engine NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 1034 of 2771

COMBINATION METERS

DI-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

CONSULT-III Function (METER/M&A)INFOID:0000000001704498

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULTS

Display Item List

NOTE:

“TIME” indicates the following.

• 0: Indicates that a malfunction is detected at present.

• 1-63: Indicates that a malfunction was dectected in the past. (Displays number of ignition switch OFF → ON

cycles after malfunction is detected. Self-diagnostic result is erased when “63” is exceded.)

DATA MONITOR

Display Item List

METER diagnosis mode Description

SELF-DIAG RESULTS Displays combination meter self-diagnosis results.

DATA MONITOR Displays combination meter input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

CONSULT-III display Malfunction Reference page

CAN COMM CIRC [U1000]Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfunction on CAN communication system, mal-

function may be misinterpreted when battery has low voltage (when main-

taining 7 - 8 V for about 2 seconds) or 10A fuse [No. 14, located in the fuse

block (J/B)] is removed.DI-19

VEHICLE SPEED CIRC [B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunctions

may be misinterpreted when battery has low voltage (when maintaining 7

- 8 V for about 2 seconds).DI-16

Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUContents

SPEED METER [km/h] X XThe value of vehicle speed signal, which is input from ABS ac-

tuator and electric unit (control unit).

SPEED OUTPUT [km/h] X XThe value of vehicle speed signal, which is transmitted to each

unit with CAN communication.

TACHO METER [rpm] X X The value of engine speed signal, which is input from ECM.

W TEMP METER [°C] X XThe value of engine coolant temperature signal, which is input

from ECM.

FUEL METER [lit.] X XThe value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] X XThe value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and fuel

consumption signal from ECM.

FUEL W/L [ON/OFF] X X Indicates [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] XIndicates [ON/OFF] condition of malfunction indicator lamp

(MIL).

AIR PRES W/L X Indicates [ON/OFF] condition of low tire pressure warning lamp.

SEAT BELT W/L X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Indicates [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Indicates [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Indicates [ON/OFF] condition of high beam indicator lamp.

Page 1036 of 2771

COMBINATION METERS

DI-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

NO >> Check power supply and ground circuit of combination meter. Refer to DI-15, "Power Supply and

Ground Circuit Inspection" .

2.CHECK COMBINATION METER (CONSULT-III)

Select “METER/M&A” on CONSULT-III and perform self-diagnosis of combination meter. Refer to DI-13,

"CONSULT-III Function (METER/M&A)" .

Self

-diagnostic results content

No malfunction detected>> Refer to DI-15, "Symptom Chart" .

Malfunction detected>> Refer to DI-13, "

CONSULT-III Function (METER/M&A)" .

Symptom ChartINFOID:0000000001704500

Power Supply and Ground Circuit InspectionINFOID:0000000001704501

1.CHECK FUSE

Check for blown combination meter fuses.

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3

.

