fails.

For easier trouble diagnosis, self-diagnostic system is adopted and

the existing diagnostic system is modified so that CONSULT can be

0 used.

Page 32 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd)

REAL TlME DIAGNOSIS IN DATA MONITOR MODE

CONSULT has two kinds of triggers and they can be selected by touching "SETTINGJy in "DATA MONITOR"

mode.

1. "AUTO TRIG" (Automatic trigger):

The malfunction will be identified on the CONSULT screen in real time.

In other words, malfunction item will be displayed at the moment the malfunction is detected by ECM. GI

DATA MONITOR can be performed continuously until a malfunction is detected. However, DATA MONI-

TOR cannot continue any longer after the malfunction detection.

2. "MANU TRIG" (Manual trigger):

Malfunction item will not be displayed automatically on CONSULT screen even though a malfunction

is detected by ECM.

DATA MONITOR can be performed continuously even though a malfunction is detected. I

AT

Use these triggers as follows: . 1. "AUTO TRIG"

While trying to detect the DTC by performing the "DTC CONFIRMATION PROCEDURE", be sure to BR

select to "DATA MONITOR (AUTO TRIG)" mode. You can confirm the malfunction at the moment it is

detected.

While narrowing down the possible causes, CONSULT should be set in "DATA MONITOR (AUTO ST

TRIG)" mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, compo-

Rs

nents and harness in the "DTC CONFIRMATION PROCEDURE, the moment a malfunction is found

the malfunction item will be displayed. (Refer to GI section,

"Incident

Simulation Tests" in

"HOW TO

PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT'.) HA

2. "MANU TRIG"

If the malfunction is displayed as soon as "DATA MONITOR" is selected, reset CONSULT to "MANU

TRIG".

By selecting "MANU TRIG" you can monitor and store the data. The data can be utilized for

further diagnosis, such as a comparison with the value for the normal operating condition.

I

I SELECT MONITOR ITEM 1

I MAIN SIGNALS

SELECTION FROM MENU

I I

-11 START I

I h SET RECORDING COND 1 1 k SET RECORDING CON0 1

I MANU TRIG I

I LONG TlME I

"AUTO TRIG"

A malfunction

can be

displayed on "DATA

MONITOR" screen

automatically

if detected. "MANU TRIG"

A

malfunction can not be

displayed

on "DATA

MONITOR" screen

automatically even

if

detected.

Page 39 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

An open circuit causes no fuel injection to the corresponding cylinder, and the heated oxygen sensor output becomes lean. When the open circuits are

observed at all cylinders, the engine will not start.

Actuator-related malfunction

Injector Symptom

characteristics and inspection hints

Drive

circuit

lgnition signal

(POW&

transistor

drive

siqnal)

(open

Injection Open

Short

Fuel pump relay

1 Open 1 Engine will not start. In case of instantaneous break, surging may occur.

A

short circuit causes continuous fuel injection to the corresponding cylinder, and

over-rich airlfuel ratio and misfire will be noted. When the short circuits are

observed at all cylinders, the engine will not start.

Foreign

material

Clogs

L

Foreign

material causes continuous fuel injection to the corresponding cylinder.

Symptoms vary with the condition how the injection port is clogged.

Aidfuel ratio

compensation factor becomes larger.

(1 10 to 125%)

Canister purge control valve Ignition primary

signal (Power

transistor ground)

Auxiliary electric fan relay

[RB25DE, RB25DETI

1 Short

Open

Open -

Open

Open

Leaks

Open

Open

lgnition coil

AAC valve

The valve purges constantly. In summertime, engine may stall at idle speed due

i to rich aidfuel ratio. In wintertime, various malfunctions may occur due to lean

airlfuel ratio.

An open circuit causes no fuel injection to the corresponding cylinder, and the '

heated oxygen sensor output becomes lean. When the open circuits are observed at all cylinders, the engine will not start. In case of instantaneous break, symptoms vary with the break time and the

vehicle's driving conditions. Light shock or surging will occur while the vehicle

is being driven.

The engine will stall when break time is long.

AAC valve is fully closed. Symptoms vary with the base engine speed. When it is

too low, engine may stall while the vehicle is decelerating or when the power

steering load or electrical load is applied.

Power

supply

s~de

primary

Second-

arY side

Power

supply

Drive

circuit

Open Open Auxiliary

electric fan will not operate even after warm-up is completed.

