relay NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 9 of 230

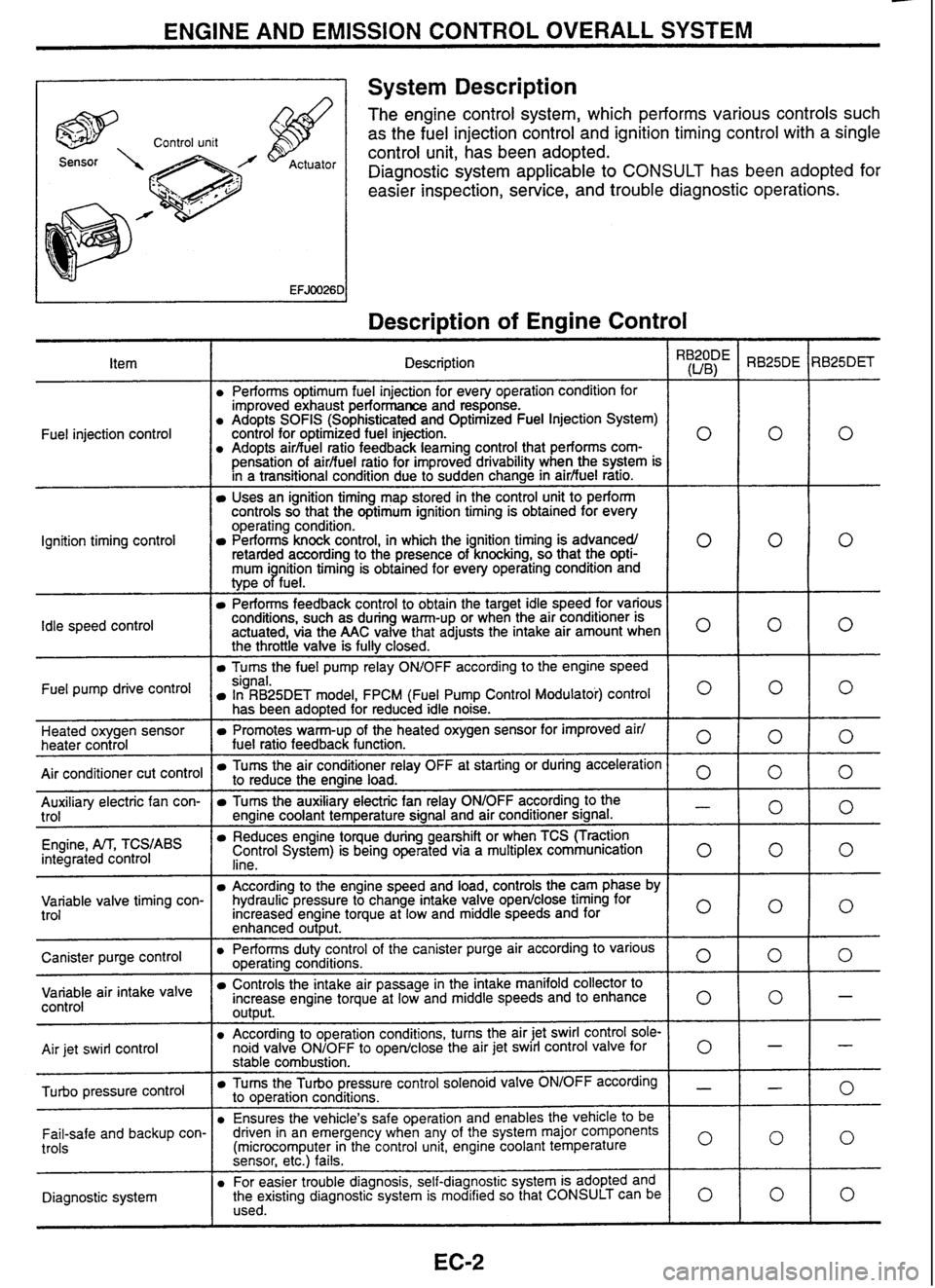

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

A 1 System Description

The engine control system, which performs various controls such

as the fuel injection control and ignition timing control with a single

control unit, has been adopted.

Diagnostic system applicable to

CONSULT has been adopted for

easier inspection, service, and trouble diagnostic operations.

Description of Engine Control

I

Description \,

Performs optimum fuel injection for every operation condition for

improved exhaust performance and response.

Adopts

SOFlS (Sophisticated and Optimized Fuel Injection System)

control for optimized fuel injection.

Adopts

airbuel ratio feedback

learning control that performs

com-

0

pensation of airfiuel ratio for improved drivability when the system is

in a transitional condiiion due to sudden change in

airfiuel ratro.

Uses an ignition timing map stored in the control unit to perform

controls so that the optimum ignition timing is obtained for every

operating condition.

Performs knock control, in which the ignition timing is advancedl

retarded according to the presence of knocking, so that the

opti- 0

mum i nition timing is obtained for every operating condition and

type

oPfue1.

Performs feedback control to obtain the target idle speed for various

conditions, such as during warm-up or when the air conditioner is

actuated, via the

AAC valve that adjusts the intake air amount when

O

the throttle valve is fully closed.

Turns the fuel pump relay OWOFF according to the engine speed

Fuel

injection control

Ignition timing control

Idle

speed

control

Fuel pump drive signal. In RB25DET model, FPCM (Fuel Pump Control Modulatoi) control O

has been adopted for reduced idle noise.

Heated oxygen sensor

heater control

Air conditioner cut control

Promotes warm-up of the heated oxygen sensor for improved air1

fuel ratio feedback function. 0

Tums the air conditioner relay OFF at starting or during acceleration to reduce the engine load. 0 -- Auxiliary electric fan con-

trol

Engine,

M, TCS,ABS integrated control

Tums the auxiliary electric fan relay ONIOFF according to the - engine coolant temperature signal and air conditioner signal.

Reduces engine toque during gearshift or when TCS (Traction

Control System) is being operated via a multiplex communication

lino 0

- -

Variable valve timing con-

trol According to the engine speed and load, controls the cam phase by

hydraulic pressure to change intake valve

open/close timing for

Increased engine torque at low and middle speeds and for

enhanced

out~ut.