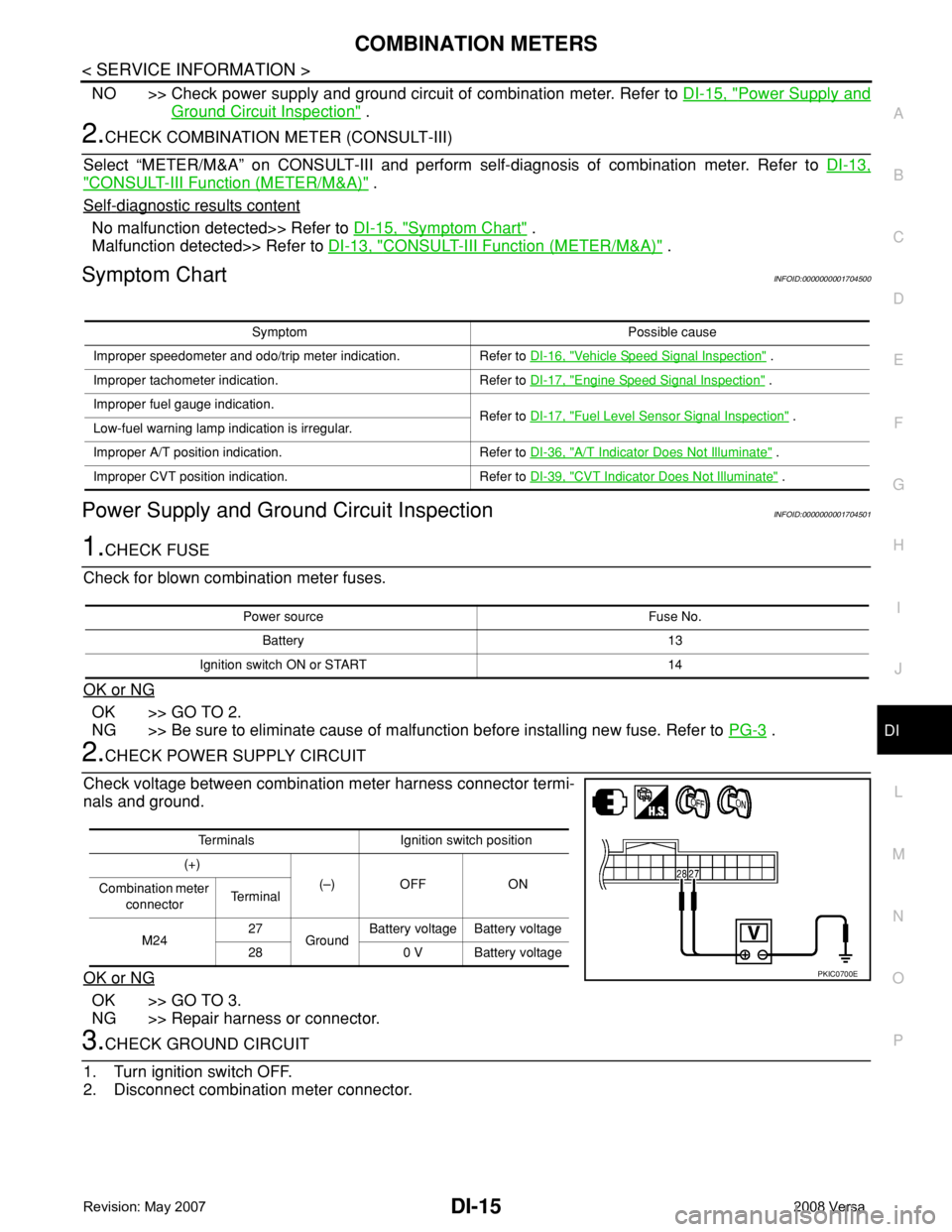

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between combination meter harness connector termi-

nals and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

Symptom Possible cause

Improper speedometer and odo/trip meter indication. Refer to DI-16, "

Vehicle Speed Signal Inspection" .

Improper tachometer indication. Refer to DI-17, "

Engine Speed Signal Inspection" .

Improper fuel gauge indication.

Refer to DI-17, "

Fuel Level Sensor Signal Inspection" .

Low-fuel warning lamp indication is irregular.

Improper A/T position indication. Refer to DI-36, "

A/T Indicator Does Not Illuminate" .

Improper CVT position indication. Refer to DI-39, "

CVT Indicator Does Not Illuminate" .

Power source Fuse No.

Battery 13

Ignition switch ON or START 14

Terminals Ignition switch position

(+)

(–) OFF ON

Combination meter

connectorTe r m i n a l

M2427

GroundBattery voltage Battery voltage

28 0 V Battery voltage

PKIC0700E

Page 1037 of 2771

DI-16

< SERVICE INFORMATION >

COMBINATION METERS

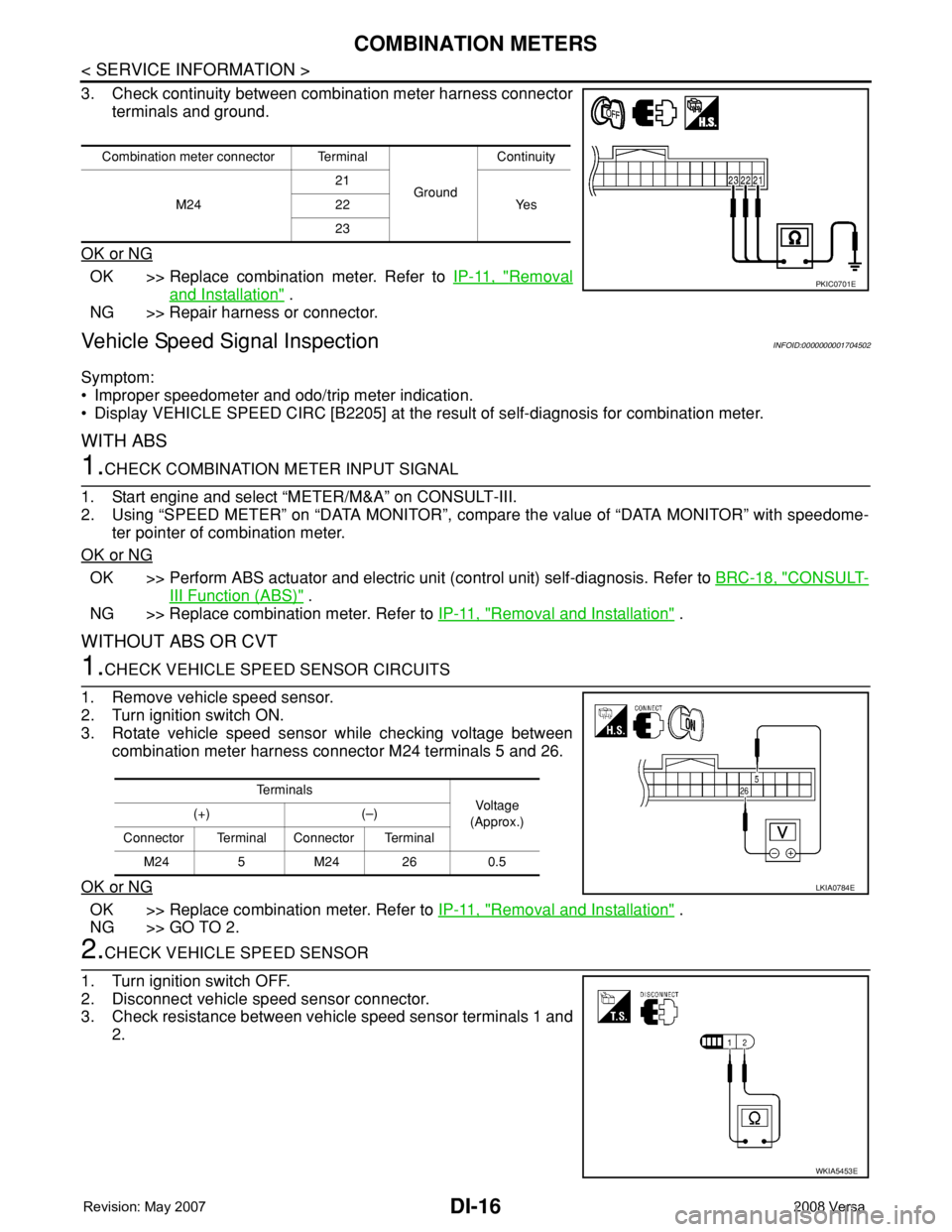

3. Check continuity between combination meter harness connector

terminals and ground.

