oil temperature NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 16 of 2771

AT-4

Diagnosis Procedure .............................................210

KEY INTERLOCK CABLE ...............................213

Removal and Installation .......................................213

ON-VEHICLE SERVICE ..................................216

Control Valve Assembly and Accumulators ...........216

Park/Neutral Position (PNP) Switch ......................219

Revolution Sensor .................................................221

Turbine Revolution Sensor (Power Train Revolu-

tion Sensor) ...........................................................

222

Differential Side Oil Seal ........................................223

AIR BREATHER HOSE ...................................225

Removal and Installation .......................................225

TRANSAXLE ASSEMBLY ..............................226

Removal and Installation .......................................226

OVERHAUL .....................................................230

Component ............................................................230

Oil Channel ............................................................237

Location of Adjusting Shims, Needle Bearings and

Thrust Washers .....................................................

238

Location of Snap Rings .........................................239

DISASSEMBLY ...............................................240

Disassembly ..........................................................240

REPAIR FOR COMPONENT PARTS ..............257

Manual Shaft .........................................................257

Oil Pump ................................................................260

Control Valve Assembly ........................................263

Control Valve Upper Body .....................................272

Control Valve Lower Body .....................................276

Reverse Clutch ......................................................279

High Clutch ............................................................284

Forward and Overrun Clutches .............................288

Low & Reverse Brake ............................................295

Rear Internal Gear and Forward Clutch Hub .........299

Output Shaft, Output Gear, Idler Gear, Reduction

Pinion Gear and Bearing Retainer .........................

302

Band Servo Piston Assembly ................................307

Final Drive .............................................................313

ASSEMBLY ......................................................318

Assembly (1) .........................................................318

Adjustment (1) .......................................................319

Assembly (2) .........................................................325

Adjustment (2) .......................................................330

Assembly (3) .........................................................333

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

341

General Specification ............................................341

Vehicle Speed at Which Gear Shifting Occurs .....341

Vehicle Speed at When Lock-up Occurs/Releases

.

341

Stall Speed ............................................................341

Line Pressure ........................................................341

Adjusting shims, Needle Bearings, Thrust Wash-

ers and Snap Rings ..............................................

341

Control Valves .......................................................343

Accumulator ..........................................................343

Clutches and Brakes .............................................343

Final Drive .............................................................345

Planetary Carrier ...................................................345

Oil Pump ...............................................................345

Input Shaft .............................................................345

Reduction Pinion Gear ..........................................345

Band Servo ...........................................................345

Output Shaft ..........................................................346

Bearing Retainer ...................................................346

Total End Play .......................................................346

Reverse Clutch End Play ......................................346

Removal and Installation .......................................346

Shift Solenoid Valves ............................................346

Solenoid Valves ....................................................346

A/T Fluid Temperature Sensor ..............................347

Revolution Sensor .................................................347

Dropping Resistor .................................................347

Turbine Revolution Sensor (Power Train Revolu-

tion Sensor) ...........................................................

