check engine light NISSAN LATIO 2008 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 1145 of 2771

BASIC SERVICE PROCEDURE

EC-71

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

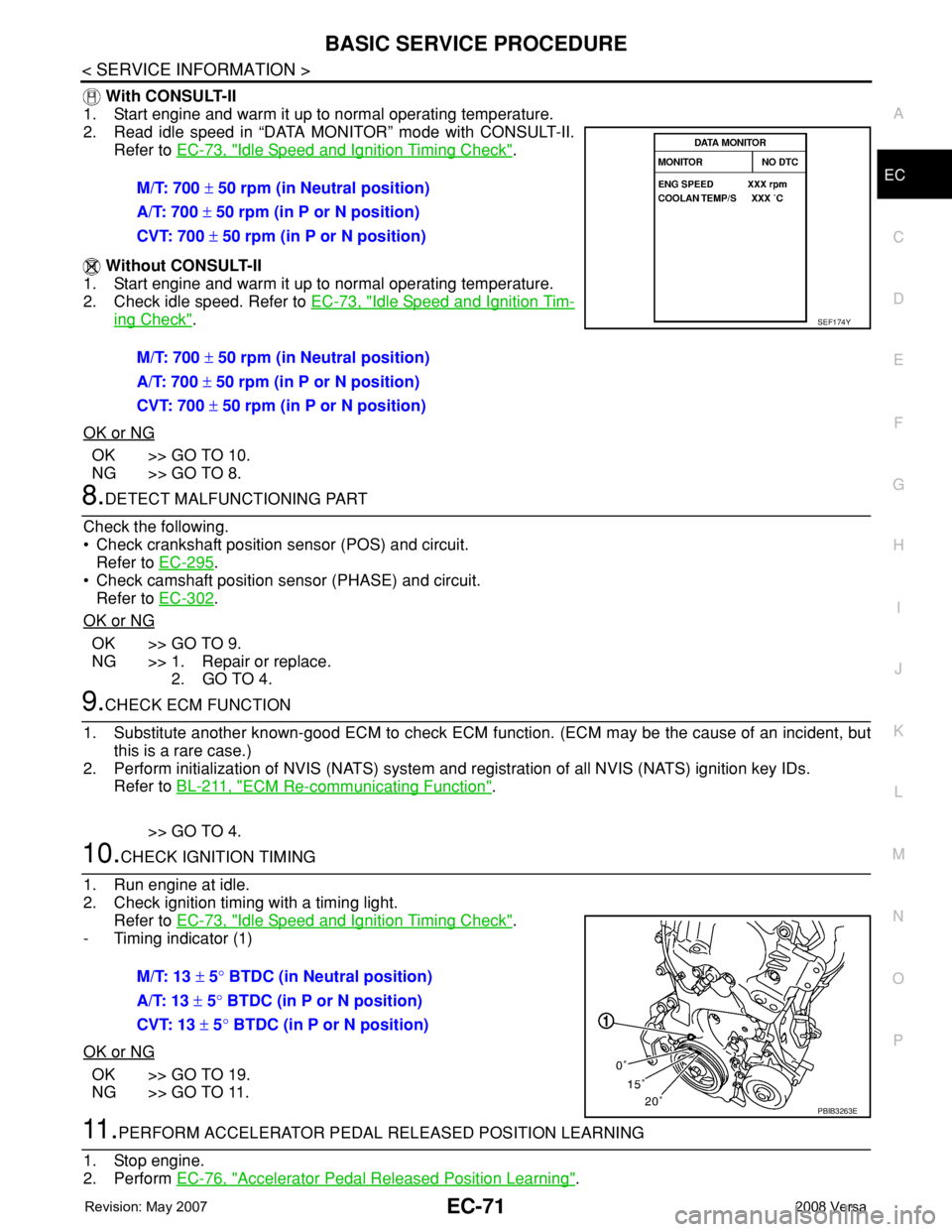

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-73, "

Idle Speed and Ignition Timing Check".

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed. Refer to EC-73, "

Idle Speed and Ignition Tim-

ing Check".

OK or NG

OK >> GO TO 10.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

• Check crankshaft position sensor (POS) and circuit.

Refer to EC-295

.

• Check camshaft position sensor (PHASE) and circuit.

Refer to EC-302

.

OK or NG

OK >> GO TO 9.

NG >> 1. Repair or replace.

2. GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs.

Refer to BL-211, "

ECM Re-communicating Function".

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer to EC-73, "

Idle Speed and Ignition Timing Check".

- Timing indicator (1)

OK or NG

OK >> GO TO 19.

NG >> GO TO 11.

11 .PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-76, "

Accelerator Pedal Released Position Learning". M/T: 700 ± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

SEF174Y

M/T: 13 ± 5° BTDC (in Neutral position)

A/T: 13 ± 5° BTDC (in P or N position)

CVT: 13 ± 5° BTDC (in P or N position)

PBIB3263E

Page 1146 of 2771

EC-72

< SERVICE INFORMATION >

BASIC SERVICE PROCEDURE

>> GO TO 12.

12.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-76, "

Throttle Valve Closed Position Learning".

>> GO TO 13.

13.PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-76, "

Idle Air Volume Learning".

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Yes >> GO TO 14.