OK or NG

OK >> Replace combination meter. Refer to IP-11, "Removal

and Installation" .

NG >> Repair harness or connector.

Vehicle Speed Signal InspectionINFOID:0000000001704502

Symptom:

• Improper speedometer and odo/trip meter indication.

• Display VEHICLE SPEED CIRC [B2205] at the result of self-diagnosis for combination meter.

WITH ABS

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “METER/M&A” on CONSULT-III.

2. Using “SPEED METER” on “DATA MONITOR”, compare the value of “DATA MONITOR” with speedome-

ter pointer of combination meter.

OK or NG

OK >> Perform ABS actuator and electric unit (control unit) self-diagnosis. Refer to BRC-18, "CONSULT-

III Function (ABS)" .

NG >> Replace combination meter. Refer to IP-11, "

Removal and Installation" .

WITHOUT ABS OR CVT

1.CHECK VEHICLE SPEED SENSOR CIRCUITS

1. Remove vehicle speed sensor.

2. Turn ignition switch ON.

3. Rotate vehicle speed sensor while checking voltage between

combination meter harness connector M24 terminals 5 and 26.

OK or NG

OK >> Replace combination meter. Refer to IP-11, "Removal and Installation" .

NG >> GO TO 2.

2.CHECK VEHICLE SPEED SENSOR

1. Turn ignition switch OFF.

2. Disconnect vehicle speed sensor connector.

3. Check resistance between vehicle speed sensor terminals 1 and

2.

Combination meter connector Terminal

GroundContinuity

M2421

Ye s 22

23

PKIC0701E

Te r m i n a l s

Voltag e

(Approx.) (+) (–)

Connector Terminal Connector Terminal

M24 5 M24 26 0.5

LKIA0784E

WKIA5453E

Page 1038 of 2771

COMBINATION METERS

DI-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

OK or NG

OK >> Check harness or connector between combination meter and vehicle speed sensor.

NG >> Replace vehicle speed sensor.

WITH CVT, WITHOUT ABS

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “METER/M&A” on CONSULT-III.

2. Using “SPEED METER” on “DATA MONITOR”, compare the value of “DATA MONITOR” with speedome-

ter pointer of combination meter.

OK or NG

OK >> Perform TCM self-diagnosis. Refer to CVT-47, "CONSULT-III Function (TRANSMISSION)" .

NG >> Replace combination meter. Refer to IP-11, "

Removal and Installation" .

Engine Speed Signal InspectionINFOID:0000000001704503

Symptom: Improper tachometer indication.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “METER/M&A” on CONSULT-III.

2. Using “TACHO METER” on “DATA MONITOR”, compare the value of “DATA MONITOR” with tachometer

pointer of combination meter.

OK or NG

OK >> Perform ECM self-diagnosis. Refer to EC-109, "CONSULT-II Function (ENGINE)" .

NG >> Replace combination meter. Refer to IP-11, "

Removal and Installation" .

Fuel Level Sensor Signal InspectionINFOID:0000000001704504

Symptom:

• Improper fuel gauge indication.

• Low-fuel warning lamp indication is irregular.

NOTE:

The following symptoms do not indicate a malfunction.

• Depending on vehicle position or driving circumstance, the fuel level in the tank shifts and the indication may

fluctuate.

• If the vehicle is fueled with the ignition switch ON, the indication will update slowly.

• If the vehicle is tilted when the ignition switch is turned ON, fuel in the tank may flow to one direction result-

ing in a change of reading.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Using “FUEL METER” on “DATA MONITOR”, compare the value of “DATA MONITOR” with fuel gauge

pointer of combination meter.

Te r m i n a l s

Resistance

value

(Approx.) (+) (–)

Component Terminal Component Terminal

Ve h i c l e

speed

sensor1Vehicle

speed

sensor2250Ω

Fuel gauge pointer Reference value of data monitor [lit.]