The valve

will not purge. Gasoline smell may be noted when the weather is hot.

Variable valve timing control

solenoid valve

Variable air intake control sole-

noid valve (NA)

Air jet swirl control solenoid

valve

[RB20DE

(UB)]

Injector ground (Total ground) lnstanta- Symptoms vary

with the break time and the vehicle's driving conditions. Surging neous break or engine stall may occur when the instantaneous break occurred during fuel

I I injection. I

Open

, Open

Short

Turbo pressure control solenoid

valve (TIC) Valve

timing not switched.

Variable air intake valve opens, and torque in low speed range is reduced.

Variable air intake valve closes, and torque in high speed range is reduced.

Open

Short Air jet

swirl control valve remains closed.

Air jet swirl control valve remains open.

Open

Open Swing valve opens earlier, and

maximum turbo pressure is reduced.

Engine will not start

because the injectors do not operate.

Page 41 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Engine mechanical-related malfunction I Symptom characteristics and inspection hints

Airffuel

ratio becomes lean.

Air sucked in at oil filler cap

Aidfuel ratio compensation factor becomes higher.

a Intake manifold induction vacuum becomes lower.

I Cracked intake manifold I

Misconnection of canister piping Use an induction vacuum (pressure) gauge for check.

' Common to all air sucking conditions from air intake system.

-

PCV valve stuck open

I Malfunctioning pressure regulator I Various symptoms occur depending on the fuel pressure.

Abnormal noise (peep) may

be heard.

Air/fuel

mixture

Improper gasoline properties Various

symptoms occur depending on the properties.

IEGRiale

stuck open

I

Clogged fuel strainer .

Clogged air cleaner element

Deposits on valve

r

Symptoms vary with the condition how they are clogged. However, the

symptoms tend to occur when the vehicle is driving at high speed and

under high load.

I

Air/fuel ratio becomes lean. Airfluel ratio compensation factor becomes

higher.

Excessive canister purge volume

I

Engine may stall when the accelerator pedal is lightly pressed. (Especially

in summertime.)

Misconnection of high-tension wire Check if the ignition timing

is correct. 1 Improperly adjusted ignition timing 1

Malfunctioning spark plug 1

Corn- I Improper valve contact I Symptoms vary with the degree of contact and the number of cylinders. '

High-tension wire leaks

Distributor

cap leaks Symptoms

vary with the degree of leaks.

Clogged catalytic converter or exhaust sys-

l tem , In many cases, engine stalls and then restarts after a while. I

pression I

Low base idle speed

pressure

Worn piston ring I

Engine may

stall while the vehicle is decelerating or when the power '

steering load or electrical load is applied.

Symptoms vary

with the degree of wear and the number of cylinders.

I

Air conditioner load too heavy I Too much refrigerant in the system. j

Others Dragging

brake

Belt tension too high

1

I Clogged radiator or capacitor I

ArJ load too heavy

Foreign material (vinyl, etc.) in fuel tank Insufficient A/T fluid (FR model)

Symptom tends to occur when fuel level in the tank becomes lower.

Page 62 of 230

TROUBLE DIAGNOSES

Control Unit Input/Output Signal Specifications

Refer to EC section ("ECM.TCM or ECM Input/Output Signal

Reference Value").

USING CONSULT -

Monitor item Indication value Operating status

Throttle position sensor Approx.

0.4 - 4.OV

Throttle fully - closed to fully-open --

AK fluid temperature sensor I Appro~. 1.5 - 0.5V I A/T fluid: Appro~. 20 - 80°C -- - - --- -

ON Overdrive control switch: OFF

Lever switch

OFF Overdrive control switch: ON

Line pressure

duty 29 - 94% Low

pressure - High pressure

Lock-up duty

4 - 94% Lock-up released - Lock-up engaged

USING CIRCUIT TESTER

Terminal

No.' 1 Condition Specifications

.- Refer to EC section

("ECM-TCM or

5 (39) Engine speed signal - ECM Input/Output Signal Reference

Value*).

Voltage increases gradually in

Throttle position sensor

signal After

engine warm-up, depress accelerator pedal

slowly. response

to throttle position.

Fully-closed throttle

: Approx. 0.5V

Fully-open throttle : Approx. 4.2V

24 (I0) Power source

31 (19) Turn

ignition switch ON. Battery

voltage

Turn ignition switch OFF. Approx.