No >> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

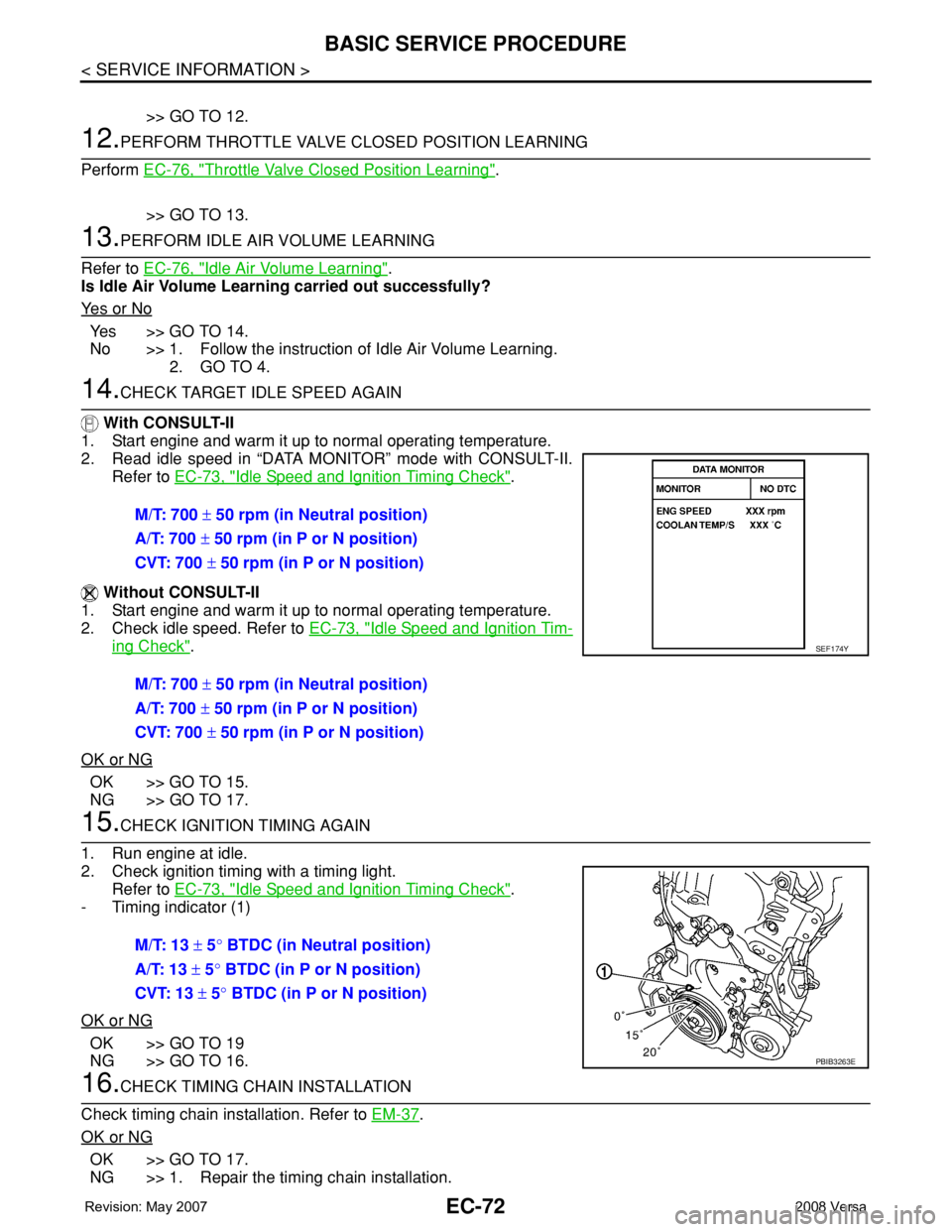

14.CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-73, "

Idle Speed and Ignition Timing Check".

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed. Refer to EC-73, "

Idle Speed and Ignition Tim-

ing Check".

OK or NG

OK >> GO TO 15.

NG >> GO TO 17.

15.CHECK IGNITION TIMING AGAIN

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer to EC-73, "

Idle Speed and Ignition Timing Check".

- Timing indicator (1)

OK or NG

OK >> GO TO 19

NG >> GO TO 16.

16.CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-37

.

OK or NG

OK >> GO TO 17.

NG >> 1. Repair the timing chain installation.M/T: 700 ± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

SEF174Y

M/T: 13 ± 5° BTDC (in Neutral position)

A/T: 13 ± 5° BTDC (in P or N position)

CVT: 13 ± 5° BTDC (in P or N position)

