sensor NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 1618 of 2771

EC-544

< SERVICE INFORMATION >

REFRIGERANT PRESSURE SENSOR

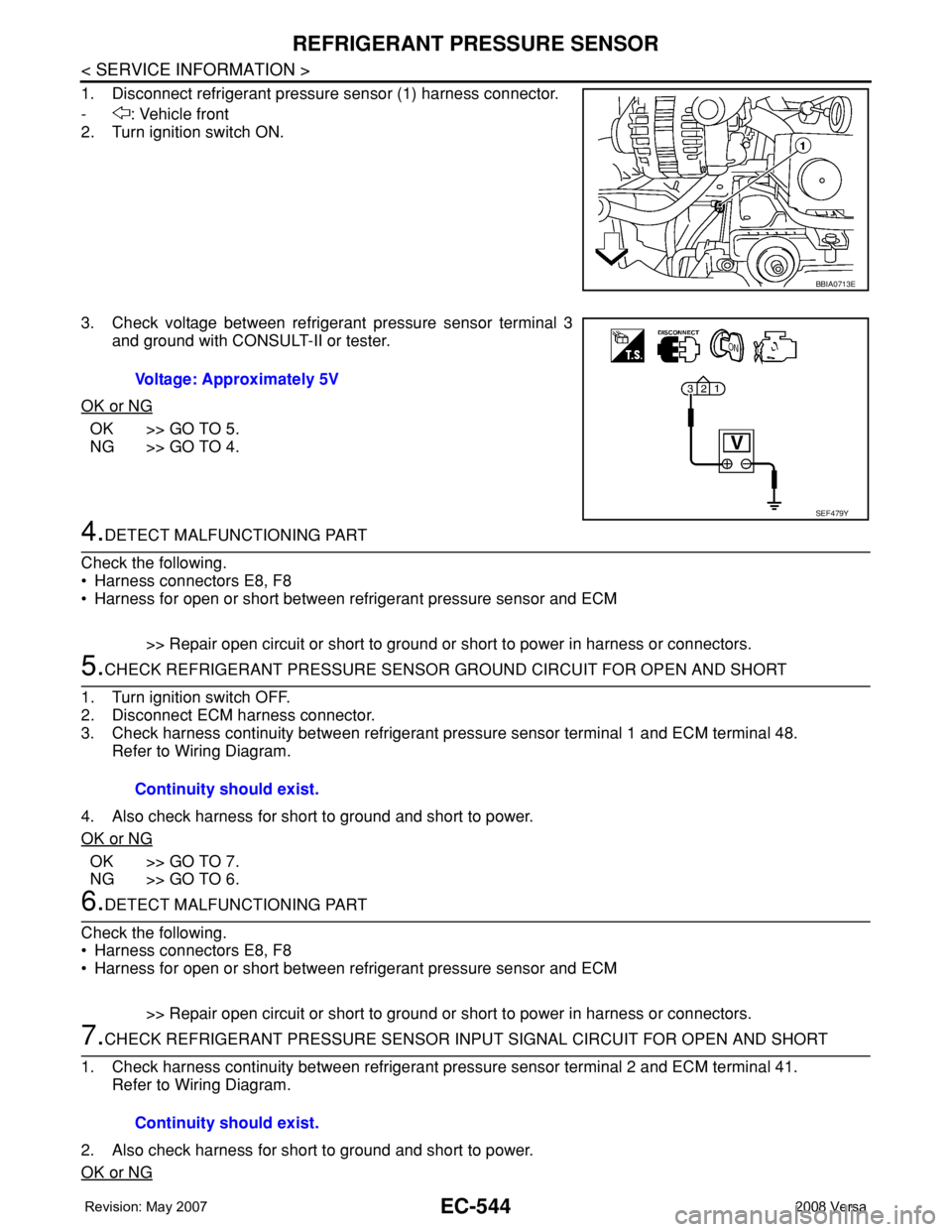

1. Disconnect refrigerant pressure sensor (1) harness connector.

- : Vehicle front

2. Turn ignition switch ON.

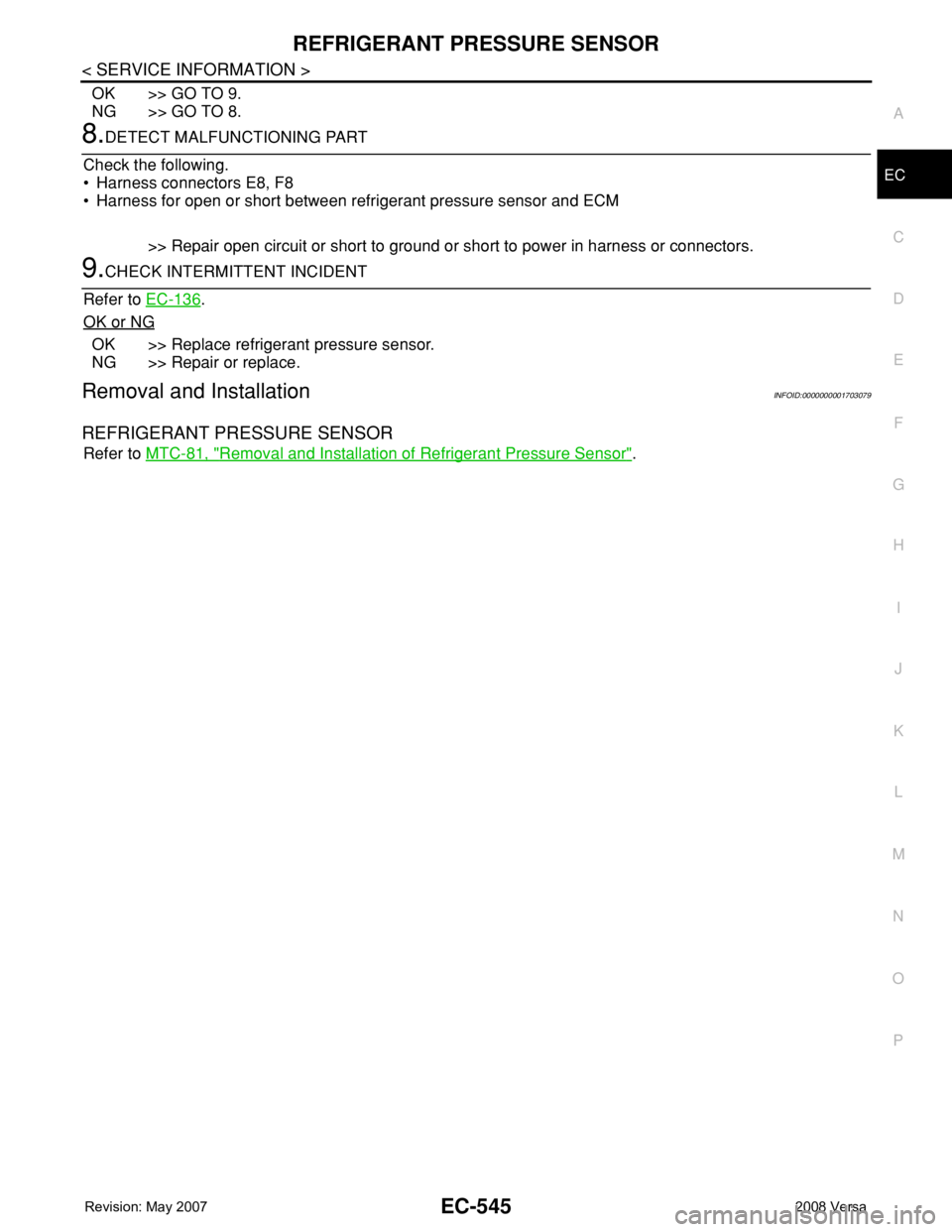

3. Check voltage between refrigerant pressure sensor terminal 3

and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between refrigerant pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between refrigerant pressure sensor terminal 1 and ECM terminal 48.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between refrigerant pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between refrigerant pressure sensor terminal 2 and ECM terminal 41.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

BBIA0713E

