sensor NISSAN LATIO 2008 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 42 of 2771

AT-30

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

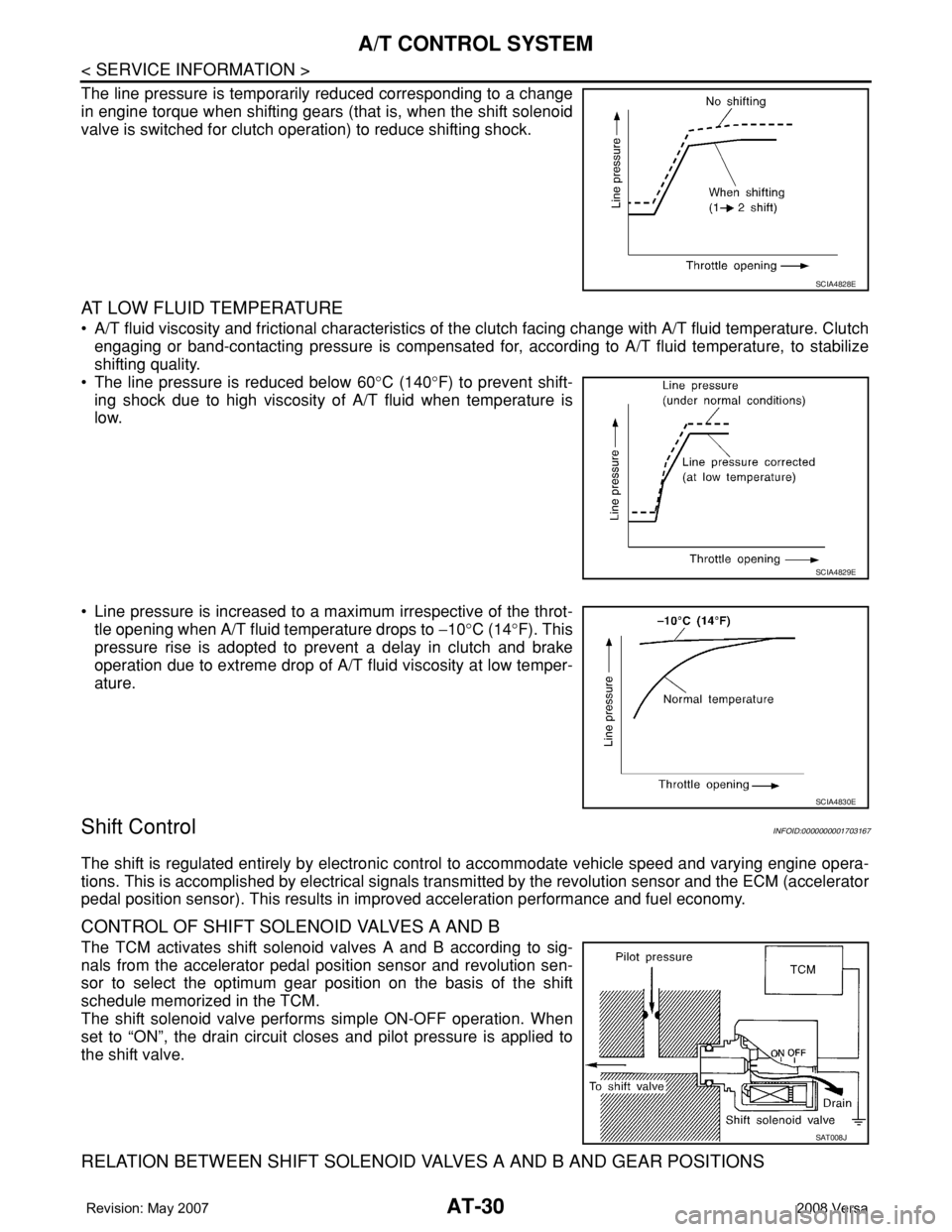

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

AT LOW FLUID TEMPERATURE

• A/T fluid viscosity and frictional characteristics of the clutch facing change with A/T fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to A/T fluid temperature, to stabilize

shifting quality.

• The line pressure is reduced below 60°C (140°F) to prevent shift-

ing shock due to high viscosity of A/T fluid when temperature is

low.

• Line pressure is increased to a maximum irrespective of the throt-

tle opening when A/T fluid temperature drops to −10°C (14°F). This

pressure rise is adopted to prevent a delay in clutch and brake

operation due to extreme drop of A/T fluid viscosity at low temper-

ature.

Shift ControlINFOID:0000000001703167

The shift is regulated entirely by electronic control to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals transmitted by the revolution sensor and the ECM (accelerator

pedal position sensor). This results in improved acceleration performance and fuel economy.