Full Approx. 49

3/4 Approx. 34

1/2 Approx. 22

1/4 Approx. 10

Empty Approx. 4

Page 1052 of 2771

WARNING LAMPS

DI-31

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

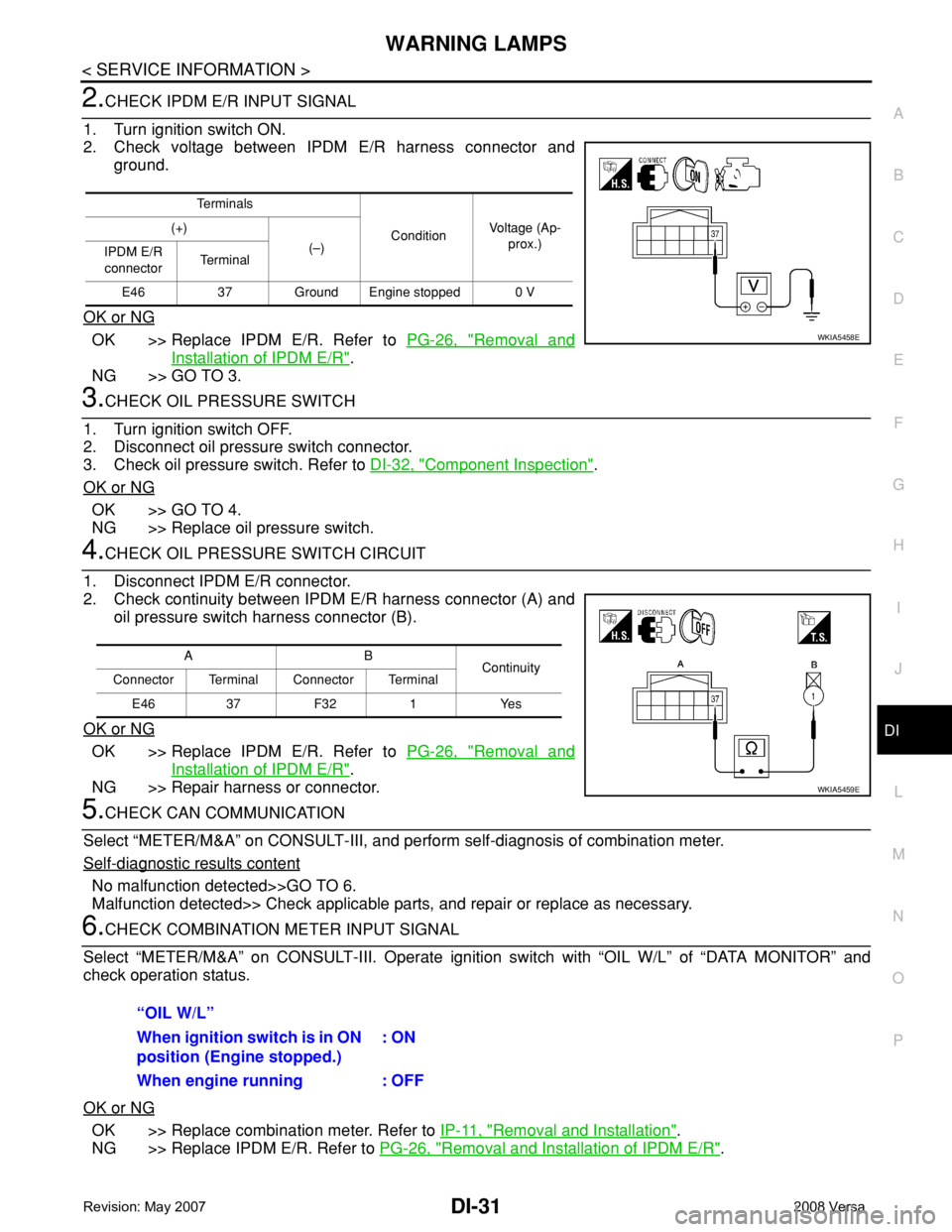

2.CHECK IPDM E/R INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R harness connector and

ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and

Installation of IPDM E/R".

NG >> GO TO 3.

3.CHECK OIL PRESSURE SWITCH

1. Turn ignition switch OFF.

2. Disconnect oil pressure switch connector.

3. Check oil pressure switch. Refer to DI-32, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Replace oil pressure switch.

4.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector (A) and

oil pressure switch harness connector (B).

OK or NG

OK >> Replace IPDM E/R. Refer to PG-26, "Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

5.CHECK CAN COMMUNICATION

Select “METER/M&A” on CONSULT-III, and perform self-diagnosis of combination meter.

Self

-diagnostic results content

No malfunction detected>>GO TO 6.

Malfunction detected>> Check applicable parts, and repair or replace as necessary.

6.CHECK COMBINATION METER INPUT SIGNAL

Select “METER/M&A” on CONSULT-III. Operate ignition switch with “OIL W/L” of “DATA MONITOR” and

check operation status.

OK or NG

OK >> Replace combination meter. Refer to IP-11, "Removal and Installation".

NG >> Replace IPDM E/R. Refer to PG-26, "

Removal and Installation of IPDM E/R".

Te r m i n a l s

ConditionVoltage (Ap-

prox.) (+)

(–)

IPDM E/R

connectorTe r m i n a l

E46 37 Ground Engine stopped 0 V

WKIA5458E

AB

Continuity

Connector Terminal Connector Terminal

E46 37 F32 1 Yes

WKIA5459E

“OIL W/L”

When ignition switch is in ON

position (Engine stopped.): ON

When engine running : OFF

Page 1054 of 2771

![NISSAN LATIO 2008 Service Repair Manual WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Check continuity between oil pressure switch and ground.

Condition

Oil pressure [kPa (bar, kg/cm2, psi)]Continuity

Engine st NISSAN LATIO 2008 Service Repair Manual WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Check continuity between oil pressure switch and ground.

Condition

Oil pressure [kPa (bar, kg/cm2, psi)]Continuity

Engine st](/img/5/57360/w960_57360-1053.png)

WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Check continuity between oil pressure switch and ground.