PBIB3263E

Page 1153 of 2771

BASIC SERVICE PROCEDURE

EC-79

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

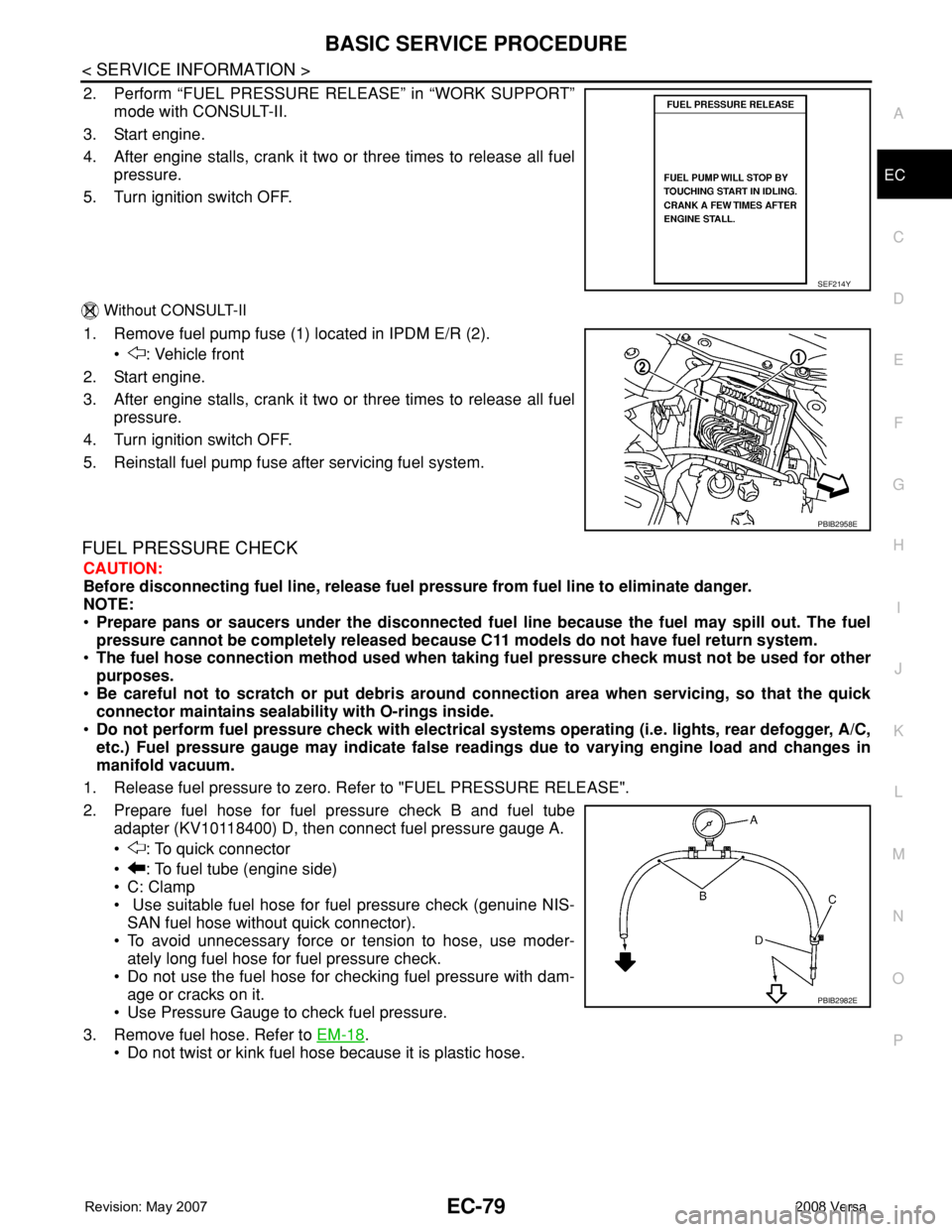

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch OFF.

Without CONSULT-II

1. Remove fuel pump fuse (1) located in IPDM E/R (2).

• : Vehicle front

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

•Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel

pressure cannot be completely released because C11 models do not have fuel return system.

•The fuel hose connection method used when taking fuel pressure check must not be used for other

purposes.

•Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains sealability with O-rings inside.

•Do not perform fuel pressure check with electrical systems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readings due to varying engine load and changes in

manifold vacuum.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE".

2. Prepare fuel hose for fuel pressure check B and fuel tube

adapter (KV10118400) D, then connect fuel pressure gauge A.

• : To quick connector

• : To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine NIS-

SAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moder-

ately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with dam-

age or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose. Refer to EM-18

.

• Do not twist or kink fuel hose because it is plastic hose.