Voltage: Approximately 5V

SEF479Y

Continuity should exist.

Continuity should exist.

Page 1619 of 2771

REFRIGERANT PRESSURE SENSOR

EC-545

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

OK >> GO TO 9.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness for open or short between refrigerant pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

OK or NG

OK >> Replace refrigerant pressure sensor.

NG >> Repair or replace.

Removal and InstallationINFOID:0000000001703079

REFRIGERANT PRESSURE SENSOR

Refer to MTC-81, "Removal and Installation of Refrigerant Pressure Sensor".

Page 1622 of 2771

EC-548

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

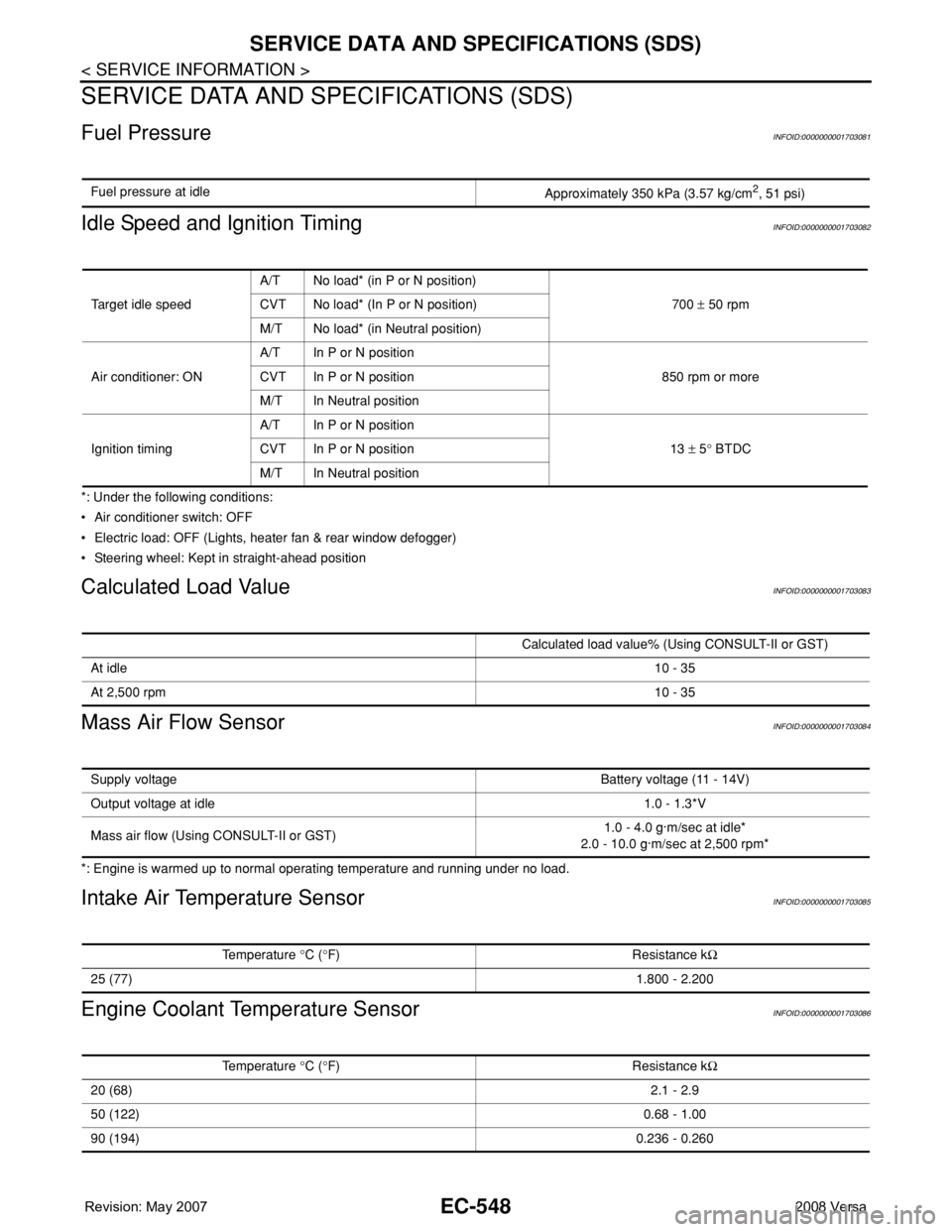

Fuel PressureINFOID:0000000001703081

Idle Speed and Ignition TimingINFOID:0000000001703082

*: Under the following conditions:

• Air conditioner switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000001703083

Mass Air Flow SensorINFOID:0000000001703084

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorINFOID:0000000001703085

Engine Coolant Temperature SensorINFOID:0000000001703086

Fuel pressure at idle

Approximately 350 kPa (3.57 kg/cm2, 51 psi)

Target idle speedA/T No load* (in P or N position)

700 ± 50 rpm CVT No load* (In P or N position)

M/T No load* (in Neutral position)

Air conditioner: ONA/T In P or N position

850 rpm or more CVT In P or N position

M/T In Neutral position

Ignition timingA/T In P or N position

13 ± 5° BTDC CVT In P or N position

M/T In Neutral position

Calculated load value% (Using CONSULT-II or GST)

At idle10 - 35

At 2,500 rpm10 - 35

Supply voltageBattery voltage (11 - 14V)

Output voltage at idle1.0 - 1.3*V

Mass air flow (Using CONSULT-II or GST)1.0 - 4.0 g·m/sec at idle*

2.0 - 10.0 g·m/sec at 2,500 rpm*

Temperature °C (°F) Resistance kΩ

25 (77)1.800 - 2.200

Temperature °C (°F) Resistance kΩ

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Page 1623 of 2771

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-549

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

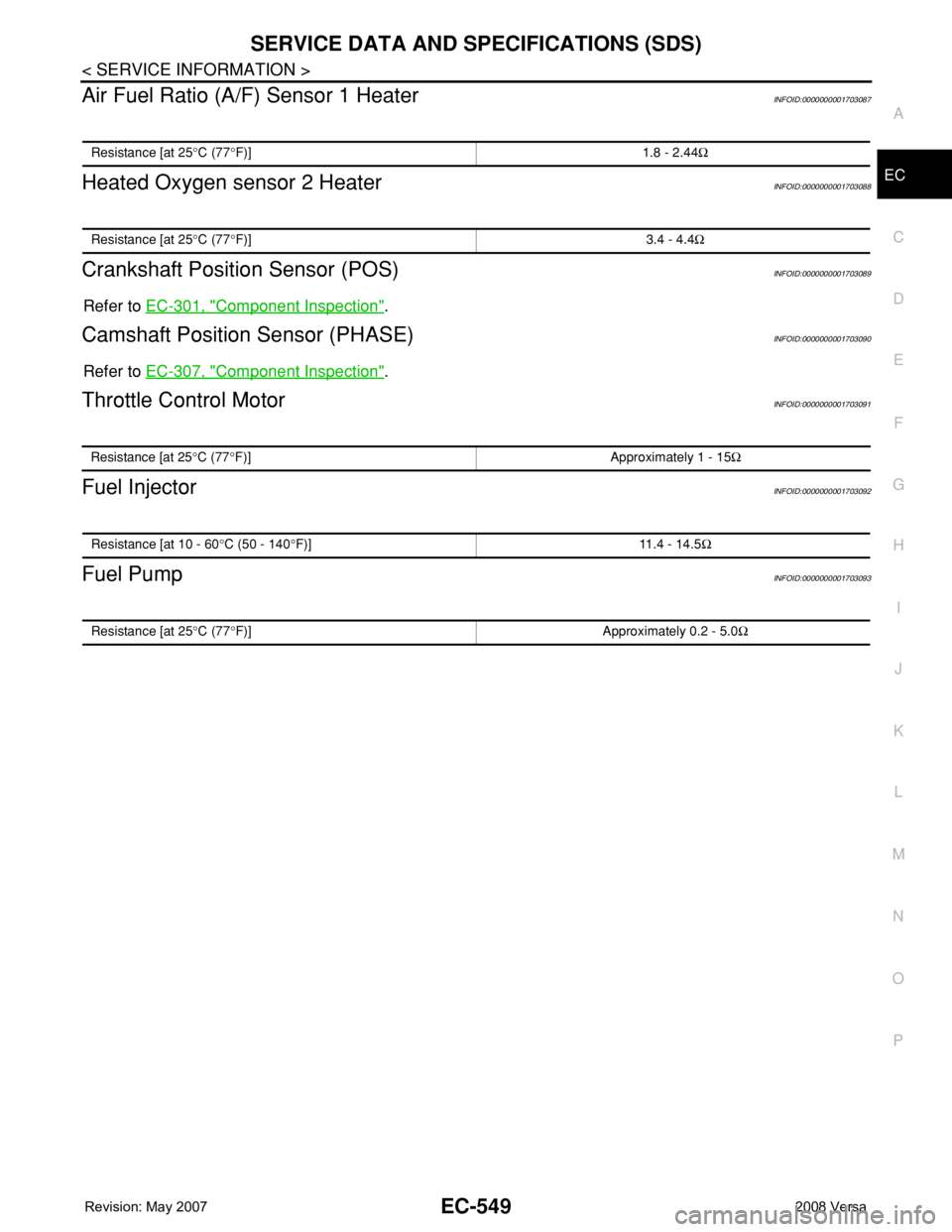

Air Fuel Ratio (A/F) Sensor 1 HeaterINFOID:0000000001703087

Heated Oxygen sensor 2 HeaterINFOID:0000000001703088

Crankshaft Position Sensor (POS)INFOID:0000000001703089

Refer to EC-301, "Component Inspection".

Camshaft Position Sensor (PHASE)INFOID:0000000001703090

Refer to EC-307, "Component Inspection".

Throttle Control MotorINFOID:0000000001703091

Fuel InjectorINFOID:0000000001703092

Fuel PumpINFOID:0000000001703093

Resistance [at 25°C (77°F)] 1.8 - 2.44Ω

Resistance [at 25°C (77°F)] 3.4 - 4.4Ω

Resistance [at 25°C (77°F)] Approximately 1 - 15Ω

Resistance [at 10 - 60°C (50 - 140°F)] 11.4 - 14.5Ω

Resistance [at 25°C (77°F)] Approximately 0.2 - 5.0Ω

Page 1667 of 2771

EI-44

< ON-VEHICLE REPAIR >

FLOOR TRIM

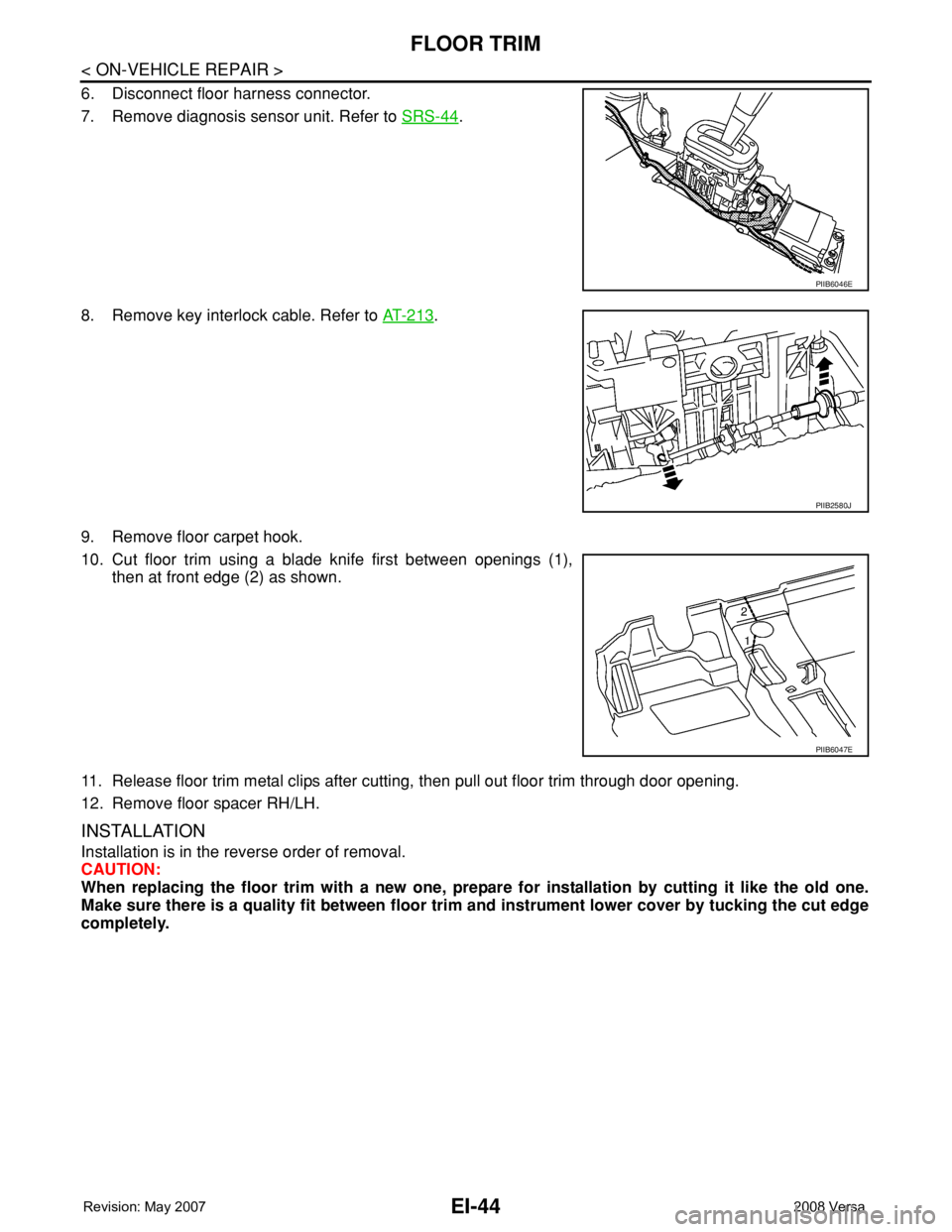

6. Disconnect floor harness connector.

7. Remove diagnosis sensor unit. Refer to SRS-44

.

8. Remove key interlock cable. Refer to AT-213

.

9. Remove floor carpet hook.

10. Cut floor trim using a blade knife first between openings (1),

then at front edge (2) as shown.

11. Release floor trim metal clips after cutting, then pull out floor trim through door opening.

12. Remove floor spacer RH/LH.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

When replacing the floor trim with a new one, prepare for installation by cutting it like the old one.

Make sure there is a quality fit between floor trim and instrument lower cover by tucking the cut edge

completely.

PIIB6046E

PIIB2580J

PIIB6047E

Page 1685 of 2771

EM-8

< SERVICE INFORMATION >

PREPARATION

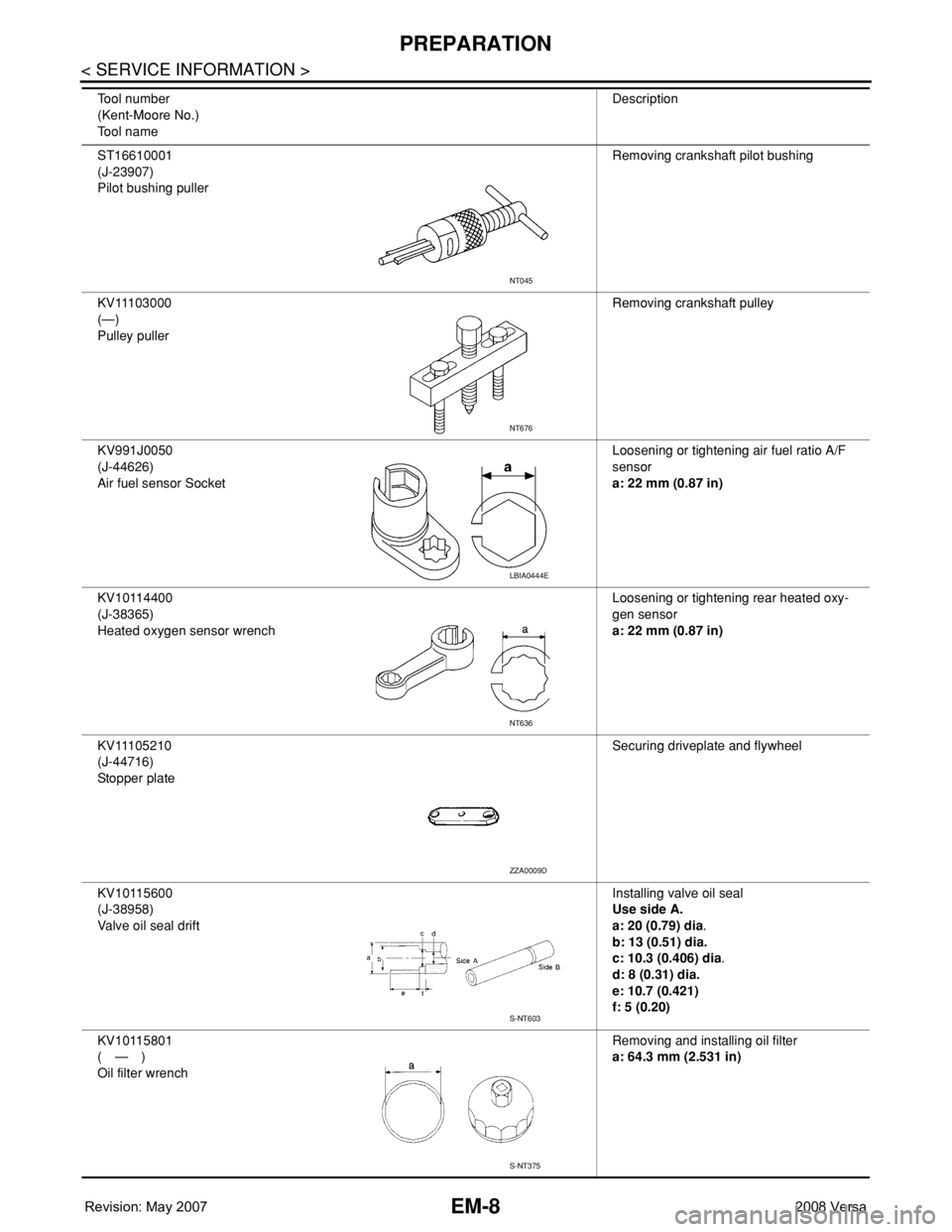

ST16610001

(J-23907)

Pilot bushing pullerRemoving crankshaft pilot bushing

KV11103000

(—)

Pulley pullerRemoving crankshaft pulley

KV991J0050

(J-44626)

Air fuel sensor SocketLoosening or tightening air fuel ratio A/F

sensor

a: 22 mm (0.87 in)

KV10114400

(J-38365)

Heated oxygen sensor wrenchLoosening or tightening rear heated oxy-

gen sensor

a: 22 mm (0.87 in)

KV11105210

(J-44716)

Stopper plateSecuring driveplate and flywheel

KV10115600

(J-38958)

Valve oil seal driftInstalling valve oil seal

Use side A.

a: 20 (0.79) dia.

b: 13 (0.51) dia.

c: 10.3 (0.406) dia.

d: 8 (0.31) dia.

e: 10.7 (0.421)

f: 5 (0.20)

KV10115801

(—)

Oil filter wrenchRemoving and installing oil filter

a: 64.3 mm (2.531 in) Tool number

(Kent-Moore No.)