Condition

Oil pressure [kPa (bar, kg/cm2, psi)]Continuity

Engine stopped Less than 29 (0.3, 0.3, 4) Yes

Engine running More than 29 (0.3, 0.3, 4) No

ELF0044D

Page 1075 of 2771

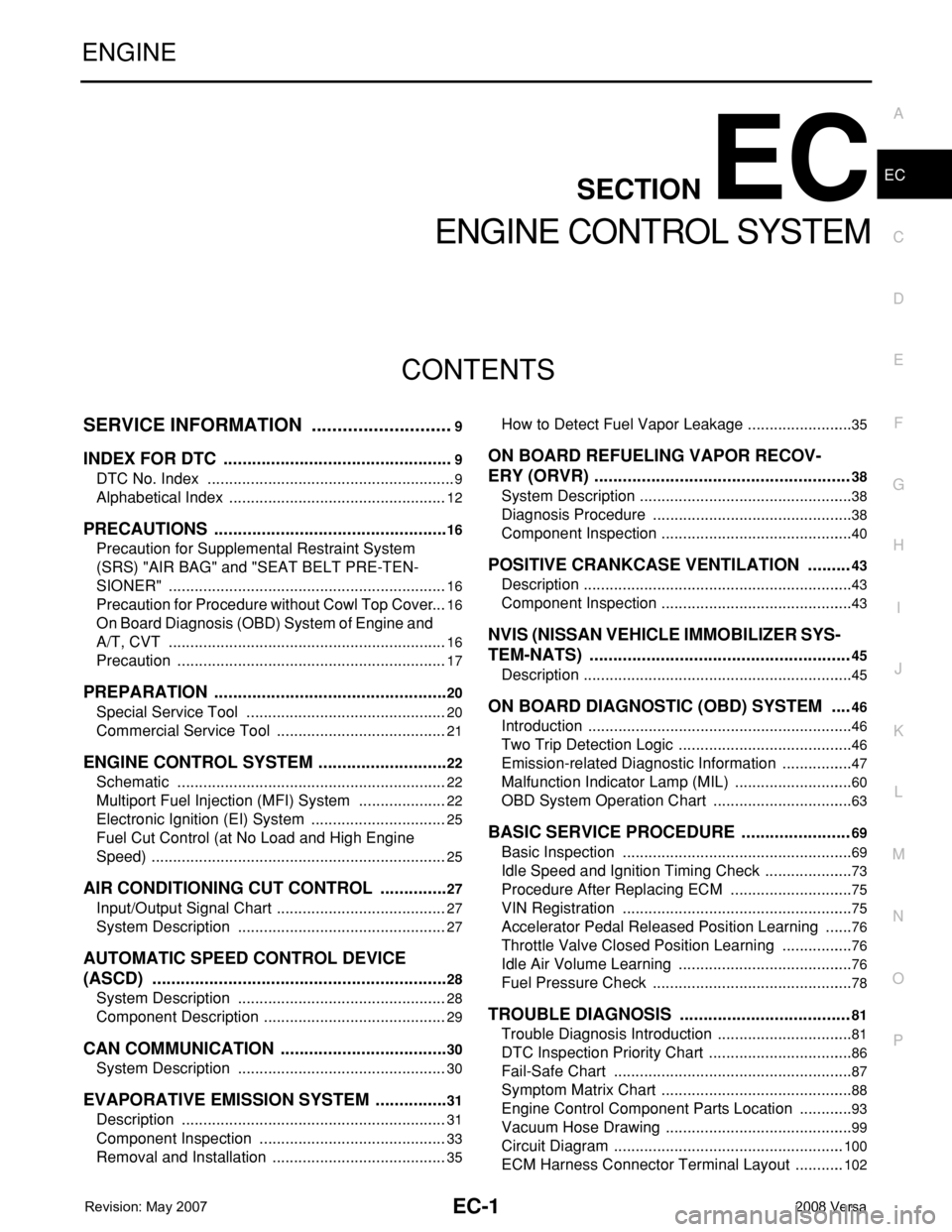

EC-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

N

O

P

CONTENTS

ENGINE CONTROL SYSTEM

SERVICE INFORMATION ............................9

INDEX FOR DTC .................................................9

DTC No. Index ..........................................................9

Alphabetical Index ...................................................12

PRECAUTIONS ..................................................16

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

16

Precaution for Procedure without Cowl Top Cover ....16

On Board Diagnosis (OBD) System of Engine and

A/T, CVT .................................................................

16

Precaution ...............................................................17

PREPARATION ..................................................20

Special Service Tool ...............................................20

Commercial Service Tool ........................................21

ENGINE CONTROL SYSTEM ............................22

Schematic ...............................................................22

Multiport Fuel Injection (MFI) System .....................22

Electronic Ignition (EI) System ................................25

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

25

AIR CONDITIONING CUT CONTROL ...............27

Input/Output Signal Chart ........................................27

System Description .................................................27

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

28

System Description .................................................28

Component Description ...........................................29

CAN COMMUNICATION ....................................30

System Description .................................................30

EVAPORATIVE EMISSION SYSTEM ................31

Description ..............................................................31

Component Inspection ............................................33

Removal and Installation .........................................35

How to Detect Fuel Vapor Leakage .........................35

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

38

System Description ..................................................38

Diagnosis Procedure ...............................................38

Component Inspection .............................................40

POSITIVE CRANKCASE VENTILATION .........43

Description ...............................................................43

Component Inspection .............................................43

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

45

Description ...............................................................45

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....46

Introduction ..............................................................46

Two Trip Detection Logic .........................................46

Emission-related Diagnostic Information .................47

Malfunction Indicator Lamp (MIL) ............................60

OBD System Operation Chart .................................63

BASIC SERVICE PROCEDURE .......................69

Basic Inspection ......................................................69

Idle Speed and Ignition Timing Check .....................73

Procedure After Replacing ECM .............................75

VIN Registration ......................................................75

Accelerator Pedal Released Position Learning .......76

Throttle Valve Closed Position Learning .................76

Idle Air Volume Learning .........................................76

Fuel Pressure Check ...............................................78

TROUBLE DIAGNOSIS ....................................81

Trouble Diagnosis Introduction ................................81

DTC Inspection Priority Chart ..................................86

Fail-Safe Chart ........................................................87

Symptom Matrix Chart .............................................88

Engine Control Component Parts Location .............93

Vacuum Hose Drawing ............................................99

Circuit Diagram ......................................................100

ECM Harness Connector Terminal Layout ............102

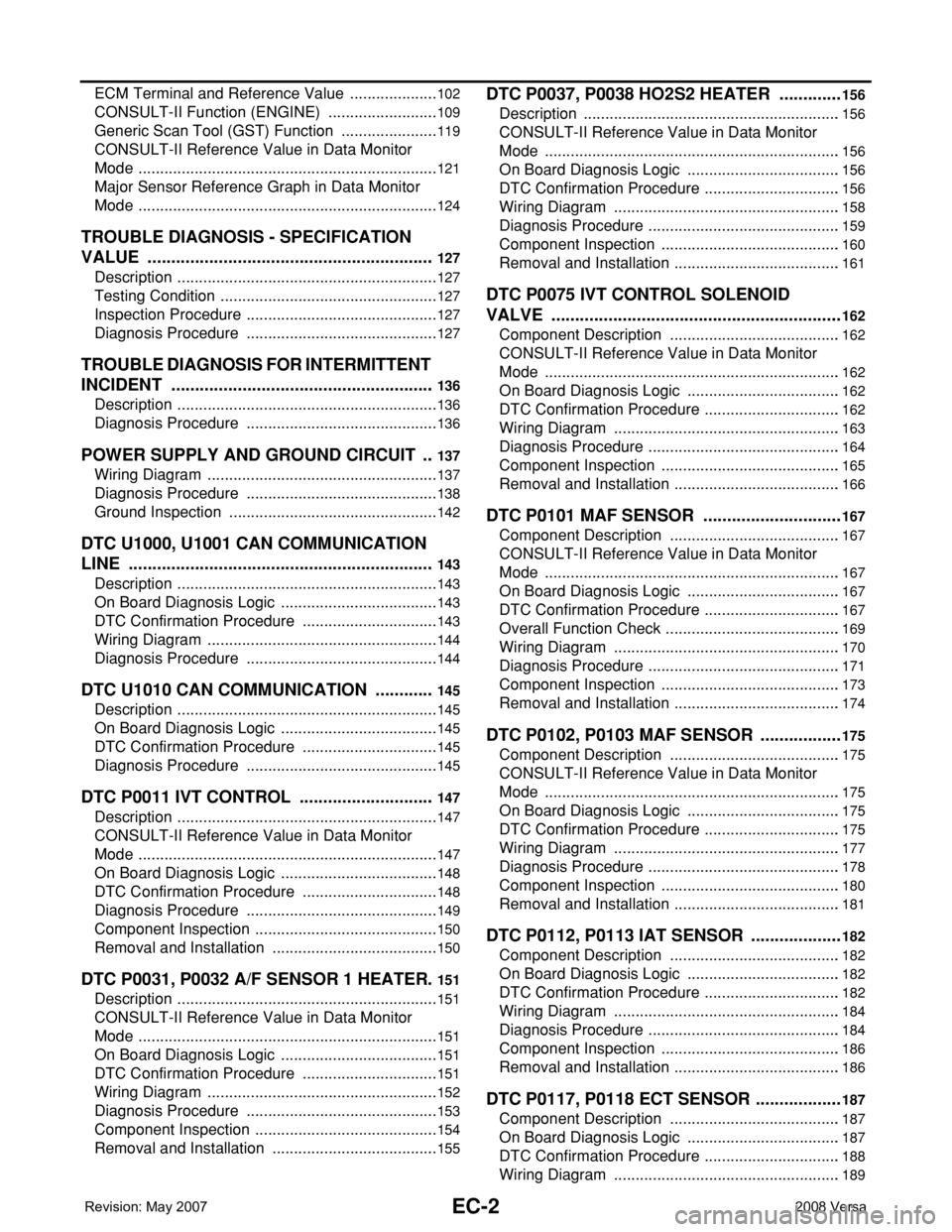

Page 1076 of 2771

EC-2

ECM Terminal and Reference Value .....................102

CONSULT-II Function (ENGINE) ..........................109

Generic Scan Tool (GST) Function .......................119

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

121

Major Sensor Reference Graph in Data Monitor

Mode ......................................................................

124

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

127

Description .............................................................127

Testing Condition ...................................................127

Inspection Procedure .............................................127

Diagnosis Procedure .............................................127

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT ........................................................

136

Description .............................................................136

Diagnosis Procedure .............................................136

POWER SUPPLY AND GROUND CIRCUIT ...137

Wiring Diagram ......................................................137

Diagnosis Procedure .............................................138

Ground Inspection .................................................142

DTC U1000, U1001 CAN COMMUNICATION

LINE .................................................................