SEF214Y

PBIB2958E

PBIB2982E

Page 1191 of 2771

TROUBLE DIAGNOSIS

EC-117

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

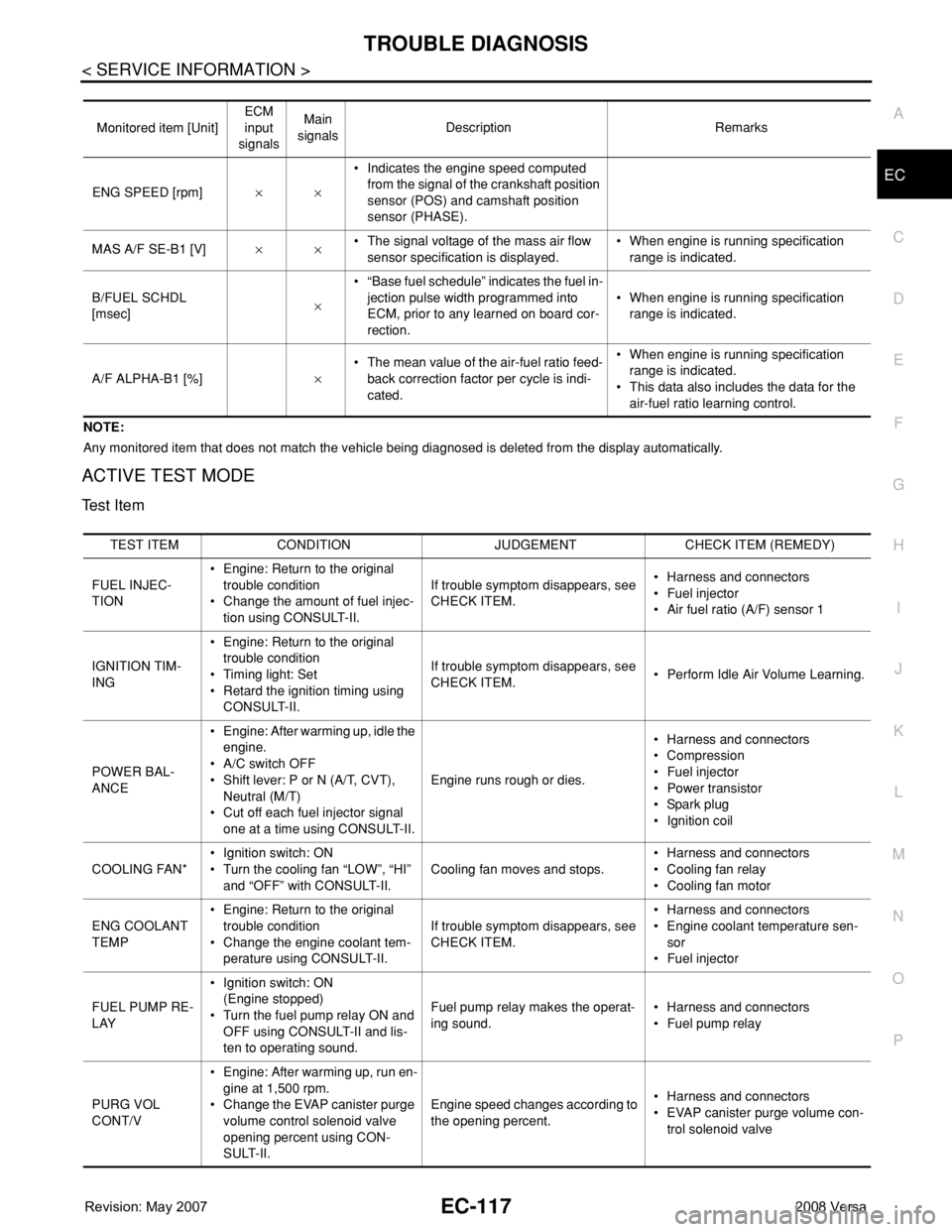

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]×ו Indicates the engine speed computed

from the signal of the crankshaft position

sensor (POS) and camshaft position

sensor (PHASE).

MAS A/F SE-B1 [V]×ו The signal voltage of the mass air flow

sensor specification is displayed.• When engine is running specification

range is indicated.

B/FUEL SCHDL

[msec]ו “Base fuel schedule” indicates the fuel in-

jection pulse width programmed into

ECM, prior to any learned on board cor-

rection.• When engine is running specification

range is indicated.

A/F ALPHA-B1 [%]ו The mean value of the air-fuel ratio feed-

back correction factor per cycle is indi-

cated.• When engine is running specification

range is indicated.

• This data also includes the data for the

air-fuel ratio learning control.

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION• Engine: Return to the original

trouble condition

• Change the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

IGNITION TIM-

ING• Engine: Return to the original

trouble condition

• Timing light: Set

• Retard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Perform Idle Air Volume Learning.

POWER BAL-

ANCE• Engine: After warming up, idle the

engine.

• A/C switch OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

• Cut off each fuel injector signal

one at a time using CONSULT-II.Engine runs rough or dies.• Harness and connectors

• Compression

• Fuel injector

• Power transistor

•Spark plug

• Ignition coil

COOLING FAN*• Ignition switch: ON

• Turn the cooling fan “LOW”, “HI”

and “OFF” with CONSULT-II.Cooling fan moves and stops.• Harness and connectors

• Cooling fan relay

• Cooling fan motor

ENG COOLANT

TEMP• Engine: Return to the original

trouble condition

• Change the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Engine coolant temperature sen-

sor

• Fuel injector

FUEL PUMP RE-

LAY• Ignition switch: ON

(Engine stopped)

• Turn the fuel pump relay ON and

OFF using CONSULT-II and lis-

ten to operating sound.Fuel pump relay makes the operat-

ing sound.• Harness and connectors

• Fuel pump relay

PURG VOL

CONT/V• Engine: After warming up, run en-

gine at 1,500 rpm.

• Change the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according to

the opening percent.• Harness and connectors

• EVAP canister purge volume con-

trol solenoid valve

Page 1389 of 2771

DTC P0441 EVAP CONTROL SYSTEM

EC-315

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Diagnosis ProcedureINFOID:0000000001702824

1.CHECK EVAP CANISTER

1. Turn ignition switch OFF.

2. Check EVAP canister for cracks.

OK or NG

OK (With CONSULT-II)>>GO TO 2.

OK (Without CONSULT-II)>>GO TO 3.

NG >> Replace EVAP canister.