I o I

Canister purge control air

intake valve control

Air

jet swirl control Performs duty

control of the canister purge air according to various ooeratina conditions.

0 -r-~ e-- ---

-

Controls the intake air passage in the intake manifold collector to

increase engine torque at low and middle speeds and to enhance

output. 0

According to operation conditions, turns the air jet swirl control sole-

noid valve ONIOFF to openlclose the air jet swirl control valve

for 0

pressure control

stable combustion.

Tums the Turbo pressure control solenoid valve ONIOFF according - to operation conditions.

Ensures the vehicle's safe operation and enables the vehicle

to be

Fail-safe and backup con-

trols

Diagnostic system driven

in an emergency when any of the system major components

(microcomputer in the control unit, engine coolant temperature

0

sensor, etc.) fails.

For easier trouble diagnosis, self-diagnostic system is adopted and

the existing diagnostic system is modified so that CONSULT can be

0 used.

Page 13 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

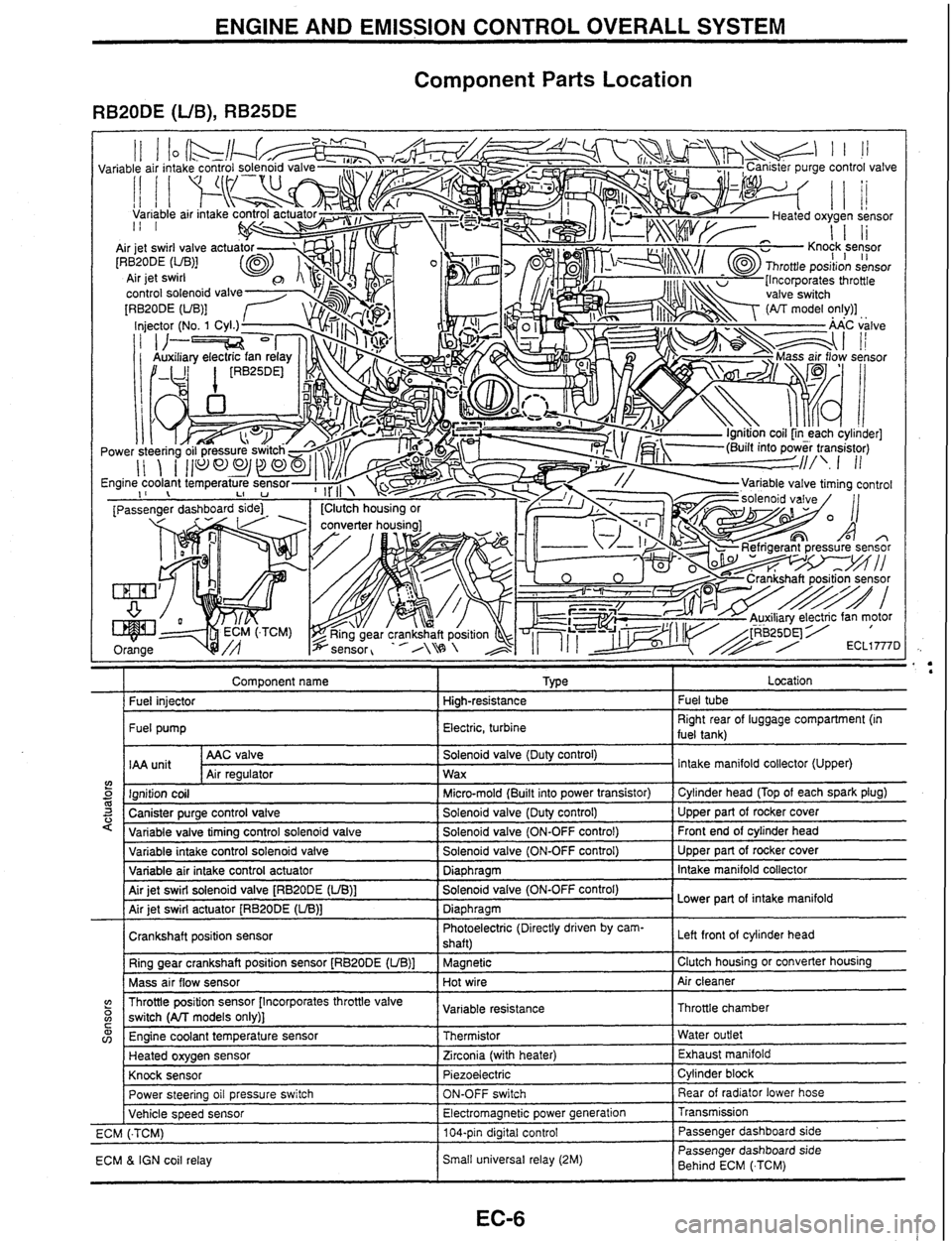

Component Parts Location

RB20DE (UB), RB25DE

Component name I Type I Location

I Fuel iniector I Hiah-resistance I Fuel tube

I Fuel pump I Electric, turbine I Right rear of luggage compartment (in

fuel tank)

AAC valve

IAA

unit Air reaulator

5 m 3 '

Solenoid valve (Duty control)

Wax

variable intake control solenoid valve

Variable air intake control actuator

Air jet swirl solenoid valve

[RBPODE (UB)]

Air jet swirl actuator

[RB20DE (LIB)]

Crankshaft position sensor Ring gear crankshaft position sensor

[RB20DE (UB)]

Mass air flow sensor Intake

manifold collector (Upper)

Ignition coil

Canister purge control valve

Variable valve tirnina control

solenoid valve

(? o C

Solenoid valve (ON-OFF control)

Diaphragm

Solenoid valve (ON-OFF control)

Diaphragm Photoelectric (Directly driven by cam-

shaft)

Magnetic

Hot wire

w v,

Micro-mold (Built into power transistor)

Solenoid valve (Duty control)

Solenoid valve (ON-OFF control) Upper part of rocker cover

Intake manifold collector

Lower part of intake manifold

Left front

of cylinder head

Clutch housing or converter housing

Air cleaner

Throttle position sensor [Incorporates throttle valve

switch

(All models only)]