347

Page 43 of 2771

A/T CONTROL SYSTEM

AT-31

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

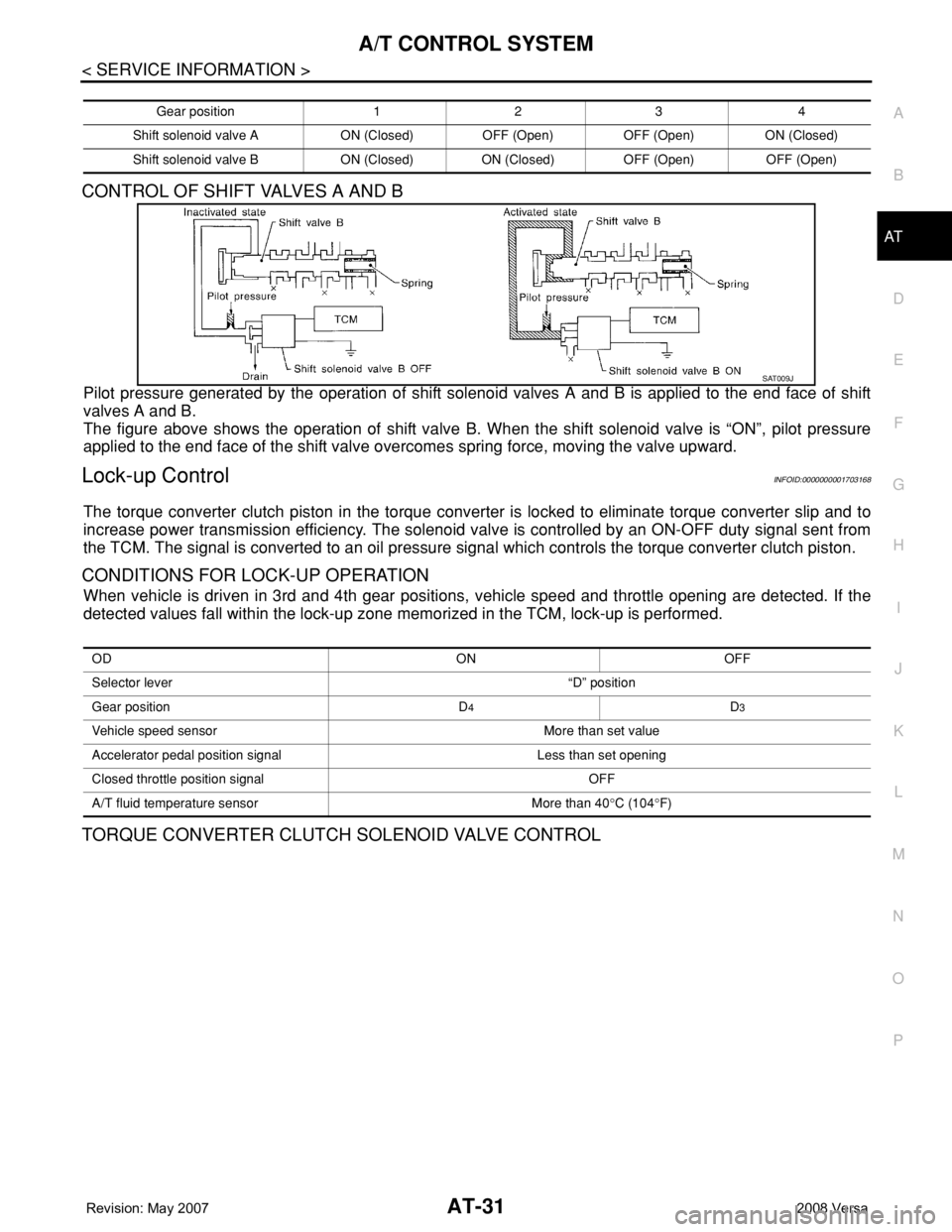

CONTROL OF SHIFT VALVES A AND B

Pilot pressure generated by the operation of shift solenoid valves A and B is applied to the end face of shift

valves A and B.

The figure above shows the operation of shift valve B. When the shift solenoid valve is “ON”, pilot pressure

applied to the end face of the shift valve overcomes spring force, moving the valve upward.

Lock-up ControlINFOID:0000000001703168

The torque converter clutch piston in the torque converter is locked to eliminate torque converter slip and to

increase power transmission efficiency. The solenoid valve is controlled by an ON-OFF duty signal sent from

the TCM. The signal is converted to an oil pressure signal which controls the torque converter clutch piston.

CONDITIONS FOR LOCK-UP OPERATION

When vehicle is driven in 3rd and 4th gear positions, vehicle speed and throttle opening are detected. If the

detected values fall within the lock-up zone memorized in the TCM, lock-up is performed.

TORQUE CONVERTER CLUTCH SOLENOID VALVE CONTROL

Gear position 1 2 3 4

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

SAT009J

OD ON OFF

Selector lever “D” position

Gear position D

4D3

Vehicle speed sensor More than set value

Accelerator pedal position signal Less than set opening

Closed throttle position signal OFF

A/T fluid temperature sensor More than 40°C (104°F)

Page 60 of 2771

AT-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Inspections Before Trouble Diagnosis

INFOID:0000000001703182

A/T FLUID CHECK

Fluid Leakage and Fluid Level Check

Check fluid leakage and check the fluid level. Refer to MA-22, "Checking A/T Fluid".

Fluid Condition Check

Check the A/T fluid condition.

STALL TEST

Stall Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF and

engine oil.

2. Drive vehicle for approximately 10 minutes or until ATF and

engine oil reach operating temperature.

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

•It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in “D”

position.

Fluid status Conceivable Cause Required Operation

Varnished (viscous

varnish state)Clutch, brake

scorchedReplace the ATF and check the A/T

main unit and the vehicle for mal-

functions (wire harnesses, cooler

pipes, etc.)

Milky white or

cloudyWater in the ATFReplace the ATF and check for plac-

es where water is getting in.

Large amount of

metal powder mixed

inUnusual wear of

sliding parts within

A/TReplace the ATF and check for im-

proper operation of the A/T.