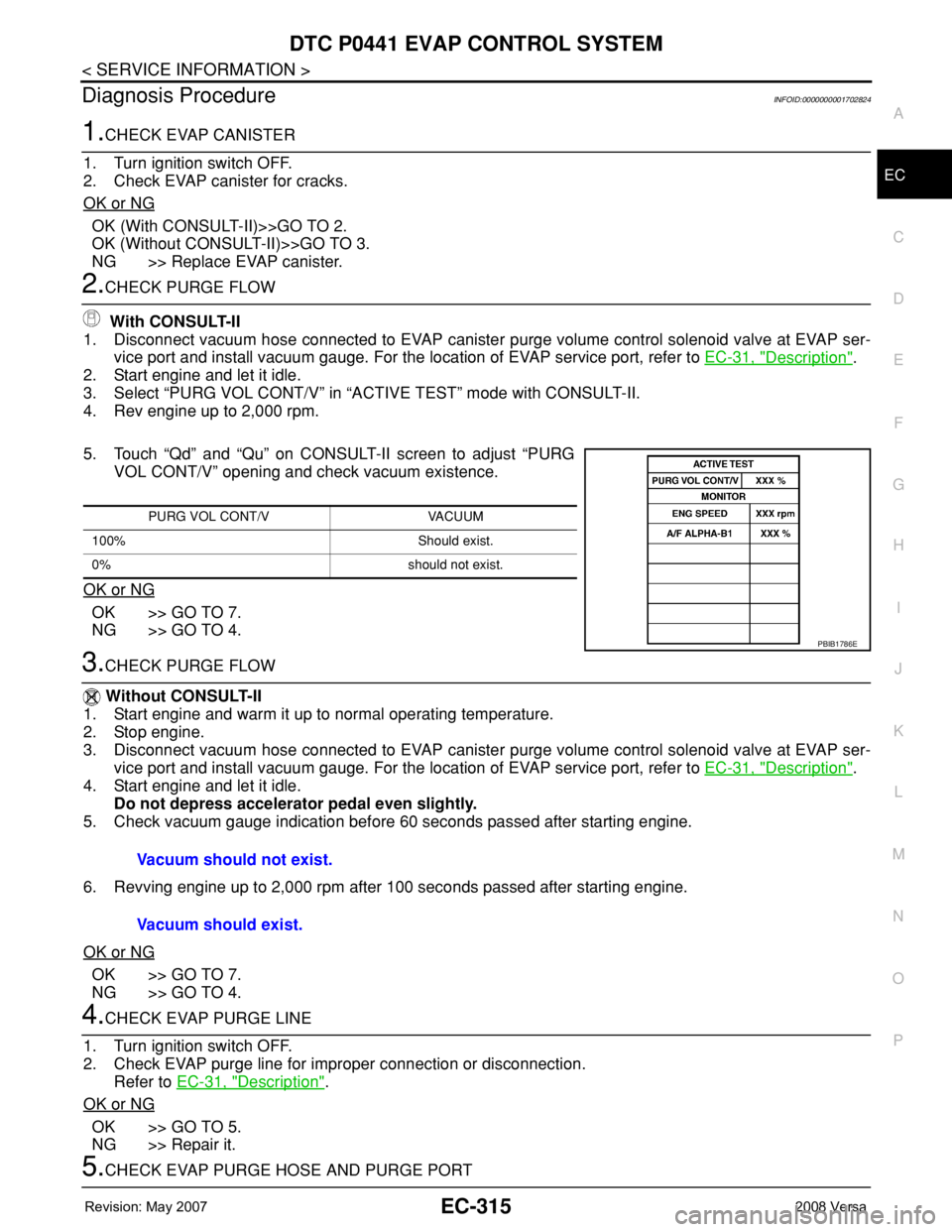

2.CHECK PURGE FLOW

With CONSULT-II

1. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the location of EVAP service port, refer to EC-31, "

Description".

2. Start engine and let it idle.

3. Select “PURG VOL CONT/V” in “ACTIVE TEST” mode with CONSULT-II.

4. Rev engine up to 2,000 rpm.

5. Touch “Qd” and “Qu” on CONSULT-II screen to adjust “PURG

VOL CONT/V” opening and check vacuum existence.

OK or NG

OK >> GO TO 7.

NG >> GO TO 4.

3.CHECK PURGE FLOW

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the location of EVAP service port, refer to EC-31, "

Description".

4. Start engine and let it idle.

Do not depress accelerator pedal even slightly.

5. Check vacuum gauge indication before 60 seconds passed after starting engine.

6. Revving engine up to 2,000 rpm after 100 seconds passed after starting engine.

OK or NG

OK >> GO TO 7.

NG >> GO TO 4.

4.CHECK EVAP PURGE LINE

1. Turn ignition switch OFF.

2. Check EVAP purge line for improper connection or disconnection.

Refer to EC-31, "

Description".

OK or NG

OK >> GO TO 5.

NG >> Repair it.

5.CHECK EVAP PURGE HOSE AND PURGE PORT

PURG VOL CONT/V VACUUM

100% Should exist.

0% should not exist.

PBIB1786E

Vacuum should not exist.

Vacuum should exist.

