oil level NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 40 of 230

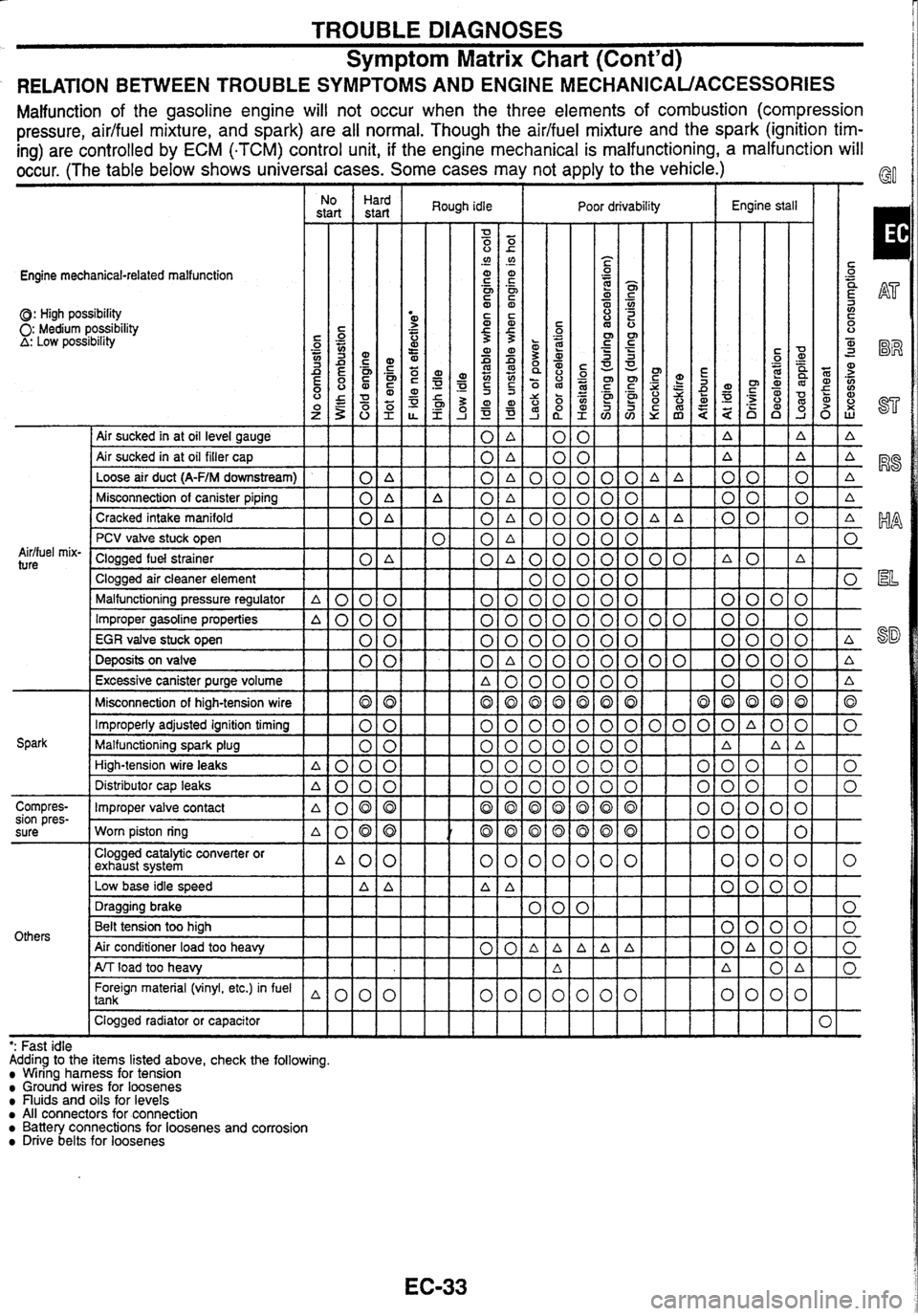

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

RELATION BETWEEN TROUBLE SYMPTOMS AND ENGINE MECHANICAUACCESSORIES

Malfunction of the gasoline engine will not occur when the three elements of combustion (compression

pressure, aidfuel mixture, and spark) are all normal. Though the

aidfuel mixture and the spark (ignition tim-

ing) are controlled by ECM

(.TCM) control unit, if the engine mechanical is malfunctioning,

a malfunction will

occur. (The table below shows universal cases. Some cases may not apply to the vehicle.)