OV

--

25 (25) 1 Ground 32 (48) Turn ignition switch ON. Approx. OV

Shift control

signal SB1 - - 28 (I4) (Except RB20DE)

Vehicle speed sensor

2 When vehicle is moved at 2 to 3 km/h for more than Voltage varies approx. between OV 29 (40) (vehicle speed

signal in 1 m. and 4.5V intermittently.

speedometer)

*: Each number in parenthesis ( ) shows the terminal No. for TCM (RB25DE).

Page 68 of 230

TROUBLE DIAGNOSES

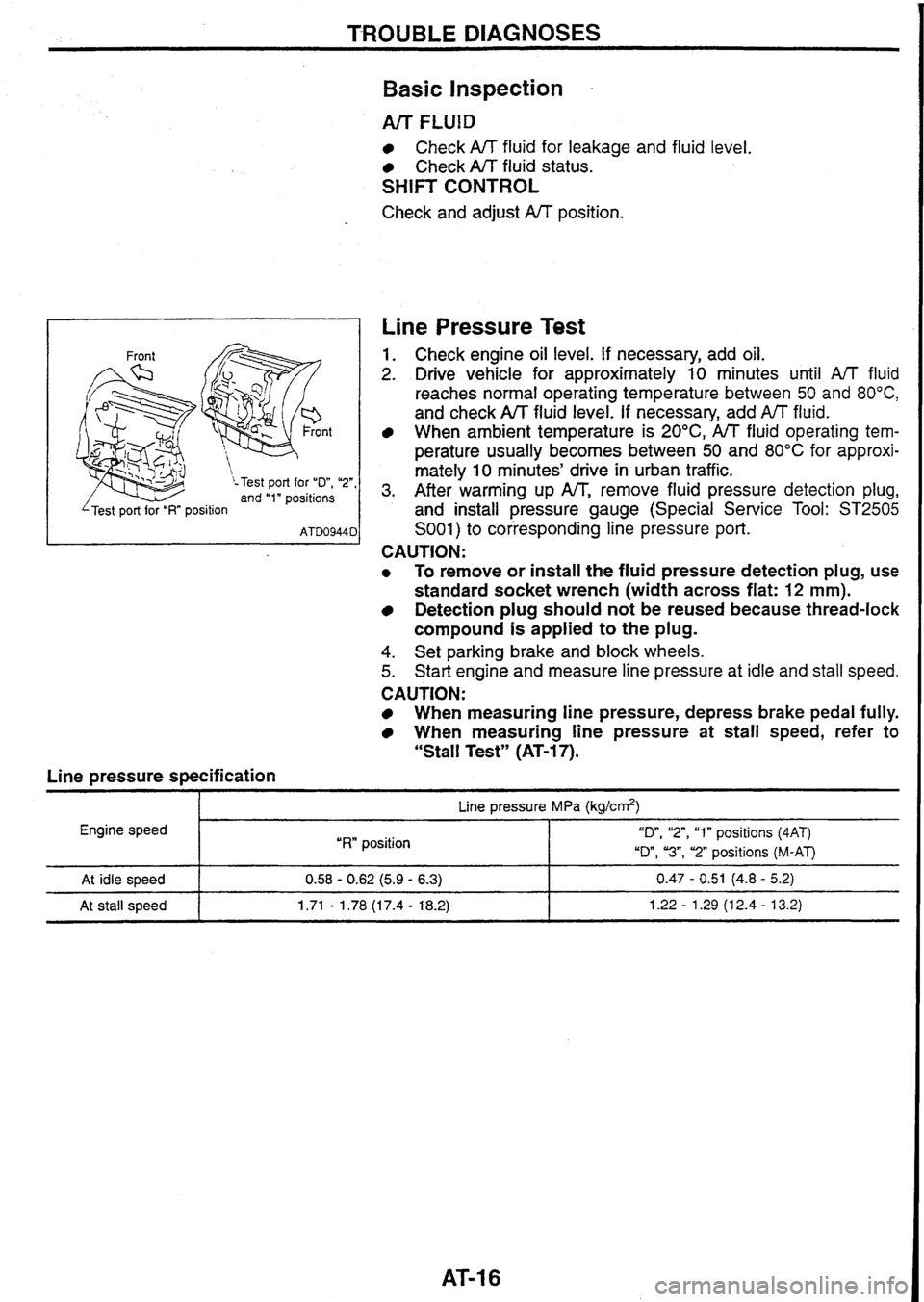

n t

\-Test port for "D", "2", and "1" positions

I 'Test port for "I?" position I

Line pressure specification

Basic Inspection

Arr FLUlD

Check A/T fluid for leakage and fluid level.