Page 1402 of 2771

EC-328

< SERVICE INFORMATION >

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702833

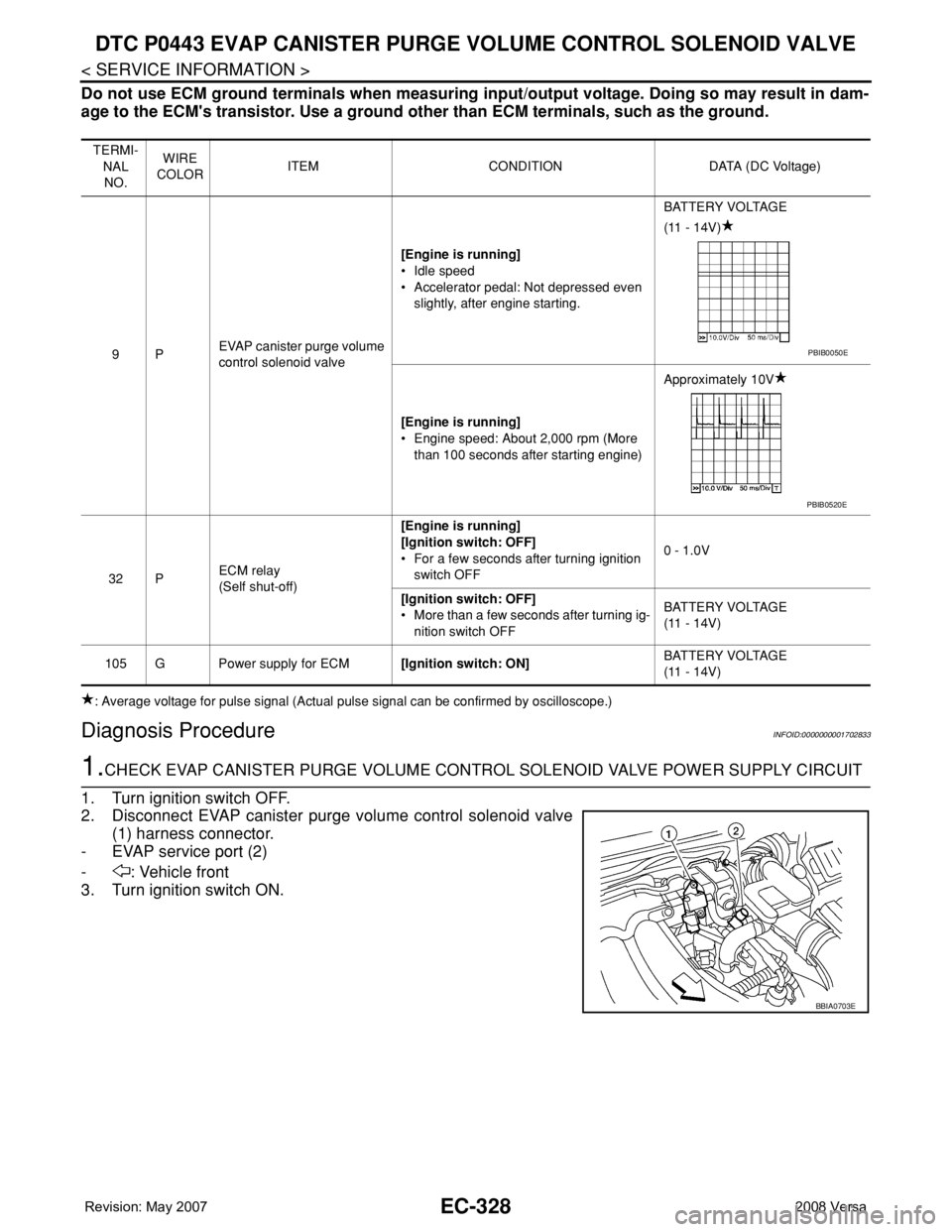

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve

(1) harness connector.

- EVAP service port (2)

- : Vehicle front

3. Turn ignition switch ON.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

9PEVAP canister purge volume

control solenoid valve[Engine is running]

• Idle speed

• Accelerator pedal: Not depressed even

slightly, after engine starting.BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

• Engine speed: About 2,000 rpm (More

than 100 seconds after starting engine)Approximately 10V

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning ig-

nition switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIB0050E

PBIB0520E

BBIA0703E

Page 1409 of 2771

DTC P0444, P0445 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID

VALVE

EC-335

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702841

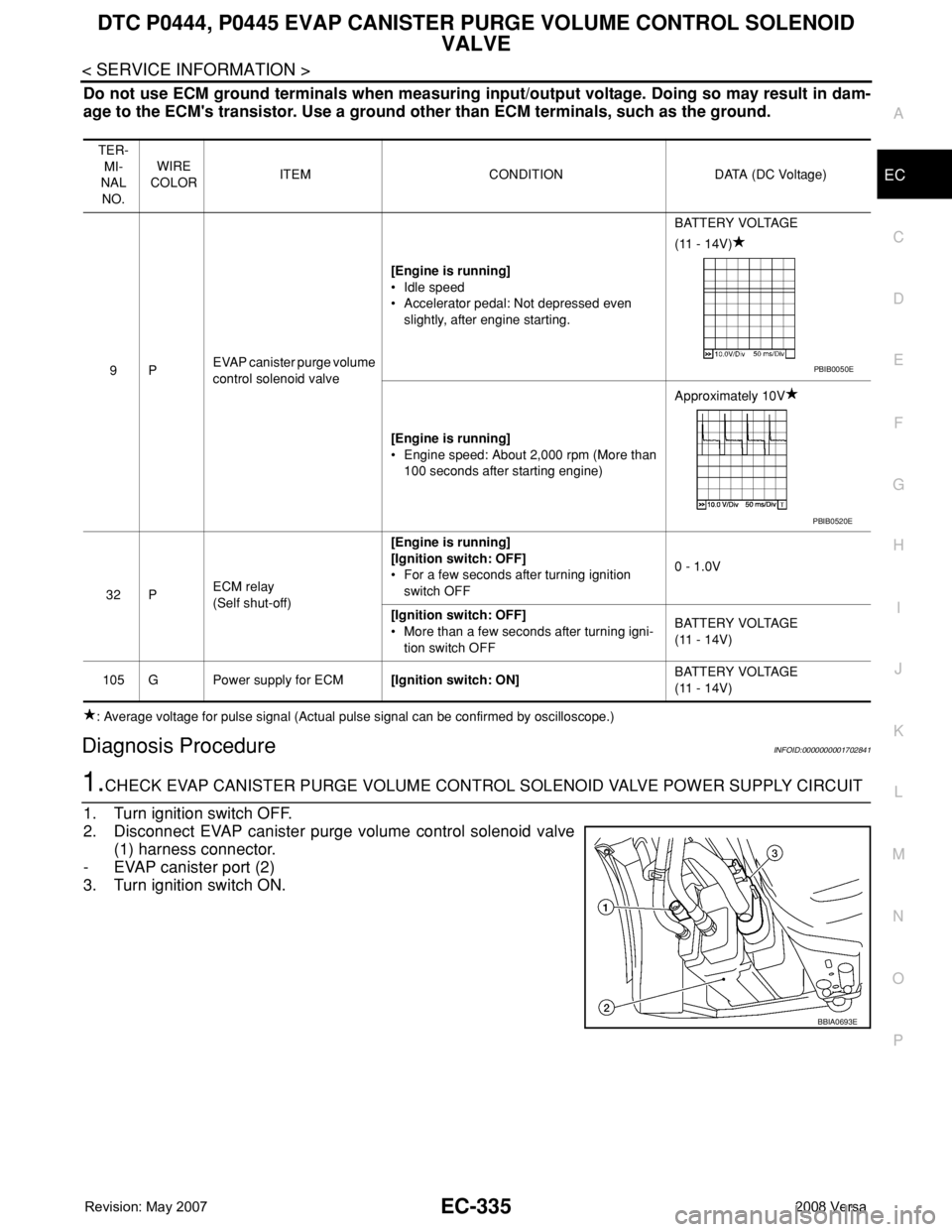

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect EVAP canister purge volume control solenoid valve

(1) harness connector.