Tool nameDescription

NT045

NT676

LBIA0444E

NT636

ZZA0009D

S-NT603

S-NT375

Page 1687 of 2771

EM-10

< SERVICE INFORMATION >

PREPARATION

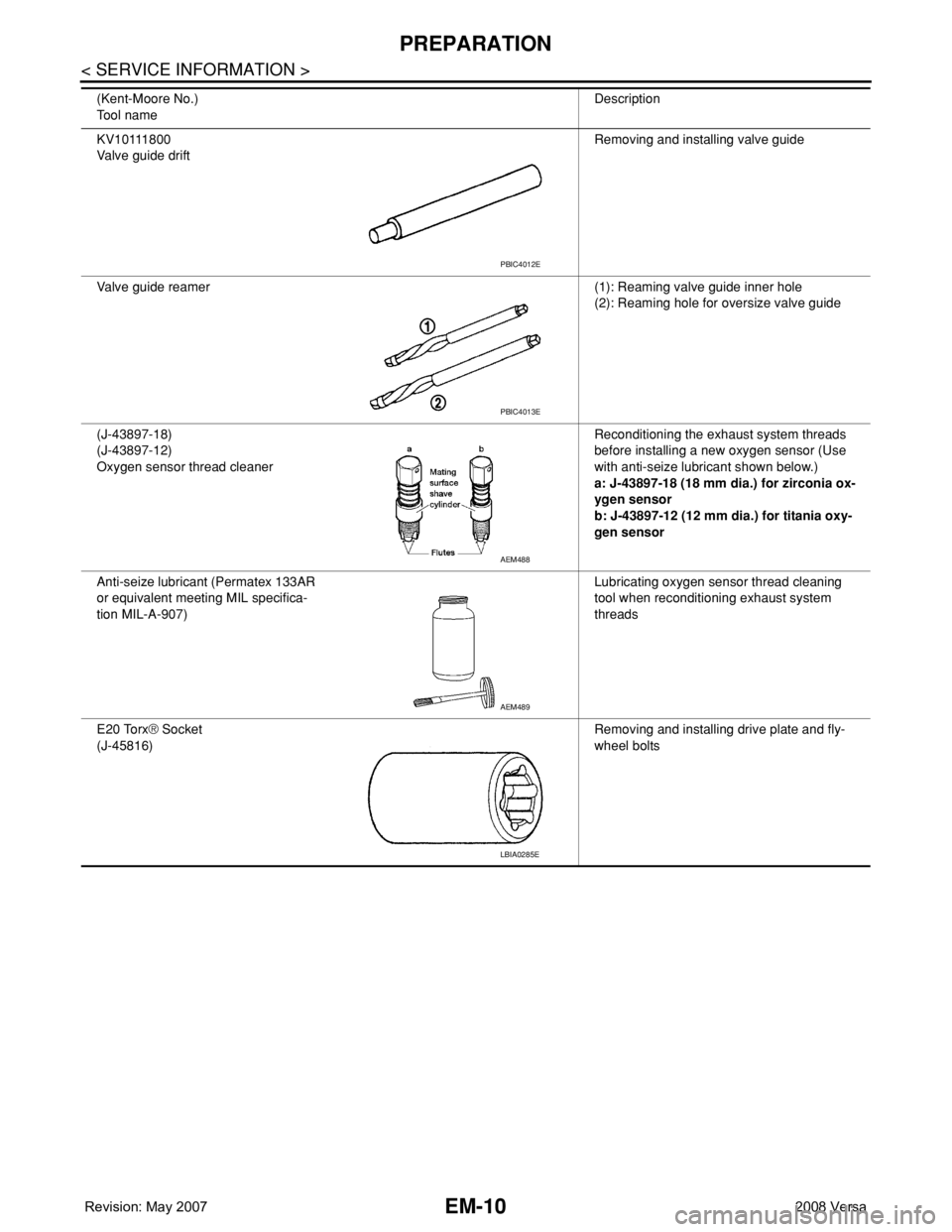

KV10111800

Valve guide driftRemoving and installing valve guide

Valve guide reamer (1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guide

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleanerReconditioning the exhaust system threads

before installing a new oxygen sensor (Use

with anti-seize lubricant shown below.)

a: J-43897-18 (18 mm dia.) for zirconia ox-

ygen sensor

b: J-43897-12 (12 mm dia.) for titania oxy-

gen sensor

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907)Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads

E20 Torx® Socket

(J-45816)Removing and installing drive plate and fly-

wheel bolts (Kent-Moore No.)

Tool nameDescription

PBIC4012E

PBIC4013E

AEM488

AEM489

LBIA0285E

Page 1693 of 2771

EM-16

< SERVICE INFORMATION >

AIR CLEANER AND AIR DUCT

AIR CLEANER AND AIR DUCT

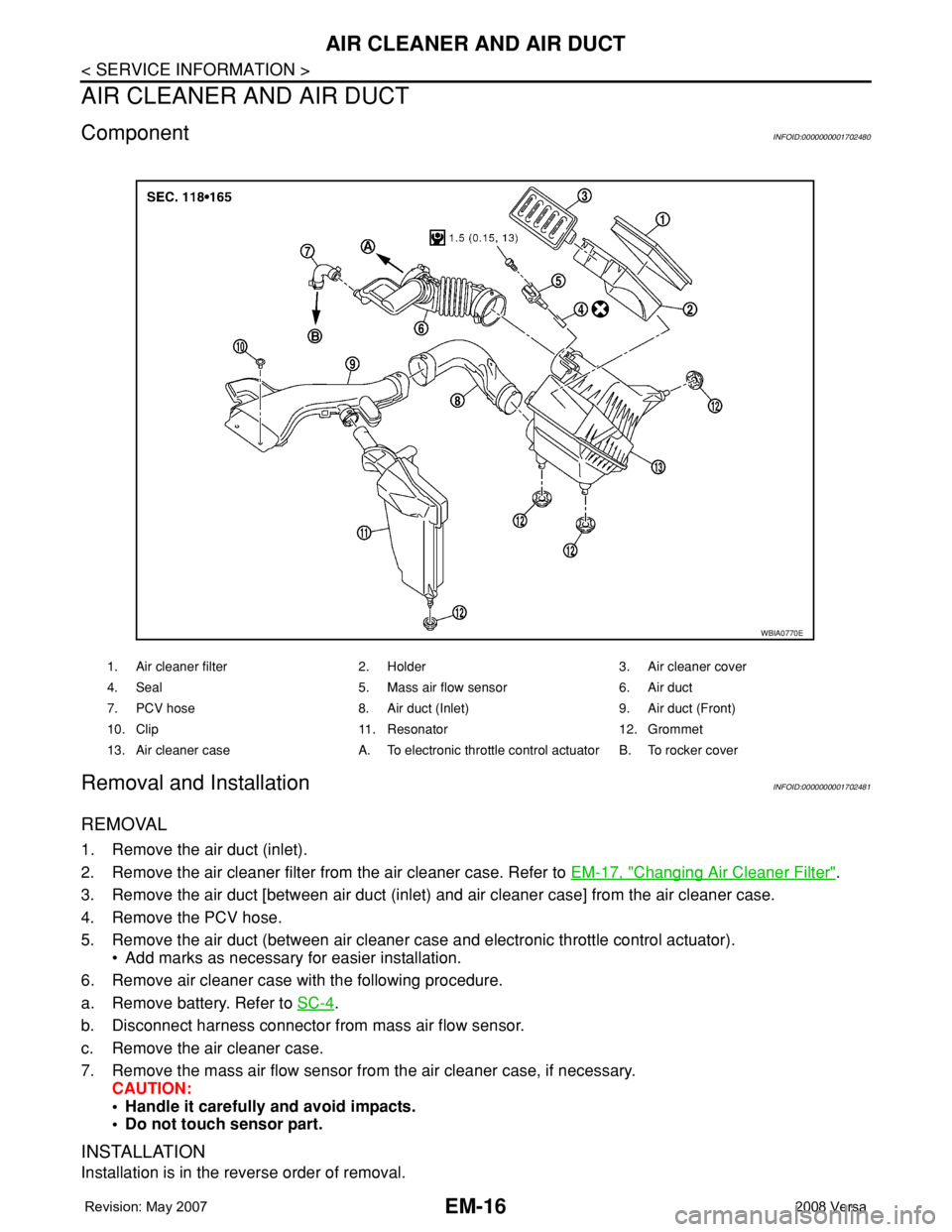

ComponentINFOID:0000000001702480

Removal and InstallationINFOID:0000000001702481

REMOVAL

1. Remove the air duct (inlet).

2. Remove the air cleaner filter from the air cleaner case. Refer to EM-17, "

Changing Air Cleaner Filter".

3. Remove the air duct [between air duct (inlet) and air cleaner case] from the air cleaner case.

4. Remove the PCV hose.

5. Remove the air duct (between air cleaner case and electronic throttle control actuator).

• Add marks as necessary for easier installation.

6. Remove air cleaner case with the following procedure.

a. Remove battery. Refer to SC-4

.

b. Disconnect harness connector from mass air flow sensor.

c. Remove the air cleaner case.

7. Remove the mass air flow sensor from the air cleaner case, if necessary.

CAUTION:

• Handle it carefully and avoid impacts.

• Do not touch sensor part.

INSTALLATION

Installation is in the reverse order of removal.

1. Air cleaner filter 2. Holder 3. Air cleaner cover

4. Seal 5. Mass air flow sensor 6. Air duct

7. PCV hose 8. Air duct (Inlet) 9. Air duct (Front)

10. Clip 11. Resonator 12. Grommet

13. Air cleaner case A. To electronic throttle control actuator B. To rocker cover

WBIA0770E

Page 1698 of 2771

EXHAUST MANIFOLD

EM-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

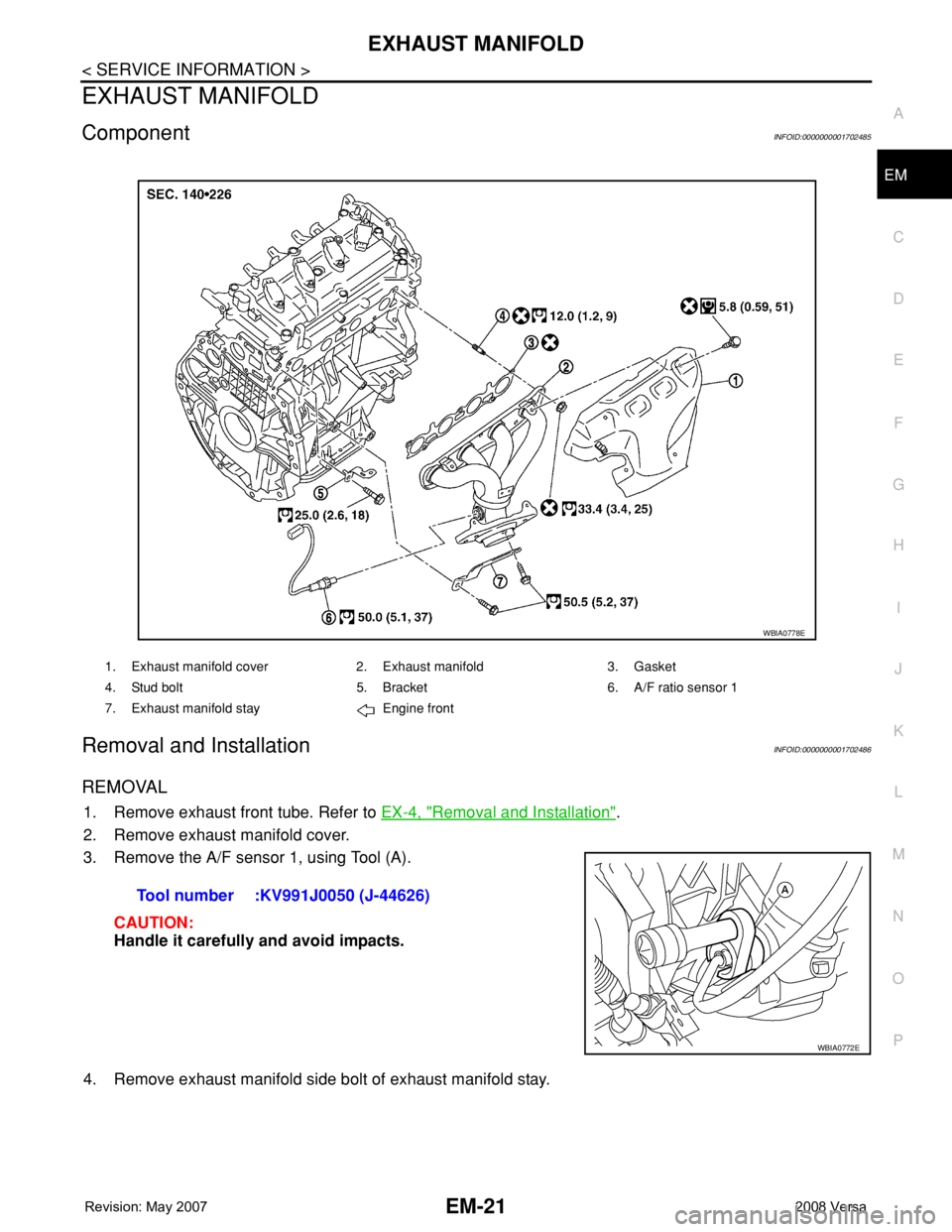

EXHAUST MANIFOLD

ComponentINFOID:0000000001702485

Removal and InstallationINFOID:0000000001702486

REMOVAL

1. Remove exhaust front tube. Refer to EX-4, "Removal and Installation".

2. Remove exhaust manifold cover.

3. Remove the A/F sensor 1, using Tool (A).

CAUTION:

Handle it carefully and avoid impacts.

4. Remove exhaust manifold side bolt of exhaust manifold stay.

1. Exhaust manifold cover 2. Exhaust manifold 3. Gasket

4. Stud bolt 5. Bracket 6. A/F ratio sensor 1

7. Exhaust manifold stay Engine front

WBIA0778E

Tool number :KV991J0050 (J-44626)

WBIA0772E

Page 1700 of 2771

EXHAUST MANIFOLD

EM-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

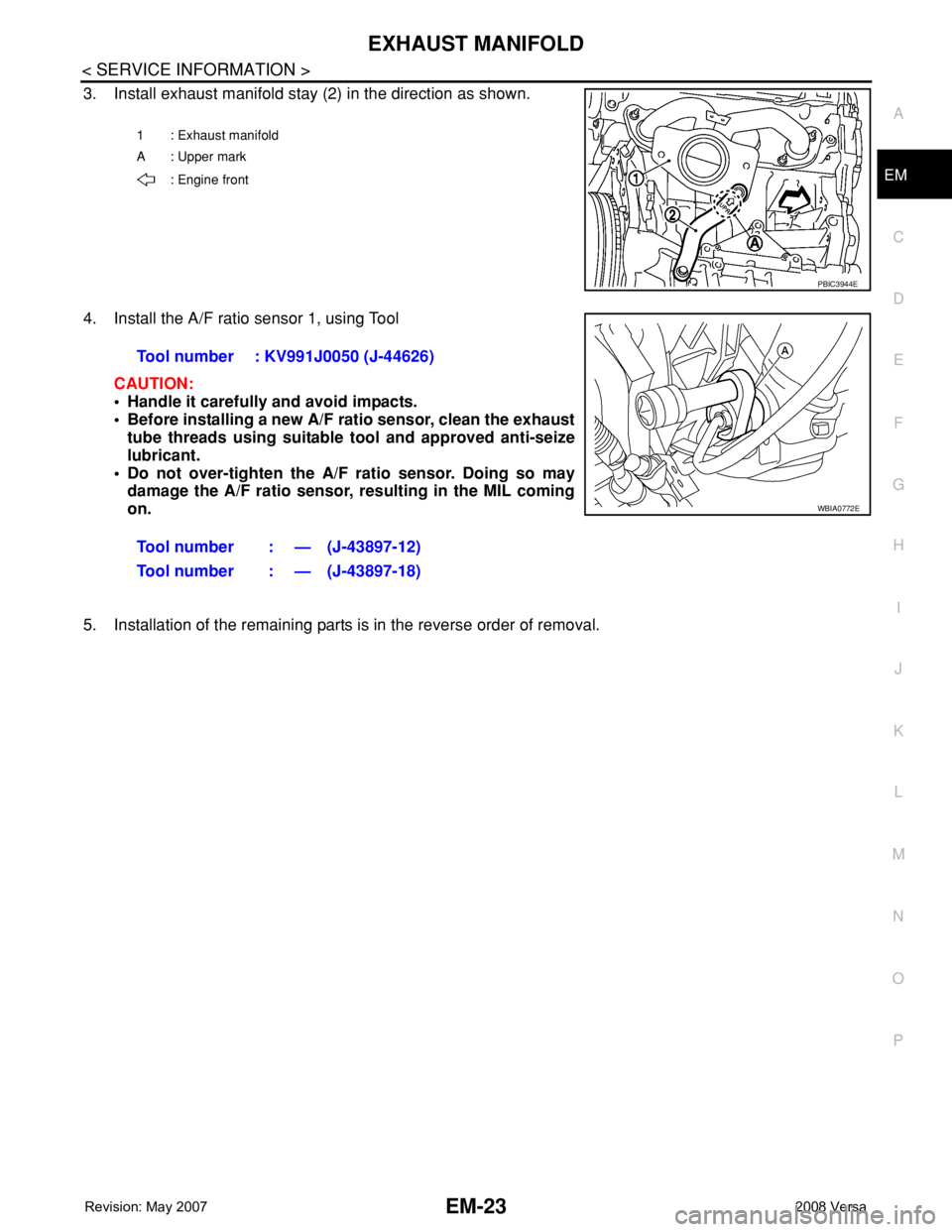

3. Install exhaust manifold stay (2) in the direction as shown.

4. Install the A/F ratio sensor 1, using Tool

CAUTION:

• Handle it carefully and avoid impacts.

• Before installing a new A/F ratio sensor, clean the exhaust

tube threads using suitable tool and approved anti-seize

lubricant.

• Do not over-tighten the A/F ratio sensor. Doing so may

damage the A/F ratio sensor, resulting in the MIL coming

on.

5. Installation of the remaining parts is in the reverse order of removal.

1 : Exhaust manifold

A : Upper mark

: Engine front

PBIC3944E

Tool number : KV991J0050 (J-44626)

Tool number : — (J-43897-12)

Tool number : — (J-43897-18)

WBIA0772E