Check A/T fluid status.

SHIFT CONTROL

Check and adjust A/T position.

Line Pressure Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add fluid.

When

ambient temperature is 20°C, A/T fluid operating tem-

perature

usually becomes between 50 and 80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. After warming up IW', remove fluid pressure detection plug,

and install pressure gauge (Special Service Tool:

ST2505

S001) to corresponding line pressure port.

CAUTION:

0 To remove or install the fluid pressure detection plug, use

standard socket wrench (width across flat:

12 mm).

Detection plug should not be reused because thread-lock

compound is applied

to the plug.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed.

CAUTION:

When measuring line pressure, depress brake pedal fully.

When measuring line pressure at stall speed, refer to

"Stall Test" (AT-17).

I p- Line pressure MPa (kg/crn2)

Engine speed

I "RW position "On, 'Z", "1" positions (4AT)

"Dm,

"3", "2" positions (M-AT)

At idle speed

At stall speed 0.58 - 0.62 (5.9 - 6.3) 0.47 - 0.51 (4.8 - 5.2)

1.71

- 1.78 (1 7.4 - 18.2) 1.22 - 1.29 (1 2.4 - 13.2)

Page 69 of 230

TROUBLE DIAGNOSES

Line Pressure Test (Cont'd)

JUDGEMENT OF LINE PRESSURE TEST

At idle

speed

At stall

speed Judgement

Line pressure is low in all

positions.

Line pressure is low in par-

ticular position.

Line pressure is

high.

Line pressure increase is

poorer than that measured at

idle speed.

Line pressure increases but

does not reach specification.

Line pressure is low in par-

ticular position. Possible

causes

Pressure supply system malfunction or low oil pump output

Examples:

0 Oil pump wear

Control piston damage

Pressure regulator valve or plug sticking, and weak spring

Fluid pressure leakage between oil strainer and pressure regulator valve through oil Eg

Pump

Low idle speed

After line pressure is supplied from manual valve, fluid pressure may leak between devices

or circuits of corresponding position.

1

Malfunctions of sensors or pressure regulation function. El

Examples:

Misadjustment of throttle position sensor

PJT fluid temperature sensor damaged ST

Poor operation of line pressure solenoid (stuck with OFF status, clogged filter, or open

harness)

Pressure modifier valve sticking F%

Pressure regulator valve or plug sticking

Malfunctions of sensors or pressure regulation function

Examples:

EILA

Misadjustment of throttle position sensor

TCM, ECM.TCM damaged la

Poor operation of line pressure solenoid (stuck or shorted with ON status)

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

sf$

Pilot valve sticking and pilot filter clogged

Malfunctions of pressure supply system, sensors, or pressure regulation function

Examples:

Misadjustment of throttle position sensor

Control piston damage

Poor operation of line pressure solenoid, and filter sticking or clogged

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

Pilot valve sticking and pilot filter clogged

After line pressure is supplied from manual valve, fluid pressure

may leak between devices

or circuits of corresponding position.

Stall Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add AfT fluid.

When ambient temperature is

20°C,

A/T fluid operating tem-

perature usually becomes between 50 and

80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. Set parking brake and block wheels.

4. Statt engine, depress brake pedal, and move selector lever to

"D" position.

Page 76 of 230

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

\ I1 // \ 11 // =-I= or =mj= // 11 \ // 11 \

1, = 2.5 sec. t, = 2.0 sec. t, = 1.0 sec.

RB20DE 10 judgement flashes.

Stan signal Malfunctioning unit and circuit I

Except RBPODE 13 judgement flashes.

signal Malfunctioning unit and circuit I

POWER INDICATOR LAMP OR DUAL MATIC A/T

WARNING LAMP INDICATION

If malfunction occurs in electrical system, indicator lamp stays on

longer at corresponding circuit.