SAT638A

ATF operating temperature: 50 - 80°C (122 - 176°F)

SAT647B

SAT513G

SAT775B

Page 63 of 2771

TROUBLE DIAGNOSIS

AT-51

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

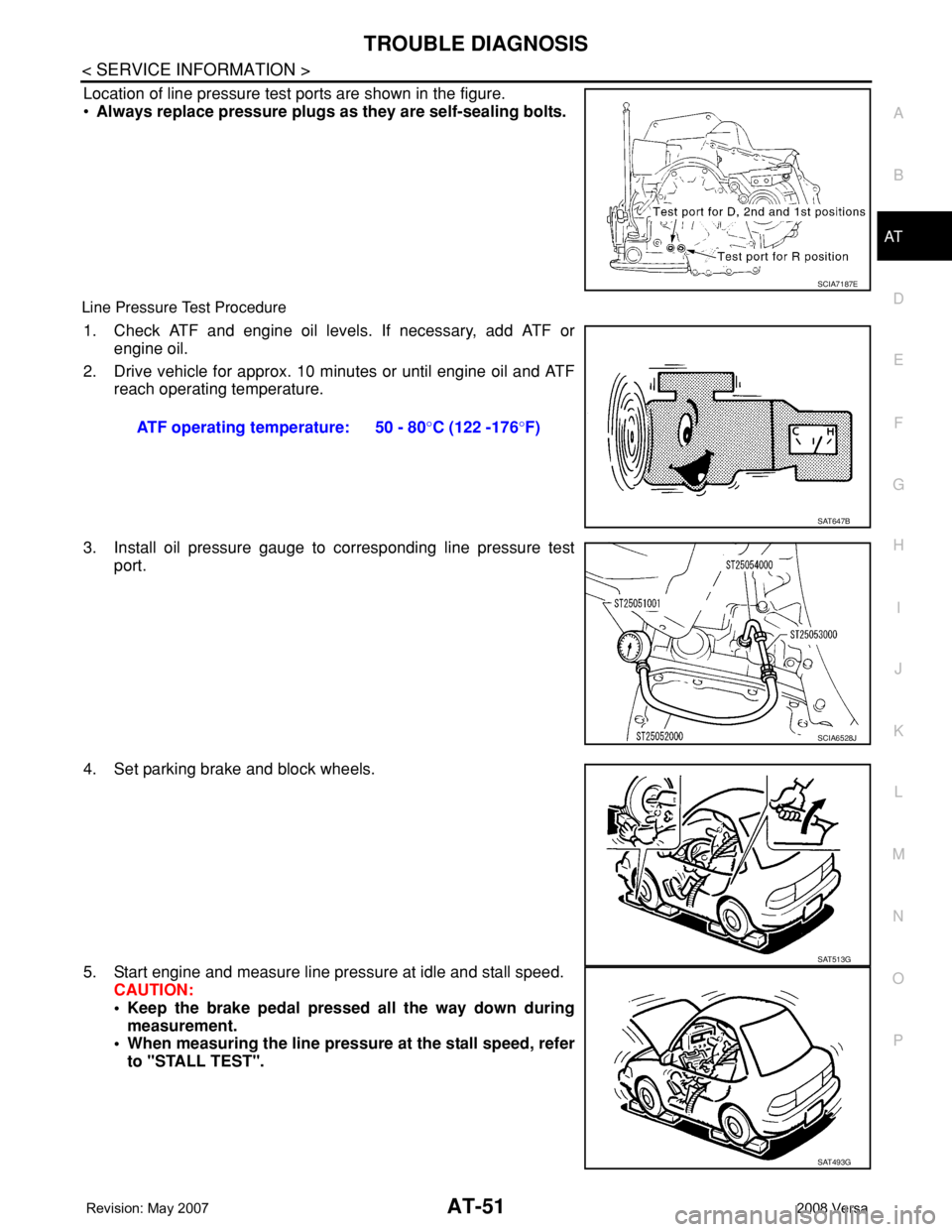

Location of line pressure test ports are shown in the figure.

•Always replace pressure plugs as they are self-sealing bolts.

Line Pressure Test Procedure

1. Check ATF and engine oil levels. If necessary, add ATF or

engine oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

3. Install oil pressure gauge to corresponding line pressure test

port.

4. Set parking brake and block wheels.

5. Start engine and measure line pressure at idle and stall speed.

CAUTION:

• Keep the brake pedal pressed all the way down during

measurement.

• When measuring the line pressure at the stall speed, refer

to "STALL TEST".