Engine mechanical-related malfunction

0: High possibility 0: Medium possibility A: Low posstbility

I No I Hard

start start

I Air sucked in at oil level gauge

Air sucked in at oil filler cap

Loose air duct

(A-F/M downstream) 0 A

Misconnection of canister piping

0 A

Cracked intake manifold

0 A

Aidfuel

mix-

ture

PCV valve stuck open

Clogged fuel strainer

0 A

Clogged air cleaner element

Malfunctioning pressure regulator

A 0 0 0

Improper gasoline properties A000

EGR valve stuck open 0 0

Deposits on valve 0 0

Excessive canister purge volume

Misconnection of high-tension wire

Improperly adjusted ignition timing

Malfunctioning spark plug

High-tension wire leaks

A000

Spark Distributor cap leaks

A000

Compres-

Improper valve contact

sion pres-

. a080

sure Worn piston ring ~080

Others

Clogged catalytic converter or

exhaust system A00

Low base idle speed A

A

Foreign material (vinyl, etc.) in fuel 1 tank

Clogged radiator or capacitor

IIII

Rough idle I Poor drivability Engine stall

- - - - - - -- ': Fast

idle

Adding to the items listed above, check the following.

Wiring harness for tension Ground wires for loosenes nuids and oils for levels All connectors for connection Battery connections for loosenes and corrosion Drive belts for loosenes

Page 41 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Engine mechanical-related malfunction I Symptom characteristics and inspection hints

Airffuel

ratio becomes lean.

Air sucked in at oil filler cap

Aidfuel ratio compensation factor becomes higher.

a Intake manifold induction vacuum becomes lower.

I Cracked intake manifold I

Misconnection of canister piping Use an induction vacuum (pressure) gauge for check.

' Common to all air sucking conditions from air intake system.

-

PCV valve stuck open

I Malfunctioning pressure regulator I Various symptoms occur depending on the fuel pressure.

Abnormal noise (peep) may

be heard.

Air/fuel

mixture

Improper gasoline properties Various

symptoms occur depending on the properties.

IEGRiale

stuck open

I

Clogged fuel strainer .

Clogged air cleaner element

Deposits on valve

r

Symptoms vary with the condition how they are clogged. However, the

symptoms tend to occur when the vehicle is driving at high speed and

under high load.

I

Air/fuel ratio becomes lean. Airfluel ratio compensation factor becomes

higher.

Excessive canister purge volume

I

Engine may stall when the accelerator pedal is lightly pressed. (Especially

in summertime.)

Misconnection of high-tension wire Check if the ignition timing

is correct. 1 Improperly adjusted ignition timing 1

Malfunctioning spark plug 1

Corn- I Improper valve contact I Symptoms vary with the degree of contact and the number of cylinders. '

High-tension wire leaks

Distributor

cap leaks Symptoms

vary with the degree of leaks.

Clogged catalytic converter or exhaust sys-

l tem , In many cases, engine stalls and then restarts after a while. I

pression I

Low base idle speed

pressure

Worn piston ring I

Engine may

stall while the vehicle is decelerating or when the power '

steering load or electrical load is applied.

Symptoms vary

with the degree of wear and the number of cylinders.

I

Air conditioner load too heavy I Too much refrigerant in the system. j

Others Dragging

brake

Belt tension too high

1

I Clogged radiator or capacitor I

ArJ load too heavy

Foreign material (vinyl, etc.) in fuel tank Insufficient A/T fluid (FR model)

Symptom tends to occur when fuel level in the tank becomes lower.