Flashing

order

t5 1 Overrun clutch solenoid

1

2

3

4

5

7 1 Lock-up solenoid

Malfunctioning

unit and circuit

Vehicle speed sensor

1

Vehicle speed sensor 2

Throttle position sensor

Shift solenoid

A

Shift solenoid B

I

W fluid temperature sensor, TCM power supply, or throttle posi-

tion sensor power supply

RB20DE

9 1 Engine speed

signal Except

RB20DE

10 1 Line

pressure solenoid I Turbine sensor

I - I Line pressure solenoid

12 1 - I Total control signal

When indicator lamp repeats flashing in 4 Hz, the following malfunctions

may exist: (Insufficient memory backup

powerflCM repiacement1Battery

has been disconnected for prolonged

periodllow battery power)

13

No flashes

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

To facilitate cause investigation of malfunction that is less likely to

reappear, the TCM always stores self-diagnostic results during cus-

tomer operation. This memory cannot be erased even if ignition

switch

is turned ON and OFF repeatedly. To erase the seif-diag-

nostic

results, turn ignition switch

OFF after self-diagnosis has

been performed, or use

"ERASE" function of CONSULT.

- - - - Shift control unit

PNP switch, idle

switch/full switch

Overdrive control switch Stop lamp switch

Page 105 of 230

TCSlABS SYSTEM

Precautions for Trouble

Diagnosis

After performing trouble diagnosis, be sure to erase trouble stored in memory.

Refer to "CONSULT for

TCS/ABS Control Unit Control System"

(BR-27), "Self-diagnosis for TCSIABS

Control Unit Control System"

(BR-34), "CONSULT for Throttle Control Unit Control System" (BR-37) or

"Self-diagnosis for Throttle Control Unit Control System"

(BR-41).

The concerns that are difficult to duplicate may be caused by faulty electrical connections. Move harnesses

or harness connectors by hand to check if there is any poor mating of connector halves or faulty connec-

tion. Do not force to open a connector terminal when using a circuit tester for inspection.

Read GI section thoroughly in advance and make sure of all the general precautions.

Basic Inspection

BASIC INSPECTION 1 - Brake fluid level and leakage

1. Check brake fluid level in reservoir tank. Replenish brake fluid if necessary.

2. Check for leakage at or around brake piping and ABS actuator. If leakage or seepage is noted, proceed

as follows:

If ABS actuator connectors are loose, tighten to specified torque. Recheck to ensure that leakage is no

longer present.

If flare nut threads at piping connectors or actuator threads are damaged, replace faulty parts with new

ones. Recheck to ensure that leakage is no longer present.

If brake fluid leaks through areas other than actuator connectors, wipe off using a clean cloth. Recheck

for leakage or seepage. If necessary, replace faulty parts with new ones.

If brake fluid leaks at or seeps through ABS actuator, wipe off using a clean cloth.

Recheck for leakage or seepage. If necessary, replace ABS actuator with new one.

CAUTION:

ABS actuator cannot be disassembled. Do not attempt to disassemble it.

3. Check brake disc rotors and pads for proper operation.

BASIC INSPECTION 2 - Loose power line terminal

Check battery terminals (positive and negative) and battery mounting (ground) for looseness. If necessary,

tighten to specified torque. Check the battery for lower voltage.

BASIC INSPECTION 3 - SLlP indicator lamp, TCS OFF indicator lamp and ABS warning

lamp

Turn ignition switch "ON" to ensure that TCS OFF indicator lamp lights up. If TCS OFF indicator lamp does

not light, check TCS OFF indicator lamp circuit.

Turn ignition switch

"ON" to ensure that SLlP indicator lamp lights

up. If SLlP indicator lamp does not light,

check SLlP indicator lamp circuit.

Turn ignition switch "ON" to ensure that ABS warning lamp lights up. If ABS warning lamp does not light,

check ABS warning lamp circuit.

Check that the SLlP indicator lamp and the ABS warning lamp go off approx.

1 second after the engine

has started. If either of the lamps still remains on, perform the self-diagnosis for TCSIABS control unit

control system and the self-diagnosis for throttle control unit control system.

After driving vehicle at approx. 30

km/h

for approx.

1 minute, check to ensure that the SLlP indicator lamp

and the ABS warning lamp are off. If either of the lamps still remains on, perform the self-diagnosis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

Check that the TCS OFF indicator lamp turns ON and OFF when the TCS OFF switch is turned to

ON

and OFF respectively, with the engine running. If the lamp status does not correspond to the switch

position, check the TCS OFF switch circuit.