- EVAP canister port (2)

3. Turn ignition switch ON.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

9PEVAP canister purge volume

control solenoid valve[Engine is running]

• Idle speed

• Accelerator pedal: Not depressed even

slightly, after engine starting.BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

• Engine speed: About 2,000 rpm (More than

100 seconds after starting engine)Approximately 10V

32 PECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.0V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

105 G Power supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIB0050E

PBIB0520E

BBIA0693E

Page 1426 of 2771

EC-352

< SERVICE INFORMATION >

DTC P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

2. Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

3. Start engine and wait at least 40 seconds.

NOTE:

Do not depress accelerator pedal even slightly.

If 1st trip DTC is detected, go to EC-352, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

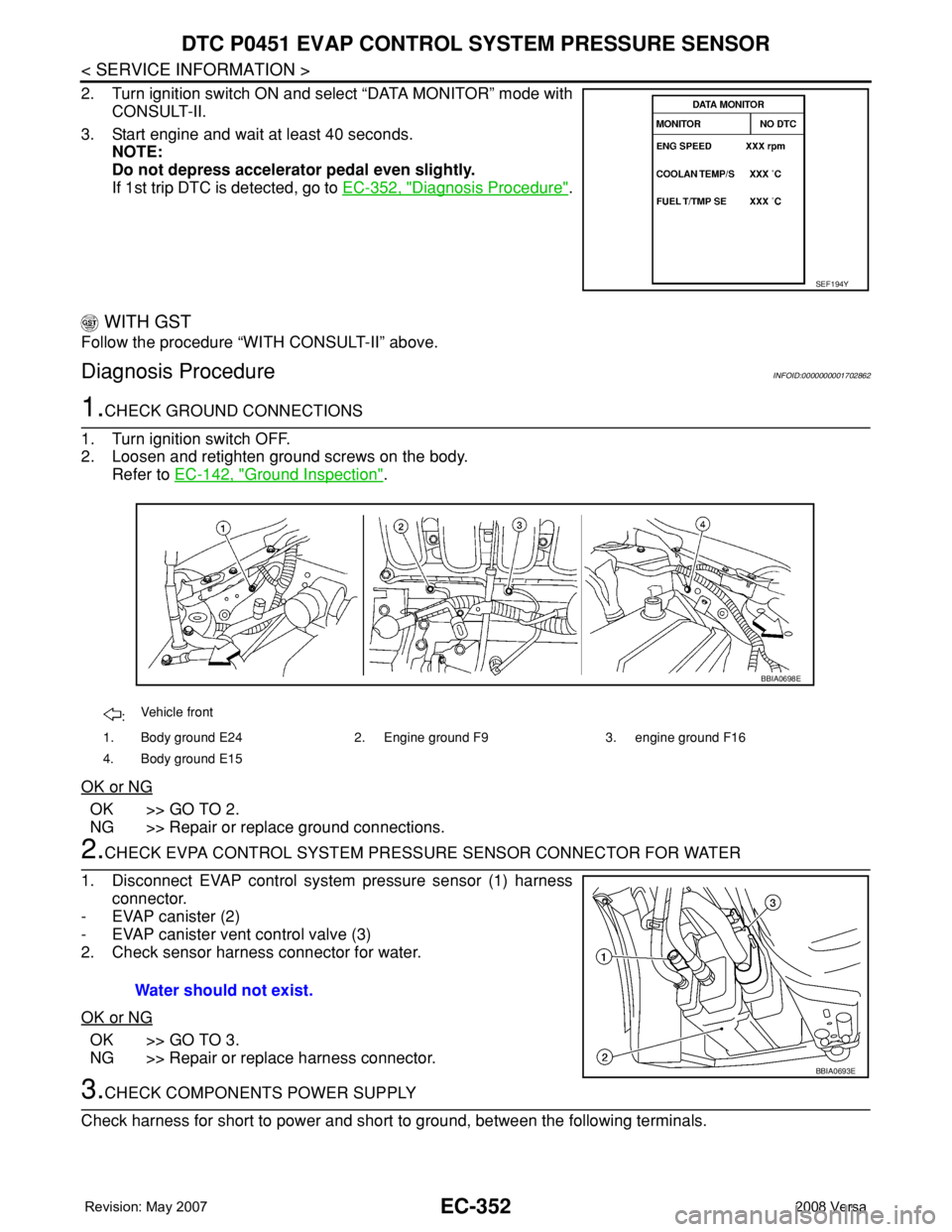

Diagnosis ProcedureINFOID:0000000001702862

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK EVPA CONTROL SYSTEM PRESSURE SENSOR CONNECTOR FOR WATER

1. Disconnect EVAP control system pressure sensor (1) harness

connector.

- EVAP canister (2)

- EVAP canister vent control valve (3)

2. Check sensor harness connector for water.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness connector.

3.CHECK COMPONENTS POWER SUPPLY

Check harness for short to power and short to ground, between the following terminals.

SEF194Y

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. engine ground F16

4. Body ground E15

BBIA0698E

Water should not exist.