Power steering oil pressure switch

Vehicle speed sensor

ECM

(.TCM)

ECM

& IGN coil relay Cylinder head

(Top of each spark plug)

Upper part of rocker cover

Front end of cylinder head

Engine coolant temperature sensor

Heated oxygen sensor

Knock sensor Variable

resistance

ON-OFF switch

Electromagnetic power generation

104-pin digital control

Small universal relay (2M) Throttle chamber

Thermistor

Zirconia (with heater)

Piezoelectric Rear of radiator lower hose

Transmission Passenger dashboard side

Passenger dashboard side

Behind ECM

(.TCM) Water

outlet

Exhaust manifold

Cylinder block

Page 14 of 230

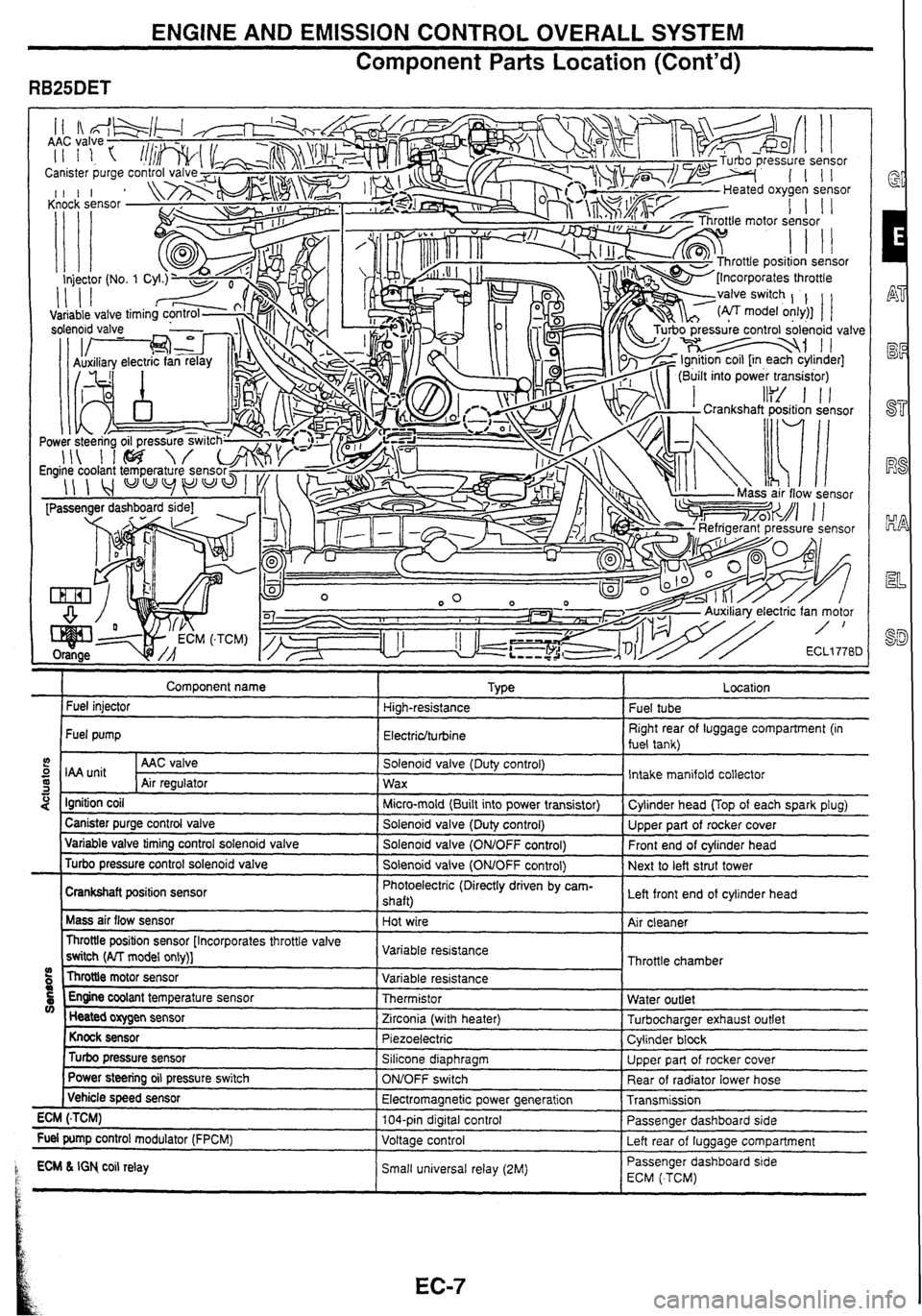

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Component

Parts Location (Cont'd)

" . . ., . .7

Comoonent name I TVLE a r Fuel injector High-resistance

Fuel pump

Electriclturbine

5 I unit I AAC valve I Solenoid valve (Duty control)

S Air reoulator 1 wax -1 I " - . -.

4 Ignition coil I Micro-mold (Built into power transistor)

I Canister purge control valve I Solenoid valve (Dutv control) ---- - Variable valve timing control solenold valve I Solenold valve (ONtOFF control)

Turbo pressure control solenoid valve

I Solenoid valve (OMOFF control)

Crankshaft position sensor Photoelectric

(Directly driven by cam-

shaft)

Mass air flow sensor

Hot wire

Throttle position sensor [Incorporates throttle valve

switch

(AlT model only)] Variable

resistance

Throttle motor sensor

09 Variable resistance

5 Engine coolant temperature sensor Thermistor V) Heated oxygen sensor

Zirconia (with heater)

Knock sensor Piezoelectric

Turbo pressure sensor Silicone diaphragm

Power

steering oil pressure switch

ONJOFF switch

( Vehicle speed sensor

Electromagnetic power generation

ECM

(.TCM) 104-pin digital control

Fuel pump control modulator (FPCM)

Voltage control

1 ECM L IGN co~l relay Small un~versal relay (2M) P t

.