Check that the TCS OFF indicator lamp goes off when the engine has started with the TCS OFF switch

OFF. If the TCS

OFF indicator lamp does not go off even 10 seconds after the engine has started, per-

form the self-diagnosis for TCSIABS control unit control system and the self-diagnosis for throttle control

unit control system.

After driving vehicle at approx.

30 kmlh for approx. 1 minute with the TCS OFF switch OFF, check to ensure

that the TCS OFF indicator lamp is off. If the TCS OFF indicator lamp lights up, perform the

self-diagno-

sis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

After performing self-diagnosis procedures, be sure to erase trouble stored in memory.

Page 110 of 230

![NISSAN GT-R 1998 Service Manual

TCS/ABS SYSTEM

CONSULT

for TCSfABS Control Unit Control

System (Contd)

DATA MONITOR MODE --

I ~elect-monitor item I

Display

signals Selection from

Remarks

menu

FR RH SEN

[kmlh] Disp NISSAN GT-R 1998 Service Manual

TCS/ABS SYSTEM

CONSULT

for TCSfABS Control Unit Control

System (Contd)

DATA MONITOR MODE --

I ~elect-monitor item I

Display

signals Selection from

Remarks

menu

FR RH SEN

[kmlh] Disp](/img/5/57354/w960_57354-109.png)

TCS/ABS SYSTEM

CONSULT

for TCSfABS Control Unit Control

System (Cont'd)

DATA MONITOR MODE --

I ~elect-monitor item I

Display

signals Selection from

Remarks

menu

FR RH SEN

[kmlh] Displays vehicle speed computed based on

front right wheel sensor signal.

zc

FR LH SEN [kmlh] Displays

vehicle speed computed based on

front left wheel sensor signal.

AT

Displays vehicle speed computed based on

rear right wheel sensor signal.

Displays vehicle speed computed based on

rear left wheel sensor signal.

REAR

SEN

[kmlhll

RR LH SEN

lkmlhll

FIR IN SOL [ON-OFF]

I O

FIR OUT SOL [ON-OFF] /

lndicates operating condition (ONIOFF) for 87 front right inlet solenoid.

lndicates operating condition (ONIOFF) for

front right outlet solenoid.

Rs

FIL IN SOL O

A FIL OUT SOL [ON-OFF] /

lndicates operating condition (ONIOFF) for

front left inlet solenoid.

y- 13 u -:-.!

Indicates operating condition (ONIOFF) for

1 front left outlet solenoid. --

REAR IN SOL [ON-OFq / A I Indicates operating condition (ONIOFF) for

" I rear inlet solenoid.

RR OUT SOL [ON-OFF]

/

ABS ACTUATOR [ON-OFF]

- - .

O

O

0

0

ABS MOTOR [ON-OFFI I - I 0

-

lndicates operating condition (ONIOFF) for SC rear outlet solenoid.

lndicates ABS actuator relay status

(ON1

OFF). Indicates

ABS motor relay status

(ONIOFF).

Indicates stop lamp switch status

(ONIOFF).

STOP LAMP SW

[ON-OFFl

I 0 I 0

ENG SPEED SIG [RUNISTOP] I 0 I 0 0 I lndicates engine operation.

WARNING LAMP

[ON-OFF]

I - I 0 0 I lndicates ABS warning lamp status.

BATTERY VOLT

iv I

I lidicates the voltage supplied to the TCSI n

THRTL OPENING 1x1 1 0 I 0

V

0

THL OP TARGET [%I I - 1 0

ABS control unit.

Indicates throttle angle condition.

- - -

lndcates throttle control unit target angle. 0-1- -- - -- - -

lndicates the value at which fuel to ECM is

cut off.

lndicates the gear position.

lndicates TCS switch status (ONIOFF).

TCS

MODE

GEAR

1016-

0 I lndicates TCS OFF indicator lamp status.

TCS

SW [ON-OFF]*

TCS OFF LAMP [ON-OFF]

SLIP

LAMP [ON-OFF]

0 I lndicates SLlP indicator lamp status.

I I

*: The TCS switch only indicates that the switch is ON or OFF. It does not necessarily correspond to the TCS operation condi-

tion (TCS OFF indicator lamp OFF or ON).

-

0

-

-

lndicates the selector position (ONIOFF)

based on the

A/T PNP switch signal or the

neutral position switch signal.

-

0

0

0

PIN POSl SIG

[ON-OFFI

I