SCIA7187E

ATF operating temperature: 50 - 80°C (122 -176°F)

SAT647B

SCIA6528J

SAT513G

SAT493G

Page 64 of 2771

AT-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Line Pressure

Judgement of Line Pressure Test

Road TestINFOID:0000000001703183

DESCRIPTION

• The purpose of the test is to determine overall performance of A/T

and analyze causes of malfunctions.

• The road test consists of the following three parts:

1. Check before engine is started. Refer to AT- 5 3

.

2. Check at idle. Refer to AT- 5 3

.

3. Cruise test

• Inspection all the item from Part 1 to Part 3. Refer to AT- 5 5

,

AT- 5 8

and AT- 5 9 .

Engine speedLine pressure [kPa (kg/cm

2 , psi)]

D, 2nd and 1st positions R position

Idle speed 500 (5.1, 73) 778 (7.9, 113)

Stall speed 1,173 (12.0, 170) 1,825 (18.6, 265)

Judgement Suspected parts

At idleLine pressure is low in all positions. • Oil pump wear

• Control piston damage

• Pressure regulator valve or plug sticking

• Spring for pressure regulator valve damaged

• Fluid pressure leakage between oil strainer and pressure regulator valve

• Clogged strainer

Line pressure is low in particular posi-

tion.• Fluid pressure leakage between manual valve and particular clutch

• For example, line pressure is:

− Low in “R” and “1” positions, but

− Normal in “D”, and “2” positions.

Therefore, fluid leakage exists at or around low and reverse brake circuit.

Refer to AT- 1 9 , "

Shift Mechanism".

Line pressure is high. • Accelerator pedal position signal malfunction

• A/T fluid temperature sensor damaged

• Line pressure solenoid valve sticking

• Short circuit of line pressure solenoid valve circuit

• Pressure modifier valve sticking

• Pressure regulator valve or plug sticking

• Open in dropping resistor circuit

At stall

speedLine pressure is low. • Accelerator pedal position signal malfunction

• Line pressure solenoid valve sticking

• Short circuit of line pressure solenoid valve circuit

• Pressure regulator valve or plug sticking

• Pressure modifier valve sticking

• Pilot valve sticking

SAT786A

Page 67 of 2771

TROUBLE DIAGNOSIS

AT-55

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

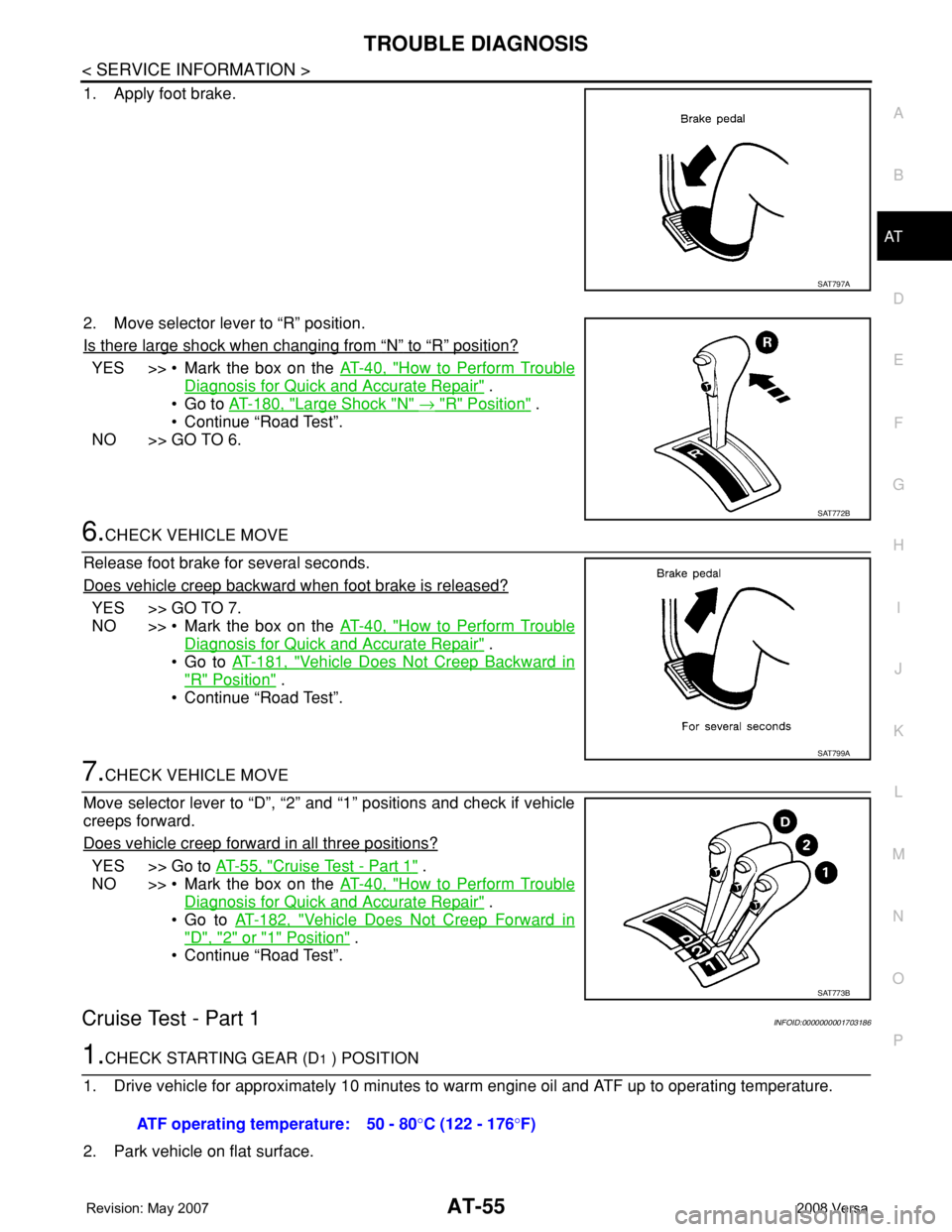

1. Apply foot brake.

2. Move selector lever to “R” position.

Is there large shock when changing from

“N” to “R” position?

YES >> • Mark the box on the AT-40, "How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-180, "

Large Shock "N" → "R" Position" .

• Continue “Road Test”.

NO >> GO TO 6.

6.CHECK VEHICLE MOVE

Release foot brake for several seconds.

Does vehicle creep backward when foot brake is released?

YES >> GO TO 7.

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-181, "

Vehicle Does Not Creep Backward in

"R" Position" .

• Continue “Road Test”.

7.CHECK VEHICLE MOVE

Move selector lever to “D”, “2” and “1” positions and check if vehicle

creeps forward.

Does vehicle creep forward in all three positions?

YES >> Go to AT-55, "Cruise Test - Part 1" .

NO >> • Mark the box on the AT-40, "

How to Perform Trouble

Diagnosis for Quick and Accurate Repair" .

•Go to AT-182, "

Vehicle Does Not Creep Forward in

"D", "2" or "1" Position" .

• Continue “Road Test”.

Cruise Test - Part 1INFOID:0000000001703186

1.CHECK STARTING GEAR (D1 ) POSITION

1. Drive vehicle for approximately 10 minutes to warm engine oil and ATF up to operating temperature.

2. Park vehicle on flat surface.

SAT797A

SAT772B

SAT799A

SAT773B

ATF operating temperature: 50 - 80°C (122 - 176°F)