Page 68 of 230

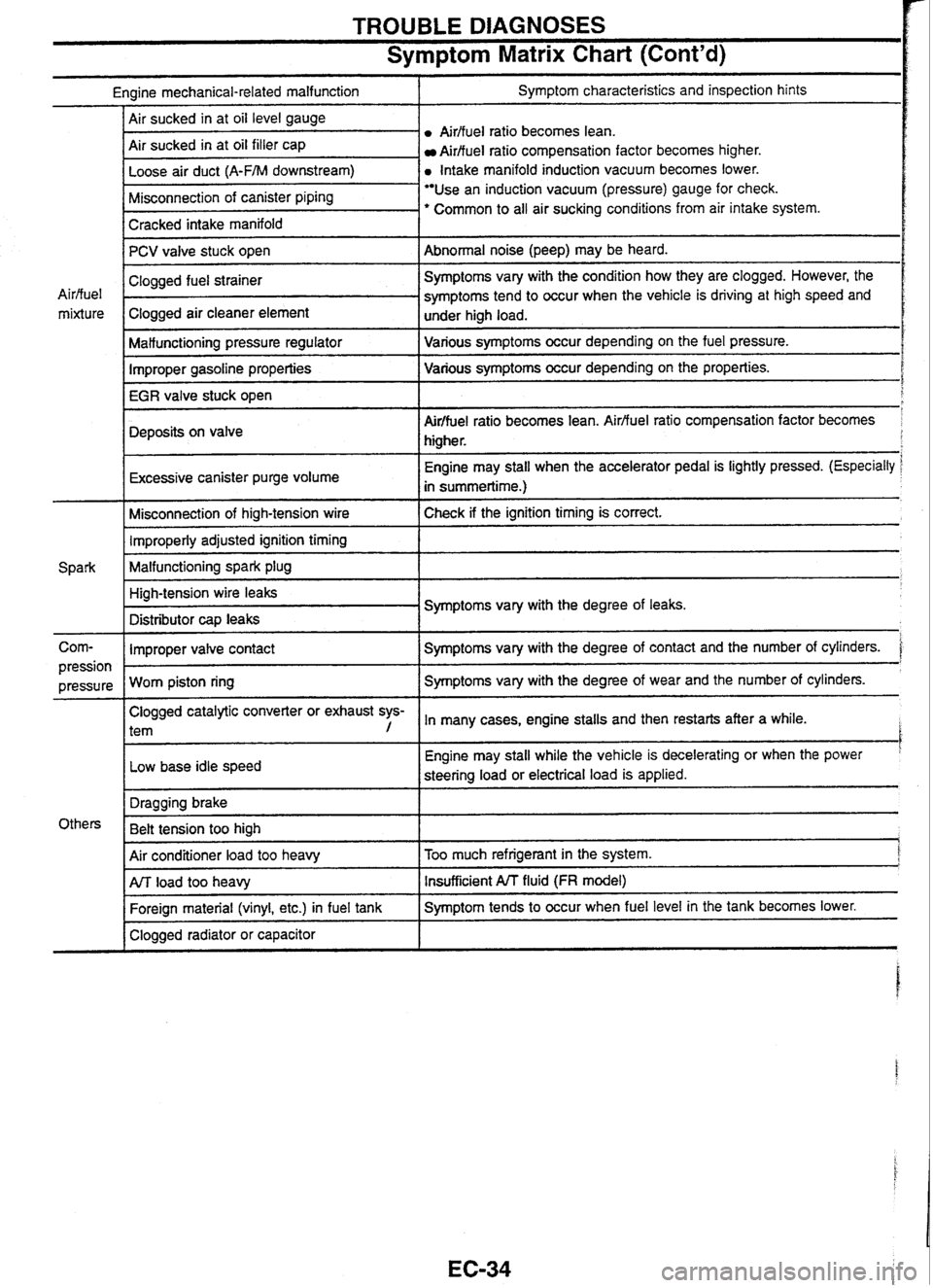

TROUBLE DIAGNOSES

n t

\-Test port for "D", "2", and "1" positions

I 'Test port for "I?" position I

Line pressure specification

Basic Inspection

Arr FLUlD

Check A/T fluid for leakage and fluid level.

Check A/T fluid status.

SHIFT CONTROL

Check and adjust A/T position.

Line Pressure Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add fluid.

When

ambient temperature is 20°C, A/T fluid operating tem-

perature

usually becomes between 50 and 80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. After warming up IW', remove fluid pressure detection plug,

and install pressure gauge (Special Service Tool:

ST2505

S001) to corresponding line pressure port.

CAUTION:

0 To remove or install the fluid pressure detection plug, use

standard socket wrench (width across flat:

12 mm).

Detection plug should not be reused because thread-lock

compound is applied

to the plug.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed.

CAUTION:

When measuring line pressure, depress brake pedal fully.

When measuring line pressure at stall speed, refer to

"Stall Test" (AT-17).

I p- Line pressure MPa (kg/crn2)

Engine speed

I "RW position "On, 'Z", "1" positions (4AT)

"Dm,

"3", "2" positions (M-AT)

At idle speed

At stall speed 0.58 - 0.62 (5.9 - 6.3) 0.47 - 0.51 (4.8 - 5.2)

1.71

- 1.78 (1 7.4 - 18.2) 1.22 - 1.29 (1 2.4 - 13.2)

Page 69 of 230

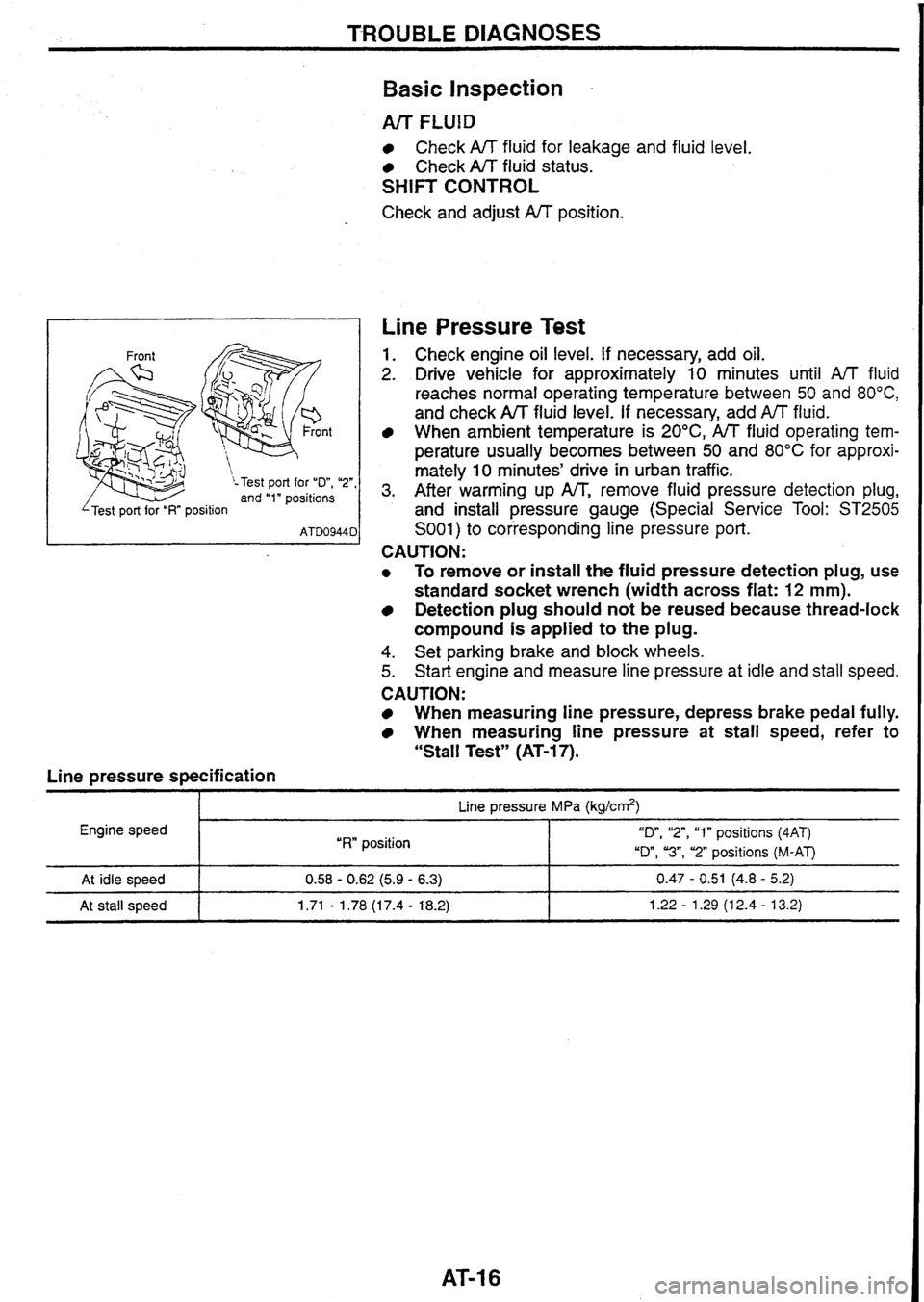

TROUBLE DIAGNOSES

Line Pressure Test (Cont'd)

JUDGEMENT OF LINE PRESSURE TEST

At idle

speed

At stall

speed Judgement

Line pressure is low in all

positions.

Line pressure is low in par-

ticular position.

Line pressure is

high.

Line pressure increase is

poorer than that measured at

idle speed.

Line pressure increases but

does not reach specification.

Line pressure is low in par-

ticular position. Possible

causes

Pressure supply system malfunction or low oil pump output

Examples:

0 Oil pump wear

Control piston damage

Pressure regulator valve or plug sticking, and weak spring

Fluid pressure leakage between oil strainer and pressure regulator valve through oil Eg

Pump

Low idle speed

After line pressure is supplied from manual valve, fluid pressure may leak between devices

or circuits of corresponding position.

1

Malfunctions of sensors or pressure regulation function. El

Examples:

Misadjustment of throttle position sensor

PJT fluid temperature sensor damaged ST

Poor operation of line pressure solenoid (stuck with OFF status, clogged filter, or open

harness)

Pressure modifier valve sticking F%

Pressure regulator valve or plug sticking

Malfunctions of sensors or pressure regulation function

Examples:

EILA

Misadjustment of throttle position sensor

TCM, ECM.TCM damaged la

Poor operation of line pressure solenoid (stuck or shorted with ON status)

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

sf$

Pilot valve sticking and pilot filter clogged

Malfunctions of pressure supply system, sensors, or pressure regulation function

Examples:

Misadjustment of throttle position sensor

Control piston damage

Poor operation of line pressure solenoid, and filter sticking or clogged

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

Pilot valve sticking and pilot filter clogged

After line pressure is supplied from manual valve, fluid pressure

may leak between devices

or circuits of corresponding position.

Stall Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add AfT fluid.

When ambient temperature is

20°C,

A/T fluid operating tem-

perature usually becomes between 50 and

80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. Set parking brake and block wheels.

4. Statt engine, depress brake pedal, and move selector lever to

"D" position.

Page 77 of 230

TROUBLE DIAGNOSES

Symptom Chart

Sharp shock in Engine brake

applied

Shifting

Malfunctions

Slip

(Racing)

hifting

.- erator pedal

Shifting

Shifting

inspection item

Fluid level and status

Control linkage

PNP switch (short/open circuit)

Throttle ~osition sensor (installed)

I Vehicle weed sensor

I Enaine meed sensor

A/T fluid temperature sensor

Engine idle speed

Line

Dressure

Control valve assembly

Shift solenoid

A

Shift solenoid B

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

Accumulator N-D

Accumulator

1-2

Accumulator 2-3

Accumulator 3-4 (N-R) Ignition coil and starter motor

Overdrive control switch

I AfT mode switch (AUTO)

Torque converter

1 Oil pump

I Reverse clutch

I High clutch

I Forward clutch

I Forward one-wav clutch

I Overrun ciutch

1 Low one-wav clutch

I Low reverse brake

Brake. band (including servo)

Parking linkage

Page 78 of 230

Symptom Chart (Cont'd)

Greater noise

Malfunctions

Inspection item No shifting

I Shifting I

Fluid level

and status 11

Control linkage

-

(I) C 0 .- c. .- (I) 0 a

v

-CU

n - 1

PNP switch

(shortlopen

circuit)

Throttle position sensor (installed)

2 2

Vehicle speed sensor

I Engine speed sensor -

-T

L o 1 Control valve assembly .- - -- Shift solenoid A 4 3

. ' Shift solenoid 6 4 cut I1

--, Line pressure solenoid .- 5 -t Lock-up solenoid ?

6 Overrun clutch solenoid 3

Accumulator N-D

1 Accumulator 1-2 I 1-

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition coil and starter motor

I Overdrive control switch I 1-

A/T mode switch (AUTO)

A/T mode switch (POWER) I - I Ail mode switch (SNOW) I

I Torque converter I I

1 Oil pump I I -- - - Reverse clutch 0 -

'g High clutch a 4 6

%I Forward clutch I I - .- a Forward one-way clutch -

$ Overrun clutch a, 8

Low one-way clutch

O Low reverse brake 7

Brake band (including servo) 7

Parking linkage

Page 79 of 230

TROUBLE DIAGNOSES

Symptom Chart (Cont'd)

xi - - ([I C V) a, C .- cn C W

t 0 .- .L 2 a, - 8 0 ([I L 0 0 Q

& 0 a, a, Q V)

5 E .- X

i! L a

zl -I - 1 -

- 2 -

-

-

-

-

-

5 - 3 - 4 -

-

-

-

-

-

-

-

-

-

-

-

-

I1 - 0 - 6 - 7 -

-

-

-

-

9 - 8 -

-

vj c 0 .- - .- V) 0 n

Q 7J C ([I

t C .- r ([I c. V) c. 0 C V) a 0 7J 0, C .- 0 C W -

- 2 - 3 -

-

- -

-

1 -

-

-

-

- - a +- ([I a a, 2 0 c. 0 C V) a, 0 u a, - 0 2

8 - 1 -

-

-

-

-

-

-

-

2 - 3 -

-

-

-

-

-

-

-

-

-

-

- I

i

g

- 4 -

-

-

-

-

-

-

B- ; 2 to a =? - 0,

2 5.j c 2.z 2 a0 - 0- z & 5 0 gE V) V)o C 02 .s nu 5 ng %-([I C O c --t .- V) a V) r aa ([I z gz a, a- c 50 -6 s

6 $2

11

2

I

I

Malfunctions

Inspection item

I I I Fluid level and status I I Control linkage 2

PNP switch (shortfopen circuit) 1 I I I Throttle position sensor (installed) 111213

Vehicle speed sensor

214

Engine speed sensor L -

AIT fluid temperature sensor

Engine idle weed

Line pressure

Control valve assembly

Shift solenoid A 3

3

Shift solenoid B 4 4

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

u I I I -

Accumulator N-D I I 1 I Accumulator 1-2

Accumulator 2-3 I Accumulator 3-4 (N-R)

Ignition coil and starter motor

Overdrive control switch

Torque converter

tg Reverse clutch .- High clutch

2 Forward clutch C .- a Forward one-way clutch -.

$ Overrun clutch 0, 8

? Low one-way clutch 3= O Low reverse brake 9

Brake band (including servo)

Parking linkage

Page 202 of 230

![NISSAN GT-R 1998 Service Manual

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electr NISSAN GT-R 1998 Service Manual

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electr](/img/5/57354/w960_57354-201.png)

ENGINE MECHANICAL I RB~ODE (UB) ]

STANDARD AND REPAIR LIMIT

Firing order I 1-5-3-6-2-4

Compression pressure

MPa

(kg/cm2)/rpm

Distortion limit mm

- - -- --- - Ignition advance device

Electronically-controlled ignition advance

Engine

oil capacity

e

Spark plug standard

Limit

. Limit

of variation between cylinders

Intake manifold

Intake manifold collector

Exhaust manifold

Cylinder head

Cvlinder block

lgnition timing (during no feed back control) 1.23

(1 2%)/300

0.93 (9.5)1300

0.1 (1.0)/300

0.1 0.1

0.3

0.2

0.1

Without filter

With filter

MakerlTypeISpark

plug gap mm

Engine idling speed

W'

Idle base speed (during no feed back control)

rPm

Density of

COIHC at idling speed

Wppm Approx.

3.8

Approx. 4.2

NG WPFR5G-11 11.0

- 1

-1

650-.50

(N or P position for

A/T)

600 (N or P position for AlT)

Less than O.l/Less than 50

I New I Used I Limit

Valve

clearance

(INTIEXH)

mm

Deflection

amount of accessory V-belt

Measured with tension gauge

N (kg) Hot

engine

.

Cold engine (at ambient temperature)

Measured by pushing at 98 N (10 kg)

mm 0.36+0.062/0.53+0.062

0.31 1~,0.04/0.50i0.04

Fuel tank capacity

e

Engine coolant total capacity [with reservoir tank (max. level)] e

Thermostat opening temperature [start to open - full open]

"C

Radiator cap opening pressure

MPa (kg/cm2) Approx.