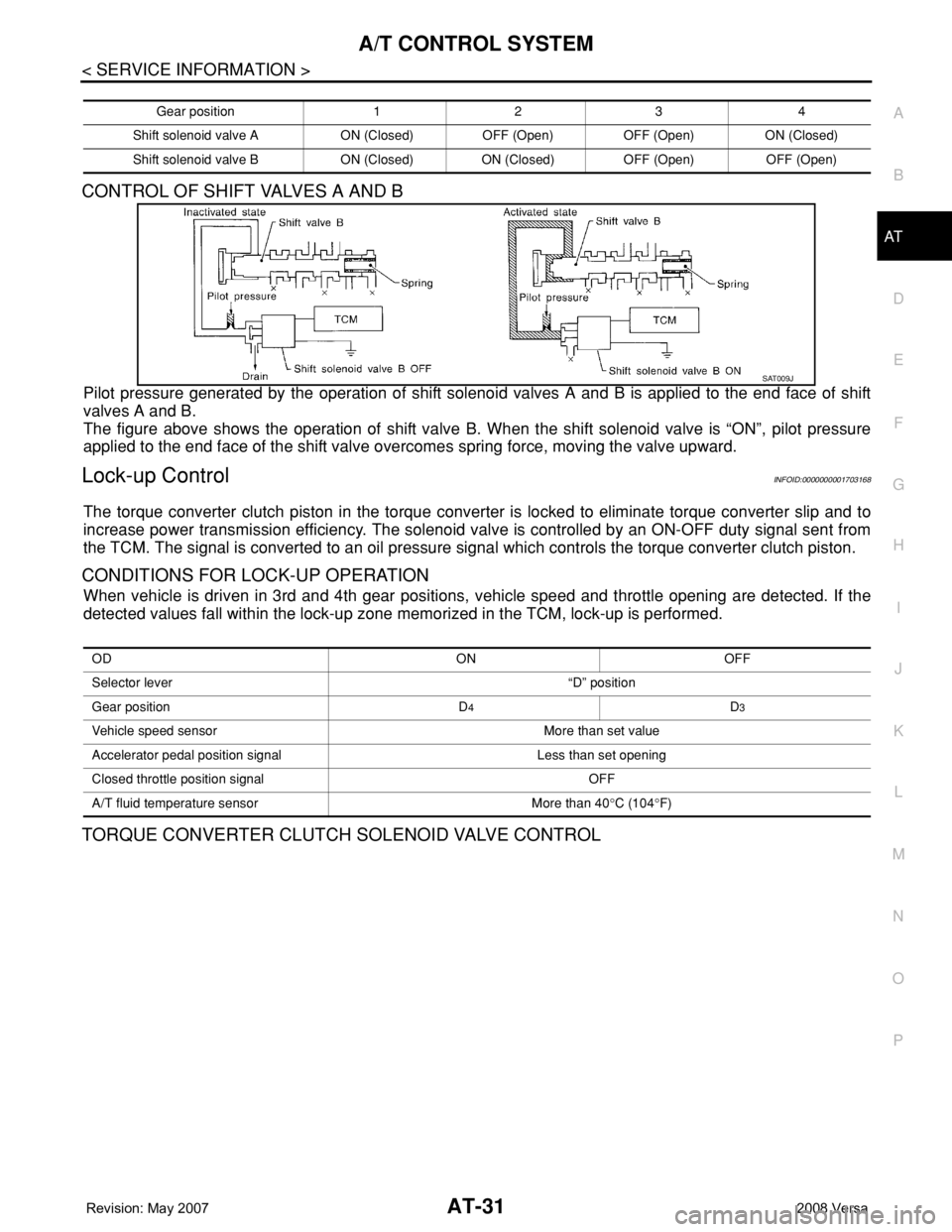

CONTROL OF SHIFT SOLENOID VALVES A AND B

The TCM activates shift solenoid valves A and B according to sig-

nals from the accelerator pedal position sensor and revolution sen-

sor to select the optimum gear position on the basis of the shift

schedule memorized in the TCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

RELATION BETWEEN SHIFT SOLENOID VALVES A AND B AND GEAR POSITIONS

SCIA4828E

SCIA4829E

SCIA4830E

SAT008J

Page 43 of 2771

A/T CONTROL SYSTEM

AT-31

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

CONTROL OF SHIFT VALVES A AND B

Pilot pressure generated by the operation of shift solenoid valves A and B is applied to the end face of shift

valves A and B.

The figure above shows the operation of shift valve B. When the shift solenoid valve is “ON”, pilot pressure

applied to the end face of the shift valve overcomes spring force, moving the valve upward.

Lock-up ControlINFOID:0000000001703168

The torque converter clutch piston in the torque converter is locked to eliminate torque converter slip and to

increase power transmission efficiency. The solenoid valve is controlled by an ON-OFF duty signal sent from

the TCM. The signal is converted to an oil pressure signal which controls the torque converter clutch piston.

CONDITIONS FOR LOCK-UP OPERATION

When vehicle is driven in 3rd and 4th gear positions, vehicle speed and throttle opening are detected. If the

detected values fall within the lock-up zone memorized in the TCM, lock-up is performed.

TORQUE CONVERTER CLUTCH SOLENOID VALVE CONTROL

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

SAT009J

OD ON OFF

Selector lever “D” position

Gear position D

4D3

Vehicle speed sensor More than set value

Accelerator pedal position signal Less than set opening

Closed throttle position signal OFF

A/T fluid temperature sensor More than 40°C (104°F)

Page 48 of 2771

AT-36

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001703172

A/T system has two self-diagnostic systems.