Page 106 of 2771

AT-94

< SERVICE INFORMATION >

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

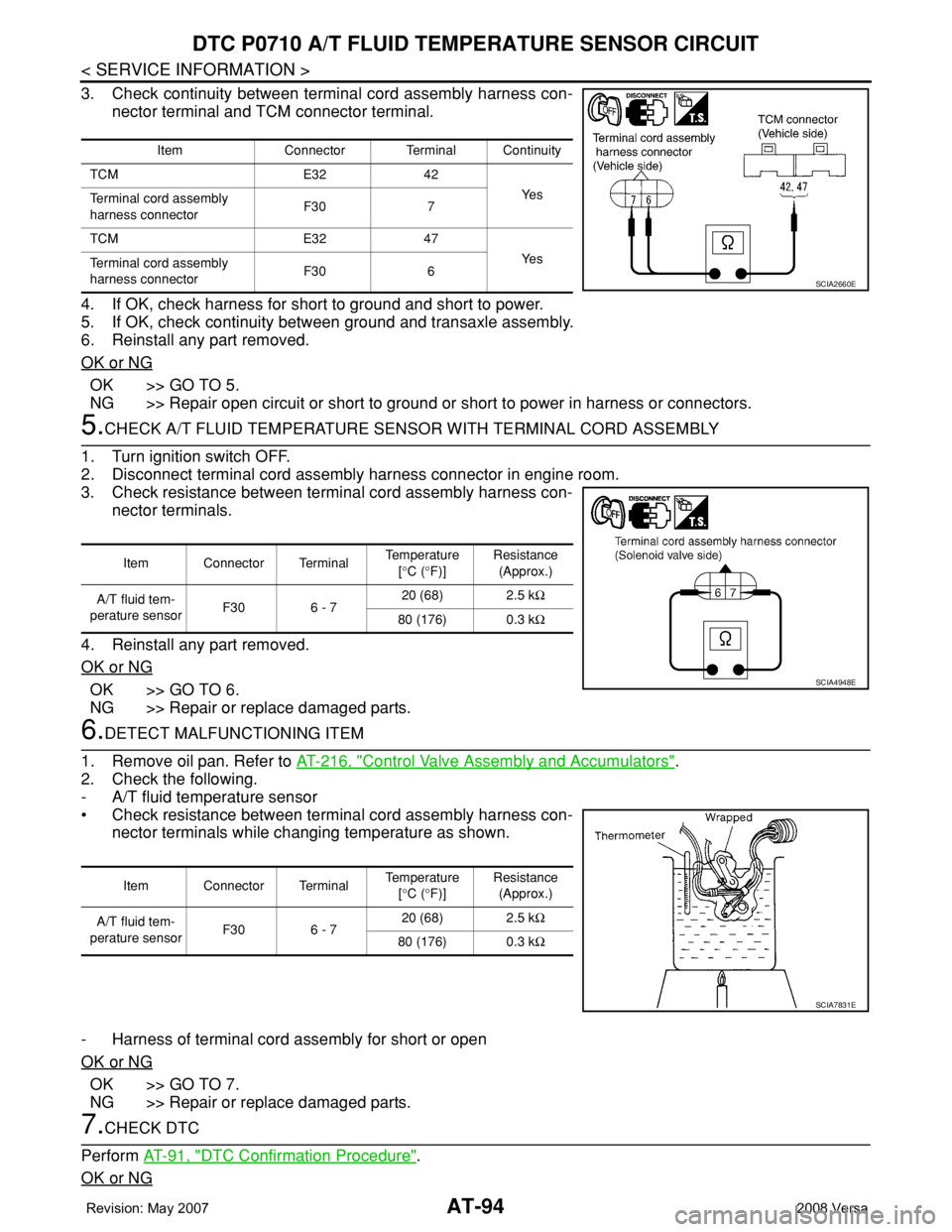

3. Check continuity between terminal cord assembly harness con-

nector terminal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. If OK, check continuity between ground and transaxle assembly.

6. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly harness connector in engine room.

3. Check resistance between terminal cord assembly harness con-

nector terminals.

4. Reinstall any part removed.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

1. Remove oil pan. Refer to AT-216, "

Control Valve Assembly and Accumulators".

2. Check the following.

- A/T fluid temperature sensor

• Check resistance between terminal cord assembly harness con-

nector terminals while changing temperature as shown.

- Harness of terminal cord assembly for short or open

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK DTC

Perform AT-91, "

DTC Confirmation Procedure".

OK or NG

Item Connector Terminal Continuity

TCM E32 42

Ye s

Terminal cord assembly

harness connectorF30 7

TCM E32 47

Ye s

Terminal cord assembly

harness connectorF30 6

SCIA2660E

Item Connector Terminal Temperature

[°C (°F)]Resistance

(Approx.)

A/T fluid tem-

perature sensorF30 6 - 720 (68) 2.5 kΩ

80 (176) 0.3 kΩ

SCIA4948E

Item Connector Terminal Temperature

[°C (°F)]Resistance

(Approx.)

A/T fluid tem-

perature sensorF30 6 - 720 (68) 2.5 kΩ

80 (176) 0.3 kΩ

SCIA7831E

Page 107 of 2771

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

AT-95

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

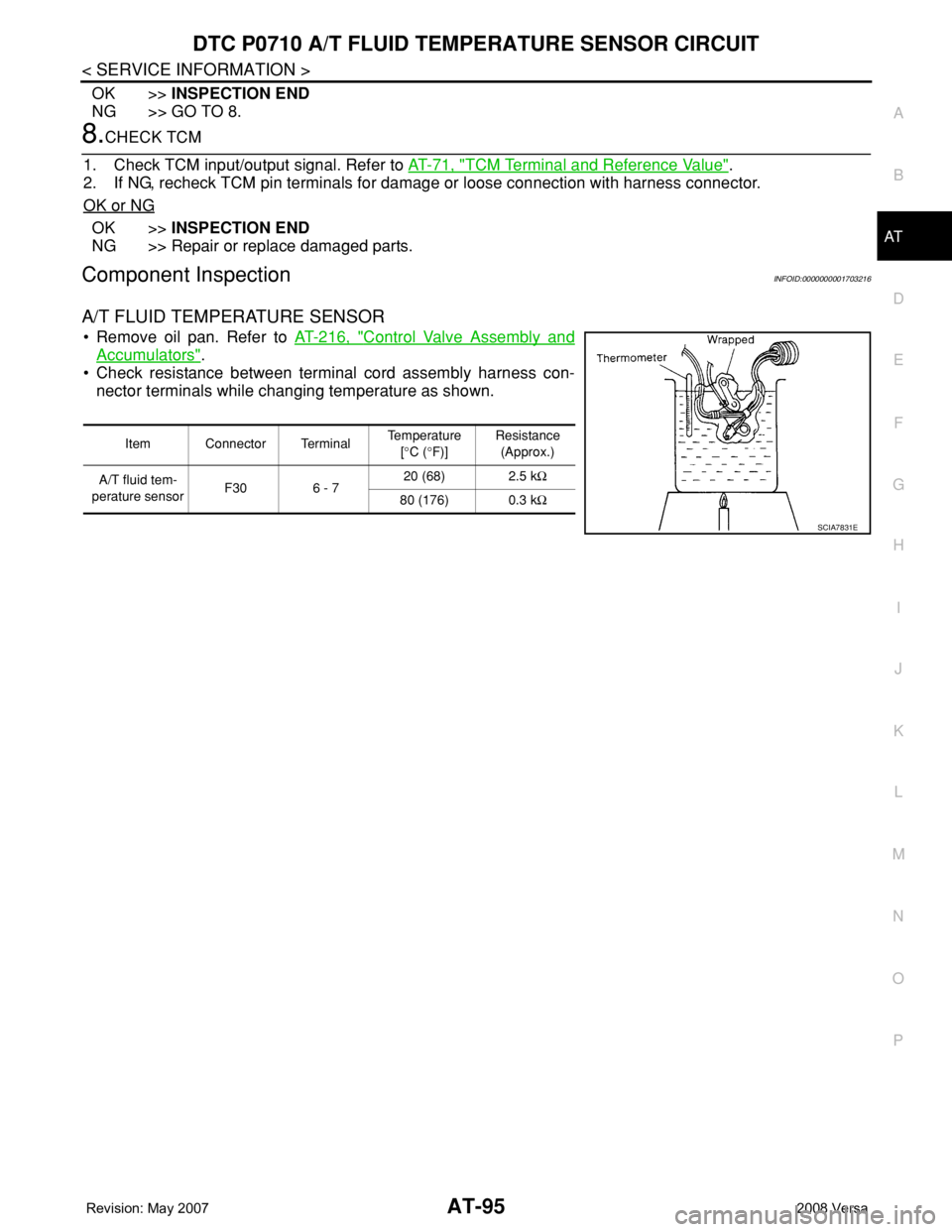

OK >>INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signal. Refer to AT-71, "

TCM Terminal and Reference Value".

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Component InspectionINFOID:0000000001703216

A/T FLUID TEMPERATURE SENSOR

• Remove oil pan. Refer to AT-216, "Control Valve Assembly and

Accumulators".

• Check resistance between terminal cord assembly harness con-

nector terminals while changing temperature as shown.

Item Connector Terminal Temperature

[°C (°F)]Resistance

(Approx.)

A/T fluid tem-

perature sensorF30 6 - 720 (68) 2.5 kΩ

80 (176) 0.3 kΩ

SCIA7831E

Page 136 of 2771

AT-124

< SERVICE INFORMATION >

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

DescriptionINFOID:0000000001703260

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis

malfunction.

• This malfunction is detected when the A/T does not shift into fourth gear position or the torque converter

clutch does not lock-up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as control valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703261

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703262

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744 A/T TCC S/V FNCTN” with CONSULT-III is detected when A/T cannot per-

form lock-up even if electrical circuit is good.

• This diagnosis monitors actual gear position by checking the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the position (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach the specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve B is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stuck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0744 A/T TCC S/V FNCTN” is detected.

Possible CauseINFOID:0000000001703263

• Line pressure solenoid valve

• Torque converter clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000001703264

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage

(cool down the fluid).

4. Select “TCC S/V FNCTN P0744” of “DTC WORK SUPPORT” mode for “A/T” with CONSULT-III and touch

“START”.

Item name Condition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Page 168 of 2771

AT-156

< SERVICE INFORMATION >

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

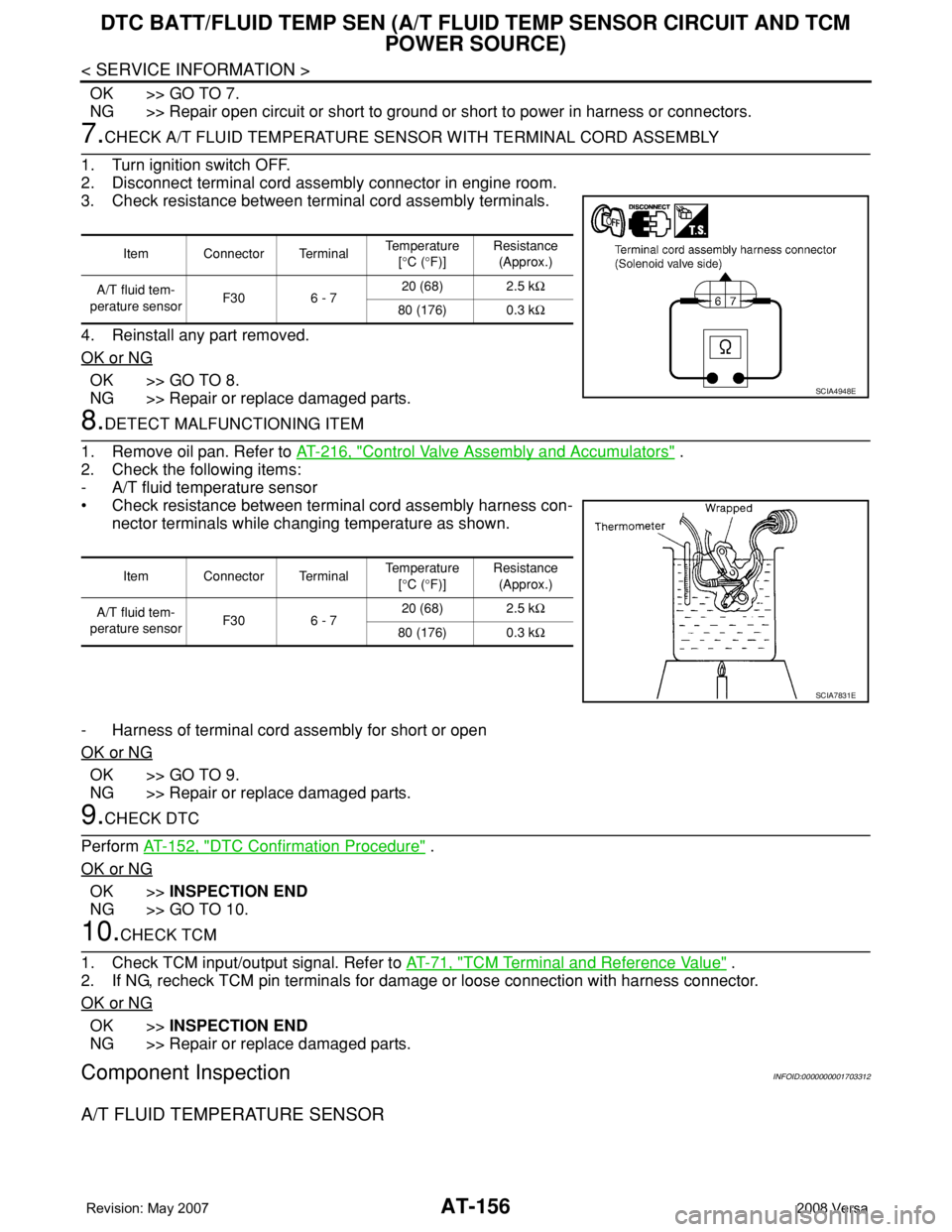

7.CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly connector in engine room.

3. Check resistance between terminal cord assembly terminals.

4. Reinstall any part removed.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.DETECT MALFUNCTIONING ITEM

1. Remove oil pan. Refer to AT-216, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- A/T fluid temperature sensor

• Check resistance between terminal cord assembly harness con-

nector terminals while changing temperature as shown.

- Harness of terminal cord assembly for short or open

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

9.CHECK DTC

Perform AT-152, "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 10.

10.CHECK TCM

1. Check TCM input/output signal. Refer to AT-71, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Component InspectionINFOID:0000000001703312

A/T FLUID TEMPERATURE SENSOR

Item Connector Terminal Temperature

[°C (°F)]Resistance

(Approx.)

A/T fluid tem-

perature sensorF30 6 - 720 (68) 2.5 kΩ

80 (176) 0.3 kΩ

SCIA4948E

Item Connector Terminal Temperature

[°C (°F)]Resistance

(Approx.)

A/T fluid tem-

perature sensorF30 6 - 720 (68) 2.5 kΩ

80 (176) 0.3 kΩ

SCIA7831E