Fuel tube

Right rear of luggage compartment (in

fuel tank)

Intake manifold collector

Cvlinder head

UOD of each soark olua)

Upper part of rocker cover

Front end of cylinder head

Next to left strut tower

Left front end of cylinder head

Air cleaner

Throttle chamber

Water outlet

Turbocharaer exhaust outlet

Cylinder

block

Upper part of rocker cover

Rear of radiator lower hose

Transmission

Passenger dashboard side

Left rear of

luaaaae comoartment

-- Passenger dashboard s~de

ECM ( TCM)

Page 18 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Circuit Diagram

RB20DE (UB).MTT, RB25DE, RB25DET.MTT MODELS

Fan motor

Auxtliary

electric

Ian

relay

-

Alr cmdll~oner compressor

Arr

conduoner

relay

14

Y Mallunct~on indcator lamp A 17

26 $7 = Power steenng 011

pressure sw~icr.

I

23

43 Engine Want

temwrature sensor B.

Tachometer drive signal Check connmr

To rear defogger relay

/ [RB2MWD TO starter motor *'""L'*" - > TO PNP switch

I TO Starter relay

[Except lor ' - RB25DE.4WDI

Page 19 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Circuit Diagram (Cont'd)

RB2ODE (UB).A/T, RB25DET.AfT MODELS

".--- , - TC rear de'ogger relay 4 49

T 176

. . .- . . . . . , ,. - . . . , 59 . : . Turbine

at -.. A sensor A

Overrun clutzh

. shdt ~lenwd valve k pressure detection switch

I' Sh:H control unit Droppins revstor 8 18 9 'S 10

Page 20 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

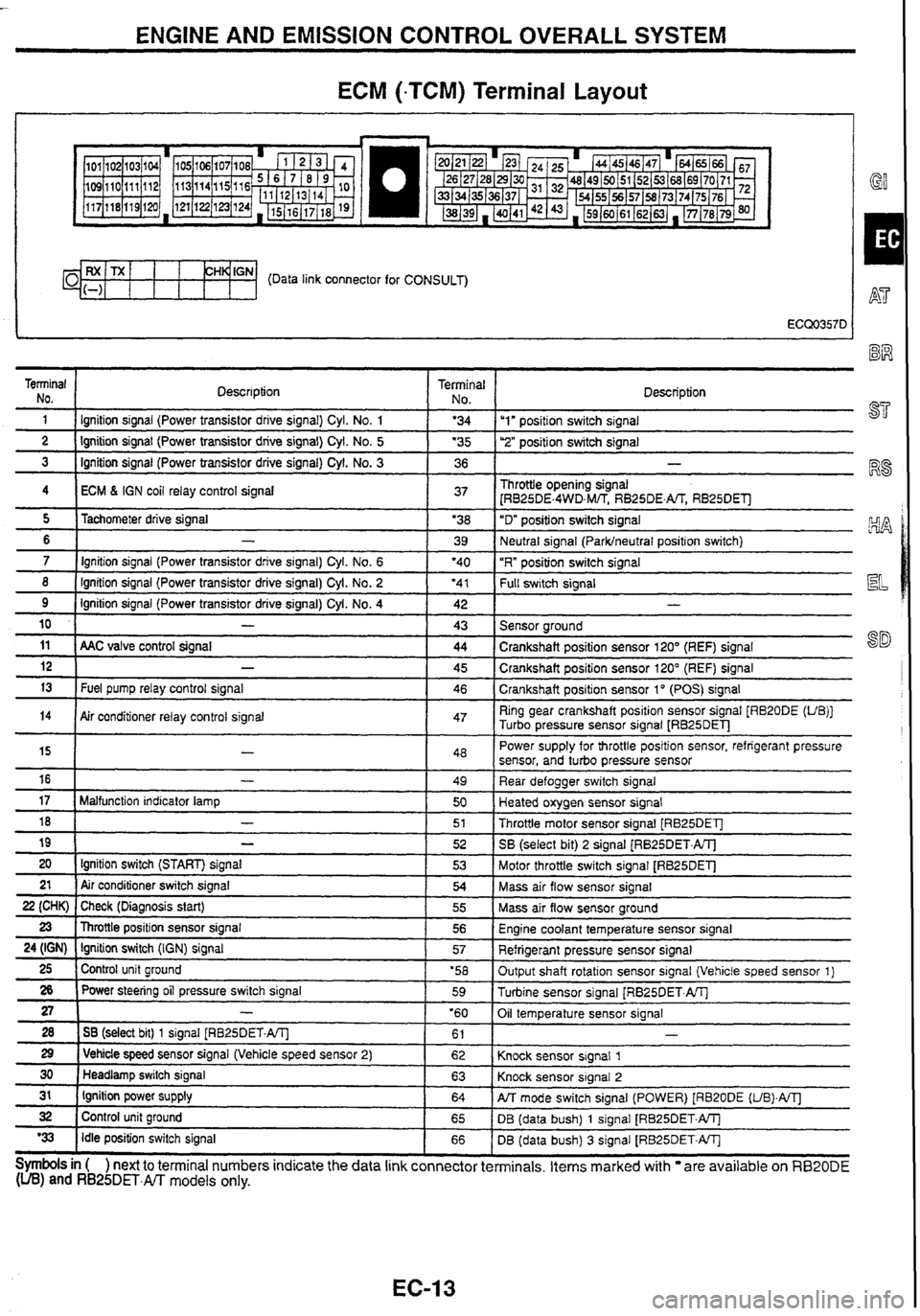

ECM (-TCM) Terminal Layout

I GY

CH~'GN- (Data link connector for CONSULT)

Terminal NO.

1 Description Terminal 1 No I Description - - 1 I lgnition

signal (Power transistor drrve signal) Cyl. No. 1 1 '34 Iu1" positron switch signal -- ---- 2 1 Ignition signal (Power transistor drive signal) Cyl. No. 5 1 '35 1 ''2" posifion switch signal - - 3 1 Ignition signal (Power transistor drive signal) Cyl. No. 3 1 36 1 -

4 I ECM 6 IGN coil relay control signal 1 37 1 Throttle opening signal

[RB25DE.4WD,M/TS RB25DE.m RB25DEll

- - - -- - - - - 8 ( Ignition signal (Power transistor drive signal) Cyl. No. 2 ( '41 1 f-k swltch signal

5

6

7

11 ( AAC valve control signal ( 44 1 Crankshaft position sensor 120' (REF) signal

Tachometer

drive signal

-

Ignition signal (Power transistor drive signal) Cyl. No. 6

9

10

'38

39

'40

Ignition signal (Power transistor drive signal)

Cyl.