BBIA0693E

Page 1523 of 2771

DTC P1715 INPUT SPEED SENSOR (TURBINE REVOLUTION SENSOR)

EC-449

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

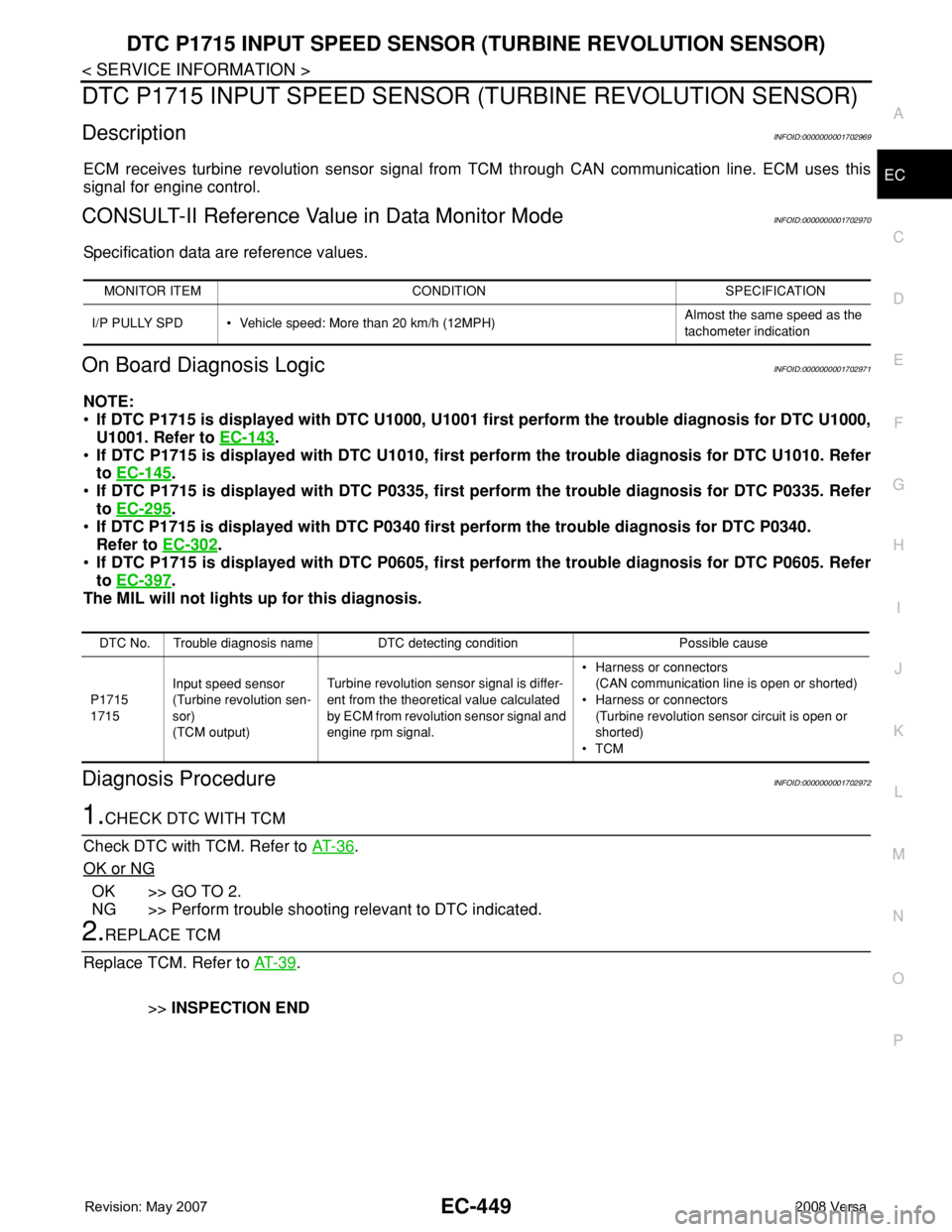

DTC P1715 INPUT SPEED SENSOR (TURBINE REVOLUTION SENSOR)

DescriptionINFOID:0000000001702969

ECM receives turbine revolution sensor signal from TCM through CAN communication line. ECM uses this

signal for engine control.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702970

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702971

NOTE:

•If DTC P1715 is displayed with DTC U1000, U1001 first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-143

.

•If DTC P1715 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-145

.

•If DTC P1715 is displayed with DTC P0335, first perform the trouble diagnosis for DTC P0335. Refer

to EC-295

.

•If DTC P1715 is displayed with DTC P0340 first perform the trouble diagnosis for DTC P0340.

Refer to EC-302

.

•If DTC P1715 is displayed with DTC P0605, first perform the trouble diagnosis for DTC P0605. Refer

to EC-397

.

The MIL will not lights up for this diagnosis.

Diagnosis ProcedureINFOID:0000000001702972

1.CHECK DTC WITH TCM

Check DTC with TCM. Refer to AT- 3 6

.

OK or NG

OK >> GO TO 2.

NG >> Perform trouble shooting relevant to DTC indicated.

2.REPLACE TCM

Replace TCM. Refer to AT- 3 9

.

>>INSPECTION END

MONITOR ITEM CONDITION SPECIFICATION

I/P PULLY SPD • Vehicle speed: More than 20 km/h (12MPH)Almost the same speed as the

tachometer indication

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1715

1715Input speed sensor

(Turbine revolution sen-

sor)

(TCM output)Turbine revolution sensor signal is differ-

ent from the theoretical value calculated

by ECM from revolution sensor signal and

engine rpm signal.• Harness or connectors

(CAN communication line is open or shorted)

• Harness or connectors

(Turbine revolution sensor circuit is open or

shorted)

•TCM

Page 1629 of 2771

EI-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

• Close a door.

• Tap or push/pull around the area where the noise appears to be coming from.

• Rev the engine.

• Use a floor jack to recreate vehicle “twist”.

• At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

• Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners

can be broken or lost during the repair, resulting in the creation of new noise.

• Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be elimi-

nated only temporarily.

• Feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing

the noise.

• Placing a piece of paper between components that you suspect are causing the noise.

• Looking for loose components and contact marks.

Refer to EI-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 x 135 mm (3.94 x 5.31 in)/76884-71L01: 60 x 85 mm (2.36 x 3.35 in)/76884-71L02: 15 x 25

mm (0.59 x 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 x 50 mm (1.97 x 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50 x 50

mm (1.97 x 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 x 50 mm (1.18 x 1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 x 25 mm (0.59 x 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll