check engine light NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 15 of 2771

AT-3

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P N Wiring Diagram - AT - SSV/B ................................

140

Diagnosis Procedure .............................................141

Component Inspection ..........................................142

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE ..............................................................

144

Description ............................................................144

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

144

On Board Diagnosis Logic ....................................144

Possible Cause .....................................................144

DTC Confirmation Procedure ................................144

Wiring Diagram - AT - OVRCSV ...........................145

Diagnosis Procedure .............................................146

Component Inspection ..........................................147

DTC VEHICLE SPEED SENSOR MTR ............149

Description ............................................................149

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

149

On Board Diagnosis Logic ....................................149

Possible Cause .....................................................149

DTC Confirmation Procedure ................................149

Wiring Diagram - AT - VSSMTR ...........................150

Diagnosis Procedure .............................................151

DTC BATT/FLUID TEMP SEN (A/T FLUID

TEMP SENSOR CIRCUIT AND TCM POWER

SOURCE) .........................................................

152

Description ............................................................152

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

152

On Board Diagnosis Logic ....................................152

Possible Cause .....................................................152

DTC Confirmation Procedure ................................152

Wiring Diagram - AT - BA/FTS ..............................153

Diagnosis Procedure .............................................154

Component Inspection ..........................................156

DTC TURBINE REVOLUTION SENSOR .........158

Description ............................................................158

CONSULT-III Reference Value in Data Monitor

Mode .....................................................................

158

On Board Diagnosis Logic ....................................158

Possible Cause .....................................................158

DTC Confirmation Procedure ................................158

Wiring Diagram - AT - PT/SEN .............................159

Diagnosis Procedure .............................................160

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

163

Description ............................................................163

On Board Diagnosis Logic ....................................163

Possible Cause .....................................................163

DTC Confirmation Procedure ................................163

Diagnosis Procedure .............................................163

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

164

Wiring Diagram - AT - MAIN .................................164

Diagnosis Procedure .............................................165

PNP, OD SWITCH AND CLOSED THROT-

TLE, WIDE OPEN THROTTLE POSITION

SIGNAL CIRCUIT ............................................

167

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

167

TCM Terminal and Reference Value .....................167

Diagnosis Procedure .............................................167

Component Inspection ...........................................171

SHIFT POSITION INDICATOR CIRCUIT ........172

Description .............................................................172

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

172

Diagnosis Procedure .............................................172

TROUBLE DIAGNOSIS FOR SYMPTOMS ....173

Wiring Diagram - AT - NONDTC ...........................173

OD OFF Indicator Lamp Does Not Come On ........176

Engine Cannot Be Started in "P" and "N" Position ..178

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

179

In "N" Position, Vehicle Moves ..............................179

Large Shock "N" → "R" Position ............................180

Vehicle Does Not Creep Backward in "R" Position ..181

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ..................................................................

182

Vehicle Cannot Be Started from D1 .......................183

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 .......................................................185

A/T Does Not Shift: D2→ D3 ..................................186

A/T Does Not Shift: D3→ D4 ..................................188

A/T Does Not Perform Lock-up .............................189

A/T Does Not Hold Lock-up Condition ...................190

Lock-up Is Not Released .......................................191

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ...................................................192

A/T Does Not Shift: D4→ D3, When OD OFF ........193

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position .................................................

194

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ..................................................

195

Vehicle Does Not Decelerate by Engine Brake .....197

TCM Self-Diagnosis Does Not Activate .................200

TRANSMISSION CONTROL MODULE ..........202

Removal and Installation .......................................202

SHIFT CONTROL SYSTEM ............................203

Control Device Removal and Installation ...............203

Control Device Disassembly and Assembly ..........206

Selector Lever Knob Removal and Installation ......206

Adjustment of A/T Position ....................................207

Checking of A/T Position .......................................207

A/T SHIFT LOCK SYSTEM .............................209

Description .............................................................209

Shift Lock System Parts Location ..........................209

Wiring Diagram - AT - SHIFT ................................210

Page 19 of 2771

PRECAUTIONS

AT-7

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001703151

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000001703152

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000001703153

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Page 50 of 2771

AT-38

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer to AT-78, "

Diagnosis Procedure

without CONSULT-III" . (The engine warm-up step can be skipped when performing the diagnosis only to

erase the DTC.)

3. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No tools)”. Refer to EC-47, "

Emission-related Diag-

nostic Information" .

Malfunction Indicator Lamp (MIL)INFOID:0000000001703176

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

• If the MIL does not light up, refer to DI-21

, or see EC-546 .

2. When the engine is started, the MIL should go off.

• If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

SEF217U

Page 57 of 2771

TROUBLE DIAGNOSIS

AT-45

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

4. 4-3. “Cruise Test”AT- 5 5

Part 1

❏AT- 1 8 3 , "

Vehicle Cannot Be Started from D1" .

❏AT- 1 8 5 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

❏AT- 1 8 6 , "

A/T Does Not Shift: D2→ D3" .

❏AT- 1 8 8 , "

A/T Does Not Shift: D3→ D4" .

❏AT- 1 8 9 , "

A/T Does Not Perform Lock-up" .

❏AT- 1 9 0 , "

A/T Does Not Hold Lock-up Condition" .

❏AT- 1 9 1 , "

Lock-up Is Not Released" .

❏AT- 1 9 2 , "

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)" .

Part 2AT- 5 8

❏AT- 1 8 3 , "Vehicle Cannot Be Started from D1" .

❏AT- 1 8 5 , "

A/T Does Not Shift: D1→ D2or Does Not Kickdown: D4→ D2" .

❏AT- 1 8 6 , "

A/T Does Not Shift: D2→ D3" .

❏AT- 1 8 8 , "

A/T Does Not Shift: D3→ D4" .

Part 3AT- 5 9

❏AT- 1 9 3 , "A/T Does Not Shift: D4→ D3, When OD OFF" .

❏AT- 1 9 4 , "

A/T Does Not Shift: D3→ 22, When Selector Lever "D" → "2" Position" .

❏AT- 1 9 5 , "

A/T Does Not Shift: 22→ 11, When Selector Lever "2" → "1" Position" .

❏AT- 1 9 7 , "

Vehicle Does Not Decelerate by Engine Brake" .

❏ Perform self-diagnosis. Enter checks for detected items. AT- 7 3

, AT- 7 8 .

❏AT- 8 3

.

❏AT- 8 6

.

❏AT- 9 1

.

❏AT- 9 6

.

❏AT- 1 0 1

.

❏AT- 1 0 5

❏AT- 1 0 8 .

❏AT- 111

.

❏AT- 11 4

.

❏AT- 11 9

.

❏AT- 1 2 4

.

❏AT- 1 2 9

.

❏AT- 1 3 4

.

❏AT- 1 3 9

.

❏AT- 1 4 4

.

❏AT- 1 4 9

.

❏AT- 1 5 2

.

❏AT- 1 5 8

.

❏AT- 1 6 3

.

❏AT- 1 6 4

.

5.❏ For self-diagnosis NG items, inspect each component. Repair or replace the damaged parts.AT- 7 3

,

AT- 7 8

6.❏ Perform “Road Test”.AT- 5 2

7.❏ Perform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible symp-

toms and the component inspection orders.)AT- 6 1

8.❏ Erase DTC from TCM and ECM memories.AT- 3 6,

AT- 7 8

Page 70 of 2771

AT-58

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

• Continue “Road Test”.

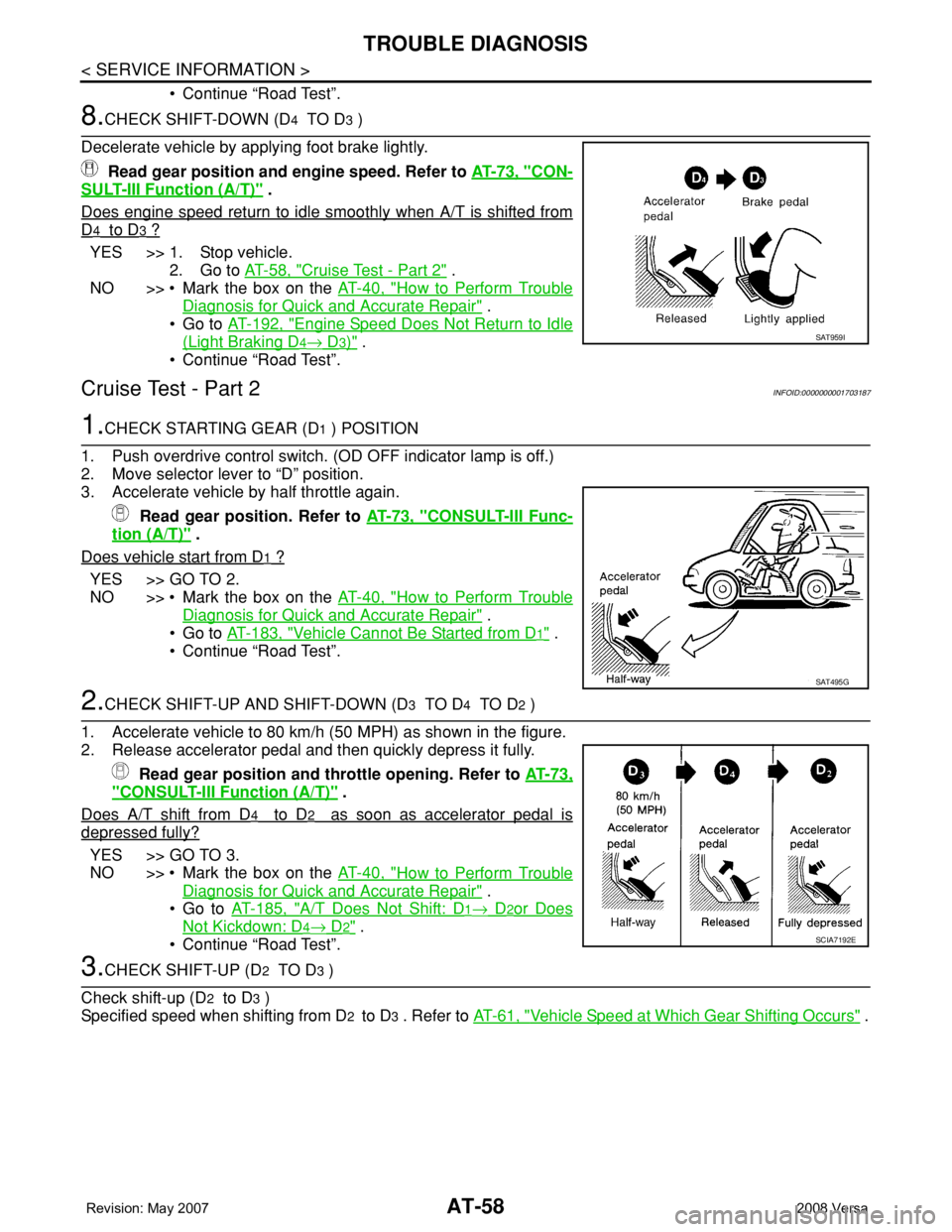

8.CHECK SHIFT-DOWN (D4 TO D3 )

Decelerate vehicle by applying foot brake lightly.

Read gear position and engine speed. Refer to AT-73, "

CON-

SULT-III Function (A/T)" .

Does engine speed return to idle smoothly when A/T is shifted from

D4 to D3 ?

YES >> 1. Stop vehicle.

2. Go to AT-58, "

Cruise Test - Part 2" .

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-192, "

Engine Speed Does Not Return to Idle

(Light Braking D4→ D3)" .

• Continue “Road Test”.

Cruise Test - Part 2INFOID:0000000001703187

1.CHECK STARTING GEAR (D1 ) POSITION

1. Push overdrive control switch. (OD OFF indicator lamp is off.)

2. Move selector lever to “D” position.

3. Accelerate vehicle by half throttle again.

Read gear position. Refer to AT-73, "

CONSULT-III Func-

tion (A/T)" .

Does vehicle start from D

1 ?

YES >> GO TO 2.

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-183, "

Vehicle Cannot Be Started from D1" .

• Continue “Road Test”.

2.CHECK SHIFT-UP AND SHIFT-DOWN (D3 TO D4 TO D2 )

1. Accelerate vehicle to 80 km/h (50 MPH) as shown in the figure.

2. Release accelerator pedal and then quickly depress it fully.

Read gear position and throttle opening. Refer to AT-73,

"CONSULT-III Function (A/T)" .

Does A/T shift from D

4 to D2 as soon as accelerator pedal is

depressed fully?

YES >> GO TO 3.

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-185, "

A/T Does Not Shift: D1→ D2or Does

Not Kickdown: D4→ D2" .

• Continue “Road Test”.

3.CHECK SHIFT-UP (D2 TO D3 )

Check shift-up (D

2 to D3 )

Specified speed when shifting from D

2 to D3 . Refer to AT-61, "Vehicle Speed at Which Gear Shifting Occurs" .

SAT959I

SAT495G

SCIA7192E

Page 85 of 2771

TROUBLE DIAGNOSIS

AT-73

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

*1: These terminals are connected to the data link connector.

*2: These terminals are connected to the ECM.

CONSULT-III Function (A/T)INFOID:0000000001703193

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE

NOTICE:

1. The CONSULT-III electrically displays shift timing and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timing and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-III and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual refers to the point where shifts start, and

- Gear position displayed on CONSULT-III indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSULT-III at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

39*2L Engine speed signal

and Refer to EC-102 .

40 O Vehicle speed sensorWhen driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always 0 V

47 BRA/T fluid temperature

sensor

and When A/T fluid temperature is 20°C

(68°F).1.5 V

When A/T fluid temperature is 80°C

(176°F).0.5 V

48 B Ground Always 0 V Te r m i n a lWire

colorItem ConditionJudgement stan-

dard (Approx.)

Diagnostic test mode Function

Work supportThis mode enables a technician to adjust some devices faster and more accurately by following the in-

dications on CONSULT-III.

Self-diagnostic results Self-diagnostic results can be read and erased quickly.

Data monitor Input/Output data in the TCM can be read.

CAN diagnostic support mon-

itorThe results of transmit/receive diagnosis of CAN communication can be read.

Function test Performed by CONSULT-III instead of a technician to determine whether each system is “OK” or “NG”.

DTC work support Select the operating condition to confirm Diagnostic Trouble Codes.

TCM part number TCM part number can be read.

Item name Condition Display value (Approx.)

VHCL/S SE-A/T

During drivingApproximately matches the speedometer

reading.

VHCL/S SE-MTR

THROTTLE POSIReleased accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

Page 91 of 2771

TROUBLE DIAGNOSIS

AT-79

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

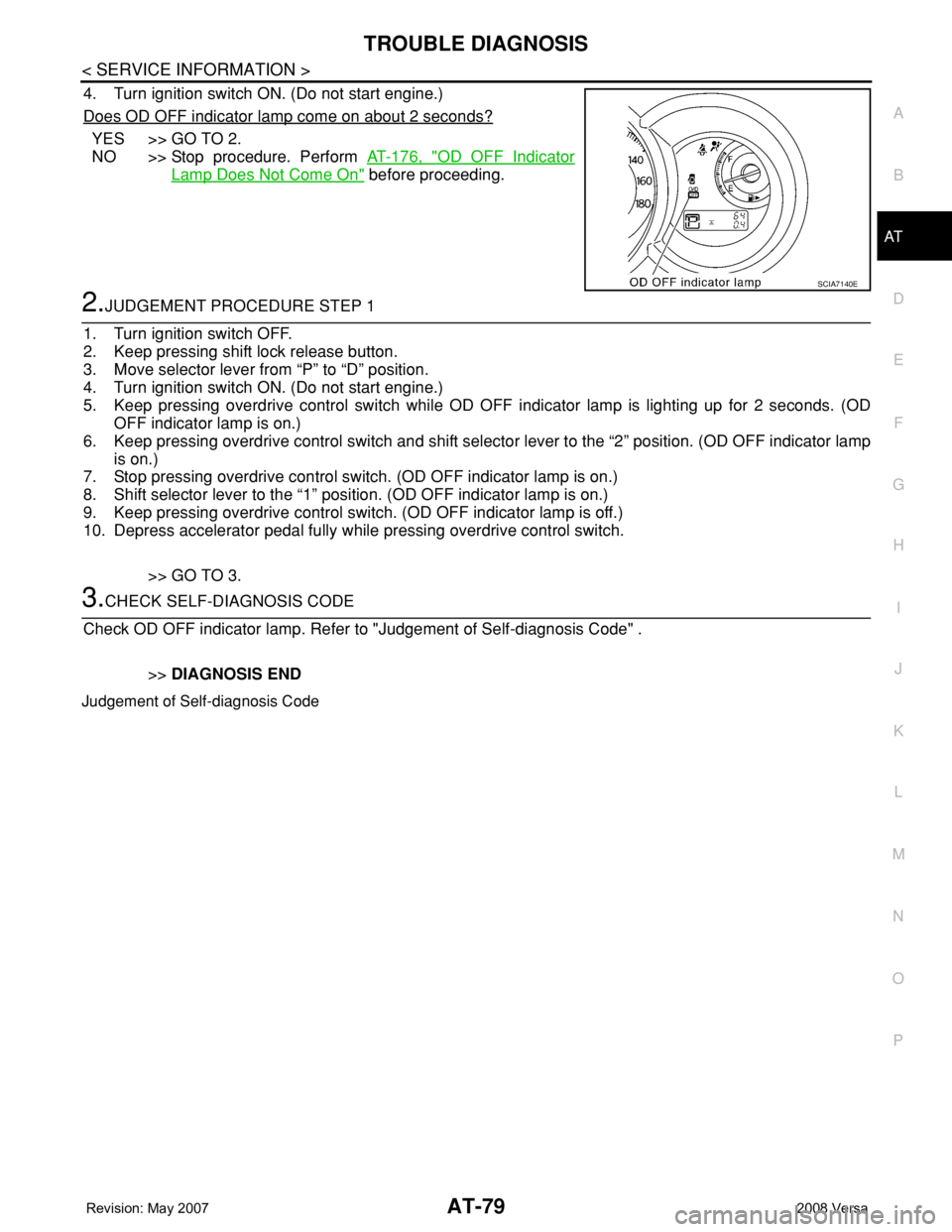

4. Turn ignition switch ON. (Do not start engine.)

Does OD OFF indicator lamp come on about 2 seconds?

YES >> GO TO 2.

NO >> Stop procedure. Perform AT-176, "

OD OFF Indicator

Lamp Does Not Come On" before proceeding.

2.JUDGEMENT PROCEDURE STEP 1

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Turn ignition switch ON. (Do not start engine.)

5. Keep pressing overdrive control switch while OD OFF indicator lamp is lighting up for 2 seconds. (OD

OFF indicator lamp is on.)

6. Keep pressing overdrive control switch and shift selector lever to the “2” position. (OD OFF indicator lamp

is on.)

7. Stop pressing overdrive control switch. (OD OFF indicator lamp is on.)

8. Shift selector lever to the “1” position. (OD OFF indicator lamp is on.)

9. Keep pressing overdrive control switch. (OD OFF indicator lamp is off.)

10. Depress accelerator pedal fully while pressing overdrive control switch.

>> GO TO 3.

3.CHECK SELF-DIAGNOSIS CODE

Check OD OFF indicator lamp. Refer to "Judgement of Self-diagnosis Code" .

>>DIAGNOSIS END

Judgement of Self-diagnosis Code

SCIA7140E

Page 204 of 2771

AT-192

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TCM

1. Check TCM input/output signals. Refer to AT-71, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)INFOID:0000000001703349

SYMPTOM:

Engine speed does not smoothly return to idle when A/T shifts from D4 to D3 on “Cruise Test — Part

1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-73, "

CONSULT-III Function (A/T)" or AT-78, "Diagnosis Procedure without

CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-73, "CONSULT-III Function (A/T)" or AT-78, "Diag-

nosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-493

.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-230, "

Component" .

2. Check A/T fluid condition. Refer to AT-48, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-216, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-240, "

Disassembly" .

4. Check the following items:

- Overrun clutch assembly. Refer to AT-288, "

Forward and Overrun Clutches" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-216, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

OK or NG

Page 381 of 2771

AV-22

< SERVICE INFORMATION >

AUDIO

Power Supply Circuit Inspection

INFOID:0000000001704663

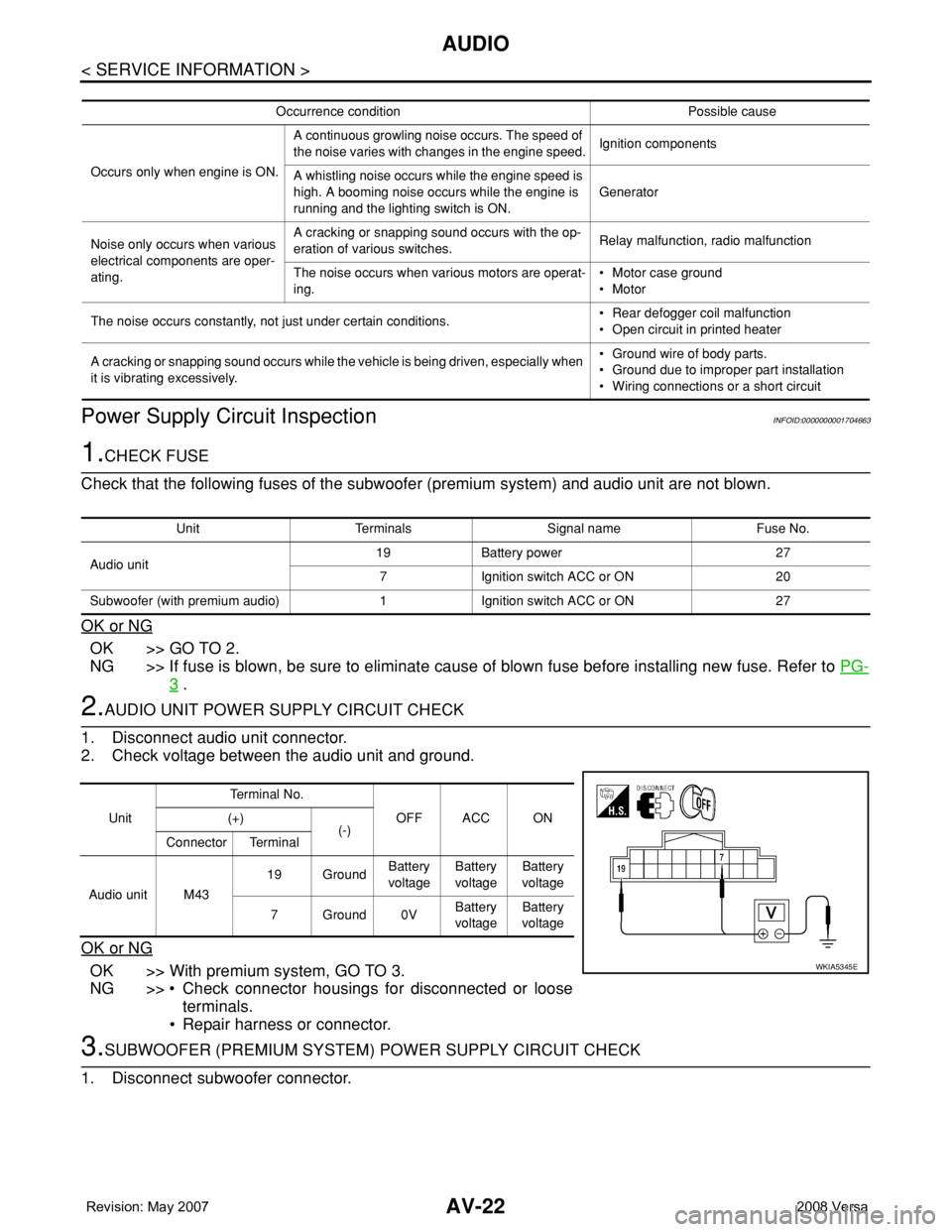

1.CHECK FUSE

Check that the following fuses of the subwoofer (premium system) and audio unit are not blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of blown fuse before installing new fuse. Refer to PG-

3 .

2.AUDIO UNIT POWER SUPPLY CIRCUIT CHECK

1. Disconnect audio unit connector.

2. Check voltage between the audio unit and ground.

OK or NG

OK >> With premium system, GO TO 3.

NG >> • Check connector housings for disconnected or loose

terminals.

• Repair harness or connector.

3.SUBWOOFER (PREMIUM SYSTEM) POWER SUPPLY CIRCUIT CHECK

1. Disconnect subwoofer connector.

Occurrence condition Possible cause

Occurs only when engine is ON.A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed.Ignition components

A whistling noise occurs while the engine speed is

high. A booming noise occurs while the engine is

running and the lighting switch is ON.Generator

Noise only occurs when various

electrical components are oper-

ating.A cracking or snapping sound occurs with the op-

eration of various switches.Relay malfunction, radio malfunction

The noise occurs when various motors are operat-

ing.• Motor case ground

• Motor

The noise occurs constantly, not just under certain conditions.• Rear defogger coil malfunction

• Open circuit in printed heater

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively.• Ground wire of body parts.

• Ground due to improper part installation

• Wiring connections or a short circuit

Unit Terminals Signal name Fuse No.

Audio unit19 Battery power 27

7 Ignition switch ACC or ON 20

Subwoofer (with premium audio) 1 Ignition switch ACC or ON 27

UnitTe r m i n a l N o .

OFF ACC ON (+)

(-)

Connector Terminal

Audio unit M4319 GroundBattery

voltageBattery

voltageBattery

voltage

7Ground0VBattery

voltageBattery

voltage

WKIA5345E

Page 442 of 2771

BL-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks.

Refer to BL-9, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loosening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100×135 mm (3.94×5.31 in)/76884-71L01: 60×85 mm (2.36×3.35 in)/76884-71L02: 15×25

mm (0.59×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50×50 mm (1.97×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50×50 mm (1.97×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30×50 mm (1.18×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15×25 mm (0.59×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.