battery NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 10 of 2771

ACCELERATOR CONTROL SYSTEM

ACC-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

ACC

N

P O

ACCELERATOR CONTROL SYSTEM

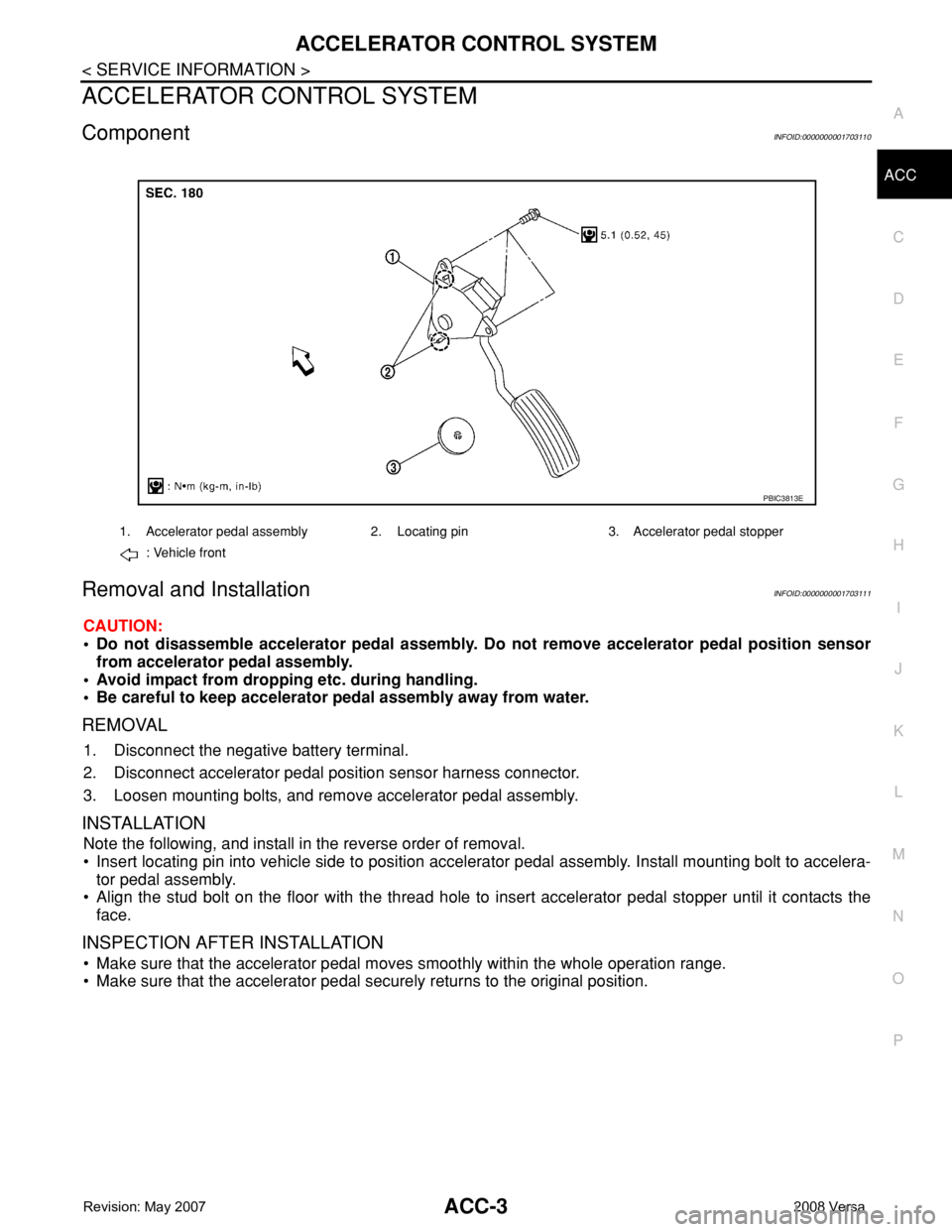

ComponentINFOID:0000000001703110

Removal and InstallationINFOID:0000000001703111

CAUTION:

• Do not disassemble accelerator pedal assembly. Do not remove accelerator pedal position sensor

from accelerator pedal assembly.

• Avoid impact from dropping etc. during handling.

• Be careful to keep accelerator pedal assembly away from water.

REMOVAL

1. Disconnect the negative battery terminal.

2. Disconnect accelerator pedal position sensor harness connector.

3. Loosen mounting bolts, and remove accelerator pedal assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Insert locating pin into vehicle side to position accelerator pedal assembly. Install mounting bolt to accelera-

tor pedal assembly.

• Align the stud bolt on the floor with the thread hole to insert accelerator pedal stopper until it contacts the

face.

INSPECTION AFTER INSTALLATION

• Make sure that the accelerator pedal moves smoothly within the whole operation range.

• Make sure that the accelerator pedal securely returns to the original position.

1. Accelerator pedal assembly 2. Locating pin 3. Accelerator pedal stopper

: Vehicle front

PBIC3813E

Page 13 of 2771

AT-1

TRANSMISSION/TRANSAXLE

D

E

F

G

H

I

J

K

L

M

SECTION AT

A

B

AT

N

O

P

CONTENTS

AUTOMATIC TRANSAXLE

SERVICE INFORMATION ............................5

INDEX FOR DTC .................................................5

Alphabetical Index .....................................................5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

7

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................10

Special Service Tool ...............................................10

Commercial Service Tool ........................................13

A/T FLUID ...........................................................15

Checking A/T Fluid ..................................................15

Changing A/T Fluid .................................................15

A/T Fluid Cooler Cleaning .......................................16

A/T CONTROL SYSTEM ....................................19

Cross-Sectional View ..............................................19

Shift Mechanism ......................................................19

TCM Function ..........................................................27

CAN Communication ...............................................28

Input/Output Signal of TCM .....................................28

Line Pressure Control .............................................29

Shift Control ............................................................30

Lock-up Control .......................................................31

Engine Brake Control (Overrun Clutch Control) ......32

Control Valve ...........................................................34

Centrifugal Cancel Mechanism ...............................34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......36

Introduction .............................................................36

OBD-II Function for A/T System ..............................36

One or Two Trip Detection Logic of OBD-II .............36

OBD-II Diagnostic Trouble Code (DTC) ..................36

Malfunction Indicator Lamp (MIL) ............................38

TROUBLE DIAGNOSIS ....................................39

DTC Inspection Priority Chart ..................................39

Fail-Safe ..................................................................39

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

40

A/T Electrical Parts Location ...................................46

Circuit Diagram ........................................................47

Inspections Before Trouble Diagnosis .....................48

Road Test ................................................................52

Check Before Engine Is Started ..............................53

Check at Idle ............................................................53

Cruise Test - Part 1 .................................................55

Cruise Test - Part 2 .................................................58

Cruise Test - Part 3 .................................................59

Vehicle Speed at Which Gear Shifting Occurs ........61

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

61

Symptom Chart ........................................................61

TCM Terminal and Reference Value .......................71

CONSULT-III Function (A/T) ...................................73

Diagnosis Procedure without CONSULT-III ............78

DTC U1000 CAN COMMUNICATION LINE .....83

Description ...............................................................83

On Board Diagnosis Logic .......................................83

Possible Cause ........................................................83

DTC Confirmation Procedure ..................................83

Wiring Diagram - AT - CAN .....................................84

Diagnosis Procedure ...............................................85

DTC P0705 PARK/NEUTRAL POSITION

(PNP) SWITCH ..................................................

86

Description ...............................................................86

CONSULT-III Reference Value in Data Monitor

Mode ........................................................................

86

On Board Diagnosis Logic .......................................86

Possible Cause ........................................................86

Page 19 of 2771

PRECAUTIONS

AT-7

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703151

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001703152

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000001703153

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 20 of 2771

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

• Be sure to turn the ignition switch OFF and disconnect battery negative cable from battery negative

terminal before any repair or inspection work. The open/short circuit of related switches, sensors,

solenoid valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connectors are free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000001703154

•Before connecting or disconnecting the TCM harness connec-

tor, turn ignition switch OFF and disconnect the battery cable

from the negative terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if igni-

tion switch is turned off.

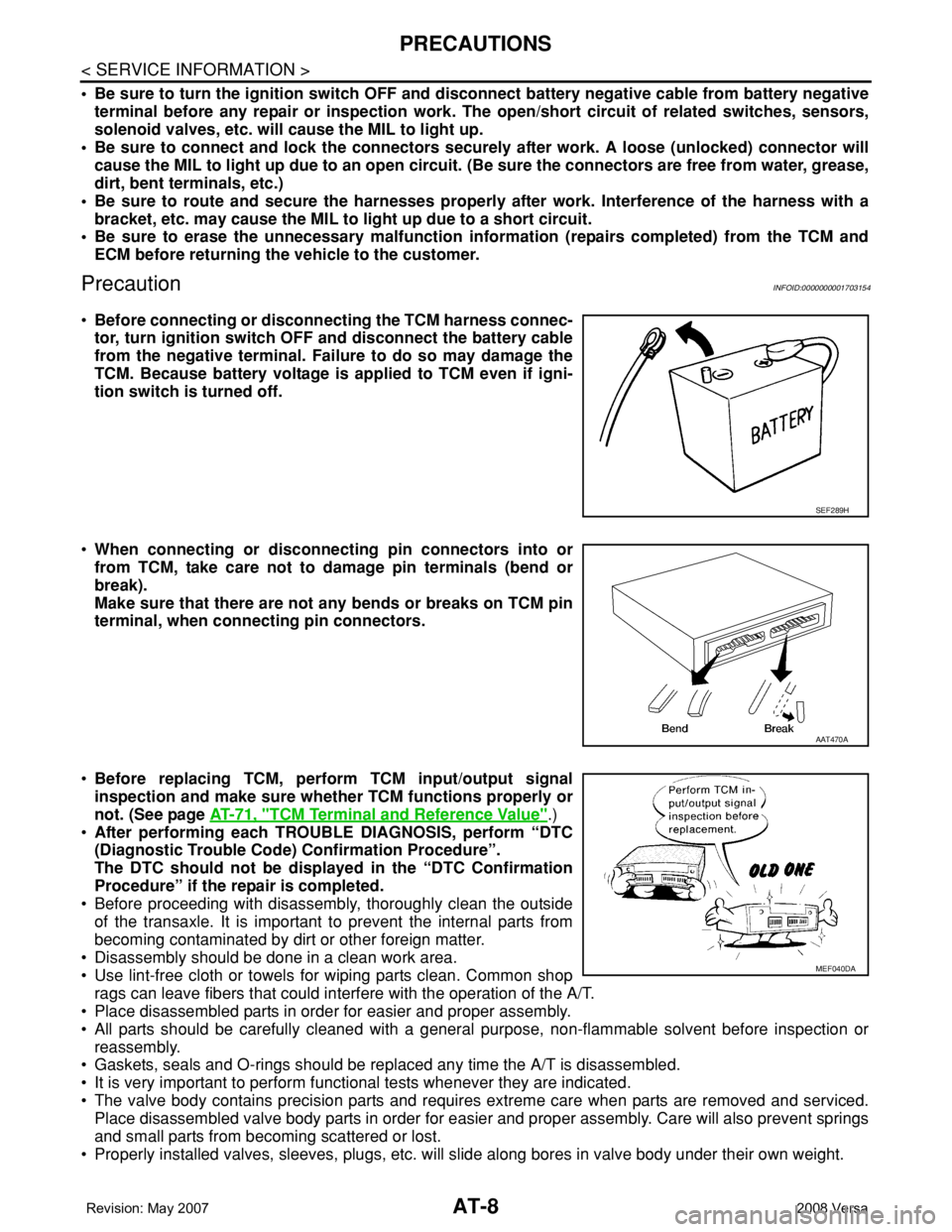

•When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM pin

terminal, when connecting pin connectors.

•Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. (See page AT-71, "

TCM Terminal and Reference Value".)

•After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) Confirmation Procedure”.

The DTC should not be displayed in the “DTC Confirmation

Procedure” if the repair is completed.

• Before proceeding with disassembly, thoroughly clean the outside

of the transaxle. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop

rags can leave fibers that could interfere with the operation of the A/T.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

• Gaskets, seals and O-rings should be replaced any time the A/T is disassembled.

• It is very important to perform functional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

SEF289H

AAT470A

MEF040DA

Page 49 of 2771

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-37

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-III screen, not on the GST. For

detail, refer to EC-109, "

CONSULT-II Function (ENGINE)" .

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame data (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT-III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

•If the battery cable is disconnected, the diagnostic trouble code will be cleared within 24 hours.

•When you erase the DTC, using CONSULT-III or GST is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-47, "

Emission-related Diagnostic Information" .

•Diagnostic trouble codes (DTC)

•1st trip diagnostic trouble codes (1st trip DTC)

•Freeze frame data

•1st trip freeze frame data

•System readiness test (SRT) codes

•Test values

HOW TO ERASE DTC (WITH CONSULT-III)

•If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-III “ON” and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer to AT-78, "

Diagnosis Procedure

without CONSULT-III" . (The engine warm-up step can be skipped when performing the diagnosis only to

erase the DTC.)

3. Select Mode 4 with Generic Scan Tool (GST). For details, refer to EC-119, "

Generic Scan Tool (GST)

Function" .

HOW TO ERASE DTC (NO TOOLS)

The OD OFF indicator lamp is located on the combination meter.

Priority Items

1

Freeze frame dataMisfire — DTC: P0300 - P0306

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 83 of 2771

TROUBLE DIAGNOSIS

AT-71

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

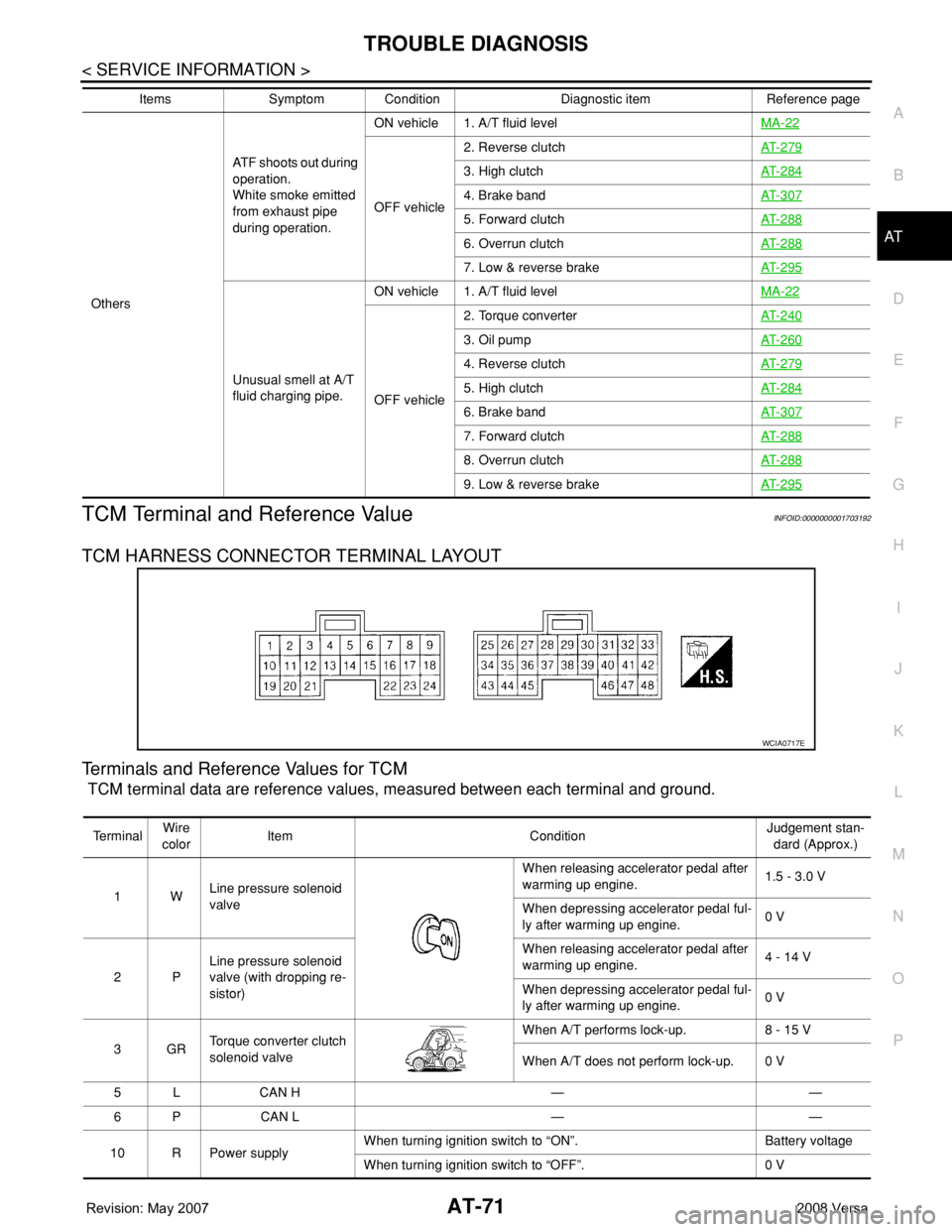

TCM Terminal and Reference ValueINFOID:0000000001703192

TCM HARNESS CONNECTOR TERMINAL LAYOUT

Terminals and Reference Values for TCM

TCM terminal data are reference values, measured between each terminal and ground.