The first is emission-related on board diagnostic system (OBD-II) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in the

ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the OD OFF indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with OBD-II self-diagnostic items. For detail,

refer to AT-73, "

CONSULT-III Function (A/T)" .

OBD-II Function for A/T SystemINFOID:0000000001703173

The ECM provides emission-related on board diagnostic (OBD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-related parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indicator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000001703174

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd trip

The “trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000001703175

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

•1st trip DTC No. is the same as DTC No.

•Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

DTC or 1st trip DTC of a malfunction is displayed in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with

CONSULT-III. Time data indicates how many times the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Page 51 of 2771

TROUBLE DIAGNOSIS

AT-39

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

TROUBLE DIAGNOSIS

DTC Inspection Priority ChartINFOID:0000000001703177

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis for

DTC “CAN COMM CIRCUIT”. Refer to AT- 8 3

.

Fail-SafeINFOID:0000000001703178

The TCM has an electronic Fail-safe mode. This allows the vehicle to be driven even if a major electrical input/

output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

Always follow the “AT-40, "

How to Perform Trouble Diagnosis for Quick and Accurate Repair" ”.

The SELF-DIAGNOSIS results will be as follows:

• The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

• During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

FAIL-SAFE FUNCTION

The following fail-safe functions allow vehicles to be driven even when sensor, switch or solenoid malfunction

occurs.

Vehicle Speed Sensor·A/T (Revolution Sensor)

Vehicle speed sensor·MTR signal is input from combination meter.

Accelerator Pedal Position Signal and Throttle Position Signal

TCM controls the throttle opening angle to a predetermined fixed position to enable driving if a malfunctioning

signal is input to TCM.

PNP Switch

When the multiple PNP switch signals are input to TCM, the priority of selector lever position becomes “D”,

“N”, “R”, “2” and “1” in order by internal TCM determination.

The use of 4th gear is inhibited until normal operation resumes. Because the hydraulic circuit of the control

valve is switched by manual valve according to the selector lever position, however, actual operating condition

of vehicle becomes as follows.