65

Approx. 9.4 82 - 95

0.06

- 0.1 0 (0.6 - 1 .O)

A/C compressor belt

Power

steering pump belt

Fan belt

Power steering pump belt

1 8-10 1 10-12 1 16

667

- 755

(68

- 77)

A/C compressor belt 1 6-8 1 7-9 / 12

Fan belt

1 3-5 1 4-6 1 7.5

559 - 637

(57

- 65)

SEC.117 Power steering

Fan belt pump be1 t

284 (29)

Page 204 of 230

ENGINE MECHANICAL

STANDARD AND REPAIR LIMIT

Firing order

Compression pressure

MPa (kg/cm2)/rpm

-

Intake manifold

Intake manifold collector

--- - Standard Limit

Limit of variation between

cylinders

0.1

0.1

Distortion limit mm

Engine oil capacity

P

Spark plug

Deflection amount of accessory

V-belt Power steering pump

belt

I

- -- - - 1.26 (1 2.8)/300

0.96 (9.8)/300

0.1

(1 .OY300

Measured with tension gauge Exhaust

manifold

Cylinder head

Cylinder block

Without filter

With filter

MakerKype/Spark

plug gap

mrn

I "

650.-50 (N or P position for CVT)

600 (N or P position for AIT)

Less than O.l/Less than 50

15U600

0.36~0.06210.53~0.062

0.31 -.0.04/0.50~0.04

Approx. 65

Approx. 9.4

82 - 95

0.06 - 0.10 (0.6 - 1 .O)

"

Engine idling speed rpm

Idle base speed (during no feed back control)

rpm

Density of

COIHC at idling speed

%/ppm

Ignition timing (during no feed back control)

BTDCO/rpm

I NC compressor err

0.3

0.2

0.1

Approx. 3.8

Approx. 4.2

NGWPFR5G-11/1.0

- 1.1

lanition

advance device

1

Valve clearance (INTIEXH) mm

(kg)

/ Fan belt Electronicallv-controlled

ianition

advance

Hot engine

Cold engine (at ambient temperature)

I power steerina DU~D belt 1 8-10

Fuel tank capacity

Q

Engine

coolant total capacity [with reservoir tank (max. level)] e

Thermostat opening temperature [start to open - full open] OC

Radiator cap opening pressure

MPa (kg/crn2)

,

I Fan belt 1 3-5

Measured

by pushing at 98

N (10 kg)

mm

I SEC.! I7 Power steering I

*I I 1

AK compressor belt 1 6-8

Fan belt pump beit

Used 1 Limit

Page 206 of 230

ENGINE MECHANICAL

STANDARD AND REPAIR LIMIT

Distortion limit mm

- - Intake manifold

Intake manifold collector

1 -5-3-6-2-4

1.20 (1

2.2)/300

0.90 (9.2)/300

0.1 (1.0)/300

Firing order

-- - 0.1

0.1

- -- - ( Cylinder block 0.1

Compression

pressure

MPa

(kg/cm2)/rpm

Exhaust manifold

Cvlinder head

Engine oil capacity Standard

Limit

-

Limit of variation between cylinders

0.3

0.2

- - -- - Spark plug I ~akerfl~~e/~~ark plug gap mm r NGKPFRGG-11/1.0 - 1.1

Without

filter

'with

filter

ignition advance device

I Electronically-controlled ignition advance

Approx.

3.9

Aoorox.

4.3

Engine idling speed

rPm

Idle

base speed (during no feed back control)

Pm

650-e50

(N or P position for

A/T)

600 (N or P position for AQ

Density of COIHC at idling speed

Wppm

Ignition timing (during no feed back control)

BTDCO/rpm Less

thanbl~ess than 50

15dY600

Valve clearance

(INT/EXH) mm

Deflection amount of accessory V-belt Hot

engine

Cold engine (at ambient temperature)

Measured

with tension gauge

(kg)

I

SEC.117 Power steering

Fan belt pump belt

0.36+0.062/0.53i0.062

0.3

1 20 .04/0.50a0.04

Fuel tank capacity

4

Engine coolant total capacity [with reservoir tank (max. level)] t

Thermostat opening temperature [start to open - full open]

OC

Radiator cap opening pressure

MPa (kg/cm2)

Power steering pump belt

Measured by pushing at 98

N (1 0 kg)

mm Approx.

65

Approx. 9.4

82

- 95

0.06

- 0.1 0 (0.6 - 1 .O)

New 1 Used 1 Limit

AfC

compressor belt

Fan belt

,

667 - 755

(68

- 77)

Power steering pump belt

' AfC compressor belt

Fan belt

559 - 637 284 (29)

(57 - 65)

667

- 755

(68

- 77)

667

- 755

(68

- 77)

559 - 637 284 (29)

(57 - 65)

559 - 637 284 (29) (57 - 65)

8-

10

6-8

3 - 5

- 10 - 12 16

7-9 12

4

- 6 7.5