OthersATF shoots out during

operation.

White smoke emitted

from exhaust pipe

during operation.ON vehicle 1. A/T fluid levelMA-22

OFF vehicle2. Reverse clutchAT- 2 7 9

3. High clutchAT- 2 8 4

4. Brake bandAT- 3 0 7

5. Forward clutchAT- 2 8 8

6. Overrun clutchAT- 2 8 8

7. Low & reverse brakeAT- 2 9 5

Unusual smell at A/T

fluid charging pipe.ON vehicle 1. A/T fluid levelMA-22

OFF vehicle2. Torque converterAT- 2 4 0

3. Oil pumpAT- 2 6 0

4. Reverse clutchAT- 2 7 9

5. High clutchAT- 2 8 4

6. Brake bandAT- 3 0 7

7. Forward clutchAT- 2 8 8

8. Overrun clutchAT- 2 8 8

9. Low & reverse brakeAT- 2 9 5

Items Symptom Condition Diagnostic item Reference page

WCIA0717E

Te r m i n a lWire

colorItem ConditionJudgement stan-

dard (Approx.)

1WLine pressure solenoid

valveWhen releasing accelerator pedal after

warming up engine.1.5 - 3.0 V

When depressing accelerator pedal ful-

ly after warming up engine.0 V

2PLine pressure solenoid

valve (with dropping re-

sistor)When releasing accelerator pedal after

warming up engine.4 - 14 V

When depressing accelerator pedal ful-

ly after warming up engine.0 V

3GRTorque converter clutch

solenoid valveWhen A/T performs lock-up. 8 - 15 V

When A/T does not perform lock-up. 0 V

5 L CAN H — —

6 P CAN L — —

10 R Power supplyWhen turning ignition switch to “ON”. Battery voltage

When turning ignition switch to “OFF”. 0 V

Page 84 of 2771

AT-72

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

11 O Shift solenoid valve AWhen shift solenoid valve A operates.

(When driving in “D

1” or “D4”.)Battery voltage

When shift solenoid valve A does not

operate.

(When driving in “D

2” or “D3”.)0 V

12 G Shift solenoid valve BWhen shift solenoid valve B operates.

(When driving in “D

1” or “D2”.)Battery voltage

When shift solenoid valve B does not

operate.

(When driving in “D

3” or “D4”.)0 V

19 R Power supplyWhen turning ignition switch to “ON”. Battery voltage

When turning ignition switch to “OFF”. 0 V

20 VOverrun clutch solenoid

valveWhen overrun clutch solenoid valve op-

erates. (When overrun clutch disen-

gaged. Refer to AT- 1 9

.)Battery voltage

When overrun clutch solenoid valve

does not operate. (When overrun clutch

engaged. Refer to AT- 1 9

.)0 V

25 B Ground Always 0 V

26 Y PNP switch “1” position

and When setting selector lever to “1” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

27 G PNP switch “2” positionWhen setting selector lever to “2” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

28 GRPower supply

(memory back-up)Always Battery voltage

29 V Revolution sensor When driving at 20 km/h (12 MPH) 150 Hz

30

*1BR CONSULT- III (RX) — —

31

*1Y CONSULT- III (TX) — —

34 LG PNP switch “D” position

and When setting selector lever to “D” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

35 SB PNP switch “R” positionWhen setting selector lever to “R” posi-

tion.Battery voltage

When setting selector lever to other po-

sitions.0 V

36 RPNP switch “N” or “P”

positionWhen setting selector lever to “N” or “P”

position.Battery voltage

When setting selector lever to other po-

sitions.0 V

38 GTurbine revolution sen-

sor (power train revolu-

tion sensor)When driving at 20 km/h (12 MPH) 360 Hz Te r m i n a lWire

colorItem ConditionJudgement stan-

dard (Approx.)

Page 86 of 2771

AT-74

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

FLUID TEMP SE When A/T fluid temperature is 20°C (68°F). 1.5 V

When A/T fluid temperature is 80°C (176°F). 0.5 V

BATTERY VOLT When turning ignition switch to “ON”. Battery voltage

ENGINE SPEED Engine runningApproximately matches the tachometer

reading.

TURBINE REV During driving (lock-up ON) Approximately matches the engine speed.

OVERDRIVE SWWhen overdrive control switch is depressed. ON

When overdrive control switch is released. OFF

PN POSI SWWhen setting selector lever to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SWWhen setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SWWhen setting selector lever to “D” position. ON

When setting selector lever to other positions. OFF

2 POSITION SWWhen setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SWWhen setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

CLOSED THL/SWReleased accelerator pedal. ON

Depressed accelerator pedal. OFF

W/O THRL/P-SWFully depressed accelerator pedal. ON

Released accelerator pedal. OFF

SHIFT S/V AWhen shift solenoid valve A operates.

(When driving in “D

1” or “D4”.)ON

When shift solenoid valve A does not operate.

(When driving in “D

2” or “D3”.)OFF

SHIFT S/V BWhen shift solenoid valve B operates.

(When driving in “D

1” or “D2”.)ON

When shift solenoid valve B does not operate.

(When driving in “D

3” or “D4”.)OFF

OVERRUN/C S/VWhen overrun clutch solenoid valve operates.

(When overrun clutch disengaged. Refer to AT-

19 .)ON

When overrun clutch solenoid valve does not

operate. (When overrun clutch engaged. Refer

to AT- 1 9

.)OFF

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

GEAR During driving 1, 2, 3, 4

SLCT LVR POSIWhen setting selector lever to “N” or “P” posi-

tions.N · P

When setting selector lever to “R” position. R

When setting selector lever to “D” position. D

When setting selector lever to “2” position. 2

When setting selector lever to “1” position. 1

VEHICLE SPEED During drivingApproximately matches the speedometer

reading. Item name Condition Display value (Approx.)

Page 88 of 2771

AT-76

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*1: Refer to AT- 3 8 , "Malfunction Indicator Lamp (MIL)" .

*2: These malfunctions cannot be displayed MIL if another malfunction is assigned to MIL.

DATA MONITOR MODE

Display Items List

X: Standard, —: Not applicable, : Option

CONTROL UNIT (ROM) • TCM memory (ROM) is malfunctioning. —AT- 1 6 3

No failure

(NO SELF DIAGNOS-

TIC FAILURE INDICAT-

ED FURTHER

TESTING MAY BE RE-

QUIRED)• No failure has been detected. — — Items (CONSULT-III

screen terms)Malfunction is detected when...OBD-II (DTC)

Reference

page MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III

or GST

Monitored item (Unit)Monitor Item Selection

Remarks

TCM INPUT

SIGNALSMAIN SIG-

NALSSELEC-

TION FROM

MENU

VHCL/S SE-A/T (km/h)X — Revolution sensor

VHCL/S SE-MTR (km/h) X —Vehicle speed display may not be accu-

rate under approx. 10 km/h (6 mph). It

may not indicate 0 km/h (0 mph) when

vehicle is stationary.

THRTL POS SEN (V) X —

FLUID TEMP SE (V) X —

BATTERY VOLT (V) X —

ENGINE SPEED (rpm) X X

TURBINE REV (rpm) X —

OVERDRIVE SW (ON/OFF) X —

PN POSI SW (ON/OFF) X —

R POSITION SW (ON/OFF) X —

D POSITION SW (ON/OFF) X —

2 POSITION SW (ON/OFF) X —

1 POSITION SW (ON/OFF) X —

ASCD-CRUISE (ON/OFF) X —

Signal input with CAN communication.

ASCD-OD CUT (ON/OFF) X —

KICKDOWN SW (ON/OFF) X —

Not mounted but displayed.

POWERSHIFT SW (ON/OFF) X —

CLOSED THL/SW (ON/OFF) X —

Signal input with CAN communication.

W/O THRL/P-SW (ON/OFF) X —

Page 100 of 2771

AT-88

< SERVICE INFORMATION >

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Diagnosis Procedure

INFOID:0000000001703207

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-III.