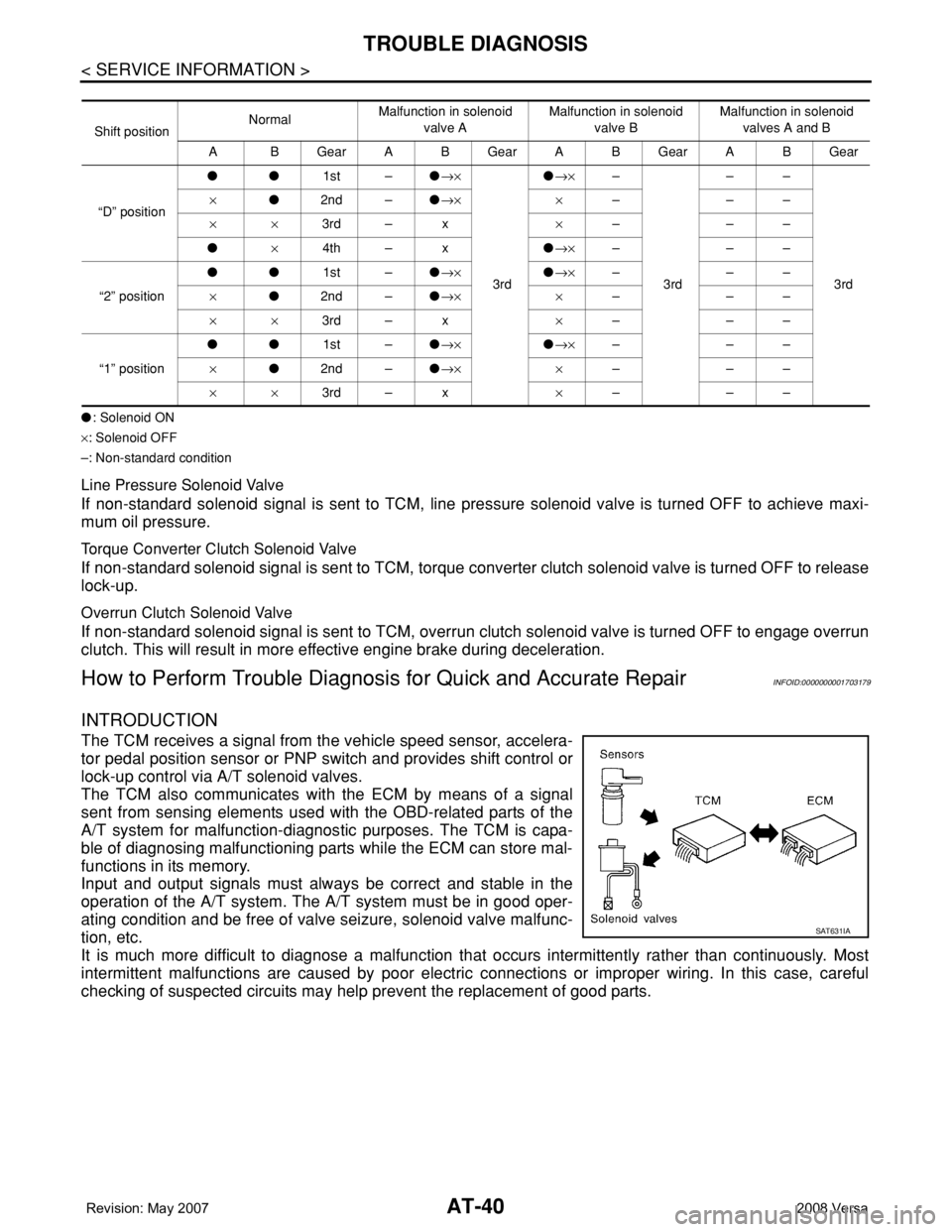

Shift Solenoid Valve A and B

If non-standard solenoid signal is sent to TCM, use of certain gears is limited. Refer to chart shown below.

Priority Detected items

1 CAN communication line

2 Except above

Actual lever position PNP switch input signal Running status

“P” “P” position and other position signals P

“R” “R” position and other position signals R

“N” “N” position and other position signals N

“D” “D” position and other position signals D

1 ⇔D2 ⇔D3 ⇔D4

“2”“2” position and other position signals (Except “1” position) 21 ⇔22 ⇔23

“2” position and “1” position signals 21 ⇔22

“1”“1” position and other position signals (Except “2” position) 11 ⇔12 ⇔13

“1” position and “2” position signals 11 ⇔12

Page 52 of 2771

AT-40

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

●: Solenoid ON

×: Solenoid OFF

–: Non-standard condition

Line Pressure Solenoid Valve

If non-standard solenoid signal is sent to TCM, line pressure solenoid valve is turned OFF to achieve maxi-

mum oil pressure.

Torque Converter Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, torque converter clutch solenoid valve is turned OFF to release

lock-up.

Overrun Clutch Solenoid Valve

If non-standard solenoid signal is sent to TCM, overrun clutch solenoid valve is turned OFF to engage overrun

clutch. This will result in more effective engine brake during deceleration.

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000001703179

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelera-

tor pedal position sensor or PNP switch and provides shift control or

lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose a malfunction that occurs intermittently rather than continuously. Most

intermittent malfunctions are caused by poor electric connections or improper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of good parts.

Shift positionNormalMalfunction in solenoid

valve AMalfunction in solenoid

valve BMalfunction in solenoid

valves A and B

A B Gear A B Gear A B Gear A B Gear

“D” position●●1st –●→×

3rd ●→×–

3rd ––

3rd ×●2nd –●→× ×–––

××3rd – x×–––

●×4th – x●→×–––

“2” position●●1st –●→×●→×–––

×●2nd –●→× ×–––

××3rd – x×–––

“1” position●●1st –●→×●→×–––

×●2nd –●→× ×–––

××3rd – x×–––

SAT631IA

Page 58 of 2771

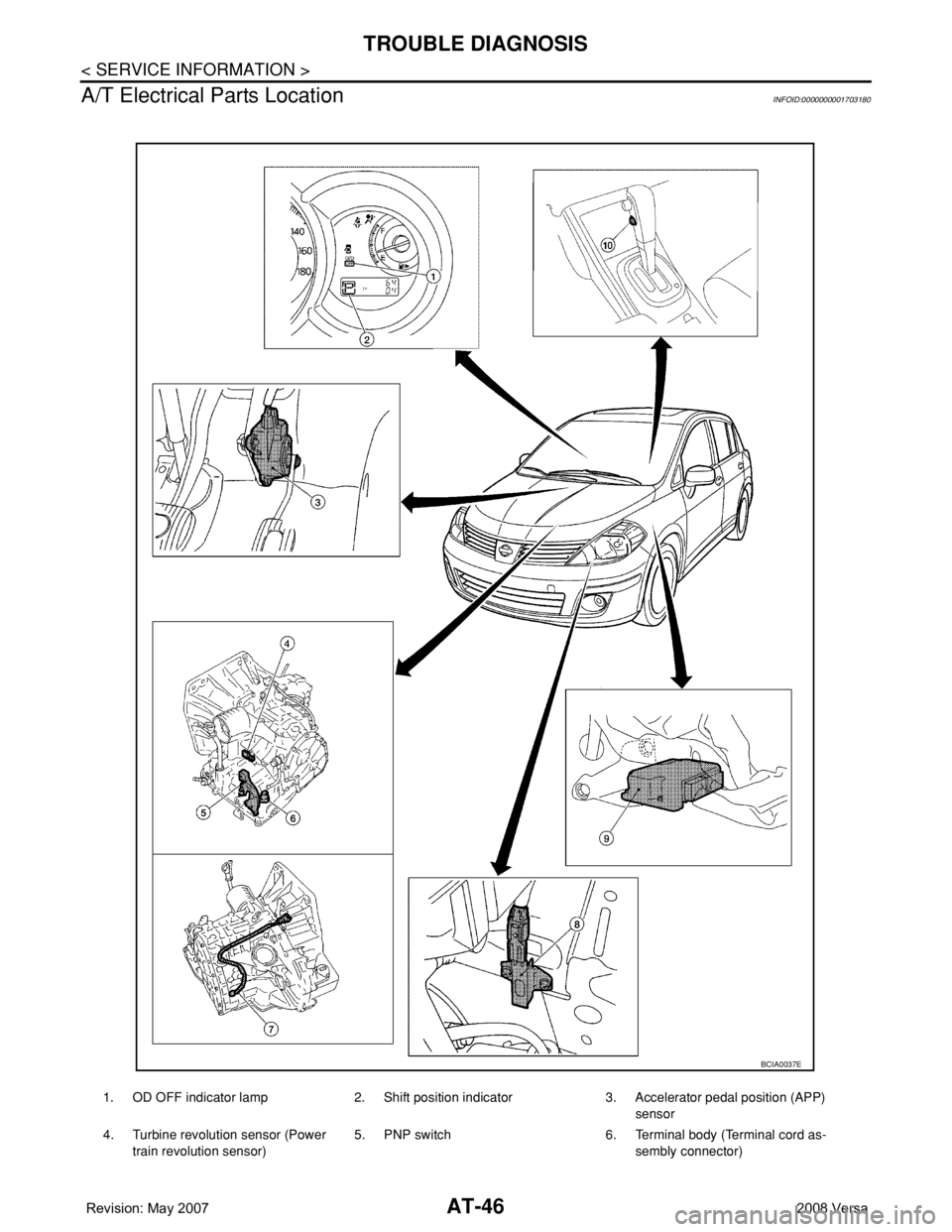

AT-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

A/T Electrical Parts Location

INFOID:0000000001703180

1. OD OFF indicator lamp 2. Shift position indicator 3. Accelerator pedal position (APP)

sensor

4. Turbine revolution sensor (Power

train revolution sensor)5. PNP switch 6. Terminal body (Terminal cord as-

sembly connector)

BCIA0037E

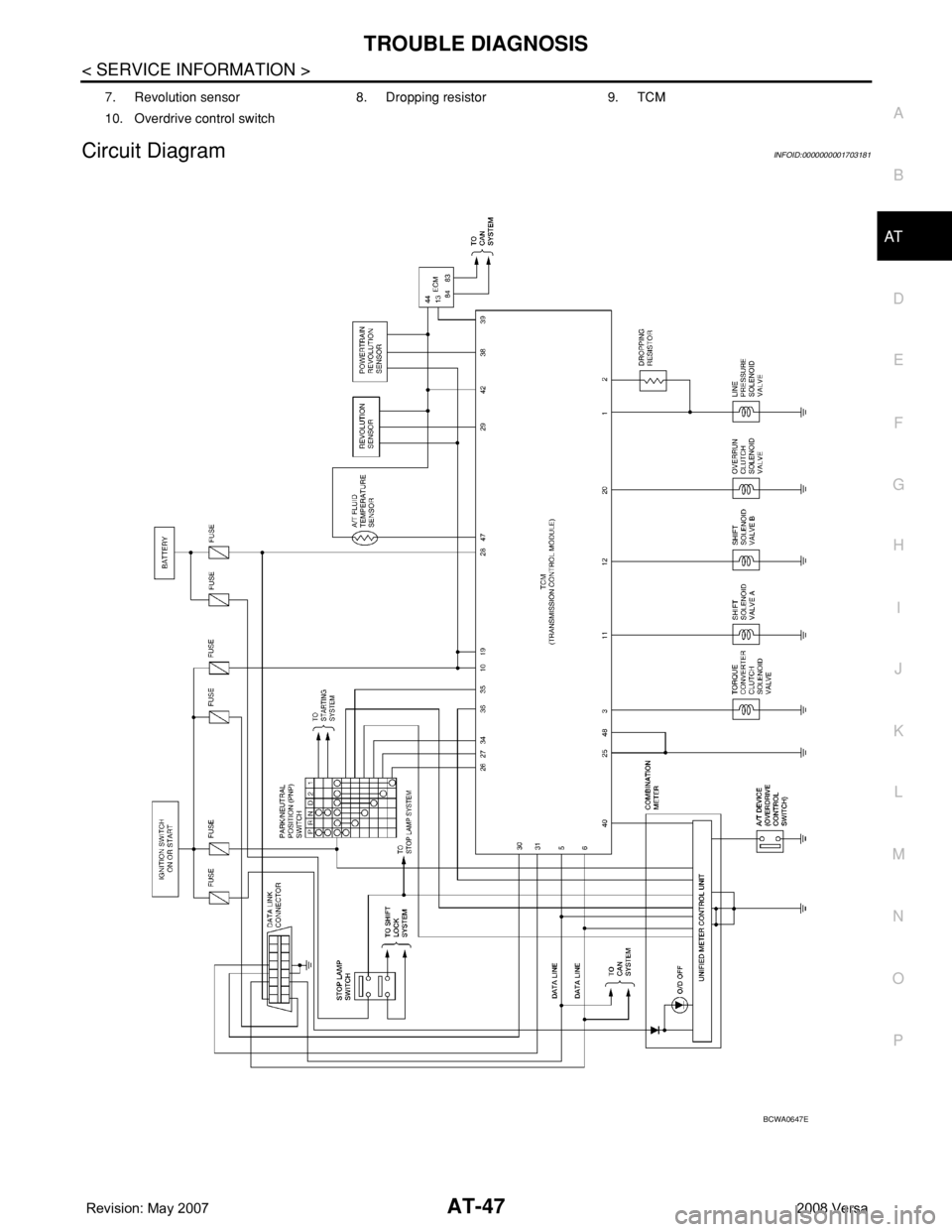

Page 59 of 2771

TROUBLE DIAGNOSIS

AT-47

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Circuit DiagramINFOID:0000000001703181

7. Revolution sensor 8. Dropping resistor 9. TCM

10. Overdrive control switch

BCWA0647E

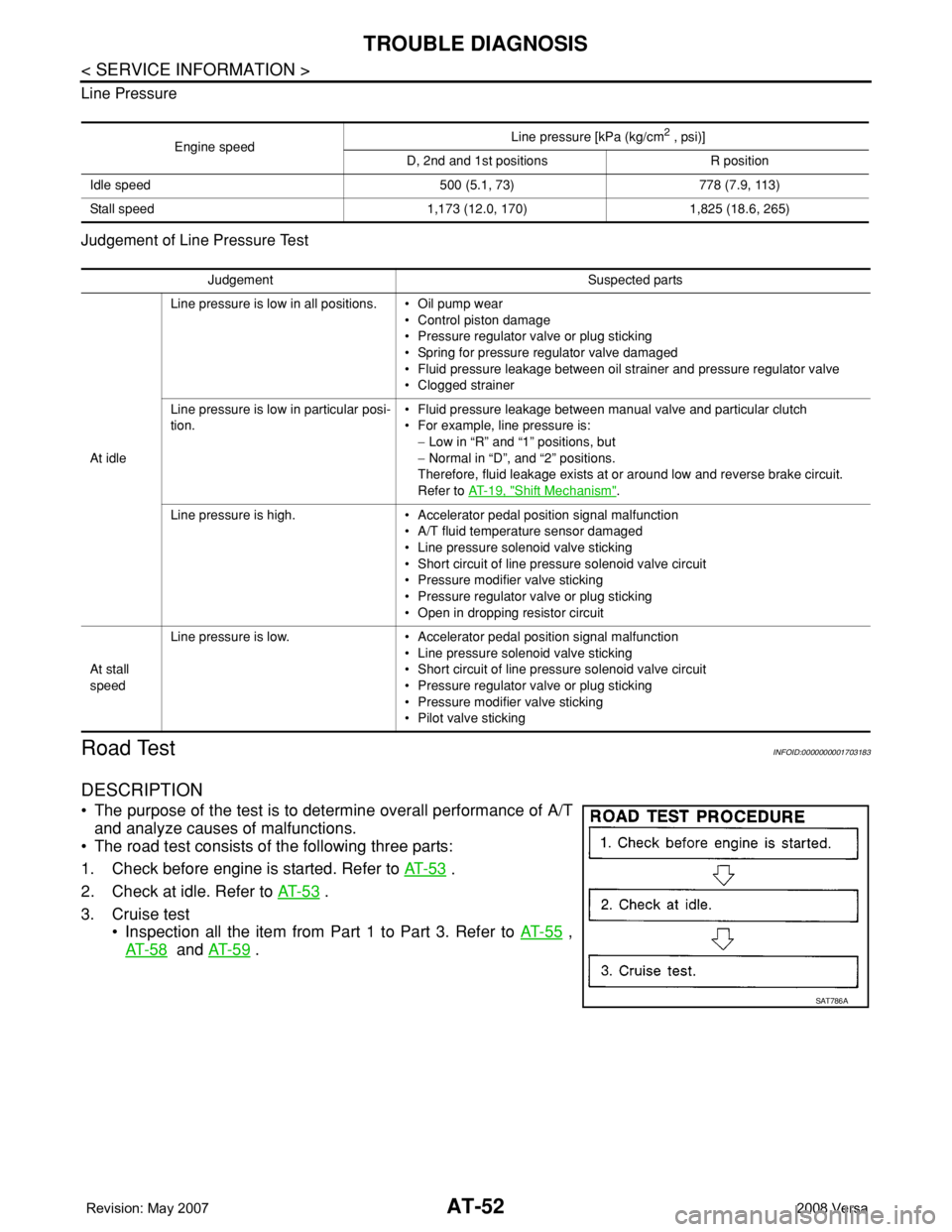

Page 64 of 2771

AT-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Line Pressure

Judgement of Line Pressure Test

Road TestINFOID:0000000001703183

DESCRIPTION

• The purpose of the test is to determine overall performance of A/T

and analyze causes of malfunctions.

• The road test consists of the following three parts:

1. Check before engine is started. Refer to AT- 5 3

.

2. Check at idle. Refer to AT- 5 3

.

3. Cruise test

• Inspection all the item from Part 1 to Part 3. Refer to AT- 5 5

,

AT- 5 8

and AT- 5 9 .

Engine speedLine pressure [kPa (kg/cm

2 , psi)]

D, 2nd and 1st positions R position

Idle speed 500 (5.1, 73) 778 (7.9, 113)

Stall speed 1,173 (12.0, 170) 1,825 (18.6, 265)

Judgement Suspected parts

At idleLine pressure is low in all positions. • Oil pump wear

• Control piston damage

• Pressure regulator valve or plug sticking

• Spring for pressure regulator valve damaged

• Fluid pressure leakage between oil strainer and pressure regulator valve

• Clogged strainer

Line pressure is low in particular posi-

tion.• Fluid pressure leakage between manual valve and particular clutch

• For example, line pressure is:

− Low in “R” and “1” positions, but

− Normal in “D”, and “2” positions.

Therefore, fluid leakage exists at or around low and reverse brake circuit.

Refer to AT- 1 9 , "

Shift Mechanism".

Line pressure is high. • Accelerator pedal position signal malfunction

• A/T fluid temperature sensor damaged

• Line pressure solenoid valve sticking

• Short circuit of line pressure solenoid valve circuit

• Pressure modifier valve sticking

• Pressure regulator valve or plug sticking

• Open in dropping resistor circuit

At stall

speedLine pressure is low. • Accelerator pedal position signal malfunction

• Line pressure solenoid valve sticking

• Short circuit of line pressure solenoid valve circuit

• Pressure regulator valve or plug sticking

• Pressure modifier valve sticking

• Pilot valve sticking

SAT786A

Page 74 of 2771

AT-62

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Perform inspections starting with number one and work up.

Items Symptom Condition Diagnostic item Reference page

No Lock-up Engage-

ment/TCC InoperativeTorque converter is

not locked up.ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Engine speed signalAT- 1 0 1

4. A/T fluid temperature sensorAT- 9 1

5. Line pressure testAT- 4 8

6. Torque converter clutch solenoid valveAT- 11 9

7. Control valve assemblyAT- 2 1 6

OFF vehicle 8. Torque converterAT- 2 4 0

Torque converter

clutch piston slip.ON vehicle1. A/T fluid levelMA-22

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. Torque converter clutch solenoid valveAT- 11 9

5. Line pressure solenoid valveAT- 1 2 9

6. Control valve assemblyAT- 2 1 6

OFF vehicle 7. Torque converterAT- 2 4 0

Lock-up point is ex-

tremely high or low.ON vehicle1. Accelerator pedal position sensorEC-4932. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Torque converter clutch solenoid valveAT- 11 9

4. Control valve assemblyAT- 2 1 6

Shift ShockSharp shock in shift-

ing from “N” to “D” po-

sition.ON vehicle1. Engine idling speedEC-73

2. Accelerator pedal position sensorEC-493

3. Line pressure testAT- 4 8

4. A/T fluid temperature sensorAT- 9 1

5. Engine speed signalAT- 1 0 1

6. Line pressure solenoid valveAT- 1 2 9

7. Control valve assemblyAT- 2 1 6

8. Accumulator N-DAT- 2 1 6

OFF vehicle 9. Forward clutchAT- 2 8 8

Too sharp a shock in

changing from D

1 to

D

2 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Line pressure testAT- 4 8

3. Accumulator servo releaseAT- 2 1 6

4. Control valve assemblyAT- 2 1 6

5. A/T fluid temperature sensorAT- 9 1

OFF vehicle 6. Brake bandAT- 3 0 7

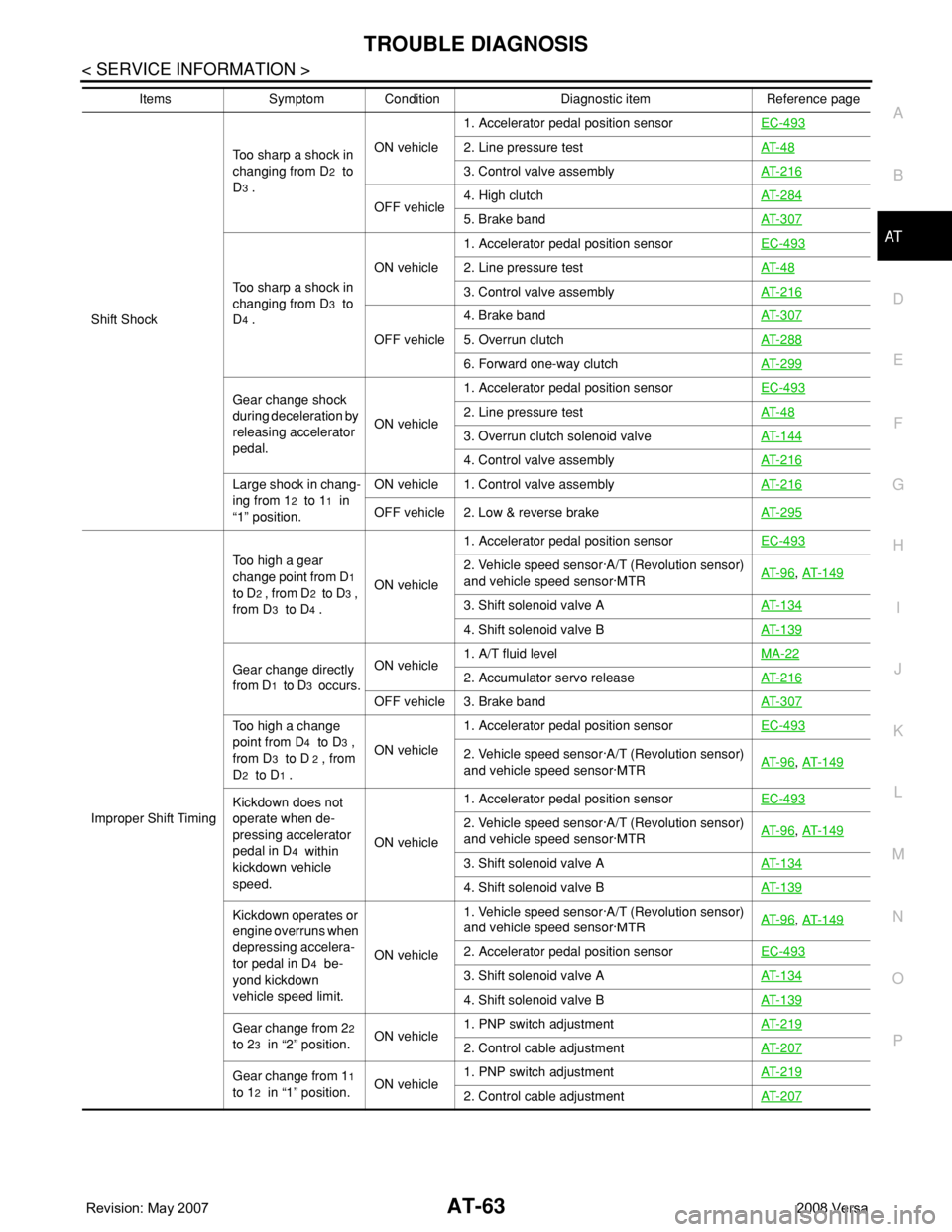

Page 75 of 2771

TROUBLE DIAGNOSIS

AT-63

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Shift ShockToo sharp a shock in

changing from D

2 to

D

3 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Line pressure testAT- 4 8

3. Control valve assemblyAT- 2 1 6

OFF vehicle4. High clutchAT- 2 8 45. Brake bandAT- 3 0 7

Too sharp a shock in

changing from D

3 to

D

4 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Line pressure testAT- 4 8

3. Control valve assemblyAT- 2 1 6

OFF vehicle4. Brake bandAT- 3 0 75. Overrun clutchAT- 2 8 8

6. Forward one-way clutchAT- 2 9 9

Gear change shock

during deceleration by

releasing accelerator

pedal.ON vehicle1. Accelerator pedal position sensorEC-4932. Line pressure testAT- 4 8

3. Overrun clutch solenoid valveAT- 1 4 4

4. Control valve assemblyAT- 2 1 6

Large shock in chang-

ing from 1

2 to 11 in

“1” position.ON vehicle 1. Control valve assemblyAT- 2 1 6OFF vehicle 2. Low & reverse brakeAT- 2 9 5

Improper Shift TimingToo high a gear

change point from D

1

to D

2 , from D2 to D3 ,

from D

3 to D4 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Shift solenoid valve AAT- 1 3 4

4. Shift solenoid valve BAT- 1 3 9

Gear change directly

from D

1 to D3 occurs.ON vehicle1. A/T fluid levelMA-222. Accumulator servo releaseAT- 2 1 6

OFF vehicle 3. Brake bandAT- 3 0 7

Too high a change

point from D

4 to D3 ,

from D

3 to D 2 , from

D

2 to D1 .ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

Kickdown does not

operate when de-

pressing accelerator

pedal in D

4 within

kickdown vehicle

speed.ON vehicle1. Accelerator pedal position sensorEC-493

2. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6, AT- 1 4 9

3. Shift solenoid valve AAT- 1 3 4

4. Shift solenoid valve BAT- 1 3 9

Kickdown operates or

engine overruns when

depressing accelera-

tor pedal in D

4 be-

yond kickdown

vehicle speed limit.ON vehicle1. Vehicle speed sensor·A/T (Revolution sensor)

and vehicle speed sensor·MTRAT- 9 6

, AT- 1 4 9

2. Accelerator pedal position sensorEC-493

3. Shift solenoid valve AAT- 1 3 4

4. Shift solenoid valve BAT- 1 3 9

Gear change from 22

to 2

3 in “2” position.ON vehicle1. PNP switch adjustmentAT- 2 1 92. Control cable adjustmentAT- 2 0 7

Gear change from 11

to 1

2 in “1” position.ON vehicle1. PNP switch adjustmentAT- 2 1 92. Control cable adjustmentAT- 2 0 7

Items Symptom Condition Diagnostic item Reference page