No. 4

-

12

13

"D" position switch signal

Neutral signal

(Parklneutral position switch)

"R" position switch signal

14

Symbols in ( ) next to terminal numbers indicate the data link connector terminals. Items marked with are available on RB20DE (UB) and RB25DET.m models only.

42

43

-

Fuel pump relay control signal

15

16

17

18

19

20 21

22 (CHK)

23

24 (IGN)

25

26

27

28

29

30

31

32

'33

- -

Sensor around

Air conditioner relay control signal 45

46

-

-

Malfunction indicator lamp

-

-

Ignition switch (START) signal

Air conditioner switch signal

Check (Diagnosis start)

Throttle position sensor signal

Ignition switch

(IGN) signal

Control unit ground

Power steering oil pressure switch signal

-

1 SB (select bit) 1 signal [RB25DET.A/Tl

1 Vehicle speed sensor signal (Vehicle speed sensor 2)

Headlamp switch signal

Ignition power supply

Control unit ground

Idle position switch signal Crankshaft

position sensor 120" (REF) signal

Crankshaft position sensor 1

" (POS) signal

47 Ring gear crankshaft position sensor signal [RB20DE (UB)]

Turbo pressure sensor signal

LRB25DEl-J

48

49

50

51

52

53

54

55

56

57

'58 59

'60 61

62

63

64

65

66 Power

supply for throttle position sensor, refrigerant pressure

sensor, and turbo pressure sensor

Rear defogger switch signal

Heated oxygen sensor signal

Throttle motor sensor signal [RB25DET]

SB

(select bit)

2 signal (RB25DET.ATJ

Motor throttle switch signal

[RB25DET]

Mass air flow sensor signal

Mass air flow sensor ground

Engine coolant temperature sensor signal

Refrigerant pressure sensor signal

Output shaft rotation sensor signal (Vehicle speed sensor 1)

Turbine sensor signal

[RB25DET.AlTj

Oil temperature sensor signal

Knock sensor signal

1

Knock sensor signal 2

PJT mode switch signal (POWER) [RB20DE (UB).A/Tl

DB (data bush) 1 signal [RB25DET.W

DB (data bush)

3 signal [RB25DET.W

Page 21 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

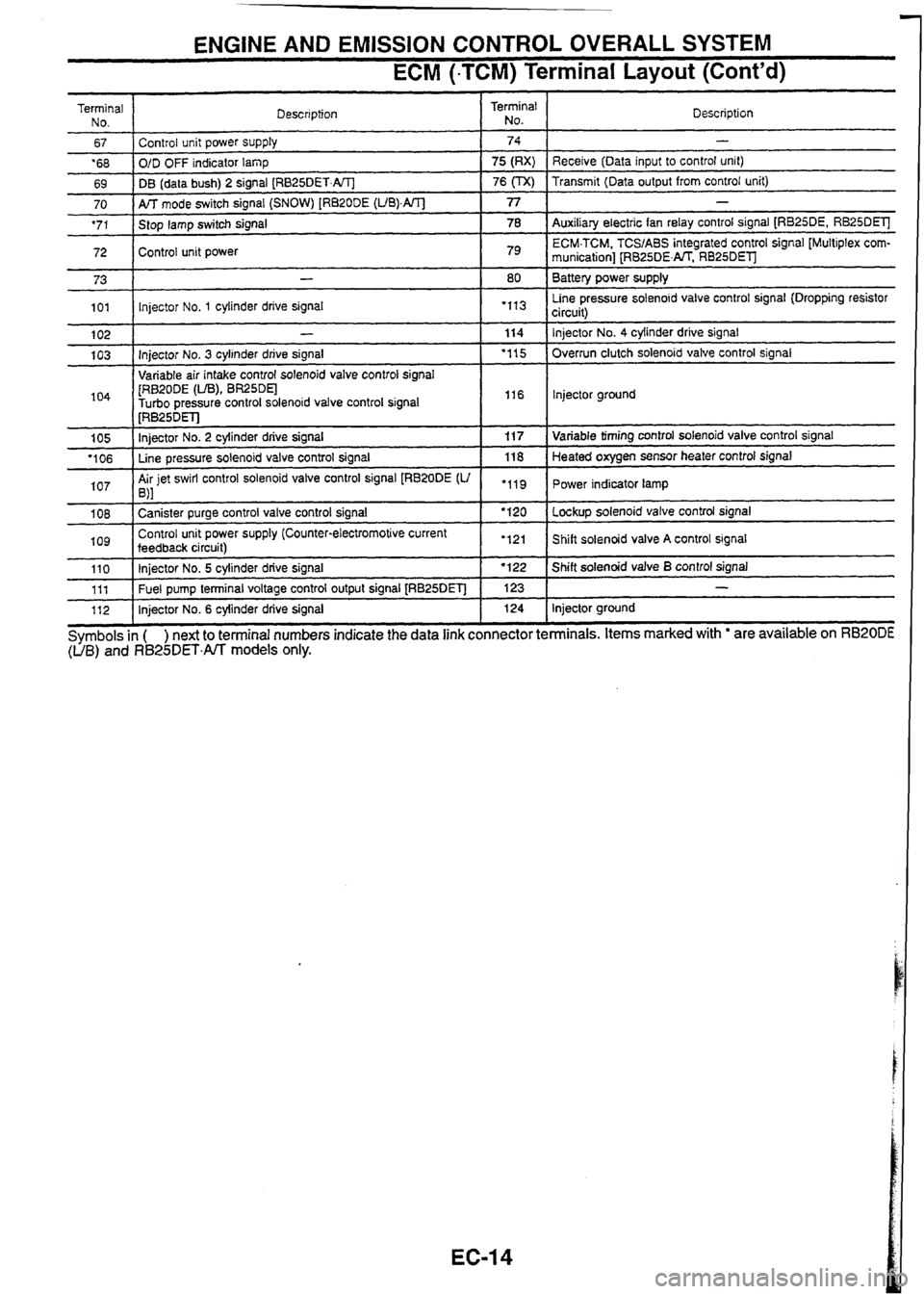

ECM (-TCM) Terminal Layout (Cont'd)

Terminal

No.