3. Read out “P·N”, “R”, “D”, “2” and “1” position switches moving selector lever to each position.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

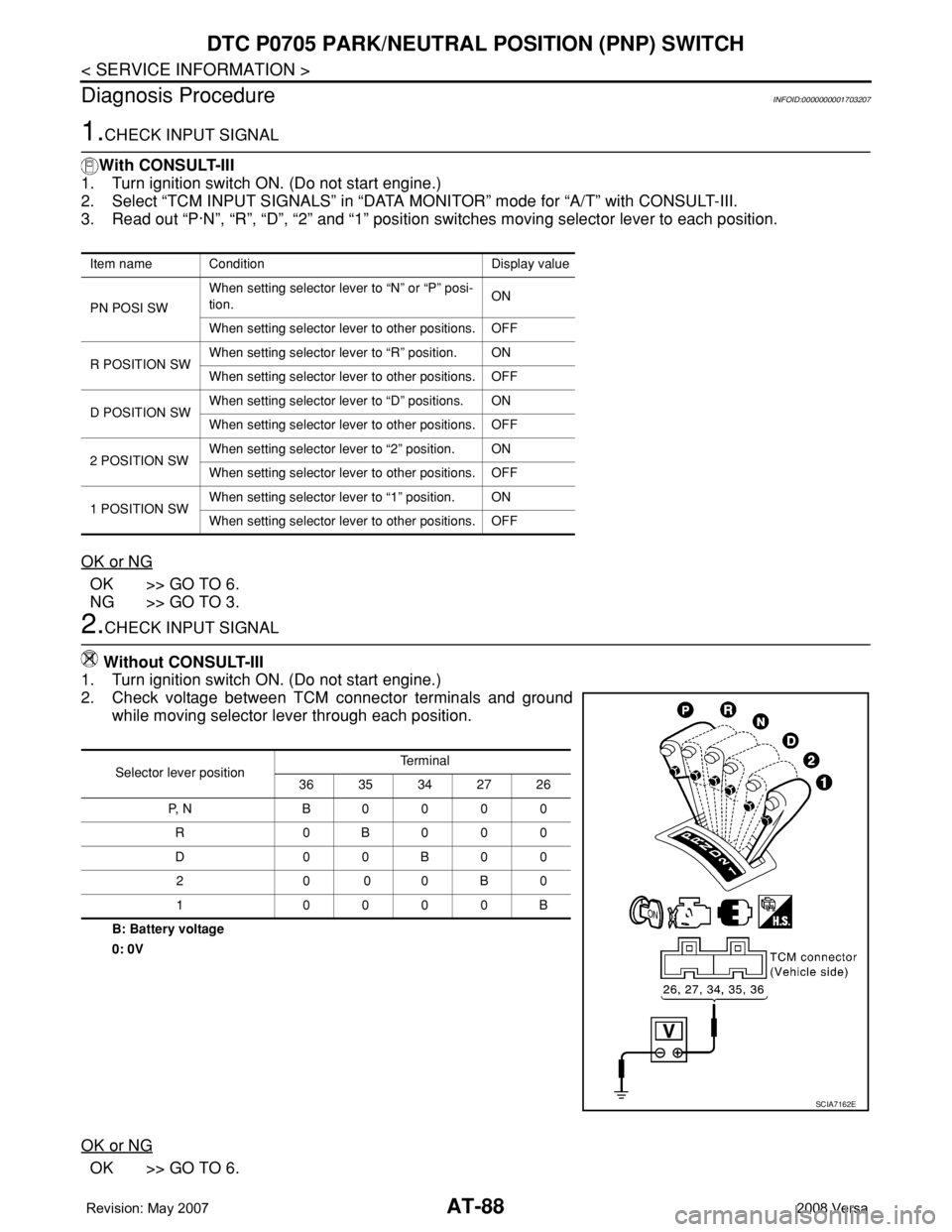

2.CHECK INPUT SIGNAL

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground

while moving selector lever through each position.

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 6.

Item name Condition Display value

PN POSI SWWhen setting selector lever to “N” or “P” posi-

tion.ON

When setting selector lever to other positions. OFF

R POSITION SWWhen setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SWWhen setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SWWhen setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SWWhen setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Selector lever positionTe r m i n a l

36 35 34 27 26

P, N B0000

R 0B000

D00B00

20 00B0

1 0000B

SCIA7162E