143

Description .............................................................143

On Board Diagnosis Logic .....................................143

DTC Confirmation Procedure ................................143

Wiring Diagram ......................................................144

Diagnosis Procedure .............................................144

DTC U1010 CAN COMMUNICATION .............145

Description .............................................................145

On Board Diagnosis Logic .....................................145

DTC Confirmation Procedure ................................145

Diagnosis Procedure .............................................145

DTC P0011 IVT CONTROL .............................147

Description .............................................................147

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

147

On Board Diagnosis Logic .....................................148

DTC Confirmation Procedure ................................148

Diagnosis Procedure .............................................149

Component Inspection ...........................................150

Removal and Installation .......................................150

DTC P0031, P0032 A/F SENSOR 1 HEATER .151

Description .............................................................151

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

151

On Board Diagnosis Logic .....................................151

DTC Confirmation Procedure ................................151

Wiring Diagram ......................................................152

Diagnosis Procedure .............................................153

Component Inspection ...........................................154

Removal and Installation .......................................155

DTC P0037, P0038 HO2S2 HEATER ..............156

Description ............................................................156

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

156

On Board Diagnosis Logic ....................................156

DTC Confirmation Procedure ................................156

Wiring Diagram .....................................................158

Diagnosis Procedure .............................................159

Component Inspection ..........................................160

Removal and Installation .......................................161

DTC P0075 IVT CONTROL SOLENOID

VALVE ..............................................................

162

Component Description ........................................162

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

162

On Board Diagnosis Logic ....................................162

DTC Confirmation Procedure ................................162

Wiring Diagram .....................................................163

Diagnosis Procedure .............................................164

Component Inspection ..........................................165

Removal and Installation .......................................166

DTC P0101 MAF SENSOR ..............................167

Component Description ........................................167

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

167

On Board Diagnosis Logic ....................................167

DTC Confirmation Procedure ................................167

Overall Function Check .........................................169

Wiring Diagram .....................................................170

Diagnosis Procedure .............................................171

Component Inspection ..........................................173

Removal and Installation .......................................174

DTC P0102, P0103 MAF SENSOR ..................175

Component Description ........................................175

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

175

On Board Diagnosis Logic ....................................175

DTC Confirmation Procedure ................................175

Wiring Diagram .....................................................177

Diagnosis Procedure .............................................178

Component Inspection ..........................................180

Removal and Installation .......................................181

DTC P0112, P0113 IAT SENSOR ....................182

Component Description ........................................182

On Board Diagnosis Logic ....................................182

DTC Confirmation Procedure ................................182

Wiring Diagram .....................................................184

Diagnosis Procedure .............................................184

Component Inspection ..........................................186

Removal and Installation .......................................186

DTC P0117, P0118 ECT SENSOR ...................187

Component Description ........................................187

On Board Diagnosis Logic ....................................187

DTC Confirmation Procedure ................................188

Wiring Diagram .....................................................189

Page 1080 of 2771

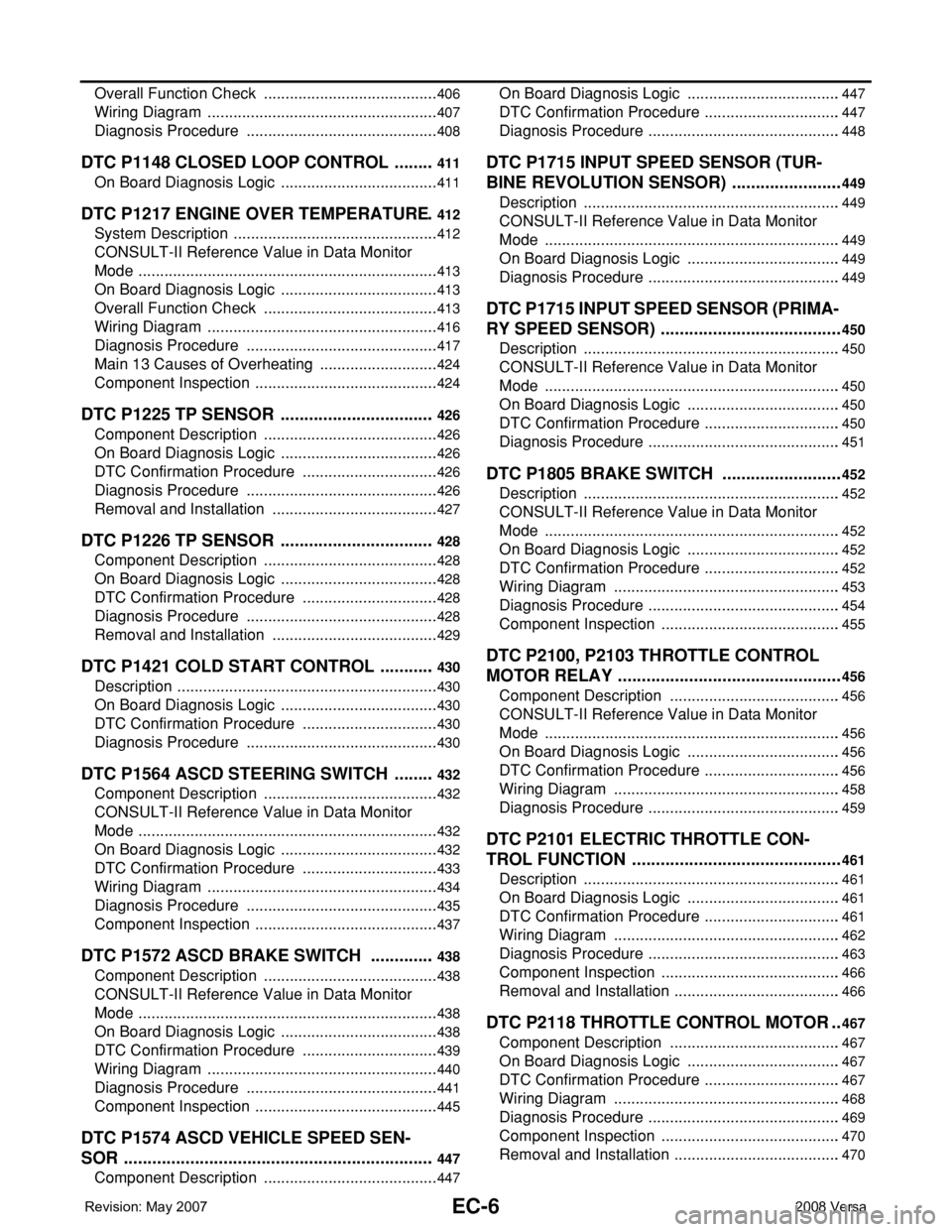

EC-6

Overall Function Check .........................................406

Wiring Diagram ......................................................407

Diagnosis Procedure .............................................408

DTC P1148 CLOSED LOOP CONTROL .........411

On Board Diagnosis Logic .....................................411

DTC P1217 ENGINE OVER TEMPERATURE .412

System Description ................................................412

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

413

On Board Diagnosis Logic .....................................413

Overall Function Check .........................................413

Wiring Diagram ......................................................416

Diagnosis Procedure .............................................417

Main 13 Causes of Overheating ............................424

Component Inspection ...........................................424

DTC P1225 TP SENSOR .................................426

Component Description .........................................426

On Board Diagnosis Logic .....................................426

DTC Confirmation Procedure ................................426

Diagnosis Procedure .............................................426

Removal and Installation .......................................427

DTC P1226 TP SENSOR .................................428

Component Description .........................................428

On Board Diagnosis Logic .....................................428

DTC Confirmation Procedure ................................428

Diagnosis Procedure .............................................428

Removal and Installation .......................................429

DTC P1421 COLD START CONTROL ............430

Description .............................................................430

On Board Diagnosis Logic .....................................430

DTC Confirmation Procedure ................................430

Diagnosis Procedure .............................................430

DTC P1564 ASCD STEERING SWITCH .........432

Component Description .........................................432

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

432

On Board Diagnosis Logic .....................................432

DTC Confirmation Procedure ................................433

Wiring Diagram ......................................................434

Diagnosis Procedure .............................................435

Component Inspection ...........................................437

DTC P1572 ASCD BRAKE SWITCH ..............438

Component Description .........................................438

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

438

On Board Diagnosis Logic .....................................438

DTC Confirmation Procedure ................................439

Wiring Diagram ......................................................440

Diagnosis Procedure .............................................441

Component Inspection ...........................................445

DTC P1574 ASCD VEHICLE SPEED SEN-

SOR ..................................................................

447

Component Description .........................................447

On Board Diagnosis Logic ....................................447

DTC Confirmation Procedure ................................447

Diagnosis Procedure .............................................448

DTC P1715 INPUT SPEED SENSOR (TUR-

BINE REVOLUTION SENSOR) ........................

449

Description ............................................................449

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

449

On Board Diagnosis Logic ....................................449

Diagnosis Procedure .............................................449

DTC P1715 INPUT SPEED SENSOR (PRIMA-

RY SPEED SENSOR) .......................................

450

Description ............................................................450

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

450

On Board Diagnosis Logic ....................................450

DTC Confirmation Procedure ................................450

Diagnosis Procedure .............................................451

DTC P1805 BRAKE SWITCH ..........................452

Description ............................................................452

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

452

On Board Diagnosis Logic ....................................452

DTC Confirmation Procedure ................................452

Wiring Diagram .....................................................453

Diagnosis Procedure .............................................454

Component Inspection ..........................................455

DTC P2100, P2103 THROTTLE CONTROL

MOTOR RELAY ................................................

456

Component Description ........................................456

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

456

On Board Diagnosis Logic ....................................456

DTC Confirmation Procedure ................................456

Wiring Diagram .....................................................458

Diagnosis Procedure .............................................459

DTC P2101 ELECTRIC THROTTLE CON-

TROL FUNCTION .............................................

461

Description ............................................................461

On Board Diagnosis Logic ....................................461

DTC Confirmation Procedure ................................461

Wiring Diagram .....................................................462

Diagnosis Procedure .............................................463

Component Inspection ..........................................466

Removal and Installation .......................................466

DTC P2118 THROTTLE CONTROL MOTOR ..467

Component Description ........................................467

On Board Diagnosis Logic ....................................467

DTC Confirmation Procedure ................................467

Wiring Diagram .....................................................468

Diagnosis Procedure .............................................469

Component Inspection ..........................................470

Removal and Installation .......................................470

Page 1082 of 2771

EC-8

Engine Coolant Temperature Sensor ....................548

Air Fuel Ratio (A/F) Sensor 1 Heater .....................549

Heated Oxygen sensor 2 Heater ...........................549

Crankshaft Position Sensor (POS) ........................549

Camshaft Position Sensor (PHASE) .....................549

Throttle Control Motor ...........................................549

Fuel Injector ..........................................................549

Fuel Pump .............................................................549