67

'68

69 Description

70

'71

72 I

Control unit power supply

O/D OFF indicator

lamp

DB (data bush) 2 signal

[RB25DET.AIT]

73

101

104

1 [RB~ODE (LIB), BR25DEl -

Turbo oressure control solenoid valve control signal I I16 I lnjector ground

Terminal

No.

AK mode switch signal (SNOW) [RB20DE (UB).AIT]

Stop lamp switch signal

Control unit power

102

103 Description

74

75 (RX)

76

(TX)

1 I . .

-

Receive (Data input to control unit)

Transmit (Data output from control unit)

77

78

79

-

Injector No. 3 cylinder drive signal

Variable air intake control solenoid valve control

sianal

105

'106

107

-

Auxiliary electric fan relay control signal [RB25DE, RB25DElJ

ECM.TCM. TCSIABS integrated control signal [Multiplex

com-

munication] [RB25DENT. RB25DEl

Battery power supply

Line pressure solenoid valve control signal (Dropping resistor

circuit)

-

lnjector No. 1 cylinder drive signal

1 08

log

80

"I3

114

'1 15

[RB~~DET]

Injector No. 2 cylinder drive signal

Line pressure solenoid valve control signal

Air jet swirl control solenoid valve control signal

[RB20DE

(U ,\I

110 111

112 Injector No.

4 cylinder

drive signal

Overrun clutch solenoid valve control signal

"11

Canister purge control valve control signal

Control unit power supply (Counter-electromotive current

feedback

circuit) 11

7

118

.119

Symbols

in ( ) next to terminal numbers indicate the data link connector terminals. Items marked with ' are available on RB20DE (UB) and R825DET.All models only.

Injector No. 5 cylinder drive signal

Fuel pump terminal voltage control output signal

[RB25DET]

Injector No. 6 cylinder drive signal Variable

timing control solenoid valve control signal

Heated oxygen sensor heater control signal

Power indicator lamp

'120

'121 Lockup solenoid valve control signal

Shift solenoid valve

A control signal I '122

123 124 Shift solenoid valve B control signal

-

Injector ground

Page 22 of 230

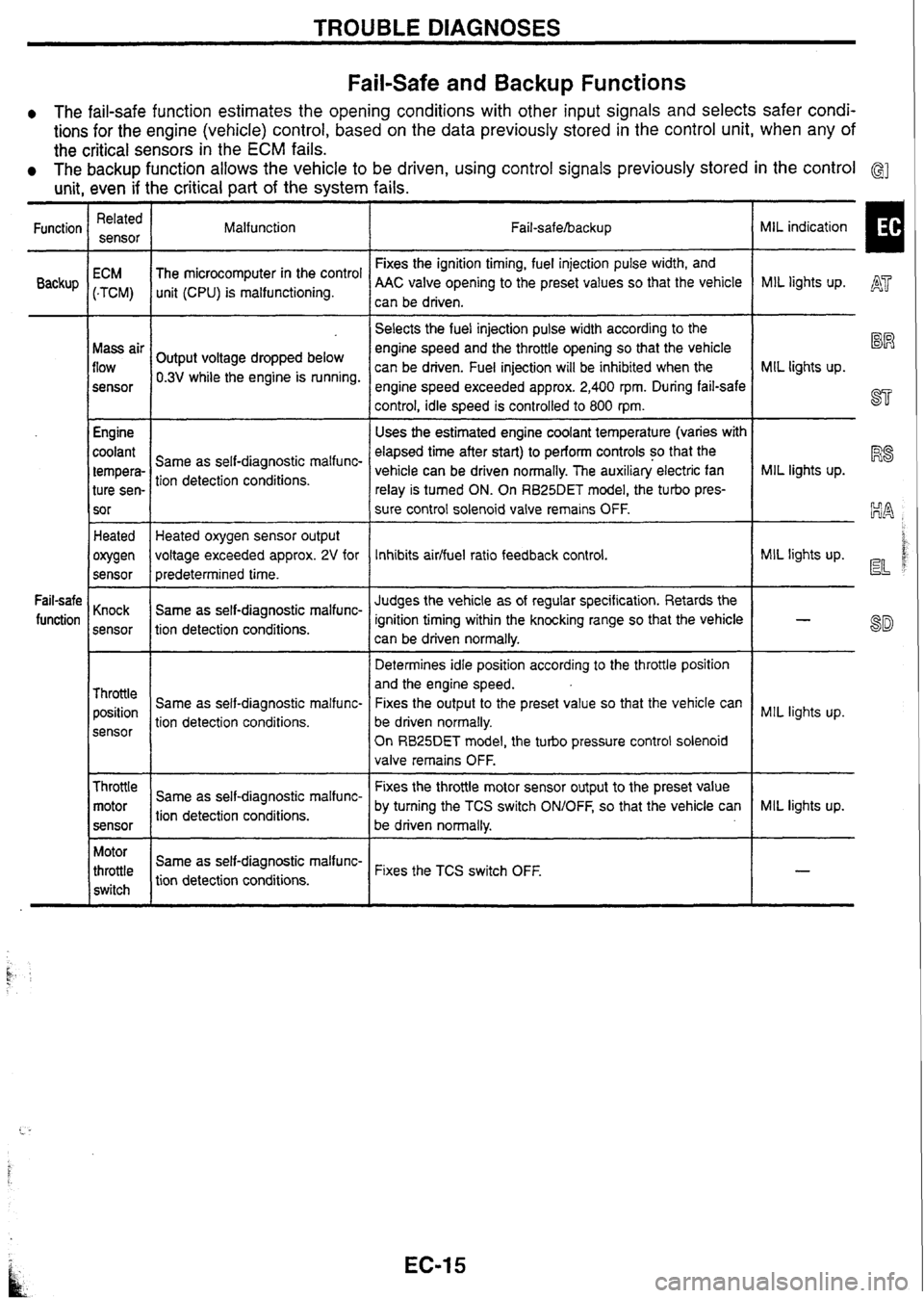

TROUBLE DIAGNOSES --- - - - -- -- - -

Fail-safe and Backup Functions

0 The fail-safe function estimates the opening conditions with other input signals and selects safer condi-

tions for the engine (vehicle) control, based on the data previously stored in the control unit, when any of

the critical sensors in the

ECM fails.

The backup function allows the vehicle to be driven, using control signals previously stored in the control G]

unit, even if the critical part of the system fails.

MIL indication

I

Related

sensor

Function

Backup Malfunction

Fail-safehacku p

Fixes the ignition timing, fuel injection pulse width, and

AAC valve opening to the preset values so that the vehicle

can be driven.

ECM

(-TCM)

Mass air

flow

sensor

Engine

coolant

tempera- ture sen-

sor The

microcomputer in the control

unit (CPU) is malfunctioning. MIL lights

up. A'

-- --

Selects the fuel injection pulse width according to the

engine speed and the throttle opening so that the vehicle

can be driven. Fuel injection will be inhibited when the

engine speed exceeded approx.

2,400 rpm. During fail-safe

control, idle speed is controlled to 800

rpm.

Uses the estimated engine coolant temperature (varies with

elapsed time after start) to perform controls so that the

vehicle can be driven normally. The auxiliary electric fan

relay is turned ON. On

RB25DET

model, the turbo pres-

sure control solenoid valve remains OFF.

%R

MIL lights up.

ST

Output voltage dropped below

0.3V while the engine is running.

MIL lights up.

R8 Same as self-diagnostic malfunc-

tion detection conditions.

Heated

owen

sensor Heated oxygen sensor output

voltage exceeded approx.

2V for

predetermined time.

Same as self-diagnostic malfunc-

tion detection conditions. MIL

lights up. d d Inhibits aidfuel ratio feedback control.

Judges the vehicle as of regular specification. Retards the

ignition timing within the knocking range so that the vehicle

can be driven normally.

Determines idle position according to the throttle position

and the engine speed.

Fixes the output to the preset value so that the vehicle can

be driven normally.

On

RB25DET model, the turbo pressure control solenoid

valve remains OFF.

Fail-safe

function Knock

sensor

Throttle position

sensor Same

as self-diagnostic malfunc-

tion detection conditions. MIL

lights up.

Throttle motor

sensor

--

Fixes the throttle motor sensor output to the preset value

by turning the TCS switch

ONIOFF, so that the vehicle can

Same

as self-diagnostic malfunc-

tion detection conditions. MIL

lights up.

be driven normally.

Motor

throttle

switch Same

as

self-diag

nostic

malfunc-

tion detection conditions. Fixes the

TCS switch OFF.

t.. -

Page 30 of 230

![NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES .

CONSULT (Contd)

Monitored item

[Unit] signals Description

Remarks

INJ

PULSE [msec]

I

When the engine is stopped, a certain

computed value is indicated. lndicates NISSAN GT-R 1998 Service Manual

TROUBLE DIAGNOSES .

CONSULT (Contd)

Monitored item

[Unit] signals Description

Remarks

INJ

PULSE [msec]

I

When the engine is stopped, a certain

computed value is indicated. lndicates](/img/5/57354/w960_57354-29.png)

TROUBLE DIAGNOSES .

CONSULT (Cont'd)

Monitored item

[Unit] signals Description

Remarks

INJ

PULSE [msec]

I

When the engine is stopped, a certain

computed value is indicated. lndicates the actual fuel injection pulse

width compensated by ECM according to

the input

siqnals.

IGN TIMING [BTDC]

I lo

lndicates the ignition timing computed by ECM according to the input signals. When the engine is stopped, a certain

value is indicated.

IACV-AACN

I%]

I lo

lndicates IACV-AACN control value com-

puted by ECM according to the input sig-

nals.

PURG VOL CN

[ONIOFF dutyj lndicates the EVAP canister purge vol-

ume control valve computed by the ECM according to the input signals. The opening becomes larger as the

value increases.

AIF

ALPHA [%]

- The mean value of the air-fuel ratio feed-

back correction factor per cycle is indi-

cated. -- - When the engine is stopped, a certain

value is indicated.

This data also includes the data for the

air-fuel ratio learning control.

AIR COND

RLY [ONIOFF] The air conditioner relay control condition

(determined by ECM according to the

input signal) is indicated.

-- - - Indicates the fuel pump relay control con-

dition determined by ECM according to

the input signals.

The control condition of the intake valve

timing control solenoid valve is indicated.

ON

... Intake valve timing control is oper-

ating. OFF

... lntake valve timing control is not

operating.

VlAS

SN [ONIOFF] RB20DE (UB), RB25DE

Control conditions computed by ECM Solenoid valve activated: ON Solenoid valve not activated: OFF

SWRL CONT SN

[ON/OFF]

0 RB20DE (UB)

COOLING FAN

[HVLOW/O FF] RB25DE, RB25DET

The control condition of the cooling fan

(determined by ECM according to the

input signal) is indicated.

HI

... High speed operation LOW ... Low speed operation

OFF ... Stop

TURBO CONT

SN 0 RB25DET Control conditions computed by ECM

Solenoid valve activated: ON Solenoid valve not activated: OFF

PD PRESSURE

SENSOR M Refrigerant pressure sensor output volt-

age Approx. 0.36V min.

(Varies with air conditioner refrigerant

pressure)

, VOLTAGE Voltage measured by the voltage probe.

Pulse width, frequency or duty cycle

measured by the pulse probe. Only "#" is displayed if item is unable to

be measured.

r Figures with "#"s are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured.

Page 31 of 230

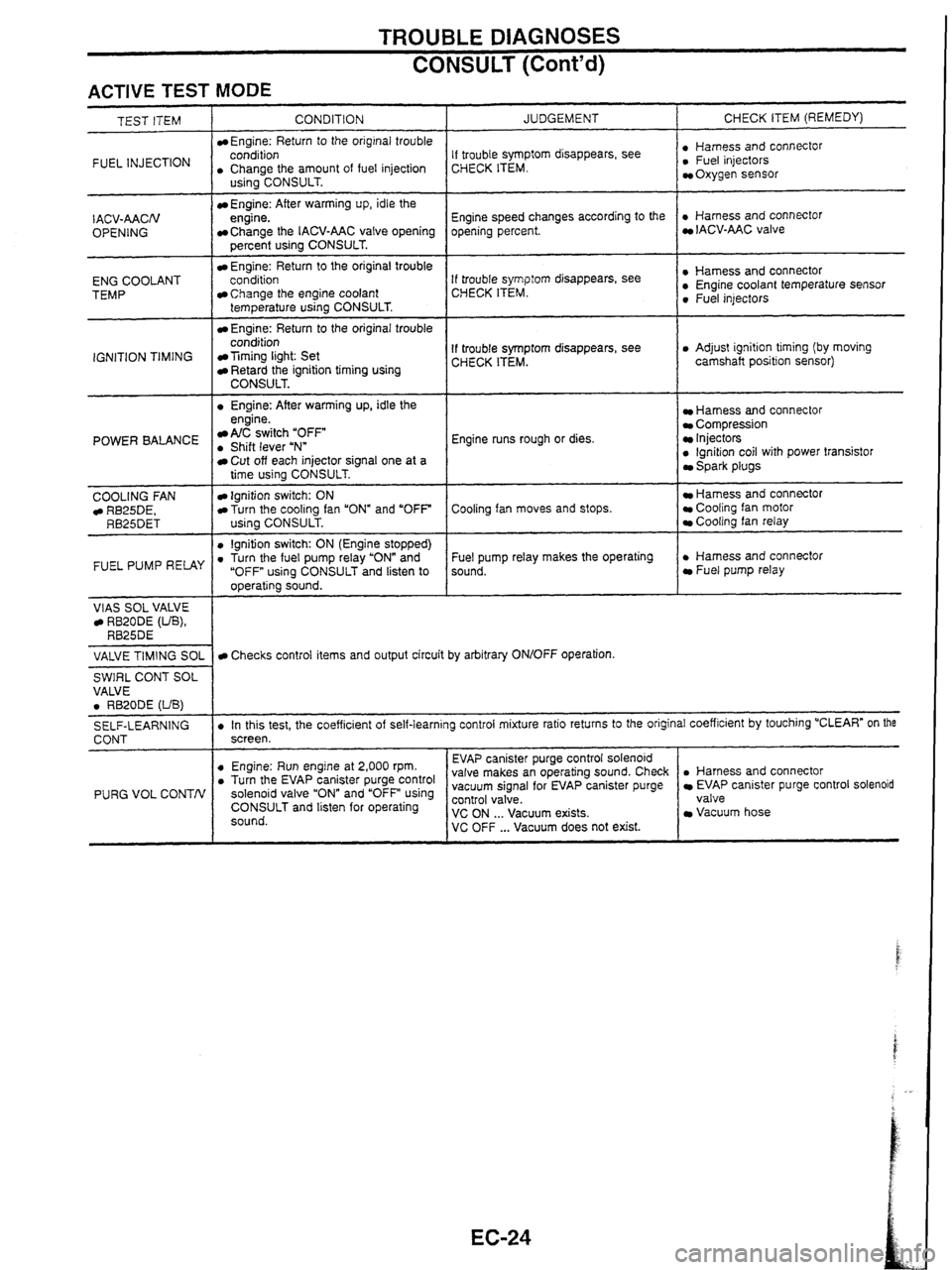

TROUBLE DIAGNOSES

CONSULT (Cont'd)

ACTIVE TEST MODE

INJECTION I . CCohArthe amount of fuel injection

TEST ITEM

CONDITION

Engine: Return

to the original trouble

- I . Engine: After warming up, idle the

IACV-AACN

OPENING

ENG COOLANT

TEMP

IGNITION TIMING

US~~~CONSULT.

Engine: After warming up, idle the

engine.

Change the IACV-AAC valve opening

percent using CONSULT.

Engine: Return to the original trouble

conditioo

Change the engine coolant

temperature using CONSULT.

Engine: Return to the original trouble

condition

Timing light: Set Retard the ignition timing using CONSULT.

POWER BALANCE engine. A/C switch "OFF . Shift lever uNn

COOLING

FAN RB25DE, RB25DET

FUEL PUMP RELAY

VlAS SOL VALVE RB20DE (UB), RB25DE

JUDGEMENT

Cut off each injector signal one at a

time using CONSULT.

Ignition switch: ON Turn the cooling fan "ON" and "OFF

using CONSULT.

0 lgnition switch: ON (Engine stopped) . Turn the fuel pump relay "ON" and

"OFF using CONSULT and listen to

operating sound. CHECK

ITEM (REMEDY)

If trouble symptom disappears, see

CHECK ITEM. : ~,"~~,,,~scOnnectOr Oxygen sensor

Engine speed changes according to the

opening percent.

. Harness and connector IACV-AAC valve

If trouble

symp:orn disappears, see

CHECK ITEM. : Sensor 0 Fuel injectors

If trouble symptom disappears, see

CHECK ITEM. 0 Adjust ignition timing (by moving

camshaft position sensor)

Engine runs rough or dies.

Harness and connector Compression Injectors 0 lgnition coil with power transistor Spark plugs

Cooling fan moves and stops.

Hamess and connector Cooling fan motor Cooling fan relay

Fuel pump relay makes the operating

sound.

. Harness and connector Fuel pump relay

VALVE

TIMING

SOL

SWIRL CONT SOL

VALVE

0 RB20DE (UB)

SELF-LEARNING

CONT

PURG VOL CONTN

Checks control items and output circuit by arbitrary ON/OFF operation.

. In this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching "CLEAR" on the

screen.

. Harness and connector EVAP canister purge control solenoid

valve

Vacuum hose

0 Engine: Run engine at 2,000 rpm. . Turn the EV~P canister purge control solenoid valve and using CONSULT and listen for operating

sound. EVAP

canister purge control solenoid

valve makes an operating sound. Check

vacuum signal for EVAP canister purge ~~~~~~a'cuum exists. VC OFF ... Vacuum does not exist.